You see “6×19 wire rope” and wonder what 6×19 wire rope means. This term describes a wire rope made from 6 strands, each containing 19 wires. Understanding wire rope classification helps you select the right product for your job. Classification affects safety, durability, and efficiency in construction and industrial settings.

Powerful Machinery provides certified Steel Wire Rope solutions trusted by professionals worldwide.

Wire rope classification follows industry standards, including ASTM specifications and steel grades. These standards influence corrosion resistance, tensile strength, and fatigue endurance, making classification essential for safe and reliable operations.

Wire rope classification determines performance and safety.

Classification ensures you choose the most effective wire rope for your needs.

Key Takeaways

6×19 wire rope consists of six strands, each with about 19 wires, providing a strong and durable option for heavy-duty tasks.

Choosing the right wire rope classification is crucial for safety and performance; always match it to your specific application needs.

Regular inspection and maintenance of wire rope can extend its service life and ensure safe operation; follow the manufacturer’s guidelines.

6×19 wire rope is ideal for applications requiring abrasion resistance, such as construction and marine environments.

Powerful Machinery offers certified wire ropes that meet international standards, ensuring reliability and safety for demanding jobs.

What Does 6×19 Wire Rope Mean?

Breaking Down the Numbers

When you ask, what does 6×19 wire rope mean, you want a clear answer. The term 6 x 19 describes the construction of the wire rope. The first number, 6, tells you the rope has six strands. The second number, 19, means each strand contains about 19 wires.

In reality, the number of wires in each strand can range from 16 to 26, depending on the specific design. This structure gives the rope a balance of strength and durability.

You often see the 6 x 19 classification in industries that need abrasion resistance. The rope’s design creates a tough outer layer, which helps it stand up to rough surfaces and heavy use.

However, this also means the rope is less flexible than ropes with more wires per strand. If you need a rope for applications with frequent bending, you might consider a different classification.

Here is a quick overview of the main components and features of 6 x 19 wire rope:

Component | Description |

|---|---|

Construction | 6×19+FC, 6×19+IWS, or IWRC |

Strand Number | 6 |

Wire Number of Each Strand | 19 |

Material | High Carbon Steel or Stainless Steel |

Rope Core | FC (Fiber core), IWS (Steel Core), or IWRC |

Available Sizes | From 3mm up to 56mm |

Surface Treatment Options | Electric Galvanization, Hot Dip Galvanization, Lubrication, PVC coating |

Lubrication | Dry for galvanized, light grease for ungalvanized, custom options available |

Packing | 1000m/reel standard, custom lengths available |

You can see that the 6 x 19 wire rope offers many choices in materials, cores, and finishes. This flexibility lets you select the right rope for your job.

Tip: The maximum breaking strength of 6 x 19 wire rope can reach up to 69 tons. However, you should always use only one-fifth of this value as the working load limit to ensure safety.

Understanding Wire Rope Classification

You might wonder why the classification system matters. When you ask, what does 6×19 wire rope mean, you are really asking how the rope’s structure affects its performance and safety. The 6 x 19 classification is just one example of how wire ropes are grouped based on their construction.

Wire rope classification helps you compare ropes quickly. For example, the 6 x 19 classification focuses on abrasion resistance, while other types, like 6×36, offer more flexibility and fatigue resistance. Here is a table to help you see the difference:

Classification | Strands | Wires per Strand | Emphasis on Resistance |

|---|---|---|---|

6×19 | 6 | 16 to 26 | Abrasion Resistance |

6×36 | 6 | 27 to 49 | Fatigue Resistance |

Industry standards, such as those from ISO and ASTM, recognize several categories of wire rope. These include standard ropes, rotation-resistant ropes, and special types for unique applications. The 6 x 19 classification falls under standard ropes, which are used in many general lifting and rigging tasks.

Type of Rope | Description |

|---|---|

Standard Rope | General classification of wire rope |

Type I Rotation Resistant Rope | Little or no tendency to rotate, at least 15 outer strands |

Type II Rotation Resistant Rope | Significant resistance to rotation, at least 10 outer strands |

Type III Rotation Resistant Rope | Limited resistance to rotation, no more than nine outer strands |

When you choose a wire rope, you must match the classification to your application. The number of strands and wires affects both strength and flexibility. The 6 x 19 wire rope gives you a strong, wear-resistant option, but it is not rotation-resistant.

If your job requires a rope that will not spin under load, you should look for a rotation-resistant type.

Selecting the right classification is not just about performance. It is also about safety. If you use the wrong rope or the wrong end connectors, you risk equipment failure and injury. Always check the classification and make sure it fits your needs.

Powerful Machinery specializes in manufacturing certified steel wire rope, including the 6 x 19 classification. You get ropes that meet or exceed international standards, such as ISO9001 and TUV Rheinland. Powerful Machinery’s expertise ensures you receive products that deliver both safety and performance in demanding environments.

When you understand what 6×19 wire rope means, you can make better decisions for your projects. You protect your team, your equipment, and your reputation by choosing the right rope every time.

6 x 19 Wire Rope Types and Features

Main Constructions and Variations

You encounter several types of 6 x 19 wire rope, each designed for specific tasks. The most common constructions include standard and filler wire designs. The standard 6×19 construction uses six strands, each with 19 wires. This structure gives you a balance between flexibility and abrasion resistance.

Filler wire constructions add smaller wires between the main wires, increasing fatigue resistance and service life.

You can choose between different core types. The Independent Wire Rope Core (IWRC) provides extra strength and crush resistance. Fiber cores offer more flexibility and absorb shock loads well. Here is a quick comparison:

Construction Type | Description |

|---|---|

IWRC | Independent Wire Rope Core |

Fiber Core | Core made of fiber materials |

The 6×19 construction features large outer wires. These wires make the rope rugged and resistant to abrasion. You find this type in construction and marine industries, where durability matters.

Stainless steel versions of 6 x 19 wire rope deliver both flexibility and wear resistance, making them ideal for machinery and equipment exposed to harsh conditions.

Key Properties and Performance

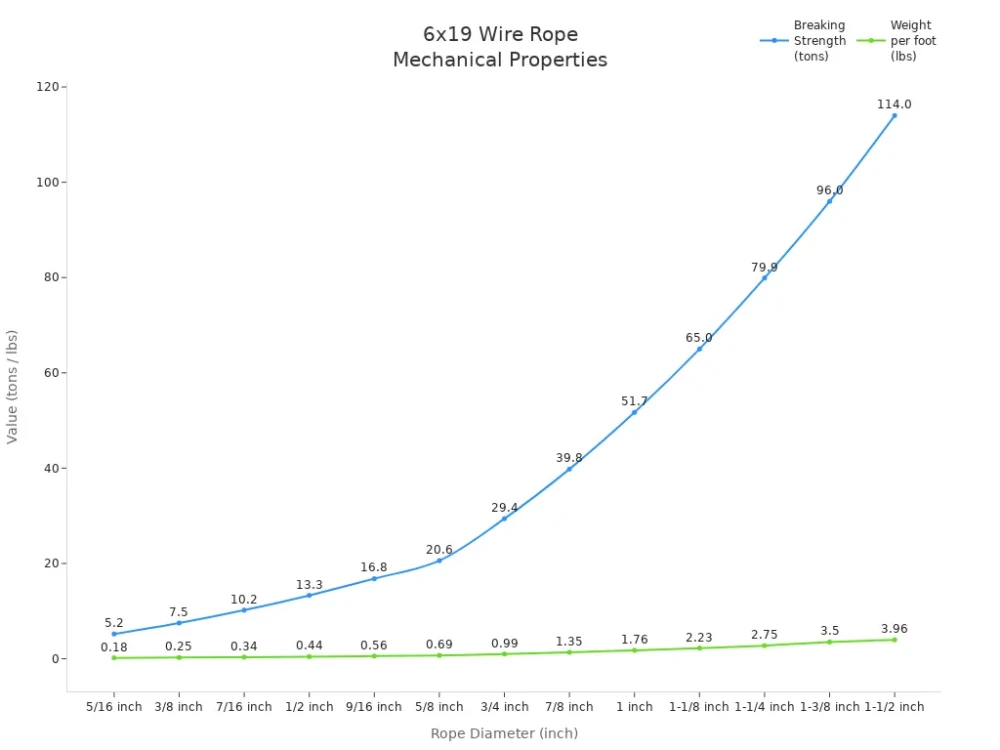

When you select a 6 x 19 wire rope, you look for strength, durability, and reliability. The rope’s mechanical properties vary by diameter. You can review the following table to understand the breaking strength and weight per foot for different sizes:

Rope Diameter (inch) | Breaking Strength (tons) | Weight per foot (lbs) |

|---|---|---|

5/16 | 5.2 | 0.18 |

3/8 | 7.5 | 0.25 |

7/16 | 10.2 | 0.34 |

1/2 | 13.3 | 0.44 |

9/16 | 16.8 | 0.56 |

5/8 | 20.6 | 0.69 |

3/4 | 29.4 | 0.99 |

7/8 | 39.8 | 1.35 |

1 | 51.7 | 1.76 |

1-1/8 | 65.0 | 2.23 |

1-1/4 | 79.9 | 2.75 |

1-3/8 | 96.0 | 3.50 |

1-1/2 | 114.0 | 3.96 |

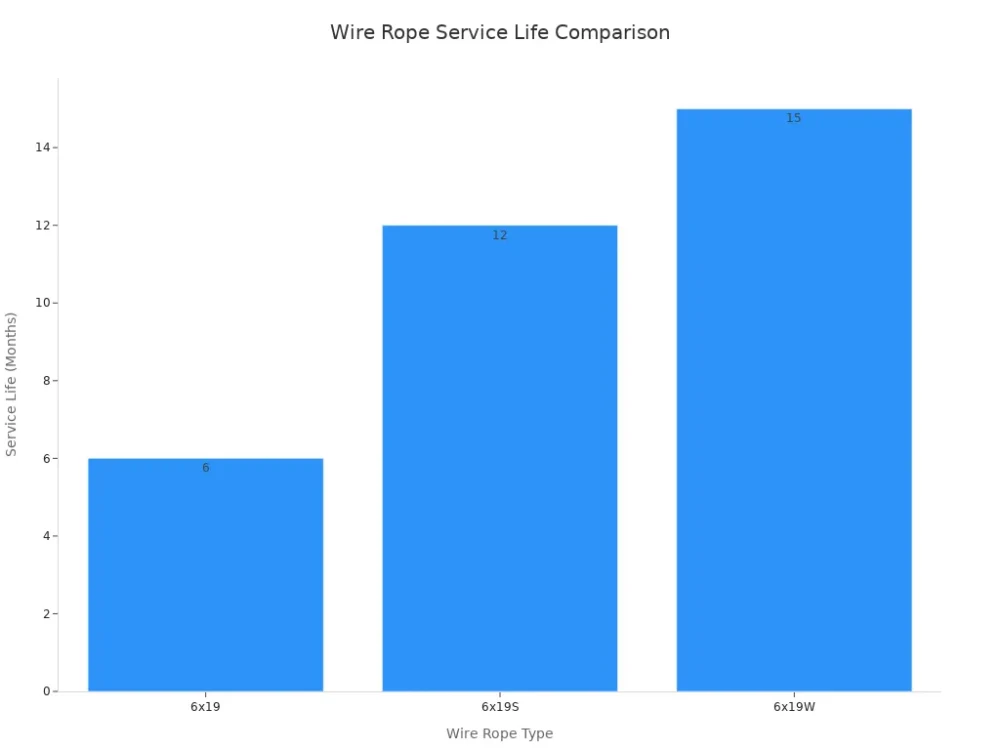

The 6×19 construction stands out for its wear and crush resistance. You benefit from medium abrasion resistance and a service life of three to six months under normal conditions.

If you need higher abrasion resistance, you might consider the 6x19S type, which lasts longer in heavy-load scenarios. For frequent bending, the 6x19W type offers better fatigue resistance and extended service life.

Wire Rope Type | Abrasion Resistance | Service Life (Months) | Suitable Applications |

|---|---|---|---|

6 x 19 | Medium | 3-6 (1-3 under bending) | General lifting tasks |

6x19S | High (30%-50% better than 6 x 19) | 6-12 (1.5-2x 6 x 19) | Heavy-load, high-wear scenarios |

6x19W | High (40%-60% better fatigue resistance) | 8-15 | Frequent bending applications |

Note: The 6 x 19 wire rope is not as flexible as the 6×36 type. You should choose the right construction based on your project’s needs.

Powerful Machinery Steel Wire Rope Advantages

When you choose Powerful Machinery’s steel wire rope, you gain access to advanced features that set your equipment apart. The non-rotating design keeps the rope stable during lifting, reducing the risk of twisting and kinking. High tensile strength ensures reliable performance in demanding applications.

You receive products that meet ISO 9001:2015 certification, reflecting strict quality management and safety standards.

Unique Features of PowerFul Machinery | Description |

|---|---|

High Tensile Strength | Designed for heavy-duty lifting, ensuring reliability in demanding applications. |

Non-Rotating Design | Enhances safety and performance, especially where stability is crucial. |

Custom Solutions | Tailored products for specific infrastructure requirements. |

ISO 9001:2015 Certification | Commitment to quality management and safety standards. |

Strict Testing | Rigorous testing for tough environments. |

You can request custom-engineered solutions to fit your unique project requirements. Powerful Machinery’s wire ropes undergo strict testing, so you know they will perform well in tough environments. You find these ropes in cranes and hoists, construction and infrastructure projects, and marine and shipping operations.

Cranes and Hoists: You use 6 x 19 wire rope for lifting operations, where it handles significant weight and maintains flexibility.

Construction and Infrastructure: You rely on this rope to suspend bridges, support structures, and operate machinery.

Marine and Shipping: You depend on 6 x 19 wire rope for mooring, towing, and rigging, even in harsh conditions.

Tip: Powerful Machinery’s steel wire rope delivers peace of mind. You get certified quality, advanced engineering, and proven reliability for your most critical lifting and rigging tasks.

Comparing Wire Rope Classification

6×19 vs 6×37 Wire Rope

When you compare wire rope classification, you notice important differences between 6×19 and 6×37 wire rope. The 6×19 wire rope features six strands, each with 19 wires. This design gives you a balance of strength and abrasion resistance. The 6×37 wire rope uses six strands, each with about 37 smaller wires.

You get more flexibility, but the rope sacrifices some strength. The following table highlights the main differences:

Feature | 6×19 Wire Rope | 6×37 Wire Rope |

|---|---|---|

Construction | Six outer strands of 19 wires each | Six outer strands of approximately 37 smaller wires |

Strength | Balance of strength and abrasion resistance | Enhanced flexibility, reduced strength |

Flexibility | Less flexible, suitable for high-load applications | More flexible, suitable for frequent bending |

Common Applications | Overhead cranes, winches, and general lifting | Mobile cranes, elevator hoist ropes, and rigging |

You often choose 6×19 wire rope for construction, heavy equipment, and mining. These applications demand resistance to abrasion and crushing. The rope’s thicker wires last longer in tough conditions. You select 6×37 wire rope when you need flexibility for frequent bending, such as in elevator systems or mobile cranes.

Fewer, thicker wires in 6×19 wire rope resist wear and tear.

6×19 wire rope lasts longer in harsh environments.

The market share for wire rope classification varies globally. The 6×19 wire rope remains popular for its balance of flexibility and abrasion resistance. Other types, like 6×36, gain preference in dynamic environments that require superior flexibility.

Choosing the Right Wire Rope for Your Needs

Selecting the correct wire rope classification depends on your application. You must consider construction, flexibility, strength, and environment. The following table shows how different classifications fit specific tasks:

Classification | Characteristics | Applications |

|---|---|---|

1×19 | Stiff, minimal flex | Guy wires, straight line use |

7×7 | Flexible, moderate strength | Rigging, towing heavy objects |

7×19 | Highly flexible, high strength | Mechanical assemblies with pulleys |

You should also think about the material. Galvanized steel offers corrosion resistance, but stainless steel works best in saltwater environments. Grades 304, 305, and 316 provide options for marine use.

When you select wire rope, review breaking strength ratings. Minimum breaking strength tells you the smallest load that causes failure. Aggregate strength measures the total strength of all wires tested individually. These ratings help you avoid overloads and ensure safety.

Powerful Machinery supports you throughout the selection process. You receive detailed information about wire rope classification and product specifications. The company guides you on maintenance practices and matches wire rope to your operational needs.

All products meet strict industry standards, giving you confidence in quality and reliability.

Tip: Always match wire rope classification to your project’s requirements. This ensures safety, performance, and long-term value.

Conclusion

You now understand that 6×19 wire rope means six strands with 16 to 26 wires per strand, designed for abrasion resistance. The table below shows how different constructions within the 6×19 classification suit various applications:

Classification | Characteristics | Typical Applications |

|---|---|---|

6 x 19 Seale | Abrasion and crush resistance | Haulage Rope, Rotary Drilling Line |

6 x 21 Filler Wire | More bending fatigue resistance | Pull Ropes, Draglines |

6 x 25 Filler Wire | Most flexible, balanced resistance | Cranes, Hoists,and Mooring Lines |

6 x 26 Warrington Seale | Good abrasion and fatigue resistance | Boom Hoists, Logging Lines |

Powerful Machinery’s certified steel wire rope delivers reliability and safety for demanding jobs.

You can consult Powerful Machinery for expert guidance and custom-engineered solutions.

Choose the right wire rope to protect your team and equipment.

FAQ

What does “6×19” mean in wire rope?

You see “6×19” and know it means the rope has six strands, each made up of about 19 wires. This construction gives you a balance of strength and abrasion resistance.

When should you choose a 6×19 wire rope?

You select 6×19 wire rope for lifting, rigging, or hoisting tasks where abrasion resistance matters more than flexibility. It works well in construction, marine, and cargo handling environments.

How do you maintain 6×19 wire rope for long service life?

You should inspect the rope regularly for wear, corrosion, or broken wires. Lubricate as recommended. Replace the rope if you see significant damage or reduced performance.

Tip: Always follow manufacturer guidelines for inspection and maintenance.

What certifications do Powerful Machinery steel wire ropes have?

You receive steel wire ropes certified to ISO9001, TUV Rheinland, and other international standards. These certifications ensure you get reliable, high-quality products for demanding applications.

Can you get custom-engineered wire rope solutions?

Yes. Powerful Machinery offers custom wire rope solutions. You can request specific sizes, constructions, or coatings to fit your project requirements.