You need to know which type of eyebolt is not allowed for rigging. Safety standards prohibit regular nut eyebolts, non-shouldered eyebolts, open or plated eyebolts, and any modified versions. These types can fail under load because they do not meet OSHA and ASTM requirements.

Using the wrong eyebolt increases the risk of accidents and equipment damage. Always select certified products designed for lifting and rigging.

Key Takeaways

Avoid using regular nut eyebolts, non-shouldered eyebolts, and modified designs for rigging. These types do not meet safety standards and can lead to accidents.

Always use shoulder eyebolts for angled lifts. They help distribute force and prevent bending or failure during side pulls.

Inspect eyebolts regularly for wear, corrosion, or damage. Replace any that show signs of deterioration to ensure safety.

Confirm the Working Load Limit (WLL) of each eyebolt before use. Never exceed this limit to prevent equipment failure.

Choose certified products that comply with OSHA and ASTM standards. This ensures safety and reliability in your rigging operations.

Which Type of Eyebolt Is Not Allowed for Rigging?

Prohibited Eye Bolt Types

When you ask which type of eyebolt is not allowed for rigging, you need to look at the design and intended use of each type. Not all eyebolts are created equal, and using the wrong one can put your entire operation at risk.

Below is a table that compares different types of eye bolts and highlights why some are not suitable for rigging hardware:

Eyebolt Type | Design Features |

|---|---|

Regular Nut Eyebolts | Feature a threaded shank but lack a shoulder, making them unsuitable for angled loads. |

Non-Shouldered Eyebolts | Similar to regular nut eyebolts, they do not have a shoulder and are only safe for vertical lifts. |

Modified Eyebolts | May include design alterations, but still lack the necessary shoulder for angled load applications. |

Compliant Rigging Eyebolts | Designed with shoulders or collars to safely handle angled loads, preventing breakage under stress. |

You should never use regular nut eyebolts, non-shouldered eyebolts, or any modified versions for rigging. These types do not meet the requirements for safe lifting, especially when the load is not perfectly vertical.

Modified eyebolts, especially those altered by welding or repair, often fail inspections and have a history of causing hardware failures in the field.

Open, closed, or plated eyebolts also fall into the category of types not allowed for rigging. These designs do not provide the strength or reliability needed for lifting heavy loads.

When you consider which type of eyebolt is not allowed for rigging, always avoid any eyebolt that lacks a proper shoulder or has been altered from its original design.

Safety Risks and Standards

Using the wrong type of eyebolt in rigging hardware can lead to serious safety hazards. Non-shouldered eyebolts, for example, should never be used outside of vertical or in-line lifting applications. If you use them for angled pulls, you risk catastrophic failure because they cannot handle side loads.

Traditional eyebolts are best for straight in-line lifts only. If you use them at an angle, you significantly reduce their working load limit and increase the chance of sideloading, which can cause the eyebolt to bend or break.

Note: Always check the minimum thread engagement. Eyebolts must have a minimum thread engagement of 1-1/2 times the diameter of the thread to ensure safety.

Regulatory standards such as OSHA 1910.184 and ASTM guidelines set strict requirements for rigging hardware. For example, open-end eye bolts must comply with dynamic load requirements under OSHA 1910.184.

However, closed and plated eyebolts do not meet these standards and should not be used for lifting. If you use eyebolts that do not meet these standards, you risk violating safety regulations and exposing your team to unnecessary danger.

Eyebolt Type | Safety Guidelines |

|---|---|

Shouldered Eyebolts | Must be used for all applications unless configuration prevents it. |

Unshouldered Eyebolts | Should not be used for angular pulls; can lead to catastrophic failures due to improper load handling. |

Minimum Thread Engagement | Eyebolts must have a minimum thread engagement of 1-1/2 times the diameter of the thread. |

Incident reports show that using modified eyebolts in rigging can lead to serious hazards. Items that have been altered or repaired, especially by welding, are often flagged during inspections and linked to hardware failures.

To maintain compliance and safety, you must inspect all rigging hardware regularly. Look for signs of bending, stretching, or damage. Overloading any component, including eyebolts, is a major cause of accidents. Always know the Rated Capacity (RC) or Working Load Limit (WLL) of each piece of equipment.

When you select rigging hardware, always choose compliant, certified products. Avoid any eyebolts that do not meet OSHA or ASTM standards. By understanding which type of eyebolt is not allowed for rigging and following best practices, you protect both your team and your equipment.

Types of Eye Bolts for Rigging Applications

Different Types of Eye Bolts and Their Uses

You need to understand the main types of eye bolts before selecting rigging hardware for your project. Each type offers unique features and load capacities. The most common types of eye bolts include shoulder eye bolts, plain or non-shoulder eye bolts, and swivel eye bolts.

Shoulder eye bolts feature a reinforced shoulder. You can use them for both straight and angular lifts. This design helps distribute tension and prevents bending under side loads.

Plain or non-shoulder eye bolts work best for vertical lifting only. These bolts lack reinforcement and can fail if you use them for side pulls.

Swivel eye bolts rotate to align with the direction of the load. You can use them in situations where the lifting angle changes or precise alignment is required.

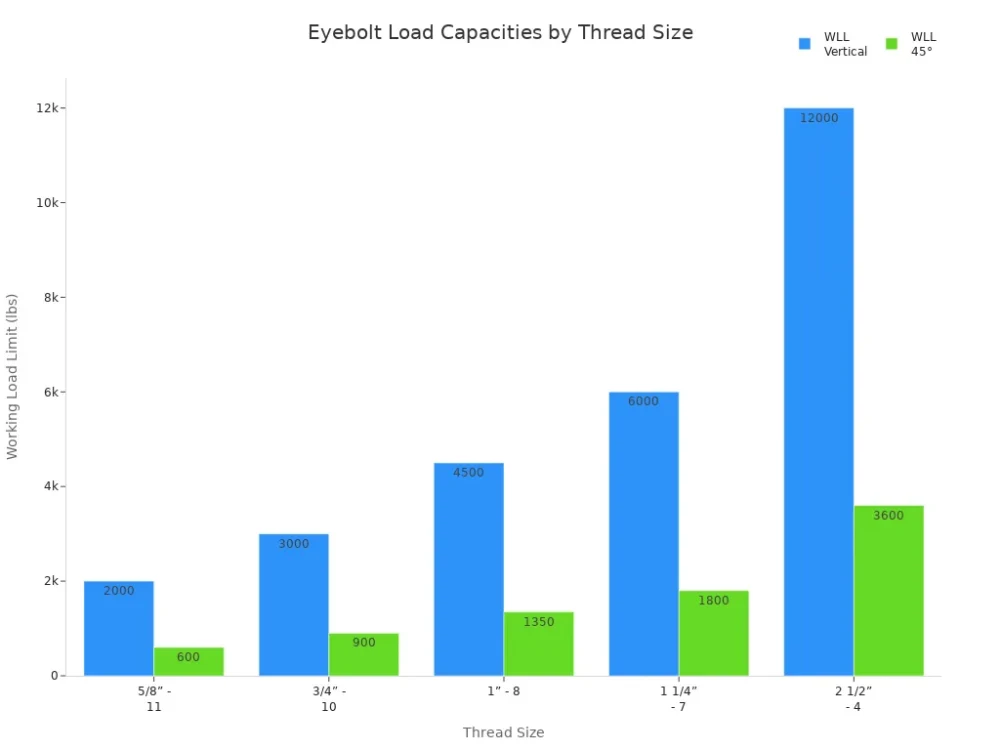

The table below shows typical working load limits for different thread sizes and lifting angles:

Thread Size | WLL Vertical (lbs) | WLL 45° (lbs) |

|---|---|---|

5/8” – 11 | 2,000 | 600 |

3/4” – 10 | 3,000 | 900 |

1” – 8 | 4,500 | 1,350 |

1 1/4” – 7 | 6,000 | 1,800 |

2 1/2” – 4 | 12,000 | 3,600 |

Before you use any type of eye bolt, always confirm the working load limit. Stainless steel eye bolts usually have lower capacities than carbon steel bolts of the same size. You should match the type of eye bolt to your lifting needs and the direction of force.

Powerful Machinery Eye Bolts And Eye Nuts Overview

Powerful Machinery offers a full range of compliant eye bolts and eye nuts for rigging hardware. You can choose from products made with high-quality carbon steel or stainless steel.

These eye bolts are heat-treated for maximum strength, with tensile ratings from 65,000 PSI to 90,000 PSI. The yield strength starts at 30,000 PSI, ensuring reliable performance in demanding environments.

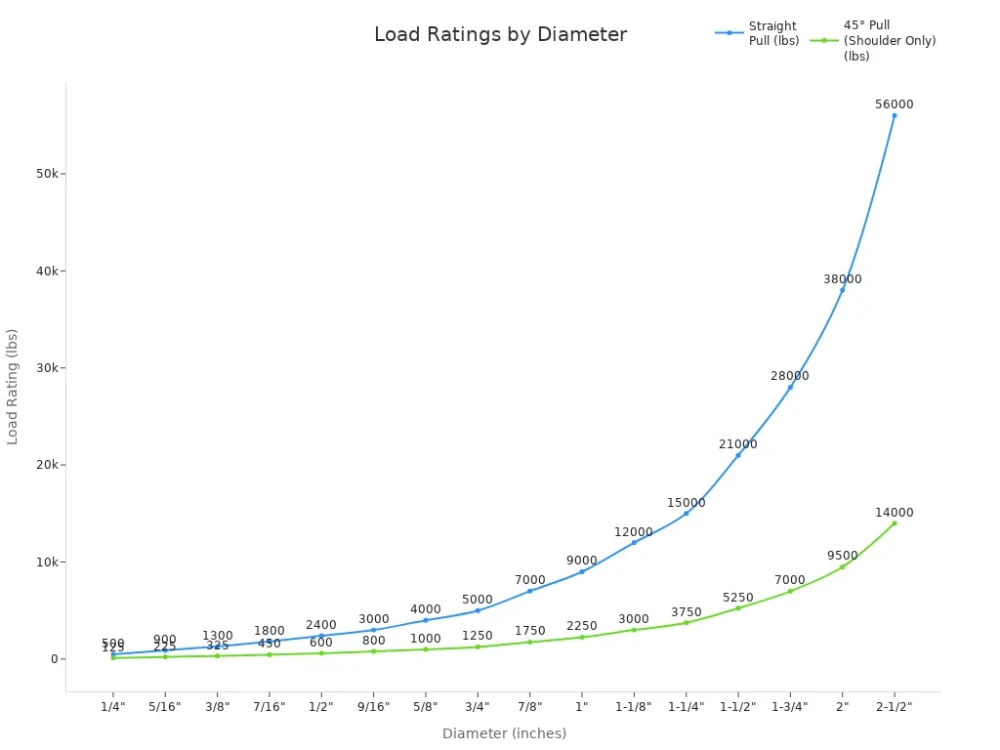

The table below highlights the load ratings for Powerful Machinery’s shoulder eye bolts:

Diameter | Straight Pull (lbs) | 45° Pull (Shoulder Only) (lbs) |

|---|---|---|

1/4″ | 500 | 125 |

1/2″ | 2,400 | 600 |

3/4″ | 5,000 | 1,250 |

1″ | 9,000 | 2,250 |

2″ | 38,000 | 9,500 |

2-1/2″ | 56,000 | 14,000 |

You gain several advantages when you select Powerful Machinery’s eye bolts. These products resist corrosion, making them ideal for marine and chemical environments.

Every item meets international safety standards, giving you confidence in your rigging hardware. You can rely on Powerful Machinery for durable, certified solutions in construction, shipping, and manufacturing.

Tip: Always choose eye bolts with a shoulder for angular lifts. This practice helps prevent accidents and ensures compliance with safety regulations.

You can find more details and specifications for Powerful Machinery’s eye bolts and eye nuts on their official website.

Safe Alternatives and Best Practices

Choosing the Right Eyebolt for Lifting

Selecting the correct types of eye bolts for your rigging hardware is essential for safe and efficient lifting operations. You should always start by confirming the Working Load Limit (WLL) of each bolt. Never exceed the maximum capacity, as this can lead to failure.

Before installation, inspect the threads for damage or debris and ensure the bolt matches the receiving hole. You must seat the shoulder of the bolt flush against the surface to prevent bending or breakage.

For angular lifts, use shoulder eye bolts and keep the angle as shallow as possible. Avoid using eye bolts designed for vertical loads in side-pull applications.

Industry experts recommend these best practices for lifting eye bolts:

Tighten bolts to the manufacturer’s recommended torque.

Inspect bolts for wear, corrosion, or distortion before each use.

Use washers to distribute stress evenly.

Select stainless steel bolts for corrosive environments.

Never use damaged or altered bolts.

Regular inspections are vital. Qualified inspectors should check your rigging hardware monthly or bi-monthly, depending on usage. Visual checks before each lift help you spot issues early. Replace any bolt showing signs of wear, heat damage, or elongation immediately.

Criteria for Eyebolt Safety and Compliance |

|---|

Free from heavy wear or corrosion |

No thread distortion or heat damage |

No signs of alteration or repair |

Clean, inspected receiving holes |

Meets performance requirements |

Tip: Always follow manufacturer guidelines and avoid over-tightening bolts. Misalignment and improper installation are common mistakes that you can easily prevent with proper training.

Powerful Machinery’s Commitment to Safety

You gain peace of mind when you choose Powerful Machinery’s certified eye bolts for your rigging hardware. These products meet international safety standards, including ISO 13849-1:2015 and IEC 62061:2005.

Each bolt features clear markings for grade and manufacturer, helping you verify compliance quickly. Powerful Machinery’s eye bolts used for overhead lifts offer high tensile strength and corrosion resistance, making them ideal for marine and outdoor environments.

You benefit from quick installation and reliable performance. The certified lifting eye bolts reduce accident risk and improve operational efficiency. Powerful Machinery’s commitment to quality ensures that every product undergoes rigorous testing and inspection.

You can trust these types of eye bolts to deliver consistent safety and reliability in demanding applications.

Note: Establish a maintenance plan that includes routine inspections and cleaning. Lubricate moving parts and replace any questionable equipment to maintain long-term safety.

Conclusion

You must avoid regular nut eyebolts, non-shouldered eyebolts, and any modified or plated designs for rigging. These types fail to meet safety standards and can cause accidents, especially during angled lifts.

Key safety points include:

Shoulder eyebolts are rated only for vertical lifting.

Angled lifts can reduce capacity by over 70%.

Any change in load direction increases the risk of failure.

Choose certified products like Powerful Machinery’s eye bolts.

To maintain compliance:

Inspect markings and rated load.

Store hardware properly.

Train your team in safe rigging practices.

FAQ

What type of eyebolt should you use for angled lifts?

You should use a shoulder eyebolt for any lift involving an angle. The shoulder design helps distribute force and prevents bending or failure during side pulls.

How do you check if an eyebolt meets safety standards?

Look for clear markings indicating load capacity and manufacturer. Verify compliance with standards like OSHA and ASTM. You can find certified products on Powerful Machinery’s website.

Can you use regular nut eyebolts for rigging?

You should never use regular nut eyebolts for rigging. These bolts lack a shoulder and cannot handle side loads, which increases the risk of accidents and hardware failure.

How often should you inspect rigging eyebolts?

You should inspect rigging eyebolts before each use and schedule monthly or bi-monthly checks. Replace any bolt showing wear, corrosion, or damage immediately.