You achieve Steel wire rope tightening by using certified hardware and following precise steps. Safety depends on inspecting the rope, selecting proper tools, and applying correct tension.

Powerful Machinery’s Steel Wire Rope ensures reliability with international certifications such as ISO 2408, EN 12385, DIN 3060, and endorsements from TÜV and SGS. Improper tightening causes accidents and equipment failure. You must trust only proven solutions and adhere to best practices for secure and lasting results.

Key Takeaways

Always inspect steel wire rope for damage before use. Look for broken wires, kinks, and corrosion to ensure safety.

Select the right type of wire rope based on your specific application needs. Consider factors like strength, corrosion resistance, and compatibility with equipment.

Use certified hardware and tools, such as turnbuckles and tension meters, to achieve proper tension and secure connections.

Follow systematic tightening steps to avoid accidents. Monitor tension carefully and document your installation for future reference.

Maintain a regular inspection and maintenance schedule to extend the life of your wire rope and ensure ongoing safety.

Steel Wire Rope Basics and Application

Rope Construction and Features

You need to understand the construction of steel wire rope before you select it for your project. Powerful Machinery’s Steel Wire Rope uses high-grade steel and a non-rotating design, which prevents twisting and kinking during operation. This feature increases safety and extends the rope’s lifespan.

You can choose from several common constructions for industrial use:

General-purpose wire ropes deliver durability and versatility for construction and manufacturing.

Stainless steel wire ropes offer excellent corrosion resistance, making them ideal for marine and chemical environments.

Compacted wire ropes provide greater strength and reduced wear, perfect for heavy-duty lifting.

Rotational resistance wire ropes prevent rotation under load, which is essential for hoisting systems and elevators.

You will find configurations such as 35W×7, 18×19, and 8×55SWS, each designed for specific load and application requirements.

Choosing the Right Rope for the Job

Selecting the right type of wire rope is critical for safety and performance. You must consider several factors:

Strength requirements

Anti-rotation properties

Anti-fatigue performance

Wear and friction resistance

Compression resistance

Anti-corrosion measures

Compatibility with equipment

When you work in environments with strong corrosion risks, you should choose galvanized steel wire ropes. If water vapor or harmful substances can reach the rope’s core, metal core coated wire rope is recommended.

Powerful Machinery offers certified wire ropes that meet international standards, ensuring you always have the right type of wire rope for your application. You must match the rope’s features to your specific needs, especially in heavy industry settings.

Application Limits and Environments

Steel wire rope serves many roles across industries. You will encounter different requirements depending on your environment. The table below outlines common applications and their specific needs:

Application | Specific Requirements |

|---|---|

Cranes and Hoists | Strength, flexibility for smooth movement |

Construction and Infrastructure | Support for structures, operating machinery |

Marine and Shipping | Corrosion resistance, ability to withstand harsh weather |

Mining and Drilling | Strength for lifting materials, supporting rigs |

Elevators and Lifts | Strength and controlled movement |

Logging and Forestry | Abrasion resistance, securing loads |

You must always select the right type of wire rope for your environment. Corrosion resistance and abrasion resistance are especially important, since most failures result from mechanical damage. Powerful Machinery’s steel wire ropes provide reliable solutions for every application, helping you maintain safety and efficiency.

Inspection and Preparation for Safety

Pre-Use Inspection Steps

You must always follow safety standards and precautions before using steel wire rope. OSHA and international guidelines require you to check for visible damage and wear. The table below summarizes the main requirements:

Standard | Requirement |

|---|---|

OSHA 29 CFR 1926.1413 | Inspect for broken wires, kinks, crushes, severe wear, heat damage, diameter loss over 10%, and loss of core support. |

ASME B30 Standards | Set procedures for inspection frequency, maintenance, and recordkeeping based on crane type and application. |

You should inspect rigging equipment before first use. Always look for broken wires, corrosion, or any sign of damage. If you find any of these issues, do not use the rope. This step helps prevent accidents and keeps your team safe.

Handling and Laying Out the Rope

Proper handling reduces the risk of accidents and extends the life of your steel wire rope. Lay out the rope on a clean, flat surface. Avoid dragging it over sharp edges or rough ground. When you uncoil the rope, rotate the reel slowly and keep tension steady.

This method prevents kinks and twists. Always use gloves and approved lifting tools to protect your hands and maintain control.

Tip: For long wire ropes, inspect at least five wraps on the drum. Get approval from authorized personnel before use.

When to Replace the Rope?

You need to know when to replace your steel wire rope to avoid accidents. Replace the rope if you see broken wires, severe corrosion, or a reduction in diameter greater than 10 percent. Heat damage and loss of core support also mean the rope is unsafe.

Frequent inspections are necessary, especially in heavy-use environments. Inspect the rope daily or before each shift. For ropes in harsh conditions, increase the inspection frequency. Regular checks and timely replacement help you meet safety standards and precautions and prevent workplace accidents.

Steel Wire Rope Tightening Tools and Hardware

When you work with steel wire rope, you need the right tools and certified hardware to ensure safety and performance. Powerful Machinery offers a complete range of accessories, including wire rope tightener, wire rope tensioner, turnbuckles, and clips.

These products meet strict international standards, giving you confidence in every installation.

Turnbuckles and Tensioners

Turnbuckles and wire rope tensioner devices help you adjust the tension in your wire rope system. You use them to fine-tune the load and keep the rope secure. A wire rope tightener allows you to apply even force, which prevents slack and reduces the risk of failure.

Certified hardware, like that from Powerful Machinery, undergoes rigorous testing to handle expected loads and stresses. This testing reduces the risk of accidents and ensures your installation remains reliable.

Here is a quick comparison of tightening tools:

Feature | Details |

|---|---|

Brand Name | SHENHONG |

Certification | ISO |

Model Number | VIT |

Usage | Tightening |

Application | Used in large and medium-sized concrete and steel structures, and for mechanical equipment installation. Suitable for bridges, ports, and telecommunications. |

Wire Rope Clips and Terminations

Wire rope clips and terminations secure the ends of your rope. You use them to create strong, safe connections. A wire rope tightener works best when paired with certified clips and end fittings.

Powerful Machinery’s accessories meet OSHA and ASME standards, which outline minimum design factors for safety. You should always use certified hardware to reduce the risk of failure and improve reliability.

Certified hardware undergoes strict load testing.

Inspectors follow guidelines to confirm load-bearing capabilities.

This process ensures your wire rope tightener and wire rope tensioner perform as expected.

Using Torque Wrenches and Tension Meters

You need torque wrenches and tension meters to measure and verify the force applied by your wire rope tightener. These tools help you achieve the correct tension, which is critical for safety.

A wire rope tensioner, when used with these measuring devices, lets you confirm that your installation meets all requirements. Regular checks with these tools help you maintain even tension and prevent uneven loading.

Tip: Always use certified measuring tools and hardware from trusted brands like Powerful Machinery. This practice ensures your steel wire rope system remains safe and dependable.

How to Tighten Steel Wire Rope Safely?

Steel wire rope tightening requires a disciplined approach and a focus on safety at every stage. You must prepare your work area, use the right tools, and follow correct techniques to tighten steel wire rope without risk. This section guides you through each step, ensuring you achieve secure and reliable results.

Preparing the Work Area

Before you begin to tighten the steel wire rope, you must create a safe and controlled environment. Proper preparation reduces the risk of injury and equipment damage. Always follow established safety protocols. The table below outlines essential steps you should take:

Safety Protocols | Description |

|---|---|

Supervision | A competent person should supervise all handling and installation to prevent serious injuries. |

Protective Clothing | Wear gloves, safety glasses, and other protective gear to guard against rope lubricants, sparks, and sharp wires. |

Hazard Check | Inspect the area for hazards such as sharp edges, moving machinery, or tripping risks. |

Equipment Positioning | Position all machinery securely and isolate it before starting the installation. |

Controlled Release | Uncoil and release the rope from its packaging slowly and in a controlled manner to avoid sudden movements. |

You should never rush this process. Take time to check your surroundings and equipment. This attention to detail forms the foundation of steel wire rope tightening and ensures safety for everyone involved.

Using Turnbuckles for Tension

Turnbuckles play a critical role when you tighten steel wire rope. They allow you to adjust the tension with precision and maintain control throughout the process. To use turnbuckles effectively, follow these steps:

Extend the turnbuckle to nearly its maximum length. This gives you the full range needed for tightening.

Attach the turnbuckle to both the wire rope assembly and the anchor point. Use shackles and ensure everything lines up correctly.

Begin tightening by hand. Turn the body of the turnbuckle until you remove all slack and can no longer turn it by hand.

Switch to a wrench or another suitable tool. Turn the turnbuckle body slowly, applying tension in small increments.

Use a tension meter to monitor the force you apply. Adjust as needed to reach the recommended tension for your application.

Once you achieve the correct tension, secure the turnbuckle. Lock it in place to prevent loosening during operation.

You must use only certified turnbuckles and accessories, such as those from Powerful Machinery, to guarantee performance and safety. This approach helps you avoid common mistakes and ensures your steel wire rope tightening meets industry standards.

Systematic Tightening Steps

You need to follow a systematic process to tighten steel wire rope safely and effectively. Adhering to correct techniques and proven tightening methods will help you avoid costly errors. Here is a step-by-step guide:

Inspect the wire rope thoroughly before installation. Look for kinks, broken wires, corrosion, or diameter changes. Never use damaged rope.

Lay out the rope straight and free from twists. Avoid bending the rope beyond its minimum bend radius. Always follow manufacturer guidelines—typically, the bend radius should be at least ten times the rope diameter.

Attach the rope to the anchor points using certified hardware. Make sure all connections are secure and properly aligned.

Begin the tightening process using the turnbuckle as described above. Take up slack by hand, then use a tool for gradual tensioning.

Monitor the tension with a calibrated tension meter. Do not over-tension or under-tension the rope. Over-tensioning can stretch and weaken the rope, while under-tensioning may cause sagging or vibration.

Check the integrity of all end terminations. Ensure wire rope clips are installed correctly—remember, always place the saddle on the live end and the U-bolt on the dead end. Use the correct number of clips and torque them to specification.

Wind the rope evenly onto drums or reels if required. Maintain tension during winding to prevent uneven layers and crushing.

Document the installation. Record tension levels, hardware used, and rope identification. Set up a maintenance schedule for regular inspection and tension checks.

Tip: Avoid common mistakes such as improper use of wire rope clips, neglecting end terminations, or ignoring environmental factors. Always choose the right rope grade for your environment and keep detailed records for future maintenance.

By following these steps, you ensure that you tighten the steel wire rope to the correct specifications. This process not only maximizes performance but also upholds safety for your team and equipment. Consistent application of these procedures will help you achieve reliable steel wire rope tightening every time.

Securing and Tying Steel Wire Rope

Securing and tying steel wire rope is a critical step in any rigging or lifting operation. You must ensure every termination is strong and reliable. A secure connection prevents slippage, protects your team, and maintains the integrity of your system.

Powerful Machinery’s certified wire rope fittings provide the assurance you need for demanding industrial environments.

Applying Wire Rope Clips Correctly

You must apply wire rope clips with precision to achieve a safe and lasting termination. Follow these steps to ensure proper installation:

Inspect your wire rope for wear and damage before applying clips.

Install the first clip one base width from the dead end, making sure the ‘U’ side covers the dead end.

Place the second clip near the loop or thimble, tightening the nuts evenly.

Add additional clips as needed, spacing them equally and tightening each one evenly.

Tip: Always use the number of clips recommended for your rope size and follow the manufacturer’s guidelines for spacing.

Secure Knots for Wire Rope

In some applications, you may need to tie a knot in your steel wire rope. While mechanical terminations are preferred for heavy loads, certain knots can provide temporary security.

Use knots like the double fisherman’s knot or the bowline for lighter tasks. Always test the knot under load before relying on it. For critical applications, choose Powerful Machinery’s certified end fittings and thimbles to guarantee maximum safety.

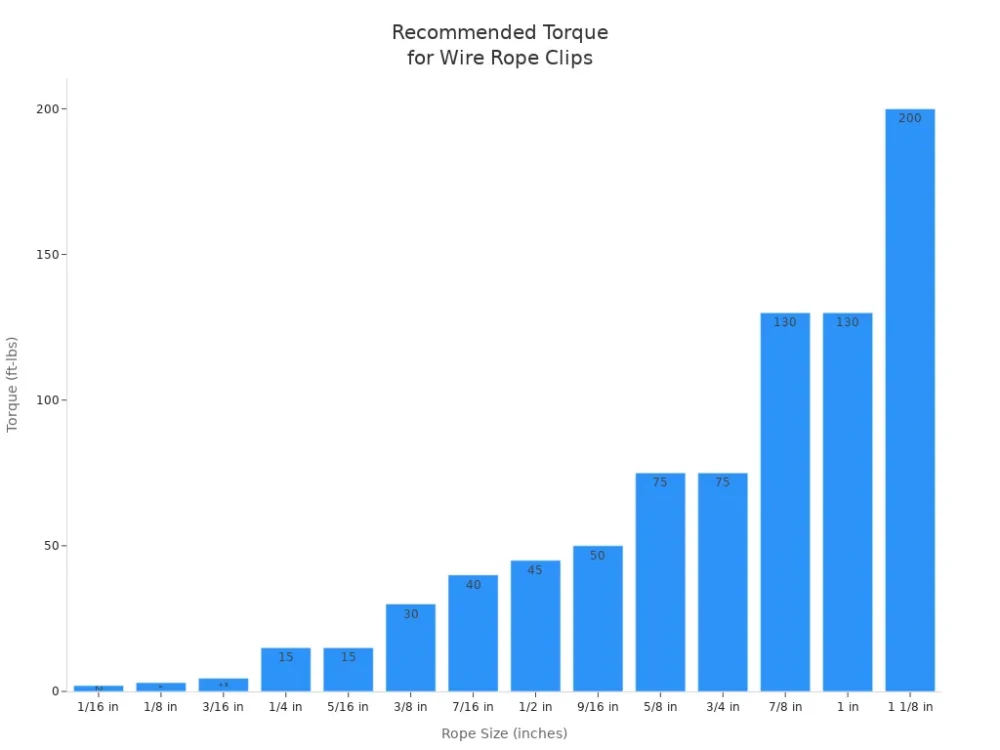

Achieving Proper Torque and Retightening

You must tighten wire rope clips to the correct torque to prevent loosening during operation. Refer to the table below for recommended torque values based on rope size:

Rope Size (in) | Torque in lbs. (ft.) |

|---|---|

1/16 | 2 |

1/8 | 3 |

3/16 | 4.5 |

1/4 | 15 |

5/16 | 15 |

3/8 | 30 |

7/16 | 40 |

1/2 | 45 |

9/16 | 50 |

5/8 | 75 |

3/4 | 75 |

7/8 | 130 |

1 | 130 |

1 1/8 | 200 |

After initial tightening, you should retighten the clips after the rope has been loaded. This step compensates for any settling and ensures long-term security. Always use a calibrated torque wrench and Powerful Machinery’s certified hardware for the best results.

Verifying Tension and Fastening

Calculating and Measuring Tension

You must verify the tension in your steel wire rope to ensure safety and performance. Accurate tension measurement prevents overloading and reduces the risk of failure. You can use several tools and methods to calculate and measure tension.

Each tool serves a specific purpose and helps you maintain control over your installation.

Equipment/Method | Description |

|---|---|

Guy grips | Clamp and secure ground wires, conductors, or cables. |

Dead-end guy grips | Define the end of the guy wire, especially for overhead lines. |

Guy assembly | Includes the wire and all hardware, such as tensioners. |

End sleeves | Prevent wire unraveling under high tension. |

Wire-pulling grips | Apply temporary tension during adjustments. |

Come-along | Hand-operated device for tension adjustments. |

Dynamometer | Measures tension directly with load cells or digital scales. |

Guy clamp | Stabilizes rods and cables on pole lines. |

Guy thimble | Forms a secure oval eye for fixing to anchors. |

Turnbuckle | Adjusts tension by pulling anchors together or apart. |

Direct Measurement Method | Uses a dynamometer for precise tension readings. |

Indirect Measurement Methods | Includes pulse, tangent intercept, and shunt dynamometer methods for tension calculation. |

Safety Procedures | Require proper equipment, crew safety, and attention to weather conditions. |

Tip: Always use a calibrated dynamometer or tension meter for the most accurate results. Record your measurements and compare them to the recommended values for your application.

Checking for Evenness and Security

You must check that your steel wire rope fastening is even and secure. Uneven tension or improper fastening can lead to dangerous situations. Follow these best practices to verify evenness and security:

Use proper termination methods to ensure safety and reliability.

Avoid leaving loose or exposed ends, as they can cause injuries or damage equipment.

Choose fully enclosed clamps, such as Electroline Clamps, to prevent cuts and snagging.

Ensure all clamps and fittings are rated for at least 90% of the wire rope’s strength.

Inspect each connection for tightness and correct alignment.

Note: Secure terminations and even tension help you maintain a safe and efficient system. Regular checks reduce the risk of accidents and equipment failure.

Maintenance and Ongoing Safety

Regular Inspection and Lubrication

You must treat maintenance as a core part of your safety program. Regular inspection helps you spot early signs of wear or damage before they become hazards. You should adjust inspection intervals based on how often you use the wire rope and the conditions it faces. For example:

Inspect ropes more often if you use them daily or in harsh environments.

Lubricate the rope periodically to prevent internal corrosion. Use a pressure lubricator for deep penetration.

Increase lubrication frequency when you operate in severe conditions, such as high humidity or saltwater.

Reapply lubricants before you notice any dryness or corrosion.

Tip: Consistent maintenance extends the life of your steel wire rope and keeps your operations safe.

Re-Torquing and Tension Checks

You need to check and adjust the tension of your wire rope as part of routine maintenance. Over time, load cycles and environmental factors can cause fittings to loosen or tension to drop. Follow these steps to maintain optimal performance:

Use a calibrated torque wrench to re-torque all clips and fittings after initial loading.

Measure rope tension with a tension meter at regular intervals.

Record each maintenance action in a log for future reference.

Address any uneven tension or loose fittings immediately.

A disciplined maintenance schedule helps you avoid unexpected failures and ensures your system remains reliable.

Environmental Care and Longevity

Environmental exposure can shorten the lifespan of your steel wire rope if you do not take proper care. Moisture from rain, humidity, or saltwater can cause corrosion, weakening the rope.

High temperatures may evaporate lubricants and reduce material strength, while cold temperatures can make steel brittle. Chemical exposure, such as acids or solvents, degrades the rope and lowers its load capacity. UV rays from sunlight can damage synthetic fibers, and friction from rough surfaces causes physical wear.

Environmental Factor | Impact on Steel Wire Rope | Maintenance Action |

|---|---|---|

Moisture | Corrosion, loss of strength | Frequent inspection, lubrication |

Temperature | Brittle or weakened steel | Adjust maintenance schedule |

Chemicals | Material degradation | Use protective coatings |

UV Radiation | Fiber breakdown | Store ropes away from sunlight |

Mechanical Wear | Physical damage | Use protective sleeves |

You can maximize longevity by storing ropes properly, applying protective coatings, and following a strict maintenance routine. Powerful Machinery designs products to withstand tough environments, but your commitment to maintenance ensures long-term safety and reliability.

Ethical Responsibility in Rigging

Consequences of Neglect

You hold a significant responsibility when you handle steel wire rope. Neglecting proper rigging practices can lead to severe outcomes. If you overlook safety protocols or skip essential steps, you put lives, equipment, and your company’s reputation at risk. Consider the following consequences:

Accidents that cause injuries or fatalities

Damage to valuable loads and equipment

Delays that disrupt project timelines

Financial losses from repairs, replacements, or downtime

Legal liability if accidents occur on your watch

You may also encounter problems such as a lack of proper field lubrication, improper reeling, using the wrong size or worn sheaves, poor storage, or bad splicing.

These mistakes often lead to failures. In fact, studies show that 27% of load drops result from poor rigging practices. Inadequate rigging remains a common cause of workplace incidents.

Note: When you neglect your duties, you do not just risk equipment—you risk lives and your professional integrity.

The Rigger’s Duty

You must follow strict ethical guidelines to ensure safety and reliability in every rigging operation. The table below outlines key principles you should uphold:

Principle | Description |

|---|---|

Inspection | Check equipment regularly to confirm safety and functionality. |

Adherence to Equipment Limits | Use rigging gear within its rated limits to prevent failures. |

Selection and Attachment Protocols | Choose and attach equipment using proper methods for secure lifts. |

Avoiding Hindrances | Keep movements clear of obstructions and hazards. |

Maintenance | Maintain equipment to keep it in a safe working condition. |

You must also meet industry standards for rigger responsibilities. Follow these steps to maintain safety:

Know your lifting device’s capabilities and limitations. Check its condition and inspection history.

Pay close attention to the hitch. Mistakes often happen here, so use care and creativity.

Understand the load. Know its weight and protect both the load and your slings from damage.

Regular inspection and maintenance are not optional—they are your duty. Always inspect slings before use and address any wear or damage immediately. Maintain your equipment, such as repainting chipped frames, to prevent corrosion and extend service life.

When you follow these best practices, you protect your team, your equipment, and your reputation as a responsible rigger.

Conclusion

You ensure safe and reliable steel wire rope installations by following these essential steps:

Inspect all ropes and hardware for defects before use.

Select the correct tightening mechanism for your application.

Apply wire rope clips properly—never saddle the live end.

Use a tension meter to confirm correct tension.

Tighten all fittings to the specified torque.

Schedule regular inspections and protect ropes from sharp edges.

Standard Organization | Contribution to Safety and Reliability |

|---|---|

WRTB | Sets safety and performance specs |

ASTM | Ensures quality and consistency |

ISO | Guarantees international compliance |

ASME | Enhances operational safety |

Powerful Machinery’s certified hardware and ongoing maintenance routines help you meet industry standards and keep your operations safe for the long term.

FAQ

What is the main advantage of using non-rotating steel wire rope?

You gain extra safety and stability with a non-rotating steel wire rope. This design prevents twisting and kinking under load. You reduce the risk of accidents and extend the rope’s service life, especially in lifting and hoisting applications.

How often should you inspect steel wire rope?

You should inspect steel wire rope before each use. For heavy-duty or harsh environments, increase inspection frequency. Regular checks help you spot wear, corrosion, or damage early, keeping your operation safe and compliant with industry standards.

Can you reuse wire rope clips after disassembly?

You should avoid reusing wire rope clips. Each installation can deform the hardware. Always use new, certified clips from Powerful Machinery to ensure maximum grip strength and safety for every application.

What tools do you need to tighten steel wire rope safely?

You need a turnbuckle or tensioner, a calibrated torque wrench, and a tension meter. These tools help you apply precise tension and secure all fittings. Certified hardware from Powerful Machinery ensures reliable performance in demanding environments.