When you ask what a grade 100 chain is, you discover a powerhouse designed for the most demanding lifting tasks. This chain is made from heat-treated alloy steel, providing 25% more strength than Grade 80 chains and meeting stringent NACM, ASTM, and OSHA standards.

Powerful Machinery, a leader in high-performance lifting solutions, provides certified chains you can trust for lifting heavy loads every day.

Chain Grade | Design Factor | Working Load Limit (WLL) | Material Composition | Typical Uses |

|---|---|---|---|---|

G100 | 4:1 | 4,300lb – 22,600lb | Heat-treated alloy steel | Heavy-duty rigging, crane operations, and material handling |

You rely on grade 100 chain for safe, reliable lifting in environments where failure is not an option. Each link delivers the strength you need for secure lifting, efficient rigging, and critical material handling.

Key Takeaways

Grade 100 chain offers 25% more strength than Grade 80 chains, making it ideal for heavy lifting tasks.

Each link in a Grade 100 chain is made from heat-treated alloy steel, ensuring durability and safety during lifting operations.

Grade 100 chains meet strict safety standards, including those set by NACM, ASTM, and OSHA, providing users with peace of mind.

The working load limit for Grade 100 chain ranges from 4,300 to 22,600 lbs, allowing for efficient lifting with smaller, lighter chains.

Always inspect your Grade 100 chain for damage before use to ensure safe and reliable lifting.

What is Grade 100 Chain?

Definition and Key Properties

When you ask what a grade 100 chain is, you look for a chain that stands out in the world of lifting. This chain uses high-performance alloy steel and advanced heat treatment.

You get a product that handles the toughest lifting jobs with ease. Each link in the chain is designed for strength, durability, and safety. You can trust it for overhead lifting, heavy-duty rigging, and material handling.

You see the difference when you compare a grade 100 chain to lower grades. The table below shows how grade 100 chain outperforms grade 80 chain in key areas:

Property | Grade 80 Chain | Grade 100 Chain |

|---|---|---|

Material | Standard Alloy | High-Performance Alloy |

Heat Treatment | Standard | Specialized |

Working Load Limit (WLL) | 12,000 lb | 15,000 lb |

Elongation | Over 20% | Over 20% |

Abrasion Resistance | Standard | Enhanced |

You notice that grade 100 chain offers a higher working load limit and better abrasion resistance. This means you can lift heavier loads with more confidence. The chain also keeps its flexibility and strength, even after repeated lifting cycles.

Powerful Machinery leads the way in manufacturing grade 100 chain. You get certified products that meet strict international standards. You can rely on their chains for safe and efficient lifting in construction, marine, and transportation industries.

Grade 100 Chain Rating

You may wonder how manufacturers assign a grade 100 rating to a chain. The process involves strict testing and quality checks. The table below explains the main criteria:

Criteria | Description |

|---|---|

Material | High-quality alloy steel |

Proof Testing | Twice the working load limit |

Minimum Break Strength | Four times the working load limit |

Compliance | Must meet or exceed OSHA, NACM, and ASTM specifications |

You see that grade 100 chain must pass proof testing at twice its working load limit. The chain must also break at four times its rated working load. This ensures you get a chain that will not fail during critical lifting operations.

When you choose a grade 100 chain from Powerful Machinery, you receive full certification and traceability. Each chain comes with marks and codes, so you know it meets all safety requirements. You can use it for lifting in the most demanding environments, knowing you have the best equipment for the job.

If you want to understand what a grade 100 chain is, remember that it means top-level strength, safety, and reliability for all your lifting needs. You can count on this chain to deliver performance every time you lift, move, or secure heavy loads.

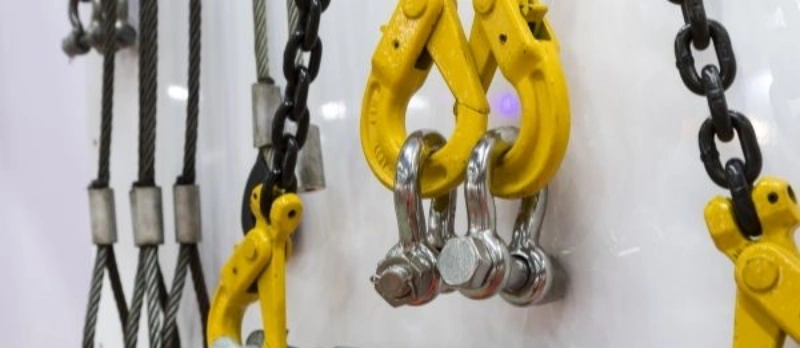

Grade 100 Alloy Rigging Chain Features

Material and Construction

When you choose a grade 100 alloy rigging chain, you select a product built for strength and reliability. Manufacturers use high-strength alloy steel to create each link. This material gives the chain superior durability and performance in tough conditions.

You benefit from a chain that offers up to 25% higher working load limits compared to Grade 80 chains. The increased strength means you can use a smaller and lighter chain for the same lifting job, making your work more efficient.

High-strength alloy steel construction

Engineered for durability and wear resistance

Ideal for demanding lifting and rigging applications

The manufacturing process includes special induction heat treatment. This step maximizes the chain’s strength and improves its ability to stretch without breaking. You get a chain that meets or exceeds all major standards for lifting safety.

Certification and Standards

You need confidence when you use chain slings for lifting heavy loads. Grade 100 alloy rigging chain meets strict certification requirements. Each chain is tested to ensure it can handle the rated working load limit.

Manufacturers certify these chains to international standards like ISO 9001-2000, NACM, ASTM, and OSHA. You can trust that every chain has passed rigorous quality checks.

Note: Certified grade 100 alloy rigging chain gives you peace of mind during lifting operations. You know the chain will perform safely and reliably.

The chain’s nominal stress capacity is determined by the minimum breaking force divided by twice the nominal cross-sectional area of a link. This specification helps you understand the chain’s strength and reliability.

Traceability and Identification

You want to verify the authenticity and safety of your lifting equipment. Grade 100 alloy rigging chain comes with clear identification marks. These include manufacturer codes, certification codes, and unique trace codes. You can track the product’s history and confirm compliance with safety standards.

Manufacturer and certification codes for batch identification

Unique trace codes for authenticity verification

Heat treatment codes show processes like quenching and tempering

DOT approval for regulated industries

Manufacturers mark chain slings and attachments for easy and permanent identification. This system supports ISO 9000 traceability, helping you maintain safety and quality in every lifting operation.

Grade 100 Chain Specs and Performance

Grade 100 Chain Working Load Limit

You need to know how much weight a chain can safely lift. The working load limit for Grade 100 chain ranges from 4,300 to 22,600 lbs, depending on the chain size. This chain is designed for extremely heavy lifting in overhead applications, rigging, towing, and construction.

You get a 25% higher working load limit compared to a Grade 80 chain of the same size. This means you can use a smaller diameter chain for the same job, making handling easier and improving safety.

Grade 100 chain slings allow you to lift heavier loads with less bulk.

You can achieve the same lifting capacity with a smaller chain size.

Grade 100 Chain Breaking Strength

You want a chain that will not fail during critical lifting operations. Manufacturers specify that the minimum breaking strength for Grade 100 chain is four times the working load limit. This strong safety factor gives you confidence during every lift.

You can rely on this chain for demanding lifting tasks, knowing it has been tested to withstand extreme forces.

Tip: Always check the chain’s specifications before using it for lifting. The safety factor ensures reliable performance, but you should never exceed the rated working load limit.

Size and Dimensions

You have options when selecting chain slings for lifting. Grade 100 chain comes in sizes from 8 mm to 22 mm. Each size offers different lifting capacities and weights. The pitch, inside width, and outside width vary by size, so you can choose the right chain for your specific lifting needs.

Smaller diameter chains can handle greater loads because of the increased tensile strength.

Chain Size (mm) | Pitch (mm) | Inside Width (mm) | Outside Width (mm) | Weight (Kg/m) |

|---|---|---|---|---|

8 | 24.00 | 10.40 | 29.60 | 1.40 |

22 | 66.00 | 28.60 | 81.40 | 10.90 |

Durability and Corrosion Resistance

You want your lifting equipment to last in tough environments. Grade 100 chain is built to withstand temperature extremes, maintaining full capacity up to 400°F. The finer grain structure improves impact resistance in cold conditions, making it suitable for sub-zero lifting operations.

You also benefit from better corrosion resistance against chemical exposure compared to Grade 80 chain. However, you should avoid using chain slings around acids or caustic chemicals.

Note: Grade 100 chain slings perform well in harsh weather and industrial settings. You get reliable lifting even in challenging conditions.

Applications and Industries

Overhead Lifting

You use an overhead lifting chain when you need to move heavy loads safely and efficiently. This type of chain is essential in many industries. You see it in steel fabrication, precast concrete, and marine environments. Crane operations and construction sites rely on overhead lifting chains for secure material handling.

Offshore and subsea projects also depend on this chain for tough jobs. You find it in shipyards, mining, and excavation work. Entertainment rigging, nuclear facilities, and energy utilities use overhead lifting chains for precise and reliable lifting.

Truck and vehicle recovery, metalworking, and manufacturing also benefit from its strength.

Steel fabrication

Precast concrete

Marine

Crane operations

Construction

Offshore & Subsea

Maritime & Shipyard

Mining & Excavation

Entertainment Rigging

Nuclear

Energy & Utilities

Truck & Vehicle Recovery

Metalworking

Manufacturing

You choose the overhead lifting chain because it gives you confidence in every lift. The chain handles high-stress environments and keeps your team safe.

Heavy-Duty Rigging

You face demanding tasks in heavy-duty rigging. Grade 100 chain is your solution when you need maximum strength and safety. You use it for critical lifting in the oil and gas industry. The chain supports large equipment and heavy machinery. You trust it for lifting operations where failure is not an option.

Chain slings made from Grade 100 chain give you the reliability you need for these tough jobs.

Tip: Always inspect your overhead lifting chain before each use. Regular checks help you maintain safety and extend the life of your equipment.

Sectors Served by Powerful Machinery

You find Powerful Machinery products in many industries around the world. Construction companies use overhead lifting chains for building and infrastructure projects. Marine and shipyard operations rely on chain slings for cargo handling and vessel maintenance.

Transportation and logistics firms use these chains for secure load movement. Mining and energy sectors trust Powerful Machinery for safe lifting in extreme conditions. Manufacturing plants use overhead lifting chains to move heavy parts and materials.

Sector | Application Example |

|---|---|

Construction | Lifting steel beams |

Marine | Securing ship components |

Transportation | Loading and unloading cargo |

Mining | Moving excavation equipment |

Manufacturing | Handling large assemblies |

You choose Powerful Machinery because you want a certified, high-performance overhead lifting chain for every lifting challenge.

Grade 100 vs Grade 80 Chain

Strength Comparison

You want to choose the right chain for your lifting needs. Grade 100 chain gives you about 25% more strength than grade 80 alloy lifting chain. This means you can use a smaller chain for the same lifting job. The higher strength also lets you handle heavier loads with more confidence.

You see this difference in the working load limit and breaking strength. Grade 100 chain stands up to tough conditions and keeps you safe during every lift.

Chain Grade | Working Load Limit (WLL) | Breaking Strength | Typical Use |

|---|---|---|---|

Grade 80 | Lower | Lower | General lifting |

Grade 100 | Higher | Higher | Heavy lifting |

Tip: Always check the chain’s rating before you start any lifting operation.

Use Cases and Benefits

You use grade 80 alloy lifting chain for many standard lifting tasks. It works well for general rigging, construction, and material handling. When you need more power, you turn to grade 100 chain. This chain is perfect for heavy-duty lifting, overhead crane work, and demanding rigging jobs.

You get better efficiency because you can use lighter chain slings for the same load. This makes your work easier and safer.

Grade 80 alloy lifting chain: Good for everyday lifting and rigging.

Grade 100 chain: Best for high-stress, heavy lifting, and critical jobs.

You save time and effort with a grade 100 chain. You also reduce the risk of equipment failure during tough lifts.

Powerful Machinery Product Range

You find both grade 100 and grade 80 alloy lifting chains in the Powerful Machinery product line. You can choose from many sizes and finishes to match your lifting needs.

Powerful Machinery tests every chain to meet strict safety standards. You get certified chain slings that work in construction, marine, and transportation industries. You can trust these products for safe and reliable lifting every day.

Note: Powerful Machinery offers full traceability and certification for every chain. You always know your lifting equipment meets the highest standards.

Selecting the Right Chain

How to Identify a Grade 100 Chain?

You want to make sure you use the right chain for lifting tasks. Grade 100 chain stands out because of its clear identification marks. You will see stamped codes on each link that show the grade, size, and manufacturer. These marks help you confirm the chain’s strength and traceability.

You should always check for certification tags attached to the chain. These tags list the chain’s grade, working load limit, and manufacturer details. You can also look for unique trace codes and heat treatment marks. These features guarantee that your chain meets strict safety standards for lifting.

Tip: Always inspect the chain before lifting. Look for cracks, elongation, or wear. Remove the chain from service if you see any damage or if the link thickness drops below 90% of the original size.

Choosing for Your Application

You need to select the right chain for your lifting job. Grade 100 chain offers higher strength and better performance in tough environments. You should consider several criteria before making your choice. The table below helps you compare important factors:

Criteria | Details |

|---|---|

Design Factor | Minimum 4:1 design factor, breaking strength is four times the working load limit. |

Shock Loading Resistance | High tensile strength protects against sudden movements during lifting. |

Wear Tolerance | Maintains strength after wear, allowing more tolerance before reaching service limits. |

Temperature Performance | Works well up to 400°F, with good impact resistance in cold conditions. |

Corrosion Resistance | Slightly better than Grade 80, but avoid acids or caustic chemicals. |

You should follow safety guidelines when choosing a chain for lifting:

Use a chain with a minimum design factor of 4:1.

Check the chain’s performance at high temperatures.

Inspect the chain visually before each lifting operation.

Remove chains if you see cracks, excessive elongation, or wear.

Use identification tags that show size, grade, and capacity.

You can trust Grade 100 chain for lifting in construction, marine, and industrial settings. Powerful Machinery provides certified chains that meet all safety requirements. You get reliable lifting performance every time.

Conclusion

You gain a real advantage when you choose Grade 100 chain for lifting. This chain gives you 25% more strength than Grade 80 at the same diameter and stays lighter for the same capacity. See the main reasons below:

Pros | Cons |

|---|---|

25% stronger than Grade 80; lighter for the same load. | Higher cost. |

Grade 100 chain works well for precision lifting and demanding jobs.

Powerful Machinery delivers certified, reliable chains for your toughest tasks.

You protect your team and equipment with high-performance, traceable products.

FAQ

What does “Grade 100” mean for lifting chains?

You see “Grade 100” as a rating for high-strength alloy steel chains. This grade means the chain has a higher working load limit and better durability than lower grades. You can use it for demanding lifting and rigging jobs.

How do you identify a Grade 100 chain?

You find stamped markings on each link. These marks show the grade, size, and manufacturer. You also see certification tags attached to the chain. Always check these before using the chain for lifting.

Can you use a Grade 100 chain in extreme temperatures?

Yes, you can. Grade 100 chain works well up to 400°F. It also keeps its strength in cold environments. You should avoid using it around acids or caustic chemicals.

What certifications should you look for?

You should look for chains certified to standards like NACM, ASTM, and OSHA. Powerful Machinery provides full certification and traceability. This ensures your chain meets all safety requirements.

Where can you buy certified Grade 100 chain?

You can buy a certified Grade 100 chain directly from Powerful Machinery. Visit qdpowerful.com to explore options and request a quote.