When you use a pallet jack, you rely on several key components to move and lift pallets safely. The forks support the pallet, while the handle gives you control over movement and direction. Wheels and stabilizing rollers help you maneuver across warehouse floors.

The hydraulic mechanism lifts or lowers the pallet with smooth precision. Understanding these parts helps you operate manual and electric models with confidence. Powerful Machinery’s expertise ensures every part meets strict safety and performance standards, making your material handling tasks more efficient.

Forks – Support and lift the pallet.

Handle – Directs movement and controls the jack.

Wheels – Allow smooth travel across surfaces.

Rollers – Stabilize the pallet during transport.

Hydraulic mechanism – Raises and lowers the load.

Key Takeaways

Understand the main components of a pallet jack, including forks, handle, wheels, and hydraulic system, to operate safely and efficiently.

Regularly inspect and maintain your pallet jack to extend its lifespan and ensure reliable performance during material handling tasks.

Choose the right type of pallet jack based on your workspace and load requirements, considering factors like load capacity and maneuverability.

Follow safety guidelines, such as wearing protective gear and centering loads, to prevent accidents and injuries while using pallet jacks.

Leverage ergonomic designs and safety features in modern pallet jacks to reduce operator fatigue and enhance control during long shifts.

Pallet Jack Main Parts

Handle and Control Lever

You control the pallet jack using the handle and control lever. These components allow you to steer, lift, and lower heavy pallets with precision. The hand control lever activates hydraulic pressure, which raises or lowers the forks. You can adjust the speed and direction, making it easy to navigate tight warehouse spaces.

The braking function helps you stop the pump truck safely. In some models, the lever tilts the forks to assist with loading and unloading. Manual pallet jacks require you to pump the handle to lift the forks, while electric pallet jacks use battery-powered motors for lifting and movement.

Tip: The ergonomic handle design on Powerful Machinery’s hand pallet truck reduces operator fatigue and improves control during long shifts.

Feature | Manual Pallet Jacks | Electric Pallet Jacks |

|---|---|---|

Handle Design | Tiller with integrated handle | A set of controls accessible from a platform |

Lifting Mechanism | The operator pumps the tiller up and down | Battery-powered motors for lifting |

Operation | Manual physical effort is required | The operator uses controls while standing on the platform |

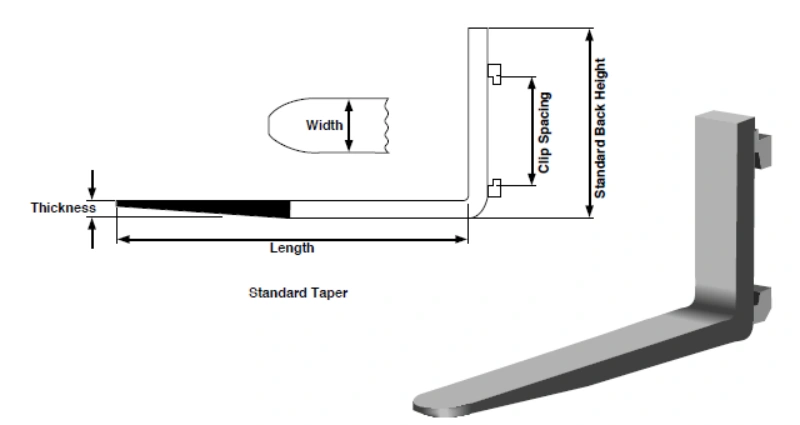

Forks and Steel Frame

The forks and steel frame form the backbone of pallet jack construction. You rely on these components to support and lift pallets safely. Manufacturers use high-strength alloy steel, chrome-manganese steel, and other durable materials to ensure the forks and frame can handle heavy loads.

The steel frame provides stability, while the forks slide under pallets for secure lifting. Powerful Machinery’s pump truck features tough C-grade steel forks and a high-balanced welded frame, which deliver maximum strength and reliability.

Type of Steel | Description |

|---|---|

High-strength alloy steel | Commonly used for forks and frames in pallet jacks |

Chrome-manganese steel | A specific type of high-strength steel is used for durability |

1045 to 1060 steel | Known for toughness and tensile strength |

4140 or 4340 steel | Offers high strength and wear resistance |

A572 Grade 50 steel | Preferred for structural applications |

The steel frame and forks work together to provide stability and support. You can trust the pump truck to lift and transport pallets without failure, even under substantial weight.

Hydraulic Pump System

The hydraulic pump system is the heart of every pallet truck. You use this system to lift and lower loads with minimal effort. The hydraulic system transfers pressure using hydraulic oil, converting power into mechanical energy. When you push the lever down, the lowering valve closes, retaining hydraulic oil in the lifting cylinder.

This action allows the forks to rise as you move the tow bar. The hydraulic pump system enables smooth and efficient lifting, making material handling easier.

The hydraulic system uses hydraulic oil to transfer pressure.

It converts power into mechanical energy for lifting and lowering.

This system drives the core functions of the pallet jack.

Note: Regular maintenance of the hydraulic pump system ensures reliable operation and extends the lifespan of your pump truck.

Steer and Load Wheels

Steer and load wheels play a crucial role in pallet jack construction. You depend on these wheels for maneuverability and floor protection. Manufacturers use materials like polyurethane, ultra-poly, nylon, and steel to build wheels that suit different environments.

Polyurethane wheels offer quiet operation and protect floors, making them ideal for customer-facing areas. Nylon wheels are more durable and work well on rough surfaces, though they can be louder.

Wheel Type | Characteristics |

|---|---|

Polyurethane | Durable, good for various surfaces |

Ultra-Poly | Enhanced durability, suitable for heavy loads |

Nylon | Lightweight, resistant to wear |

Steel | Strong, used for heavy-duty applications |

Wheel Type | Maneuverability | Floor Protection |

|---|---|---|

Polyurethane | Quieter, suitable for smooth floors | Less likely to mark floors, ideal for customer-facing applications |

Nylon | More durable, better for rough floors | Can mark floors, louder than polyurethane |

Steer wheels are larger, usually 7 or 8 inches in diameter, which helps you turn the pallet truck easily. Load wheels support the weight and ensure smooth movement across different surfaces.

Tow Bar and Linkages

The tow bar and linkages connect the main components of the pallet jack, allowing you to control lifting and movement. The tow bar resembles a tiller and helps you steer the pump truck. When you pump the tow bar, you generate hydraulic pressure that raises the forks.

Linkages connect the wheels to the levers, enabling the forks to move up and down efficiently. These components ensure that you can handle loads safely and with minimal effort.

Tip: Powerful Machinery’s pump truck uses robust tow bars and precision linkages to deliver smooth lifting and reliable performance in demanding environments.

You now understand the essential components and functions of pallet jack construction. Each part works together to provide safe, efficient, and reliable material handling, whether you use manual or electric types of pallet jacks.

Pallet Jack Functions and Operation

Manual Pallet Jack Operation

You use a manual pallet jack to move and lift loads in warehouses, retail stores, and factories. The operation of pallet trucks starts with positioning the steel forks under the pallet. You grip the handle and pump it up and down, which activates the hydraulic lifting system. This action raises the load smoothly.

You steer the pallet jack using the tiller, guiding it through tight spaces. Manual pallet jack functions rely on your physical strength, but the mechanical advantage makes lifting heavy loads easier. Minimal training is needed, so you can learn the operation quickly.

Electric Pallet Jack Operation

Electric pallet jack functions offer advanced features for handling larger loads and longer travel distances. You operate these trucks using a set of controls, often from a standing platform. The electric motor powers both movement and lifting, reducing operator fatigue.

You can maneuver heavy loads with less effort, making the electric pallet jack’s functions ideal for busy warehouses. Training requirements increase because you must learn to use the controls and safety features.

Powerful Machinery’s product range includes electric models designed for efficiency and reliability in demanding environments.

Feature | Manual Pallet Jack | Electric Pallet Jack |

|---|---|---|

Power Source | Operated manually, relying on physical strength | Powered by a motor, requiring less physical effort |

Maneuverability | Good in tight spaces due to shorter head length | Easier to maneuver with motor assistance |

Load Capacity | Can lift 2,000 to 10,000 pounds, but strenuous for heavy loads | Can carry heavier loads with less operator fatigue |

Travel Distance | Suitable for moving loads up to 40 feet | Better for longer distances in large warehouses |

Cost | Generally lower initial cost | Higher initial cost but may save on labor costs |

Training Requirements | Minimal training needed | May require more training to operate safely |

Hydraulic Lifting System

The hydraulic lifting system powers the core pallet jack functions. You begin by pushing the operating lever down to the lift position, closing the lowering valve, and retaining hydraulic oil in the lifting cylinder. You move the tow bar up and down, forcing oil into the cylinder and lifting the forks.

Each upward movement draws hydraulic oil from the storage tank, while a back-pressure valve prevents backflow. Depressing the tow bar feeds more oil into the lift cylinder, raising the load further.

Repeating this motion increases the oil in the cylinder, elevating the forks. You set the lever to neutral for transport, then pull it up to lower the forks and return the oil to the tank.

Fluid displacement moves hydraulic oil through internal chambers.

Handle movement generates mechanical pressure for lifting.

Pressurized fluid gradually raises the load.

Steel fork arms slide smoothly under pallets, constructed for strength.

The hydraulic cylinder converts your effort into a vertical lifting motion.

Precision engineering allows controlled lifting with minimal effort.

You benefit from a system that combines mechanical advantage and hydraulic power, making the operation of pallet trucks efficient and safe.

Specialized Pallet Trucks by Powerful Machinery

Hand Pallet Truck Features

You gain a distinct advantage when you choose Powerful Machinery’s manual pallet trucks. These trucks deliver ergonomic comfort and robust safety features. The cushioned handle reduces strain, allowing you to operate for longer periods without discomfort.

Overload protection and a hydraulic safety valve help prevent accidents during heavy lifting. You select from a range of load capacities, so you can match the truck to your specific needs. Some models include an integrated weighing scale, which lets you monitor inventory in real time.

Feature | Description |

|---|---|

Ergonomic Design | The handle is designed with a cushioned grip to reduce strain during operation. |

Safety Features | Includes overload protection and a hydraulic safety valve to prevent accidents. |

Load Capacity Options | Various options are available to handle different weights confidently. |

Customization Options | Different fork sizes, pump types, and the ability to add a company logo for branding. |

Integrated Weighing Scale | Provides real-time weight measurement for better inventory management. |

You notice that Powerful Machinery’s manual pallet trucks meet and often exceed industry standards. The high-strength steel construction and cast hydraulic pumps ensure durability and reliable performance.

Feature | Industry Standard | Powerful Machinery’s Hand Pallet Trucks |

|---|---|---|

Load Capacity | 2,000 kg to 3,000 kg (4,400 lbs to 6,600 lbs) | Varies, with some models exceeding 5 tons |

Lift Height | 185mm to 205mm (7 to 8 inches) | Similar, with options for higher lifts |

Material Quality | High-strength steel, durable finishes | High-strength steel, robust construction |

Hydraulic Pump | Cast pumps are preferred for durability | Cast pumps are used in higher-end models |

Customization and Applications

You customize manual pallet trucks to fit your workspace and load requirements. You request larger or longer fork sizes for oversized materials. You select pump types and add your company logo for branding. These options help you optimize your equipment for unique tasks.

You order trucks with extended forks for bulky loads.

You choose models with higher lift heights for specialized storage.

You add branding to promote your business identity.

Manual pallet trucks serve you in warehouses, factories, and retail stores. You use them for moving pallets, stacking goods, and handling oversized loads. Custom models help you meet safety guidelines and navigate tight spaces.

You rely on these trucks for loads over 10,000 pounds, especially when handling steel or metal materials.

Application Type | Description |

|---|---|

Load Requirement | Custom pallet trucks are needed for loads over 10,000 pounds, especially for large materials like steel or metal. |

Height Requirement | Some operations require forks that exceed standard heights for moving or storing loads. |

Safety | Compliance with safety guidelines may necessitate unique equipment. |

Space Restrictions | Custom solutions are ideal for confined spaces or areas with tight storage and turning radius. |

You benefit from a solution that adapts to your workflow. Powerful Machinery’s manual pallet trucks and electric pallet jacks provide reliable performance and flexibility for demanding environments.

Safe Operation and Maintenance

Pallet Jack Safety Guidelines

You protect yourself and your team by following strict safety guidelines every time you use material handling equipment. Before operating a pallet jack, inspect the equipment for damage or wear. Use gloves and eye protection to reduce injury risk. Never exceed the weight-bearing capacity of your equipment.

Center the load under the forks to prevent tipping. Push the load instead of pulling for better control. Maintain a safe speed and keep a one-inch clearance between the pallet and the floor. Alert co-workers before lowering a loaded pallet jack. Plan your route and remove obstacles to ensure a clear path.

Powerful Machinery’s equipment undergoes rigorous testing to meet international safety standards, giving you confidence in every lift.

Tip: Operator training improves safety and reduces accidents. Always review safety guidelines before starting work.

Pre-Use Inspection Checklist

You extend the lifespan of your equipment and prevent accidents by performing a thorough inspection before each use. Follow this checklist to ensure your pallet jack is ready for operation:

Check for cracks or visible damage on the frame and forks.

Inspect the hydraulic system for leaks or malfunctions.

Verify wheel condition and remove any debris.

Test the handle and control lever for smooth operation.

Confirm that load capacity markings are visible.

Ensure the lowering valve functions correctly.

Lubricate moving parts as needed.

Store equipment with forks lowered after use.

Inspection Step | What to Look For | Action Required |

|---|---|---|

Frame and Forks | Cracks, bends, or wear | Repair or replace |

Hydraulic System | Leaks, low oil, damage | Refill or fix leaks |

Wheels | Debris, flat spots, wear | Clean or replace |

Handle/Lever | Stiffness, loose parts | Adjust or lubricate |

Maintenance Tips

You keep your equipment in top condition by following a regular maintenance schedule. Perform daily checks to catch early signs of wear. Clean wheels to prevent damage from debris. Check and refill hydraulic oil as needed. Lubricate key components monthly, including wheels and axles.

Adjust the chain and lowering valve if you notice lifting issues. Schedule professional inspections based on usage and manufacturer recommendations. Use your equipment correctly by avoiding slopes and not exceeding load capacity.

Powerful Machinery’s focus on safety and reliability means you can trust your equipment to perform in demanding environments.

Note: Regular maintenance and proper usage help you avoid costly repairs and extend the life of your equipment.

Choosing the Right Pallet Jack

Assessing Workspace and Load Needs

You need to evaluate your workspace and load requirements before selecting a pallet jack. Start by measuring aisle widths and checking for obstacles. Consider the types of pallets you handle and the environment, such as smooth warehouse floors or rough outdoor surfaces.

To determine the capacity, review your typical and maximum load weights. Choose a model with a load capacity that exceeds your heaviest load by at least 20%. Fork length and width affect stability and maneuverability. Longer forks support heavier loads but may be less agile in tight spaces.

High-quality wheels improve weight distribution and stability.

Factor | Description |

|---|---|

Load Capacity | Ensure the pallet can support the required weight without compromising structural integrity. |

Compatibility | The pallet must be compatible with your handling equipment, including forklifts and pallet jacks. |

Cost vs. Longevity | Higher upfront costs for metal and plastic pallets may lead to long-term savings due to their lifespan. |

Lifecycle and Maintenance | Wooden pallets require repairs, while plastic and metal pallets offer longer life-cycles with minimal maintenance. |

Electric Pallet Jack vs Manual Pallet Jack

You must compare the types of pallet jacks to find the best fit for your operation. Manual models work well for smaller loads and tight spaces. They require minimal training and have lower maintenance costs. Electric types offer higher lifting capacity and faster transport for heavy loads.

These models reduce physical strain and boost productivity, but they cost more and need regular charging and maintenance.

Feature | Manual Pallet Jacks | Electric Pallet Jacks |

|---|---|---|

Pros | No training required, smaller and agile, lower cost and maintenance | Can lift heavier loads, faster transportation, and higher lifting capacity |

Cons | Physically demanding, limited capacity, operator fatigue | Higher initial cost, requires maintenance and charging, larger and less maneuverable |

Tip: Manual pallet jacks suit ground-level operations and short distances. Electric models excel in large warehouses with frequent heavy lifting.

Product Selection Tips

You should focus on several factors when choosing from Powerful Machinery’s product range. Ensure the machine matches your application needs and complies with production requirements. Look for proven quality and reliability to avoid downtime.

Consider warranty options and the availability of spare parts for long-term support. Reliable delivery and local service partners help you maintain your equipment efficiently. Transparent communication between you and the supplier ensures you balance price and quality.

Factor | Description |

|---|---|

Application Compliance | Ensure the machine meets your specific needs and requirements for production. |

Quality | Look for machinery with a proven track record of longevity and efficiency to avoid losses in revenue and time. |

Warranty | Consider the warranty options available, including the possibility of negotiating extended coverage for your equipment. |

Availability of Spare Parts | Ensure that spare parts will be available for at least 10 years after purchase, even if new models are released. |

Service | Find local partners for maintenance and repairs to avoid delays caused by language barriers and ensure quick service. |

Transparency | Seek a balance between price and quality, facilitated by clear communication between all parties involved in the procurement process. |

Reliability | Confirm that the delivery times are reliable to avoid disruptions in your production schedule, which can impact cash flow and business development. |

Note: Powerful Machinery offers a wide selection of types and capacities, allowing you to choose the right pallet jack for your specific needs.

Conclusion

You improve safety and efficiency when you understand each part of a pallet jack and follow best practices for operation. Regular maintenance and proper equipment selection deliver measurable benefits:

Benefit | Evidence |

|---|---|

Increased Productivity | 20% increase in productivity due to efficient handling of pallets. |

Reduced Injuries | Significant reduction in musculoskeletal injuries, enhancing safety. |

Operational Efficiency | Streamlined workflow, reducing bottlenecks and increasing throughput. |

Cost Savings | Lower maintenance costs by reducing wear on forklifts. |

Space Optimization | Better space utilization with narrow aisle pallet jacks. |

OSHA requires up-to-date maintenance records, and routine inspections help prevent workplace risks. You can rely on Powerful Machinery’s certified products for reliable material handling solutions.

FAQ

What is the difference between a manual and an electric pallet jack?

Manual pallet jacks require you to pump the handle to lift and move loads. Electric pallet jacks use a motor for lifting and transporting. You experience less physical strain with electric models, which suit larger warehouses and heavier loads.

How do you maintain a pallet jack for long-term use?

Tip: Clean wheels regularly, check hydraulic oil levels, and lubricate moving parts monthly. Inspect the forks and frame for damage. Follow the manufacturer’s maintenance schedule to extend the lifespan of your equipment.

Can you use a pallet jack on uneven surfaces?

You can operate a pallet jack on smooth ramps or flat outdoor areas. Move slowly, keep the load balanced, and avoid large obstacles. Powerful Machinery’s PU wheels help you achieve smoother movement on various surfaces.

What safety precautions should you follow when using a pallet jack?

Safety Step | Why It Matters |

|---|---|

Wear protective gear | Prevent injuries |

Center the load | Avoid tipping |

Push, don’t pull | Maintain control |

Inspect before use | Detect damage early |