You need to know the main difference between pallet jacks and liftgates. A pallet jack allows you to move goods across short distances within a facility, while a liftgate lets you safely load and unload cargo from trucks without a dock. Forklifts offer higher lifting capacity and stacking ability in the logistics industry.

Choosing the right equipment improves efficiency, safety, and cost-effectiveness.

Type of Pallet Jack | Cost-Effectiveness | Operational Efficiency |

|---|---|---|

Cost-effective but labor-intensive | Limited by operator capability | |

Electric Pallet Jack | Higher costs but enhances productivity | Reduces worker strain and improves efficiency |

Liftgates provide a secure platform for loading and unloading, reducing accident risks.

They minimize manual lifting, enhancing staff safety.

Liftgates streamline operations by reducing the number of staff needed for moving goods.

Key Takeaways

Pallet jacks are ideal for moving goods over short distances within facilities, making them perfect for tight spaces.

Liftgates provide a safe platform for loading and unloading cargo from trucks, especially when no dock is available.

Forklifts excel in lifting heavy loads and stacking goods at greater heights, making them essential for large warehouses.

Choosing the right equipment based on your logistics needs boosts efficiency and enhances workplace safety.

Proper training for operators is crucial to prevent accidents and ensure safe operation of pallet jacks, liftgates, and forklifts.

Pallet Jack: Definition, Features, and Use Cases

What Is a Pallet Jack?

A pallet jack is a type of material handling equipment you use to lift and move pallets over short distances. You often see pallet jacks in warehouses, retail stores, and manufacturing facilities.

Industry experts classify pallet jacks as straightforward forklifts, making them one of the most basic tools for moving heavy loads. You need proper training to operate a pallet jack safely, especially when handling powered models. This equipment helps you transport goods efficiently and reduces manual lifting.

Tip: You can improve workplace safety by ensuring every operator receives training before using a pallet jack.

Key Features of Powerful Machinery Pallet Trucks

Powerful Machinery’s pallet trucks offer robust steel construction and a reliable hydraulic pump. You benefit from ergonomic handles that make operation comfortable and reduce fatigue. The polyurethane wheels glide smoothly and protect your floors from damage.

These pallet trucks handle a wide range of pallet sizes and weights, with load capacities from 2,000 to 5,500 pounds. You can easily maneuver them in tight spaces, which is essential for crowded warehouses.

Safety Measure | Impact on Workplace Safety Statistics |

|---|---|

Comprehensive employee training | Prevents up to 70% of forklift accidents in the U.S. |

Proper maintenance of equipment | Reduces risk of accidents and injuries related to equipment failure |

Installation of protection devices | Minimizes damage from impacts and enhances safety measures |

You get a durable, cost-effective solution that requires minimal maintenance and no electricity. Powerful Machinery’s pallet trucks help you maintain a safe and productive work environment.

Common Applications in Logistics

You use pallet jacks in many logistics scenarios. They are ideal for moving goods in supermarkets, warehouses, and manufacturing plants. You can also find specialized models for outdoor use, such as all-terrain pallet jacks in garden nurseries or construction sites.

Heavy-duty pallet jacks handle large loads in demanding environments.

Type of Pallet Jack | Typical Load Capacity | Common Use Scenarios |

|---|---|---|

Manual Pallet Jack | 2,000 – 5,500 pounds | Supermarkets, Warehousing, Manufacturing |

Rider Pallet Jack | Varies (depends on model) | Warehouses, Manufacturing (for longer distances) |

All-terrain Pallet Jack | Up to 4,500 pounds | Garden Nurseries, Gravel Pits, Construction |

Heavy-duty Pallet Jack | Up to 15,000 pounds | Large load handling in various environments |

You rely on pallet jacks for efficient material handling in tight spaces and for short distances. Powerful Machinery’s pallet trucks deliver the strength and reliability you need for daily operations.

Liftgates: Function and Benefits

What Is a Liftgate?

You encounter a liftgate as a hydraulic or electric device installed at the rear of a truck. This equipment raises cargo from ground level to the truck’s tailgate height or lowers it safely to the ground.

In freight shipping, liftgates serve as optional equipment, especially when you need to move cargo at locations without loading docks or forklifts. You rely on a liftgate to bridge the gap between the truck and street level, making loading and unloading freight safer and more efficient.

Note: Liftgate service becomes essential when your delivery or pickup site lacks a dock or forklift. You must arrange for trucks equipped with liftgates to ensure smooth freight handling.

How Liftgates Work in Freight Shipping

Liftgates operate using hydraulic mechanisms. You activate the system, and the platform moves up or down, powered by components such as hydraulic pumps, fluid reservoirs, cylinders, and control valves. This technology allows you to handle shipping heavy or oversized cargo without manual lifting.

The liftgate attaches to the rear of the truck, providing a stable platform for loading and unloading freight. You improve efficiency and reduce injury risks by using liftgates for cargo that cannot be lifted by hand.

Main mechanical components:

Hydraulic pump

Hydraulic fluid reservoir

Hydraulic cylinders

Control valves

You find several types of liftgates in freight shipping, each designed for specific cargo needs:

Railgate lift gates: Ideal for industrial freight and heavy cargo.

Cantilever lift gates: Offer stability on uneven surfaces.

Column lift gates: Ensure perfect leveling for loading and unloading freight.

Slider lift gates: Maximize cargo area for commercial freight shipping.

When to Use Liftgates?

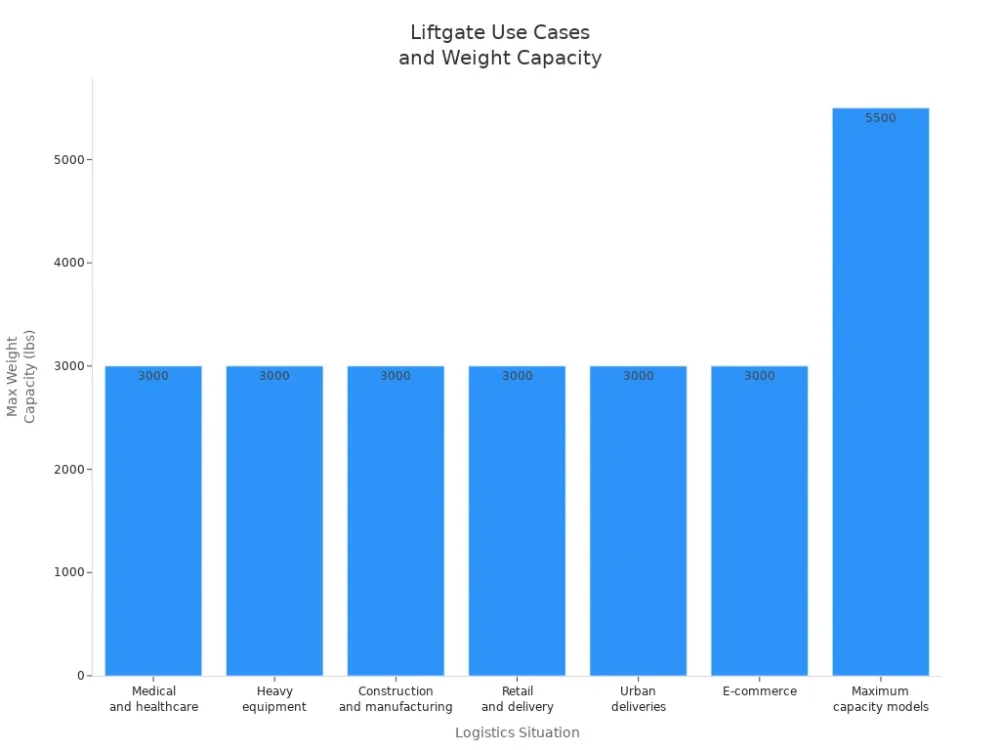

You use liftgates in logistics when you must deliver or pick up cargo at sites without loading docks. Liftgates prove essential for medical logistics, construction, retail, urban deliveries, and e-commerce.

Most liftgates support weight capacities between 1,000 and 3,000 pounds, with some models handling up to 5,500 pounds. You select the right liftgate based on your cargo type and freight requirements.

Common Situations in Logistics | Typical Weight Capacity Supported |

|---|---|

Medical and healthcare logistics | 1,000 – 3,000 pounds |

Heavy equipment and machinery | 1,000 – 3,000 pounds |

Construction and manufacturing | 1,000 – 3,000 pounds |

Retail and delivery services | 1,000 – 3,000 pounds |

Urban deliveries | 1,000 – 3,000 pounds |

E-commerce | 1,000 – 3,000 pounds |

Maximum capacity of some models | Up to 5,500 pounds |

You depend on liftgates to streamline loading and unloading freight, especially when shipping heavy or oversized cargo. Liftgates help you maintain safety and efficiency in every freight operation.

Forklifts: Capabilities and Best Uses

What Are Forklifts?

You use forklifts as powerful warehouse equipment designed to lift, move, and stack heavy loads. Industry standards classify forklifts by their power source and best use. The table below shows the main types you will encounter:

Class | Power Source | Key Features | Best Use |

|---|---|---|---|

I | Electric Motor | Quiet operation, zero emissions | Indoor applications (e.g., warehouses) |

II | Electric Motor | Narrow aisle design, articulated masts | High-density warehouses need efficient navigation |

VII | Internal Combustion Engine | Large, heavily treaded tires | Outdoor worksites with challenging terrains |

You select the right forklift based on your environment and the type of material you need to handle.

Forklift Advantages in Warehousing

Forklifts give you several advantages over other warehouse equipment. You can handle massive pallets and reduce unloading times. You stack goods efficiently, especially in high-density storage areas. Forklifts offer high load capacity, often ranging from several tons to more than 10 tons.

You benefit from loaders equipped with forks for stacking at significant heights. Diesel-powered forklift loaders handle heavy loads with strong chassis and hydraulic systems that support capacities exceeding 10 tons.

You move large quantities of goods quickly.

You stack products at heights unreachable by pallet jacks or liftgates.

You rely on forklifts for safe and efficient handling of bulky items.

Tip: Always check the manufacturer’s load capacity rating before lifting heavy pallets.

When to Choose Forklifts?

You choose a forklift when you need to lift heavy or bulky items and reach greater heights than pallet jacks or liftgates allow. Forklifts excel in warehouses, construction sites, and outdoor worksites where you must move large loads.

You must ensure operators receive formal instruction, hands-on training, and evaluation before using a forklift. Regulatory requirements include daily inspections, safe driving practices, and proper load management. Operators must wear personal protective equipment and follow strict safety protocols.

Forklift operator training includes:

Online instruction meeting OSHA standards

On-site equipment demonstration

Safety knowledge assessment and hands-on evaluation

You use forklifts when your operation demands high-capacity lifting, efficient stacking, and safe movement of goods in busy environments. Forklifts remain essential warehouse equipment for logistics professionals who need reliable performance and safety.

Pallet Jacks vs Liftgates vs Forklifts: Comparison

Function and Operation

When you compare pallet jacks vs liftgates vs forklifts, you see that each tool serves a unique role in material handling. You need to understand how each one operates to choose the right equipment for your workflow.

Pallet jacks help you lift and move pallets across short distances inside warehouses or retail spaces. You operate them by hand, which gives you excellent control and maneuverability in tight aisles.

Liftgates assist you in raising or lowering goods between the ground and a truck’s cargo area. You activate a hydraulic or electric system, which provides a stable platform for heavy items like appliances or machinery.

Forklifts allow you to lift, transport, and stack much heavier loads at greater heights. You need a trained operator for safe use, and you must perform regular maintenance to keep the machine in top condition.

You should always match your equipment to your operational needs. For example, pallet jacks and forklifts work best inside warehouses, while liftgates are essential for deliveries at locations without loading docks.

Tip: Evaluate your facility layout and delivery requirements before deciding between pallet jacks, liftgates, or forklifts.

Weight Capacity and Handling

You must consider weight capacity and handling when comparing pallet jacks vs liftgates and forklifts. Each tool has specific strengths that affect your workflow and safety.

Equipment Type | Typical Load Capacity | Lifting Height | Maneuverability | Operator Requirement |

|---|---|---|---|---|

Pallet Jack | 2,000 – 5,500 lbs | Up to 7.5 inches | High (tight spaces) | Basic training |

Liftgate | 1,000 – 5,500 lbs | Truck bed height | Moderate (truck-based) | Basic operation |

Forklift | 3,300 – 10,000+ lbs | Up to 20+ feet | Moderate (needs space) | Certified operator |

You see that pallet jacks handle moderate weights and excel in narrow aisles. Liftgates support heavy items during loading and unloading but do not move goods inside a facility. Forklifts offer the highest lifting capacity and can stack goods at significant heights, making them ideal for large warehouses or construction sites.

You should also look at handling features. For example, a typical pallet jack has a turning radius of about 55.7 inches and fits in aisles as narrow as 87 inches. Forklifts require more space but provide greater lifting power. Liftgates operate at the truck’s rear, so you need clear access for safe use.

Best Use Scenarios

You want to select the right tool for your specific logistics scenario. Here’s how pallet jacks, liftgates, and forklifts fit into different workflows:

Use pallet jacks for moving pallets between shelves, loading docks, and trucks within a warehouse. They are perfect for short distances and tight spaces.

Choose liftgates when you deliver or pick up heavy cargo at locations without a loading dock or forklift. They are essential for urban deliveries, retail shipments, and medical equipment logistics.

Rely on forklifts for stacking, high-volume material movement, and handling bulky or oversized loads. Forklifts shine in large warehouses, manufacturing plants, and construction sites.

If you need to decide between a liftgate vs forklift, consider your environment. Use a liftgate for street-level deliveries and a forklift for stacking and transporting goods inside your facility.

Note: You can improve efficiency and safety by integrating the right combination of pallet jacks vs liftgates vs forklifts into your logistics workflow.

When you understand the differences between pallet jacks vs liftgates vs forklifts, you make smarter choices for your business. You boost productivity, protect your staff, and ensure smooth operations across every stage of your supply chain.

Pallet Jack vs Liftgate: Choosing the Right Tool

Assessing Your Logistics Needs

Selecting the right equipment for moving goods is a critical decision in any shipping operation. You need to evaluate your logistics needs before choosing between a pallet jack and a liftgate.

Start by looking at the type of goods you handle, the volume of shipping, and the physical layout of your facility. Each factor influences which tool will deliver the best results for your workflow.

Here is a table to help you assess the most important factors:

Factor | Description |

|---|---|

Product Characteristics | Consider the weight, size, and fragility of your goods. |

Throughput Requirements | Think about how many goods you move and how quickly you need to ship them. |

Storage Constraints | Check ceiling height, aisle width, and floor conditions in your facility. |

Budget Considerations | Review your budget for equipment investment and ongoing costs. |

Equipment Versatility | Choose equipment that can adapt to different shipping tasks and future needs. |

Maintenance Requirements | Factor in the time and cost needed to keep your equipment in top shape. |

Integration Potential | Make sure your choice works well with your current systems and processes. |

You should also consider your warehouse layout, inventory flow, and racking systems. If you ship fragile or oversized goods, you may need specialized equipment. Always match your choice to your current and future business needs.

Tip: Choosing the right material handling equipment directly impacts your profitability and safety. Take time to analyze your shipping requirements and facility constraints before making a decision.

Workflow Integration Tips

Integrating a pallet jack or liftgate into your workflow can improve efficiency and safety. You want to ensure that your equipment matches your shipping volume and the types of goods you move.

For example, a pallet jack works best for moving goods across short distances inside a warehouse or retail space. You can easily maneuver it in tight aisles and use it to load or unload goods from trucks at a dock.

A liftgate becomes essential when you deliver goods to locations without a loading dock. It allows you to safely raise or lower heavy shipments from the truck to the ground. You should plan your shipping routes and delivery points to determine if a liftgate is necessary.

If your operation involves frequent deliveries to urban sites or customer locations, a liftgate can save time and reduce manual labor.

To maximize efficiency, train your staff on proper equipment use. Schedule regular maintenance to prevent breakdowns during shipping. Use equipment that integrates with your warehouse management system for better tracking of goods.

When you align your equipment with your workflow, you reduce delays and improve the safety of your shipping process.

Note: The right combination of pallet jacks and liftgates can streamline your shipping operations and help you handle a wider variety of goods.

Practical Advice for Powerful Machinery Customers

If you are a Powerful Machinery customer, you have access to high-quality pallet trucks designed for demanding shipping environments. Here are some practical tips to help you get the most from your equipment:

Assess the weight of your pallets. Never overload your pallet jack. This prevents equipment failure and keeps your team safe.

Consider your operational flow. If you move goods frequently, an electric pallet jack can reduce fatigue and boost productivity.

Evaluate your environment. Choose wheel materials that match your floor surfaces. Make sure your pallet jack fits in your aisles and storage areas.

Determine your budget. Look at the total cost of ownership, including maintenance and service, not just the purchase price.

Powerful Machinery’s pallet trucks offer robust steel construction, ergonomic handles, and smooth-rolling polyurethane wheels. You can use them for a wide range of shipping tasks, from moving goods in warehouses to loading trucks at the dock.

Their versatility makes them ideal for logistics companies, retail stores, and manufacturing plants.

When you compare pallet jack vs liftgate, think about your shipping locations and the types of goods you handle. A pallet jack gives you flexibility and control inside your facility. A liftgate ensures safe delivery when you ship goods to sites without a dock.

By choosing the right tool, you protect your staff, speed up your shipping process, and keep your goods moving efficiently.

Remember: Powerful Machinery’s pallet trucks are built to handle the demands of modern shipping. They help you move goods safely, efficiently, and reliably in every logistics scenario.

Conclusion

You need to match your equipment to your logistics requirements for safe and efficient operations. The table below highlights the main differences:

Equipment | Function | Capacity | Use Case |

|---|---|---|---|

Pallet Jacks | Move pallets and dock work | Up to 8,000 lbs | Tight spaces, warehouse, mobile deliveries |

Liftgates | Lift freight to/from ground and truck | ~1,500 lbs | No dock locations, special handling |

Forklifts | Lift and move heavy loads | 3,000 lbs or more | Large cargo, dockless handling |

A thorough assessment of your logistics needs improves safety and efficiency. You protect your team, optimize performance, and ensure compliance. Powerful Machinery’s pallet trucks deliver reliability and strength for your material handling challenges.

FAQ

What is the main difference between a pallet jack and a liftgate?

You use a pallet jack to move pallets inside a facility. A liftgate helps you load or unload cargo from a truck when no dock is available. Each tool serves a unique purpose in logistics.

How much weight can Powerful Machinery pallet trucks handle?

You can move loads ranging from 2,000 to 5,500 pounds with Powerful Machinery pallet trucks. The exact capacity depends on the model you select for your operation.

Tip: Always check the load rating before lifting heavy pallets.

When should you use a liftgate for deliveries?

You need a liftgate when your delivery location does not have a loading dock or forklift. Liftgates make loading and unloading safer and faster for heavy or bulky items.

Do you need special training to operate a pallet jack?

You should receive basic training before using a pallet jack. Training helps you avoid accidents and ensures safe operation, especially with powered models.

Equipment | Training Needed |

|---|---|

Pallet Jack | Basic |

Liftgate | Basic |

Forklift | Certified |