Chain strength refers to the ability of a chain to withstand tension and resist breaking when used in industrial applications. You rely on chain strength to prevent load drops and workplace injuries during lifting, rigging, or cargo handling.

In 2023, load drops from poor rigging practices accounted for 27% of reported workplace incidents, each costing an average of $43,000. Powerful Machinery delivers certified, high-performance chains designed for safety and reliability in demanding environments.

Key Takeaways

Understand chain strength to select the right chain for your needs. Choose based on grade, material, and application suitability.

Always use the working load limit (WLL) for daily operations. This ensures safety and prevents accidents during lifting and rigging.

Inspect chains regularly for wear, corrosion, or damage. Early detection of issues can prevent costly failures and enhance safety.

Select the appropriate chain grade for your specific tasks. Higher grades offer better strength and durability for heavy lifting and critical applications.

Follow safety standards and manufacturer guidelines. Compliance ensures reliable performance and protects your team and equipment.

Understanding Chain Strength

What Is Chain Strength?

You need to understand chain strength before you select the right chain for your operation. Chain strength describes the maximum force a chain can handle without breaking or deforming. This property depends on several factors, including the chain’s grade, material, and construction.

Each grade represents a different level of tensile strength and application suitability.

Here is a comparison of common chain grades and their typical uses:

Chain Grade | Ultimate Breaking Strength (Tensile Strength) | Applications |

|---|---|---|

Grade 30 | Low strength, suitable for light applications | Light lifting |

Grade 43 | Medium strength, used in general applications | General use |

Grade 70 | Higher strength, often used in transport | Transport |

Grade 80 | High strength, used in lifting and rigging | Heavy lifting |

Grade 100 | Very high strength, for critical applications | Critical use |

Grade 120 | Maximum strength, specialized applications | Specialized |

Chain strength also depends on the working load limit (WLL) and the safety factor. The WLL tells you the maximum load a chain can safely support during use. The safety factor provides a margin between the chain’s actual breaking point and its rated capacity, ensuring you have a buffer for unexpected stresses.

You should also consider the most common causes of chain failure. These include excessive loading, plate fatigue, corrosion, and high-speed operational challenges. The table below outlines these risks:

Cause of Failure | Description | Impact on Chain Life |

|---|---|---|

Excessive Loading | Loading beyond design capacity leads to premature failure. | Accounts for ~40% of failures. |

Plate Fatigue | Fatigue from repeated stress cycles causes wear and tear. | Reduces overall chain lifespan. |

Corrosion | Environmental exposure leading to degradation of the chain material. | Can significantly weaken chains. |

High-Speed Operational Challenges | Vibration and stress from high-speed operations affect chain integrity. | Increases risk of failure. |

Understanding these factors helps you choose the right chain and avoid costly mistakes.

Why Chain Strength Matters?

You rely on chain strength to keep your lifting, rigging, and cargo operations safe and efficient. When you use a chain with the correct strength rating, you reduce the risk of accidents and equipment failure. Strong chains provide reliable connections, which means you can trust them to hold heavy loads without sudden breaks.

Chain strength also improves operational efficiency. Stronger chains allow you to use lighter assemblies, which reduces fatigue for your team and speeds up rigging tasks. Chains wear gradually, so you can spot issues early during inspections and replace them before they become dangerous.

If you ignore chain strength, you increase the risk of failure. Overloading, fatigue, and corrosion can all lead to accidents, downtime, and expensive repairs. By understanding and respecting chain strength, you protect your team, your equipment, and your bottom line.

Measuring Chain Strength

Chain Tensile Strength

You need to know how to measure chain strength before you trust it in the field. The industry uses a standard method to test tensile strength. This process checks how much force a chain can handle before it stretches or fails. The test uses a chain at least five pitches long.

The chain connects to a testing machine that allows free movement. The machine applies force slowly, not faster than 50.8mm per minute, until the chain breaks. If the chain breaks at the grip, the test does not count. You cannot reuse the chain after this destructive test.

Here is a summary of the standard method:

Key Point | Description |

|---|---|

Test Chain Length | The chain must be at least five pitches in length for accurate tensile strength measurement. |

Mounting Method | The chain should be connected to the testing machine in a way that allows free movement during testing. |

Tensile Force Application | The tensile force should be applied slowly, not exceeding 50.8mm/min, until the chain breaks. |

Invalid Test Conditions | If the break occurs at the connection to the grip, the test is invalid. |

Destructive Testing Note | The test is destructive; the chain should not be reused after testing. |

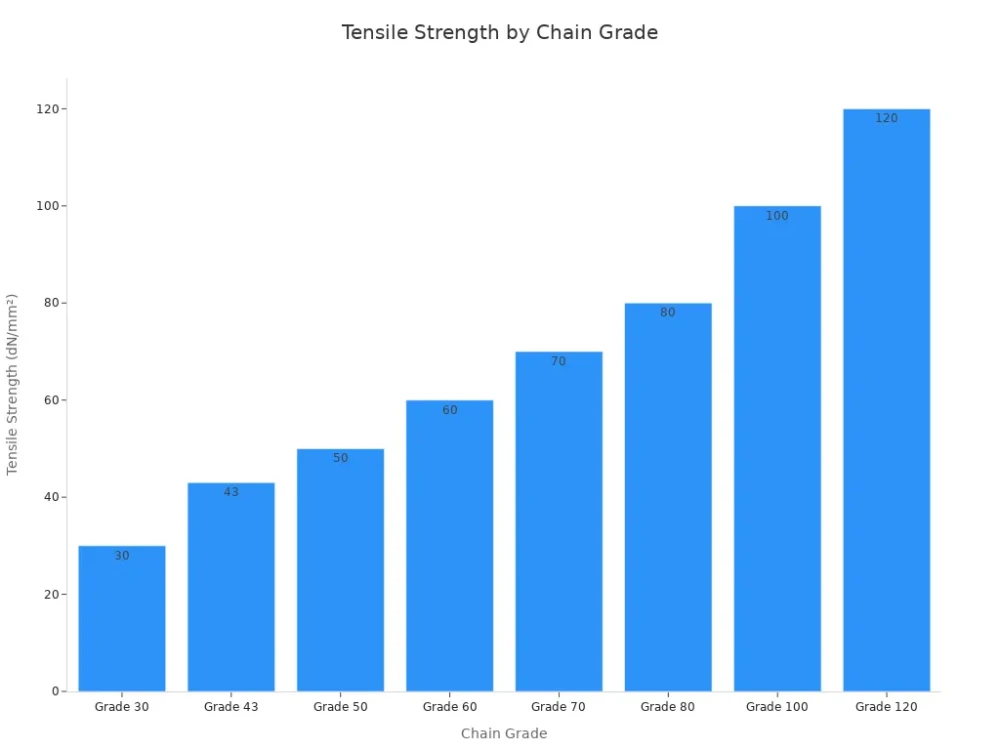

You can see how different chain grades compare in tensile strength values:

Chain Grade | Tensile Strength (dN/mm²) |

|---|---|

Grade 30 | 30 |

Grade 43 | 43 |

Grade 50 | 50 |

Grade 60 | 60 |

Grade 70 | 70 |

Grade 80 | 80 |

Grade 100 | 100 |

Grade 120 | 120 |

Chain Breaking Strength

You must understand the ultimate breaking strength to ensure safety. This value shows the maximum force a chain can take before it fails. The test uses a special bed that pulls the chain until it breaks.

For example, a 5/16″ grade 70 transport chain reached a breaking force of 19.35 kips, which is higher than the NACM standard of 18.8 kips. Some chains do not meet this benchmark and break at lower forces. You should always check that your chain meets or exceeds the industry standard for ultimate breaking strength.

Chain Strength Rating

You will see two main ratings when you select a chain: chain strength rating and working load limit (WLL).

Chain strength rating shows the tensile strength, measured in Newtons per square millimeter. This tells you the maximum load the chain can handle before failure.

Working load limit (WLL) is the highest weight you can safely lift with the chain. You get this number by dividing the minimum breaking load by a safety factor.

The difference is important. Ultimate breaking strength tells you when the chain will fail. WLL gives you a safe working range.

Tip: Always use the WLL for daily operations, not the ultimate breaking strength. This keeps your team and equipment safe.

Chain Grades and Strength

Chain Grades Explained

You need to understand chain grades before you select the right chain for your operation. Each chain grade represents a specific level of strength, durability, and application suitability. Manufacturers assign a chain grade based on the material composition, heat treatment, and mechanical properties.

You will find that higher chain grades offer greater tensile strength and working load limits.

Here is a table that summarizes the most common chain grades, their strength descriptions, and typical applications:

Chain Grade | Strength Description | Typical Applications |

|---|---|---|

Grade 30 | General-purpose economical chain; low tensile strength; prone to stretching under heavy loads. | Light construction, agricultural applications, marine industry. |

Grade 43 | Stronger than Grade 30; better resistance to wear and tear. | Container securement, logging, farming, towing, and marine applications. |

Higher strength, heat-treated carbon steel; load rating approximately 20% higher than Grade 43. | Used by truckers, loggers, and highway crews for load securement and towing. | |

Grade 80 | Economical choice for overhead lifting; high-strength, heat-treated alloy chain. | Sling component for overhead lifting, heavy-duty tow chain. |

Grade 100 | High-strength, heat-treated alloy chain; approximately 25% higher strength than Grade 80. | Sling component for overhead lifting; popular in construction, manufacturing, and rigging. |

Grade 120 | Ultra-premium high-strength chain; approximately 50% higher strength compared to Grade 80. | Designed for rigorous overhead lifting applications. |

You should always match the chain grade to your specific task. For example, you would use Grade 43 for general towing, while Grade 100 or Grade 120 would suit critical lifting operations.

Powerful Machinery Chain Grades

Powerful Machinery provides a full range of certified chain grades to meet the demands of various industries. You can choose from G43, G70, G80, and G100 chains, each designed for specific applications.

These chains use high-quality materials such as alloy steel and stainless steel, ensuring durability and resistance to wear.

You will find that Powerful Machinery’s chain grades comply with major international standards. The company’s products meet OSHA 1910.184 and ASME B30.9 requirements, which govern the use, inspection, and testing of lifting slings and chains.

This commitment to certification gives you confidence in the safety and reliability of every chain grade.

Standard | Description |

|---|---|

OSHA 1910.184 | Governs the use, inspection, and removal criteria for all types of lifting slings in general industry. |

ASME B30.9 | Guides the fabrication, marking, and testing of slings, including properties of different chain grades. |

You can rely on Powerful Machinery’s chain grades for construction, marine, transportation, and cargo handling. The company’s G80 and G100 chains are especially popular for overhead lifting and heavy-duty rigging. If you need a chain for transport or load securement, G43 and G70 offer excellent performance.

Note: Powerful Machinery’s chains are available in various link configurations and sizes, allowing you to select the best option for your project.

Comparing Chain Grades

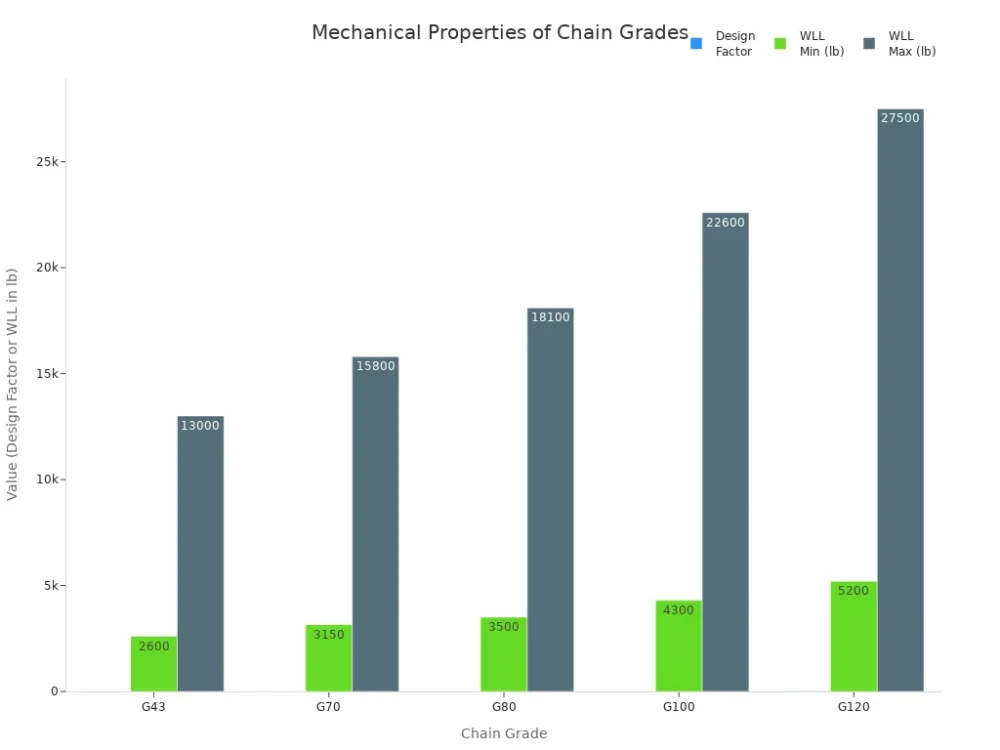

You must compare chain grades carefully to ensure you select the right product for your needs. Each chain grade offers a unique combination of design factor, working load limit, and material composition. The table below highlights the key differences among G43, G70, G80, G100, and G120:

Chain Grade | Design Factor | Working Load Limit (WLL) | Material Composition | Typical Uses |

|---|---|---|---|---|

G43 | 3:1 | 2,600lb – 13,000lb | Carbon Steel | Agriculture, towing, logging, trucking, and general use |

G70 | 4:1 | 3,150lb – 15,800lb | High-strength carbon steel | Trucking, securing large cargo, transportation |

G80 | 4:1 | 3,500lb – 18,100lb | High-tensile alloy steel | Heavy-duty towing, rigging, and overhead lifting |

G100 | 4:1 | 4,300lb – 22,600lb | Heat-treated alloy steel | Heavy-duty rigging, crane operations, and material handling |

G120 | 6:1 | 5,200lb – 27,500lb | High-strength alloy steel | Overhead lifting in industrial conditions |

You will notice that as the chain grade increases, both the working load limit and the design factor improve. For example, G100 chains achieve higher tensile strength through advanced alloy composition and heat treatment. This allows them to support about 25% more load than G80 chains.

You also gain better resistance to shock loading, which is essential in lifting operations where sudden movements can occur.

When you select a chain grade, always consider the application, required load capacity, and safety standards. Powerful Machinery’s certified chain grades give you the flexibility to meet any challenge, from everyday transport to the most demanding lifting environments.

Tip: Always check the chain grade marking on the chain links before use. This ensures you are using the correct chain for your application and maintaining compliance with safety regulations.

Chain Strength by Size and Material

Size and Strength Relationship

You should always consider the size of a chain when you evaluate its strength. The diameter of each chain link plays a critical role in determining how much weight the chain can handle. As the diameter increases, the cross-sectional area of the link grows much faster.

This happens because the area is proportional to the square of the diameter. For example, if you double the diameter, the cross-sectional area becomes four times larger. This change leads to a significant boost in both the breaking strength and the working load limit, as long as the material stays the same.

Tip: Even a small increase in chain diameter can make a big difference in safety and performance. Always check the diameter before you select a chain for heavy-duty tasks.

You will find that Powerful Machinery offers chains in a wide range of diameters and link configurations. This variety allows you to match the chain size to your specific lifting or securing needs. You can choose short, medium, or long link chains to optimize for flexibility or strength.

Alloy Steel vs Stainless Steel Chains

You must also choose the right material for your chain. The two most common options are alloy steel and stainless steel. Each material has unique advantages for different environments.

Material | Strength | Corrosion Resistance |

|---|---|---|

Alloy Steel Chains (G80) | Matches the mechanical strength of G80 SS | Prone to rust, needs re-coating every six months |

Grade 80 Stainless Chains | Same as G80 alloy steel | Rust-proof, with only minor surface oxidation after testing |

Alloy steel chains, such as G80, deliver high mechanical strength. You can use them for heavy lifting and demanding rigging jobs. However, these chains can rust if you do not maintain them. You need to re-coat them regularly, especially in outdoor or marine settings.

Stainless steel chains, like Grade 80, provide the same strength as alloy steel but offer much better corrosion resistance. Laboratory tests show that stainless chains only develop minor surface oxidation, even after long exposure. You can rely on them in harsh or wet environments where rust is a concern.

Note: Choose alloy steel chains for maximum strength in dry conditions. Select stainless steel chains when you need both strength and resistance to corrosion.

Chain Working Load Limits and Safety

Determining Working Load Limits

You must calculate the working load limit before you use any chain in lifting or rigging. The working load limit is the maximum weight you can safely apply to a chain during regular operations.

Manufacturers determine this value by dividing the minimum breaking strength by a safety factor. The safety factor varies by region and application. For example:

Region | Safety Factor |

|---|---|

North America | 5:1 |

Europe | 10:1 or higher |

Asia | Lower for simple pulling or lashing |

Always use the manufacturer’s minimum breaking load for accurate calculations. The grade and diameter of the chain also affect the final working load limit. The safety factor provides a margin to accommodate unexpected stresses, wear, or misuse. You should verify local regulations to ensure compliance.

Calculate the working load limit by dividing the minimum breaking strength by the safety factor.

Select the chain grade and diameter based on your application.

Confirm values with manufacturer specifications.

Adhering to chain working load limits is critical for safety. Exceeding these limits can cause catastrophic failures and injuries. You protect your team and equipment by respecting these values.

WLL vs Breaking Strength

You need to understand the difference between the working load limit and the breaking strength. The working load limit is the safe limit for daily use. Breaking strength is the absolute maximum force a chain can withstand before failure.

Manufacturers set the working load limit below the breaking strength to ensure safety.

Aspect | Working Load Limit (WLL) | Breaking Strength |

|---|---|---|

Purpose | Safety limit for regular use | Absolute maximum force capacity |

Set by | Manufacturer | Material properties/testing |

Used for | Daily operations | Testing and certification |

Value | Less than Breaking Strength | Greater than WLL |

Always use the working load limit for operational decisions. Never rely on breaking strength for routine tasks.

Safety Standards and Certifications

You must follow safety standards to ensure reliable chain performance. International safety standards require rigorous testing, quality control, and regular audits. Certified chains undergo comprehensive mechanical property tests, including breaking strength and fatigue resistance.

Powerful Machinery complies with EN 818-2 and ISO 6082, ensuring chains meet recognized safety standards. Regular inspections help identify wear and damage, reducing risks.

Advanced materials and technologies allow Powerful Machinery chains to withstand extreme conditions, enhancing safety in heavy industrial applications.

Safety is not optional. You safeguard lives, equipment, and productivity by choosing certified chains and following safety standards.

Chain Strength Guide for Selection

Choosing the Right Chain

You must evaluate several factors before you select a chain for lifting or cargo work. Start by matching the chain grade to your load requirements. Higher grades support heavier weights and offer better durability. Consider the environment where you will use the chain.

For outdoor or marine settings, choose a chain with high corrosion resistance. Analyze your operation’s duty cycle. If you use the chain frequently or for long periods, select a chain designed for intense use. Review the inspection process.

Chains make it easy to spot wear or damage, so you can maintain safety with regular checks.

Factor | Description |

|---|---|

Durability | Chains are rugged and ideal for general-purpose lifting. |

Lifting Speed | Chains lift slower than wire ropes. |

Operation Characteristics | Chains handle non-vertical lifts better, but you should avoid side pulling. |

Inspection Complexity | Wear and damage are visible, making inspections straightforward. |

Duty Cycle | Match the chain to the intensity of use to prevent failure. |

Operational Frequency | Choose a chain that fits your operational needs for safety and longevity. |

Tip: Always analyze your operational needs and match the chain’s features to your specific application.

Powerful Machinery Chains for Cargo and Lifting

You can rely on Powerful Machinery for a complete range of cargo chain solutions. The company offers chains in grades G43, G70, G80, and G100, each designed for different lifting and cargo chain applications. These chains deliver high durability, temperature tolerance, and cut resistance.

Grade 100 chains are 25% stronger than Grade 80, while Grade 120 chains offer 50% more strength. All chains meet NACM, ASTM, and OSHA standards for overhead lifting. You can choose from standard or adjustable types to fit your lifting needs.

The heavy powder coating on KWB slings boosts corrosion resistance, making them ideal for harsh environments. Lighter, higher-grade cargo chain options help you lift more with less effort.

Powerful Machinery also provides custom-engineered cargo chain solutions. The engineering team works with you from design to production, ensuring your cargo chain fits unique dimensions, materials, or applications.

Practical Safety Tips

You should always follow these safety tips when using a cargo chain:

Inspect each cargo chain before every use for signs of wear, stretching, or corrosion.

Never exceed the working load limit of your cargo chain.

Store cargo chain in a dry, clean area to prevent rust.

Use only a certified cargo chain for overhead lifting or critical cargo applications.

Train your team on proper cargo chain handling and inspection procedures.

Replace any cargo chain that shows visible damage or deformation.

Record all inspections and maintenance for each cargo chain.

Safety starts with the right cargo chain and regular inspections. Protect your team and your equipment by following best practices.

Cargo Chain Applications

Uses in Transport and Rigging

You depend on cargo chains every time you secure a heavy load for transport or rigging. In the transport and logistics industry, keeping cargo safe is not just a best practice—it is a legal requirement.

You see thousands of commercial vehicles on the road each year, each carrying a valuable load such as machinery, construction materials, or industrial products. The safety of each load relies on the strength and reliability of the chain you use.

You use cargo chains for many tasks, including:

Transporting large machinery from one site to another

Securing steel beams and pipes on flatbed trailers

Handling logging and heavy agricultural transport

Managing long-haul trucking with commercial-grade trailers

When you select the right chain, you prevent the load from shifting or falling during transit. You also protect your team and other drivers on the road. In rigging, you use chains to lift, move, or position a load safely. You must always match the chain’s grade and size to the weight and type of load you handle.

Industry Examples

You find cargo chains in action across many industries. Each sector relies on chain strength to keep operations safe and efficient. The table below shows how different industries use chains and why chain strength matters for each load:

Industry | Example of Chain Use | Importance |

|---|---|---|

Construction | Grade 80, 100, or 120 alloy chains for cranes lifting massive loads | Essential for safety, as failure can lead to catastrophic events |

Transportation | Grade 70 transport chains to secure heavy machinery on flatbed trucks | Critical for keeping the load secure during transport |

Mining | Heavy chain link systems in conveyor systems for abrasive, heavy loads | Necessary for efficiency and safety in harsh environments |

Marine | Stud link and open link anchor chains for anchoring vessels | Crucial for the safety of marine operations |

Offshore Oil Rigs | Mooring systems to withstand hurricane-force winds and waves | Vital for stability and safety in extreme weather |

You see that chain strength plays a key role in every application. For example, using a Grade 100 chain gives you better resistance to shock loading, which improves safety in overhead work areas.

Lighter chain slings help you control the load and reduce physical strain, making your job safer and more efficient. You must always inspect your chains and follow safety standards to ensure each load reaches its destination without incident.

Conclusion

You play a vital role in ensuring safe lifting and cargo operations. Remember these essentials:

Select chains based on grade, configuration, and certification.

Inspect chains before each use to spot hazards.

Maintain accurate inspection records.

Consult product guides and seek expert advice for chain selection and maintenance.

Choosing certified, high-quality chains from Powerful Machinery gives you confidence in every lift. Always prioritize pre-operation checks, proper setup, and safe lifting techniques to protect your team and equipment.

FAQ

What is the difference between a chain’s working load limit and its minimum breaking load?

You use the working load limit for daily operations. The minimum breaking load shows the maximum force the chain can withstand before failure. Always select a chain based on the working load limit, not the minimum breaking load, to ensure safety.

How do you choose the right chain grade for your application?

You should review a chain grade chart to compare strength and application suitability. Match the chain grade to your load requirements and environment. For lifting, select higher grades. For general use, lower grades may work. Always check the manufacturer’s recommendations.

Can you use heavy-duty chains outdoors or in marine environments?

You can use heavy-duty chains outdoors or in marine settings if you select the right material. Stainless steel chains resist corrosion better than alloy steel. Always inspect your chain for rust or wear before each use to maintain safety and performance.

What makes a high-strength chain different from standard chains?

A high-strength chain uses advanced alloy materials and special heat treatments. You get increased tensile strength and a higher working load limit. These chains suit demanding lifting, rigging, and cargo applications where safety and reliability matter most.

How often should you inspect your chain for safe operation?

You should inspect your chain before every use. Look for signs of wear, stretching, or corrosion. Regular inspections help you spot problems early and prevent accidents. Replace any chain that shows damage or does not meet safety standards.