You may wonder which type of hitch doubles the capacity of the sling. The answer is the basket hitch. When you use a basket hitch, you maximize the strength of your sling. This hitch allows you to achieve up to 200% of the single-leg vertical hitch’s lifting capacity.

You increase safety and efficiency during lifting operations with this method. Choosing the right sling hitch helps you protect your team and your equipment. Powerful Machinery supplies certified sling hitches and lifting solutions trusted by professionals worldwide.

Key Takeaways

The basket hitch doubles the lifting capacity of a sling by distributing the load across two legs, maximizing safety and efficiency.

Always maintain a vertical angle for the sling legs to achieve the full 200% lifting capacity; lower angles increase tension and risk overload.

Inspect slings before each use to ensure they are in good condition and suitable for the load; this helps prevent accidents.

Choose the right hitch based on the load’s shape and stability; basket hitches are ideal for balanced loads, while choker hitches suit irregular items.

Consult certified suppliers like Powerful Machinery for high-quality slings and expert support to ensure safe lifting operations.

Basket Hitch Overview

What Is a Basket Sling Hitch?

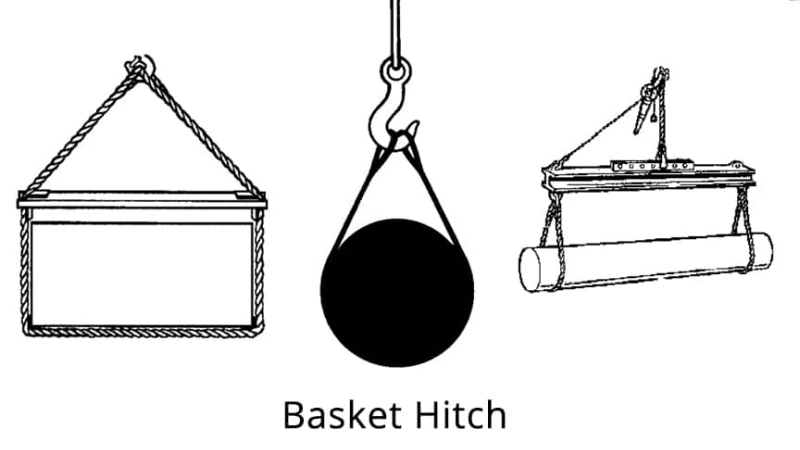

You need to understand the basic setup of a basket hitch before you use it for any lifting operation. According to recognized standards like ASME and OSHA, a basket sling hitch is a method of sling loading where the sling passes under the load.

Both ends of the sling, with end attachments such as eyes, connect to a hook or a single master link. This configuration allows you to distribute the weight evenly and maximize the strength of your lifting sling.

Term | Definition |

|---|---|

Basket Sling Hitch | Method of sling loading where the sling is passed under the load with both ends, end attachments (eyes) on the hook, or a single master link. |

You often see basket hitches used in construction, marine, and cargo handling industries. Powerful Machinery provides certified lifting slings and hardware that meet strict international standards. You can rely on their products for safe and efficient material handling.

How a Basket Hitch Works?

When you use a basket hitch, you take advantage of both ends of the sling to support the load. Each end of the sling carries its rated capacity independently. For example, if your lifting sling is rated for 1 ton, both ends together can support up to 2 tons.

This setup keeps the tension consistent throughout the sling and doubles the overall lifting capacity.

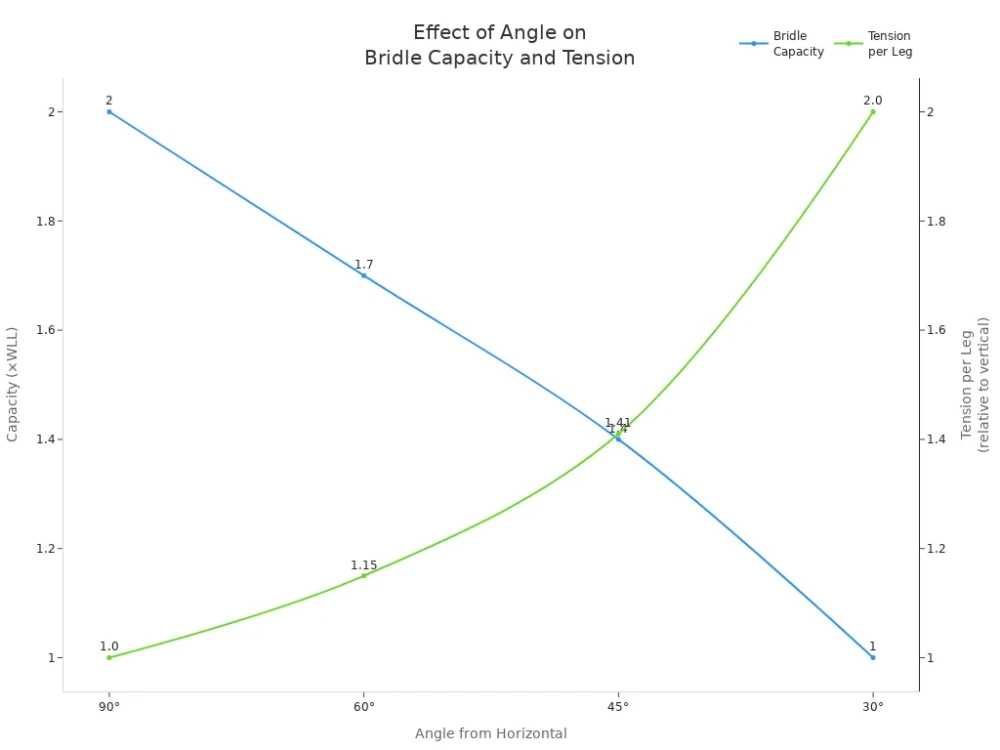

In a basket hitch, the angle from horizontal affects the capacity and tension. At a 90° angle, you achieve the maximum capacity—twice the working load limit (WLL) of a single sling leg. As the angle decreases, the capacity drops and the tension per leg increases.

The table below shows how capacity and tension change with different angles:

Angle from Horizontal | 2 Leg Bridle Capacity | Tension per Leg (relative to vertical) |

|---|---|---|

90° | 2 × WLL | 1.0× |

60° | 1.7 × WLL | 1.15× |

45° | 1.4 × WLL | 1.41× |

30° | 1 × WLL | 2.0× |

Tip: Always check the angle of your basket hitch during setup. You maximize the lifting sling’s capacity at a 90° angle. Powerful Machinery’s certified lifting slings help you achieve safe and reliable lifts in demanding environments.

Why Basket Hitch Doubles Sling Capacity?

Mechanics of Capacity Increase

You need to understand how the basket hitch achieves its impressive lifting capacity. When you set up a basket hitch, you create a configuration where the sling passes under the load, and both ends attach to the lifting hook or master link. This setup allows the load to be distributed evenly across two legs of the sling.

Each leg supports half of the total load, which means the working load limit effectively doubles compared to a single-leg vertical sling hitch.

The mechanical principle behind this increase is straightforward. The basket hitch shares the load between two points, so each leg only carries half the weight. When you keep the sling legs vertical, forming a perfect “U” shape, you maximize the lifting capacity.

The friction between the sling and the load also helps stabilize the lift, reducing the risk of slippage.

The basket hitch achieves a full doubling of sling capacity when the sling legs are vertical, forming a ‘U’ shape. In this position, each leg bears half the load, enabling the system to lift 200% of the single-leg vertical Working Load Limit (WLL).

Industry standards, such as ASME B30.9, define the conditions for this capacity increase. The table below summarizes these requirements:

Capacity Doubling Condition | Limitations |

|---|---|

Both legs vertical | Up to 200% of WLL |

D/d ratio respected | Must be maintained |

You can see real-world examples of this principle in action. For instance:

In a rigging operation involving a 72,000 lbs pipe, the use of three synthetic web slings was analyzed.

Each sling had a rated capacity of 67,200 lbs when used in a basket hitch configuration.

If all slings had been rigged as basket hitches, they could have collectively lifted the entire load, demonstrating the potential to double the sling capacity.

Safety Conditions for Doubling

You must always follow strict safety conditions to achieve the full doubling effect of a basket hitch. The most important factor is the angle of the sling legs. Only when the legs are vertical do you get the full 200% lifting capacity. As the angle decreases, the tension on each leg increases, and the actual lifting capacity drops.

At a 60° angle, each sling leg bears 1.155 times its share of the load.

At a 45° angle, each leg handles 1.414 times its share of the load.

At a 30° angle, each leg supports 2.0 times its share of the load.

The basket hitch configuration allows for a doubling of the sling’s capacity when the legs are vertical, effectively lifting 200% of the single-leg vertical Working Load Limit (WLL).

As the angle of the sling legs decreases from vertical, the capacity diminishes due to increased tension forces on each leg, leading to potential overload.

Best practices suggest maintaining sling angles at 60° or greater to ensure safety and optimal lifting capacity.

If you do not meet these angles or safety conditions, you risk overloading the sling. Lower angles increase the tension on each leg, which can exceed the rated lifting capacity and lead to catastrophic failure.

In configurations like a choker hitch, the angle plays a critical role in determining the compression and friction on the sling, where lower angles can lead to increased stress and reduced rated lifting capacity.

Failure to adhere to the correct sling-to-load angle can significantly increase the tension on the sling, potentially surpassing its rated capacity and leading to catastrophic failure during lifting operations.

As the angle between the sling legs and the horizontal decreases, the tension on the sling increases, which can reduce the lifting capacity and increase the risk of failure.

Tip: Always inspect your sling hitch setup before every lift. Make sure the sling legs are as close to vertical as possible. Use certified slings and hardware from trusted suppliers like Powerful Machinery to ensure your lifting operations remain safe and efficient.

Comparing Sling Hitch Types

Basket vs Vertical Sling Hitch

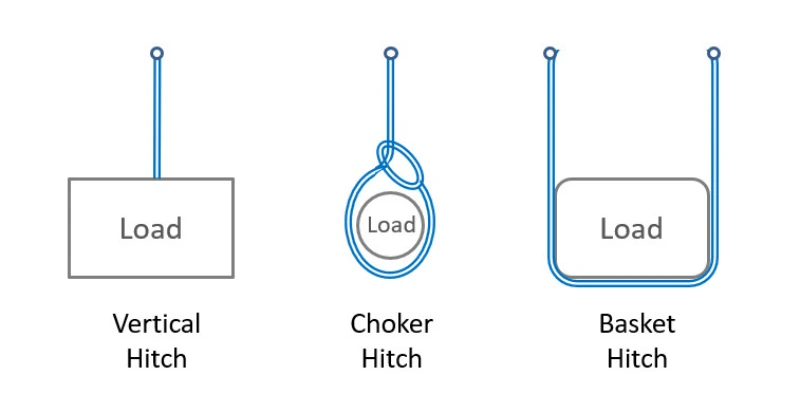

You encounter several types of hitches when you plan a lifting operation. The vertical sling hitch is the most basic. You attach one end of the sling to the hook and the other to the load.

This hitch supports the load with a single leg. The working load limit matches the sling’s rated capacity. You use this method for straightforward lifts where the load has a clear attachment point.

The basket hitch offers a major advantage. You pass the sling under the load and connect both ends to the hook. This setup creates two legs that share the load equally. You double the lifting capacity compared to the vertical sling hitch. The load remains stable, and the tension distributes evenly.

You see basket hitches used in construction and offshore platforms. In these environments, basket hitches secure modules against swells and manage dynamic shifts for stable installations far from shore.

Sling Hitch Type | Sling Setup | Load Distribution | Maximum Capacity |

|---|---|---|---|

Vertical Sling Hitch | Single leg | One point | 1 × WLL |

Basket Hitch | Two legs (U-shape) | Evenly shared | 2 × WLL |

You maximize safety and efficiency when you select the right sling hitch for your lifting needs.

Basket vs Choker Sling Hitch

You may consider the choker hitch for loads that lack clear lifting points. You wrap the sling around the load and pass one end through the other. The sling tightens as you lift. This hitch grips the load securely, but it does not double the capacity.

The choker hitch creates friction and compression, which can reduce the rated lifting capacity. You must watch the angle and tension. The load may shift, and the sling can experience uneven stress.

The basket hitch stands out among all types of hitches. Only the basket hitch doubles the sling’s capacity. The choker hitch provides control for irregular loads, but it cannot match the basket hitch for heavy lifting. You use choker hitches for pipes, bundles, or loads that need extra grip.

You rely on basket hitches for stable, high-capacity lifts.

Basket hitch: Doubles capacity, ideal for balanced loads.

Choker hitch: Secures irregular loads, does not double capacity.

Vertical sling hitch: Basic setup, supports rated load.

Powerful Machinery supplies a full range of sling hitch solutions. You find certified lifting slings, wire rope, and hardware for every application. You choose from basket hitches, vertical sling hitches, and choker hitches to match your load and lifting scenario.

You trust Powerful Machinery for reliable products that meet strict international standards.

Tip: Always match the sling hitch to your load and lifting environment. You improve safety and maximize performance with the right choice.

Determine the Right Sling Hitch

Best Practices for Sling Selection

You must determine the right sling hitch for every lifting operation. Start by assessing the load shape, weight, and environment. Select a hitch that matches the load’s stability and attachment points. Basket hitches work best for balanced loads and maximize capacity.

Vertical hitches suit straightforward lifts, while choker hitches secure irregular items.

Follow these best practices to ensure safe and efficient lifting:

Inspect each sling before use for signs of wear or damage.

Choose a sling with a working load limit that exceeds the load’s weight.

Consider environmental factors such as temperature, chemicals, and moisture.

Use synthetic slings for delicate or irregularly shaped items to prevent damage.

Partner with certified suppliers like Powerful Machinery for custom-engineered solutions and expert support.

Operators must receive proper training in rigging fundamentals and hitch techniques. Training should include hands-on experience, written materials, and knowledge testing. Operators must assess each load and select the correct hitch configuration.

Standard/Guideline | Description |

|---|---|

IMCA Guidelines | Safe use of lifting equipment in marine environments, focusing on inspections and handling. |

DNV-GL Standards | Certification for lifting equipment in the maritime industry, ensuring safety and performance. |

API RP 2D | Standards for offshore cranes and rigging, emphasizing inspections and safe practices. |

ATEX Certification | Safety standards for hazardous environments, preventing the ignition of flammable gases. |

FAA Regulations | Guidelines for aerospace lifting equipment, focusing on precision and safety. |

NADCAP Accreditation | Certification for aerospace manufacturing and maintenance, ensuring high safety and quality. |

Powerful Machinery’s products meet international standards such as ISO9001, ISO14001, TUV Rheinland, EURO CERT, OSHA, and ASTM.

Limitations and Safety Tips

You must understand the limitations of each hitch to avoid accidents. Basket hitches only double capacity when both legs remain vertical. Incorrect sling angles reduce capacity and increase tension, risking overload. Always use an angle chart to verify sling configuration.

Common mistakes include poor angle calculations and lifting from a single attachment point. Avoid these errors by keeping the load level and increasing the angle when necessary.

Follow these maintenance practices to extend sling life and maintain safety:

Adhere to the working load limit for each sling and hitch configuration.

Clean slings regularly to remove dirt and chemicals.

Protect slings with edge guards and avoid dragging.

Store slings in a controlled environment.

Replace damaged slings immediately.

Regulations require periodic inspections based on service conditions:

Service Condition | Inspection Frequency |

|---|---|

Normal Service | Yearly |

Severe Service | Monthly to Quarterly |

Special Service | As recommended by a Qualified Person |

Keep written records of inspections to ensure compliance. In marine or chemical environments, inspect slings weekly. High-temperature conditions require more frequent checks.

Tip: Always consult with Powerful Machinery for custom-engineered sling solutions and certified lifting hardware. Expert support helps you select the right hitch, maintain safety, and maximize efficiency.

Conclusion

You now know that only the basket hitch doubles the capacity of your sling. Proper sling selection protects your team and equipment. Consider these key factors for workplace safety:

Assess the load’s size, weight, and lifting points.

Check the number of sling legs and their angle.

Never exceed the rated capacity.

Inspect slings before each use.

Industry experts recommend consulting certified providers like Powerful Machinery to guarantee OSHA compliance, reduce incidents, and ensure peace of mind. Rely on expert support for safe, efficient lifting every time.

FAQ

What is the main advantage of a basket hitch?

You double your sling’s lifting capacity with a basket hitch. This setup distributes the load evenly across two sling legs. You achieve maximum efficiency and safety for balanced loads.

When should you avoid using a basket hitch?

You should avoid a basket hitch if the load lacks balance or secure lifting points. Unstable loads can shift and cause accidents. You must choose a hitch that matches the load’s shape and stability.

How do you calculate the working load limit for a basket hitch?

You multiply the sling’s rated capacity by two when both legs remain vertical. If the sling legs angle outward, you must reduce the capacity. Always check the manufacturer’s angle chart for accurate calculations.

Can you use a basket hitch with any type of sling?

You can use basket hitches with wire rope, chain, or synthetic slings. You must ensure the sling type and hardware meet the load’s requirements. Always follow industry standards and manufacturer guidelines.

Why choose Powerful Machinery for lifting solutions?

You receive certified, high-performance lifting products from Powerful Machinery. The company provides custom-engineered solutions, international certifications, and expert support. You ensure safety and reliability for every lifting operation.