When you choose a chain hoist, you need to know its lifting capacity to ensure proper lifting and avoid accidents. Powerful Machinery’s certified products give you reliable performance for every application.

You protect yourself and your team when you understand the limits and use equipment that meets international safety standards. Powerful Machinery’s Chain Hoist combines durability and trusted engineering for secure lifting in demanding environments.

Key Takeaways

Understand the lifting capacity of chain hoists to ensure safe operations. Choose a hoist with a capacity that exceeds your load requirements.

Regularly inspect and maintain your chain hoist to preserve its lifting performance. Check for wear and lubricate moving parts to extend equipment life.

Select the right type of chain hoist based on your lifting needs. Consider manual, electric, or pneumatic options depending on the load and environment.

Always verify safety features like overload protection and secure locking mechanisms. These features help prevent accidents and ensure safe lifting.

Consult with experts for guidance on selecting and using chain hoists. Their support can help you achieve optimal performance and compliance with safety standards.

Chain Hoist Lifting Capacities

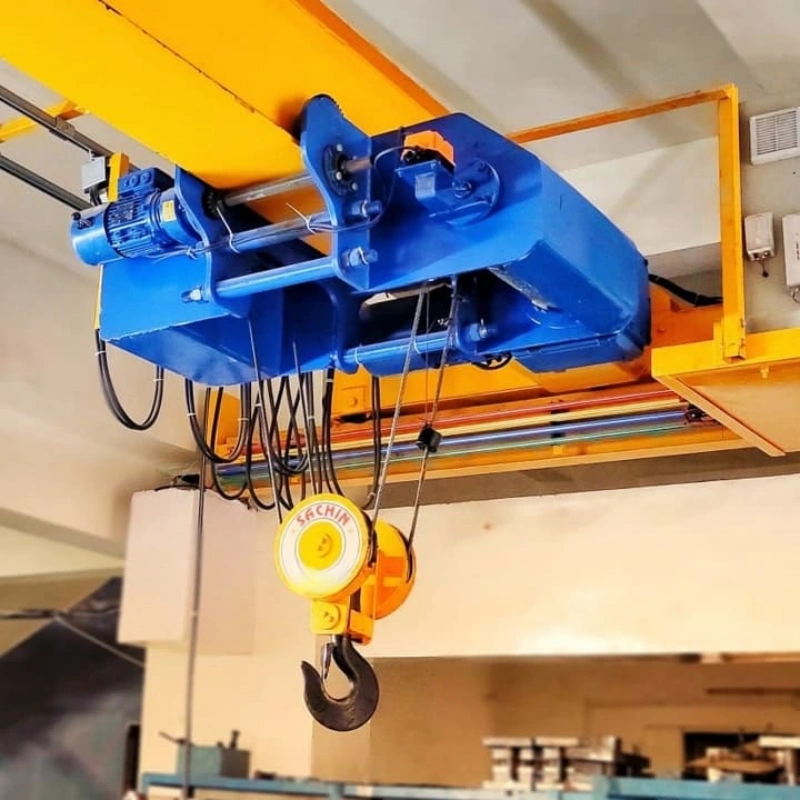

When you select a chain hoist, understanding its lifting capacities is essential for safe and efficient lifting. Powerful Machinery offers a wide range of chain hoists designed to meet the needs of different industries.

You can rely on their certified products to deliver consistent lifting performance, whether you need manual, electric, pneumatic, or heavy-duty models.

Manual Chain Hoist Capacities

Manual chain hoists provide reliable lifting for many applications. You operate these hoists by hand, which gives you precise control over the load. Powerful Machinery’s manual chain hoists come in various capacities, making them suitable for everything from light-duty tasks to heavy industrial lifting.

The lifting capacity range for manual chain hoists typically spans from 0.5 tons to 20 tons.

Type of Hoist | Lifting Capacity Range |

|---|---|

Manual Chain Hoists | 0.5 to 20 tons |

Electric Chain Hoists | 0.125 tons to over 50 tons, with some specialized models lifting to 100 tons |

You can trust Powerful Machinery’s manual chain hoists because they meet strict international standards. These hoists hold certifications such as CE Marking and ASME Standards, which verify their lifting capacity and safety.

Certification | Description |

|---|---|

CE Marking | Indicates compliance with European directives, including the Machinery Directive (2006/42/EC), ensuring safety and performance standards are met. |

ASME Standards | Represents compliance with North American standards, specifically ASME B30.16 for Overhead Hoists and ASME B30.21 for Lever Hoists, ensuring design and performance reliability. |

Manual chain hoists work well in construction, manufacturing, and logistics. You benefit from their robust construction and secure locking mechanisms, which help prevent accidental release of the load.

Electric Chain Hoist Capacities

Electric chain hoists offer higher lifting capacities and faster operation. You use these hoists when you need to lift heavier loads or require frequent lifting cycles. Powerful Machinery’s electric chain hoists feature capacities from 0.5 tons to over 20 tons, which match or exceed industry averages.

Lifting Capacity Range |

|---|

0.5 tons to over 20 tons |

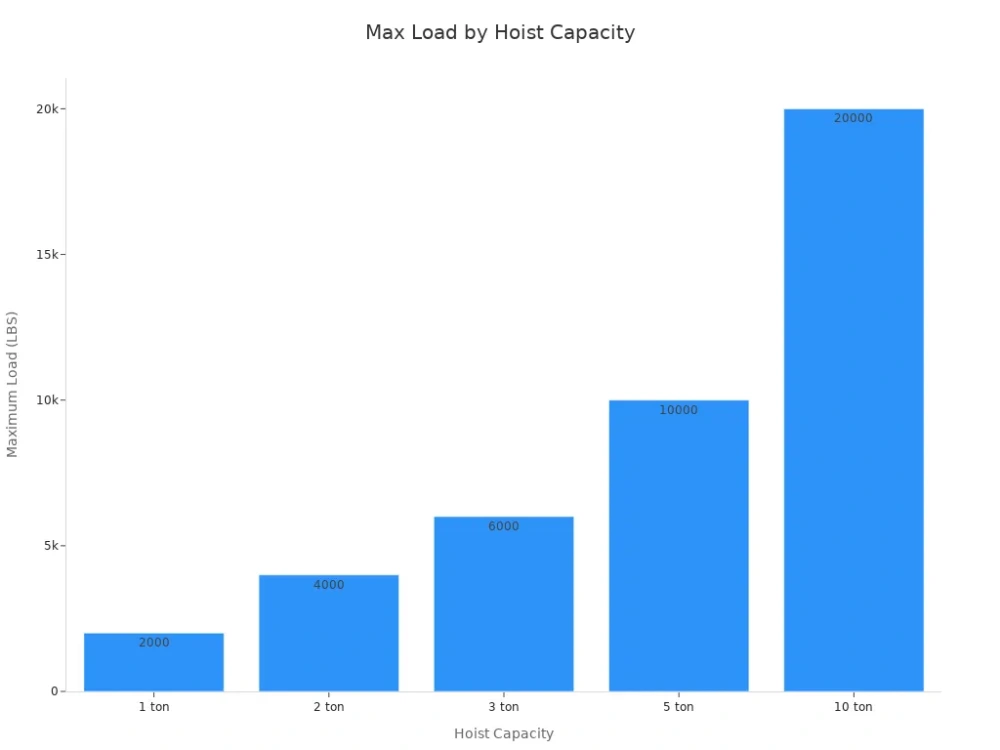

Electric chain hoists are ideal for demanding environments. You find them in factories, warehouses, and construction sites where lifting heavy loads is routine. The following table shows common applications and maximum load for different electric chain hoist capacities:

Hoist Capacity | Maximum Load | Maximum Lift | Applications |

|---|---|---|---|

1 ton | 2,000 LBS | 20’ | General lifting tasks |

2 ton | 4,000 LBS | 20’ | Medium-duty applications |

3 ton | 6,000 LBS | 20’ | Heavy lifting in construction |

5 ton | 10,000 LBS | 20’ | Heavy-duty industrial tasks |

10 ton | 20,000 LBS | 20’ | Heaviest duty applications |

You achieve optimal lifting capacity by matching the hoist to your lifting height and speed requirements. Powerful Machinery’s electric chain hoists include advanced overload protection, which helps you maintain safe lifting operations.

Pneumatic Chain Hoist Capacities

Pneumatic chain hoists use compressed air for lifting. You choose these hoists for environments where electricity is not practical or where you need spark-free operation. Powerful Machinery’s pneumatic chain hoists offer capacities from 250 kg to 10 tons.

Chain Hoist Types | Capacity |

|---|---|

Pneumatic Hoist | 250 kg to 10 tons |

You benefit from pneumatic chain hoists in industries such as mining, chemical processing, and shipbuilding. Powerful Machinery ensures that operators receive proper training and certification for safe use. The process includes:

Operator Training: Covers basic operation, safety procedures, load assessment, and maintenance basics.

Safety Certification: Involves a written examination and practical assessment to ensure competency.

Continuous Education: Emphasizes the need for ongoing training to keep operators updated on new technologies and safety practices.

You maintain effective lifting capacity by following these safety protocols and using certified equipment.

Heavy Duty and Specialized Models

Heavy-duty and specialized chain hoists handle the largest loads in the most demanding industries. You need these hoists for projects that require lifting capacities above 10 tons. Powerful Machinery designs these models for sectors such as construction, steel production, shipbuilding, mining, and power generation.

Industry | Description |

|---|---|

Heavy-Duty Construction | For major infrastructure projects. |

Steel and Metal Production | Handling extremely heavy metal rolls or machinery. |

Shipbuilding | For the largest ship components and structures. |

Mining | Managing the heaviest ores and excavation equipment. |

Large Power Plants | Handling enormous machinery and equipment components. |

You rely on Powerful Machinery’s expertise to select the right chain hoist lifting capacity for your application. Their products meet or exceed international standards, ensuring you get reliable lifting performance and safety.

Tip: Always verify the rated lifting capacity and certifications before you begin any lifting operation. This step helps you avoid overload and ensures safe handling of every load.

Key Factors Affecting Lifting Performance

Mechanical Components and Build Quality

You depend on the mechanical components and build quality of a chain hoist for reliable lifting. Powerful Machinery uses high-grade alloy steel and advanced heat treatment to maximize strength and durability.

The gears and chains must meet strict metallurgical standards to prevent stress concentrations and fatigue. Precision machining ensures smooth gear engagement and efficient lifting. The table below shows how these factors influence lifting performance:

Factor | Description |

|---|---|

Material | High-grade alloy steel (Grade 80 or Grade 100) delivers high tensile strength and toughness. |

Heat Treatment | Quenching improves resistance to elongation and wear. |

Link Dimensions | Pitch, diameter, and cross-sectional area affect load-bearing capacity. |

Consistency of Materials | Uniformity prevents premature fatigue and failure. |

Dimensional Tolerances | Precision machining boosts mechanical efficiency. |

You benefit from Powerful Machinery’s commitment to international standards, which ensures every chain hoist delivers consistent lifting performance.

Motor Power and Power Supply

Motor power plays a vital role in lifting speed and capacity for electric chain hoists. More powerful motors generate greater lifting force, allowing you to handle heavier loads. You find motor ratings in horsepower or kilowatts, which help you select the right hoist for your needs.

Electric chain hoists offer main and fine lifting speeds, with some models reaching up to 20 meters per minute for lighter loads. You can choose between single-phase and three-phase power supplies. Single-phase works for light-duty lifting, while three-phase supports higher capacities in industrial settings.

Powerful Machinery provides flexible power options to match your lifting requirements.

Safety Features and Overload Protection

Safety features protect you and your team during lifting operations. Powerful Machinery’s chain hoists include overload protection that activates at 150% of the rated load, preventing damage from excessive loading. You also benefit from reduced physical strain, emergency stop functions, and anti-drop devices.

These safety features minimize the risk of accidents and ensure secure lifting. You maintain control and confidence when you use equipment designed for safety.

Safety Feature | Benefit |

|---|---|

Reduced Physical Strain | Lowers the risk of injuries by reducing manual effort. |

Overload Protection | Prevents lifting beyond rated capacity. |

Emergency Stop Features | Stops operation instantly in emergencies. |

Anti-Drop Devices | Keeps loads secure during lifting. |

Load Condition and Lift Height

The condition of the load and the lift height directly impact safe lifting capacity. As lift height increases, the chain’s weight adds to the total load, requiring you to reduce the effective lifting capacity.

Higher lifts create more stress on the mechanism and increase the risk of load sway, which can exceed the rated capacity. Operator fatigue also rises with greater heights. Manual chain hoists typically offer a standard lift height of 10 feet, while electric models reach 20 feet.

You can customize both types for longer lifts, but always adjust the load for safety.

Customization and Attachments

You enhance lifting performance by customizing your chain hoist and using specialized attachments. Powerful Machinery offers options to adjust lifting height, platform size, and weight capacity. You can add wheels or tracks for mobility and safety features like guardrails and sensors.

Attachments such as hooks, shackles, clamps, magnets, and vacuum lifters provide precise control over different loads. Always ensure that attachments match the hoist’s rated capacity to maintain safe lifting.

Tip: Consult Powerful Machinery for custom-engineered solutions that fit your unique lifting needs and maximize safety features.

Choosing the Right Chain Hoist

Determining Load Requirements

You must start by understanding the load you need to lift. Accurately determining the load is the foundation of choosing the right chain hoist. Follow these steps to ensure you select equipment that matches your needs:

Calculate the total load weight, including the object and any attachments.

Add the weight of rigging gear, such as slings, shackles, or hooks.

Consider the nature of the lift. Dynamic forces, such as swinging or sudden stops, can increase the effective load.

Always select a chain hoist with a Working Load Limit (WLL) that exceeds your calculated requirements. This safety margin protects both your team and your equipment.

By following these steps, you ensure the chain hoist lifting capacity matches your application. You avoid overload situations and maintain optimal performance.

Evaluating Environment and Duty Cycle

The environment and duty cycle play a major role in lifting operations. You need to assess where and how often you will use the hoist. Environmental factors such as humidity and temperature can affect both performance and safety.

Humidity

Temperature

Powerful Machinery’s chain hoists are engineered for a wide range of conditions. The corrosion-resistant models feature nickel-chrome plating and stainless-steel components. These hoists withstand moisture, chemicals, and outdoor exposure.

You can use them in clean rooms, food processing, marine engineering, and chemical industries. The open frame design allows for easy cleaning and inspection. Cambered technology and double pawl braking mechanisms provide extra durability and overload protection.

Duty Cycle | Description |

|---|---|

H1 | Infrequent Use: Hoists for standby or maintenance use, with very few lifts per day. |

H2 | Light Duty: General machine shop, service, and maintenance use where the hoist is used intermittently. |

H3 | Standard Duty: Hoists used in more regular production, handling up to 50% of their rated capacity on average. |

H4 | Heavy Duty: High-volume production and warehouse applications with frequent lifts at or near rated capacity. |

H5 | Severe Duty: For hoists in continuous or near-continuous operation, such as on a fast-moving assembly line. |

You should always match the chain hoist lifting capacity and features to your environment and duty cycle. This ensures reliable lifting and extends the life of your equipment.

Compliance with Safety Standards

Compliance with industry standards is essential for legal operation and workplace safety. You must verify that your chain hoist meets all relevant regulations before use. Powerful Machinery’s products comply with major international standards, giving you confidence in every lift.

Standard | Description |

|---|---|

SQP2:2018 | Revised Code of Practice impacting the design and use of electric chain hoists in the entertainment industry, incorporated into EN 17206 standard. |

ASME B30 | Safety standards for cranes, hoists, and rigging provide guidelines for safe operation and compliance. |

Powerful Machinery’s lever chain hoist and mini lever hoist models hold CE and ISO certifications. These certifications demonstrate a commitment to safety and compliance with industry standards. You can trust that every product has passed rigorous testing for lifting performance and overload protection.

Powerful Machinery’s Chain Hoist Selection

Choosing the right chain hoist involves more than just checking the load. Powerful Machinery supports you through every step of the selection process. Their team helps you identify the best solution for your unique lifting requirements.

Determine the required capacity for your heaviest load.

Select the suspension type—fixed or trolley-mounted—based on your workspace.

Evaluate lift, reach, and headroom to ensure proper fit.

Verify available power sources for electric or pneumatic hoists.

Choose the right control system for your operation: manual, electric, or pneumatic.

Select the lifting speed that matches your workflow.

You benefit from custom-engineered solutions tailored to your environment and operational needs. Powerful Machinery’s experts help you:

Know the needed capacity for every lift.

Identify dimensional boundaries to avoid hazards.

Choose a hoist rated for your specific environment, including extreme temperatures or corrosive conditions.

Select the right operation type for your job.

Tip: Consult Powerful Machinery for guidance on choosing the right chain hoist. Their experience ensures you get the best performance, safety considerations, and compliance with industry standards for every lifting task.

Safety and Maintenance Practices

Manufacturer Guidelines and Safety Features

You must follow manufacturer guidelines to maximize lifting safety and performance. Powerful Machinery’s chain hoist includes advanced safety features such as overload protection, secure locking mechanisms, and ergonomic handles. You should inspect and test safety features before each lifting operation.

These features help prevent accidental release of the load and protect your team. Always check the user manual for specific instructions on maintaining your chain hoist and using safety features correctly.

Safety Feature | Purpose |

|---|---|

Overload protection | Prevents lifting beyond the rated load |

Secure locking | Stops accidental load release |

Ergonomic handle | Reduces operator fatigue |

Routine Inspection and Maintenance

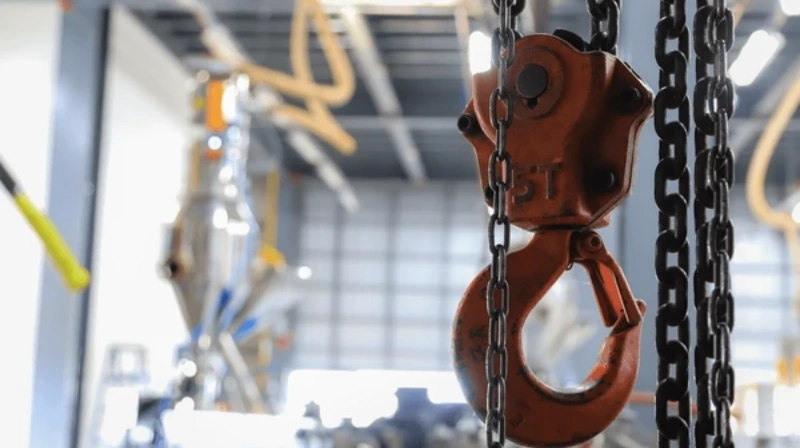

Regular inspections and maintenance keep your chain hoist in top condition. You need to inspect the chain and hook for wear, cracks, or deformation. Lubricate moving parts to reduce friction and extend equipment life.

Maintaining your chain hoist means checking for proper function and replacing worn components before they fail. Regular maintenance and inspection help you avoid unexpected breakdowns and keep lifting operations safe.

Tip: Schedule regular inspections and maintenance to catch issues early and maintain lifting reliability.

Preserving Lifting Capacities

Maintaining your chain hoist preserves its lifting capacity and ensures safe operation. You must avoid overloading and always use the correct attachments for each load. Regular maintenance enhances safety by protecting employees and equipment.

You reduce the total cost of ownership by minimizing accidents and failures. Enhanced safety reduces the likelihood of accidents and load failures. Increased equipment lifespan prevents premature wear and costly replacements. Operational efficiency improves when you minimize downtime from unexpected issues.

Proactive replacement of worn components reduces the risk of in-service failures.

Scheduled maintenance during planned shutdowns increases uptime and avoids unexpected breakdowns.

Powerful Machinery’s Support and Service

Powerful Machinery provides ongoing support to help you maintain safe and reliable lifting operations. Their after-sales service includes technical assistance and maintenance advice.

You receive guidance on maintenance and inspection schedules, troubleshooting, and best practices for lifting heavy loads. This support ensures your chain hoist operates safely and efficiently throughout its lifespan.

Note: Powerful Machinery’s commitment to safety and reliability gives you confidence in every lifting task.

Conclusion

You improve workplace safety and efficiency when you understand the chain hoist lifting capacity. Powerful Machinery’s Chain Hoist gives you reliable lifting for demanding environments. You select the right equipment by considering load requirements, environment, and safety standards.

Regular inspection and maintenance help you preserve lifting performance.

You protect your team by following proper lifting practices.

You achieve consistent results with certified lifting solutions.

For expert advice on lifting applications, consult Powerful Machinery and ensure every lifting operation meets the highest standards.

FAQ

How do you determine the right chain hoist capacity for your lifting needs?

You must calculate the total weight of your load, including any attachments. Always select a chain hoist with a rated capacity higher than your maximum lifting requirement. This approach ensures safe lifting and prevents equipment overload.

What regular maintenance does a chain hoist require for safe lifting?

You should inspect the chain, hooks, and gears before each use. Lubricate moving parts as recommended. Replace worn components immediately. Regular maintenance keeps your lifting equipment reliable and extends its service life.

Can you use a chain hoist for vertical and horizontal lifting?

You use a chain hoist primarily for vertical lifting. For horizontal movement, you need additional equipment like a trolley. Always follow manufacturer guidelines to ensure safe lifting in every direction.

What safety features should you look for in a lifting chain hoist?

You should look for overload protection, secure locking mechanisms, and ergonomic handles. These features help you maintain safe lifting operations and protect both operators and loads.

Does Powerful Machinery offer support for lifting equipment selection and use?

Yes, you receive expert guidance from Powerful Machinery’s team. They help you choose the right lifting solution, provide technical support, and offer maintenance advice for all lifting applications.