You often ask, “How long is a chain hoist?” Powerful Machinery provides manual and electric chain hoists with standard lift heights, as shown below:

Type of Hoist | Standard Lift Height | Customization Options |

|---|---|---|

10 feet (3 meters) | Additional chain lengths available | |

20 feet (6 meters) | Custom lengths can be designed as needed |

Lift height refers to the vertical distance your hoist can raise a load. This measurement plays a vital role in matching the hoist to your workspace and lifting application. You need to consider the weight of your load, the environment, and safety requirements.

Facilities like ship wharves, steel mills, vehicle workshops, and renewable energy sites often require specific lift heights for efficient operation. Powerful Machinery delivers certified solutions and expertise to meet your lifting needs.

Key Takeaways

Understand the lift height to match your chain hoist to your workspace. Measure from the floor to the highest point you need to lift.

Choose between manual and electric chain hoists based on your lifting needs. Manual hoists are great for lighter loads, while electric hoists handle heavier tasks efficiently.

Consider customization options for unique lifting requirements. Powerful Machinery offers extended chain lengths and variable speed controls to fit your specific needs.

Prioritize safety by selecting certified hoists with advanced safety features. Always check for certifications to ensure compliance with safety standards.

Regular maintenance extends the lifespan of your hoist. Conduct daily inspections and protect your equipment from harsh environmental conditions.

Understanding Chain Hoist Lift Height

What is Lift Height?

You need to understand lift height before choosing a chain hoist for your project. In industrial lifting terminology, lift height means the maximum height that the hook of a chain hoist can safely reach from the floor. This measurement determines how high you can raise your load.

If you work in a warehouse, construction site, or manufacturing plant, you must match the lift height to your workspace and lifting needs. Manual and electric chain hoists from Powerful Machinery offer different lift heights to suit various environments.

Selecting the right lift height helps you avoid operational delays and ensures safe lifting.

Tip: Always measure the distance from the floor to the highest point you need to lift your load. This step helps you choose the correct hoist model.

Measuring Lift Height

You can measure lift height by checking the vertical distance between the hook’s lowest position and its highest possible reach. Use a tape measure or a laser distance meter for accuracy. Start at the floor level and measure up to the point where you want the load to go.

Record this measurement and compare it to the specifications of available chain hoists. Powerful Machinery lists standard lift heights for each model, making your selection process easier. If your workspace has unique requirements, you can request custom lift heights to match your needs.

Key Terms: Hand Chain Drop, Headroom

When you review chain hoist specifications, you will see terms like hand chain drop and headroom. These terms help you understand how the hoist fits into your workspace.

Hand Chain Drop: This refers to the length of the hand chain that hangs down for manual operation. You need enough chain drop for comfortable use, especially if you work at different heights.

Headroom: This is the distance between the spot on the hook from which the object will be carried and the place where the hoist, or lift and trolley, links with the main frame the hoist is hung from. Lower headroom allows you to lift loads higher in spaces with limited clearance.

Understanding these terms helps you select manual and electric chain hoists that fit your environment and lifting tasks. You can optimize your workspace and improve safety by choosing the right specifications.

Manual and Electric Chain Hoists: Standard and Custom Heights

Powerful Machinery Manual Chain Hoist Lift Heights

You can rely on Powerful Machinery’s manual chain hoists for dependable lifting in many environments. These hoists come with a standard lift height of 10 feet (3 meters), which suits most general lifting tasks in workshops, warehouses, and construction sites.

You get a compact and lightweight design that makes transport and setup easy. The SK Series manual chain hoist offers a range of capacities, from 0.5 to 20 tons, so you can match the hoist to your load requirements.

Manual chain hoists work best for lighter loads and less frequent lifting. You benefit from low maintenance and simple operation, especially in places without a power supply.

If you need to lift loads in tight spaces or areas with limited headroom, you can choose a low-headroom model. This option maximizes your available vertical space and keeps your workflow efficient.

Note: Manual chain hoists from Powerful Machinery allow you to add extra chain length if your project requires a higher lift. This flexibility ensures you always have the right tool for the job.

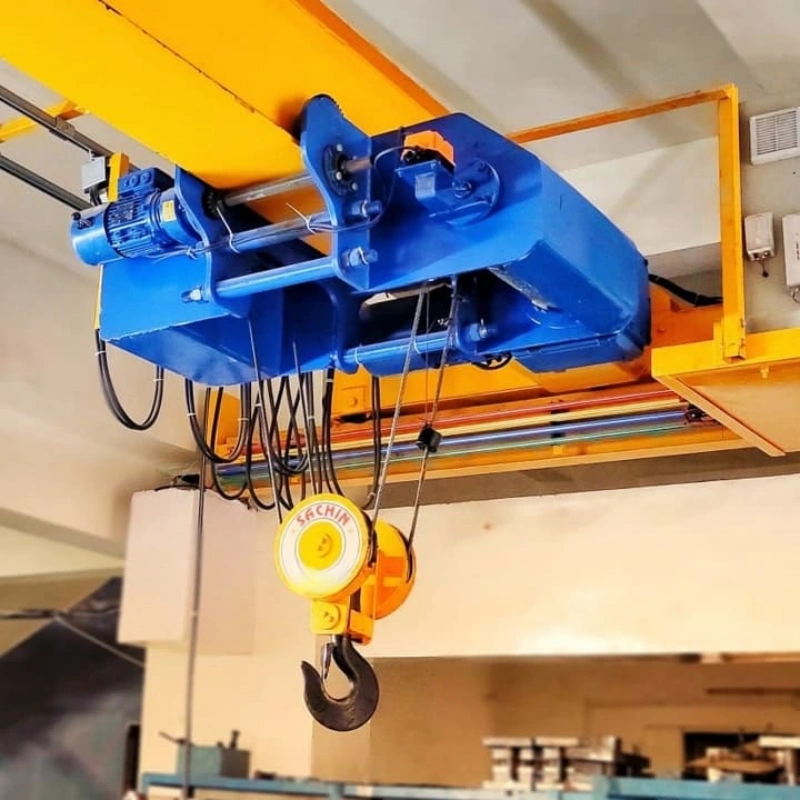

Powerful Machinery Electric Chain Hoist Lift Heights

When you need to handle heavier loads or frequent lifting, electric chain hoists from Powerful Machinery provide a powerful solution. The standard lift height for these hoists is 20 feet (6 meters), which covers most industrial and commercial applications.

You can select from models with capacities ranging from 0.5 to 5 tons, each designed for high-frequency use and efficient operation.

Electric chain hoists excel in busy warehouses, manufacturing plants, and construction sites. You get faster lifting speeds and reduced operator fatigue. The compact design of the HHSY Electric Chain Hoist also makes it ideal for spaces with limited headroom.

You can combine these hoists with permanent magnet lifters or other attachments to expand your lifting capabilities.

The table below compares manual and electric chain hoists in terms of lift height and typical applications:

Type of Hoist | Lift Height Considerations | Applications |

|---|---|---|

Electric Chain Hoists | Designed for high-frequency lifting, suitable for larger lift heights in industrial settings. | Large-scale manufacturing, busy warehouses, and construction sites |

Manual Chain Hoists | Lower lift height capabilities are ideal for lighter loads. | Smaller workshops, maintenance areas, and infrequent lifting tasks |

Low Headroom Hoists | Optimized for limited vertical space, maximizing lift height in tight areas. | Low-ceilinged warehouses, compact workshops |

Customization Options

You may find that your lifting environment requires more than standard specifications. Powerful Machinery offers a wide range of customization options for both manual and electric chain hoists. You can request extended chain lengths for high ceilings or large structures.

Variable speed controls help you adjust lifting speed for precision tasks. Specialized hooks and attachments ensure a secure grip on unique loads. Overload protection adds an extra layer of safety by stopping the hoist if the load exceeds capacity.

Remote control operation lets you manage lifting from a safe distance, which is especially useful in hazardous or hard-to-reach areas.

Here is a summary of available customization options:

Customization Option | Description |

|---|---|

Extended Chain Length | Increases lifting height by adding more chain length, useful for high ceilings or large structures. |

Variable Speed Controls | Allows adjustment of lifting/lowering speed for precision tasks, enhancing control during operation. |

Specialized Hooks & Attachments | Provides hooks designed for specific objects, ensuring a secure grip and safe operation. |

Overload Protection | Detects when the load exceeds capacity, halting operation to prevent accidents. |

Remote Control Operation | Enables control from a distance, beneficial in hazardous environments or where visibility is limited. |

Choosing between standard and custom lift heights depends on your specific needs. Standard lift heights work well for most general applications and offer quick delivery. Custom solutions give you the flexibility to meet unique project requirements, ensuring safety and efficiency in every lift.

Tip: You can always consult with Powerful Machinery to discuss your lifting challenges. Their team will help you select the right manual and electric chain hoists, whether you need standard models or fully customized solutions.

Choosing Chain Hoist Length

Assessing Lifting Needs

You must evaluate your lifting requirements before selecting the correct chain hoist length. Powerful Machinery offers a wide range of manual and electric chain hoists, each designed for specific tasks and environments.

Begin by identifying the distance between the installation point and the highest position you need to lift your load. This measurement determines the minimum chain length required for safe operation.

Consider the following factors when assessing your lifting needs:

Factor | Description |

|---|---|

Lifting Distance | Measure the vertical distance from the hoist’s mounting point to the load’s highest required position. |

Hoist Weight Capacity | Ensure the hoist can handle the maximum load weight, including safety margins. |

Suspension | Choose the appropriate suspension type, such as hook or lug, based on your workspace and headroom. |

Load Characteristics | Understand the load’s weight, center of gravity, and whether it is static or dynamic. |

Environmental Factors | Evaluate the worksite conditions, including humidity, dust, and chemical exposure. |

Tip: Always measure your lifting distance accurately. This step helps you avoid purchasing a hoist with insufficient chain length, which can lead to operational delays or safety risks.

Factors Affecting Selection

Selecting the right chain hoist length involves more than just measuring distance. You must account for several variables that influence performance and safety. Powerful Machinery provides solutions tailored to your specific environment and load requirements.

Accurate load weight measurement is essential. You must know the exact weight to prevent overloading the hoist.

The center of gravity affects how the load will balance during lifting. Unbalanced loads require special attention.

Static loads remain steady during lifting, while dynamic loads may shift or move. Dynamic loads often need additional safety measures.

Environmental conditions play a significant role. Extreme temperatures, corrosive atmospheres, and high humidity can impact hoist performance. You may need weather-resistant enclosures or motors with high IP ratings for outdoor use.

Compatibility with existing equipment ensures seamless integration. Check the mounting points and suspension types to match your workspace.

Note: Powerful Machinery offers chain hoists with TEFC motors and weather-resistant enclosures for challenging environments. These features protect your equipment and extend its lifespan.

Suspension and Headroom

Suspension type and available headroom are critical when choosing chain hoist length. The way you mount the hoist affects both safety and operational efficiency.

Hook suspension allows quick installation and flexibility. It works well in spaces with adequate headroom.

Lug suspension provides a fixed mounting option. It is ideal for permanent installations or areas with limited vertical space.

Available headroom determines how much vertical space you have for lifting. Measure from the ceiling or beam to the floor to ensure proper clearance.

Limited headroom requires low-headroom hoists. These models maximize lifting capability in tight spaces and prevent collisions with overhead structures.

Alert: Always verify headroom before installation. Insufficient clearance can restrict lifting height and compromise safety.

Powerful Machinery’s product range includes manual and electric chain hoists designed for various suspension types and headroom constraints. You can select models with compact designs for low-ceiling environments or choose extended chain lengths for high-ceiling applications.

Matching the hoist to your workspace ensures efficient lifting and reduces the risk of accidents.

Safety and Ordering Tips

Safety Features and Standards

You need to prioritize safety when selecting a chain hoist for your operations. Powerful Machinery builds every chain hoist with advanced safety features that meet strict international standards.

The Safety Plus Hoist Monitor and Safety Plus Brake System help you maintain control and prevent accidents. These systems comply with IEC62061 and achieve Safety Integrity Level 3, which means you get reliable protection in demanding environments.

Powerful Machinery’s products carry certifications such as ISO9001, ISO4301-1, and TUV Rheinland. These certifications guarantee that your equipment meets global standards for quality, safety, and efficiency. You can review the table below to see how these standards apply:

Safety Feature | Description |

|---|---|

Safety Plus Hoist Monitor | Monitors hoist operation, designed for high safety integrity. |

Safety Plus Brake System | Certified brake system for secure load handling. |

ISO Certification | Ensures compliance with international safety and quality standards. |

ASME, OSHA, ANSI | Regulate construction, inspection, and maintenance for lifting devices. |

Tip: Always check for certifications before purchasing. Certified hoists help you reduce risk and comply with workplace regulations.

Maintenance and Environment

You extend the lifespan of your chain hoist by following a regular maintenance schedule. Daily checks for wear or damage keep your equipment safe. Lubricate the load chain to prevent corrosion and reduce friction. Inspect electrical components if you use electric hoists.

Operator training ensures everyone uses the equipment correctly.

Environmental factors like moisture, dust, and temperature swings can affect performance. You should protect your hoist from harsh conditions and clean it regularly. Corrosion and dirt can build up quickly in outdoor or industrial settings. Chemical exposure and humidity also cause wear and tear.

Conduct daily visual inspections.

Lubricate chains as recommended.

Train operators on proper use and maintenance.

Protect hoists from moisture and chemicals.

Alert: Overloading, improper lubrication, and shock loading are common causes of chain hoist failure. Always follow manufacturer guidelines.

Specifying Chain Length

You must specify the correct chain length to ensure compatibility with your lifting system. Measure the lowest point the hook must reach, such as the ground or a platform. Determine the highest point the hook must lift to, usually just below the beam or trolley. Use this formula:

Chain Length = Highest Lifting Point - Lowest Lifting Point

If your measurements are close, round up to avoid a chain that is too short. Electric hoists typically last 10 to 20 years, while manual hoists can last even longer with proper care. Always match chain length to your workspace and lifting needs.

Note: Consult Powerful Machinery’s experts for help with custom chain lengths or unique environments. Their team ensures you get the right solution for safe and efficient lifting.

Conclusion

You improve safety and efficiency when you understand the chain hoist lift height.

Vertical lifts prevent dangerous side loads and reduce risk.

Standard lift heights suit most jobs, but you can request custom options for unique needs.

Powerful Machinery offers manual hoists for portability and electric hoists for speed and heavy loads.

Safety features like overload protection help protect your team.

You find certified products for every application.

Consult Powerful Machinery for expert guidance and custom solutions tailored to your lifting challenges.

FAQ

How do you choose the right chain hoist length for your project?

You measure the vertical distance from the lowest to the highest lifting point. Add a safety margin. Review Powerful Machinery’s specifications. Consult their experts for custom requirements.

Can you request a custom chain length from Powerful Machinery?

Yes, you can request custom chain lengths. Powerful Machinery offers tailored solutions for manual and electric chain hoists. You get the right fit for your workspace.

Tip: Contact Powerful Machinery’s team for personalized recommendations.

What safety certifications do Powerful Machinery chain hoists have?

You find certifications such as ISO9001, TUV Rheinland, and OSHA. These certifications ensure your equipment meets international safety and quality standards.

Certification | Standard Met |

|---|---|

ISO9001 | Quality Management |

TUV Rheinland | Safety Compliance |

OSHA | Workplace Safety |

How often should you inspect and maintain your chain hoist?

You should inspect your chain hoist daily for wear or damage. Lubricate chains regularly. Train operators to follow maintenance guidelines. Schedule professional inspections at least once a year.