Yes, you can use beam clamps for lifting when you follow proper procedures and stay within their rated limits. A beam clamp attaches securely to a steel beam and creates a stable anchor point for hoisting heavy loads.

You need to select the right beam clamp for the job, inspect it before use, and ensure proper installation. Certified products from Powerful Machinery help you maintain high safety standards and reduce risk during lifting operations.

Key Takeaways

Beam clamps provide a secure anchor point for lifting heavy loads when used correctly.

Always check the load capacity and ensure the clamp is compatible with the beam before lifting.

Regularly inspect beam clamps for wear and functionality to maintain safety during operations.

Use certified beam clamps from trusted manufacturers to ensure compliance with safety standards.

Follow best practices for installation and operation to prevent accidents and ensure effective lifting.

What Are Beam Clamps?

Definition and Function

A beam clamp is a mechanical fastener that grips the flange of an I-beam or H-beam. You use it to create a secure anchor point for lifting operations. The clamp attaches to the beam using a threaded bolt or lever mechanism. This setup allows you to suspend heavy loads safely and efficiently.

Beam clamps serve as non-permanent and reusable solutions for load attachment. You can rely on them for rigging, hoisting, or even fall protection systems. Powerful Machinery manufactures certified beam clamps that meet strict industry standards, giving you confidence in every lifting task.

Tip: Always check the clamp’s rating before starting any lifting operation. Using the right beam clamp helps prevent accidents and ensures a stable connection.

Key Features

Beam clamps offer several features that make them essential in lifting and rigging operations:

You can use beam clamps for lifting heavy loads.

They suspend equipment and secure temporary structures.

You facilitate movement along a beam with the right clamp.

The clamping mechanism provides a secure connection, reducing the risk of accidental detachment.

Beam clamps connect beams and structural components to supports such as walls and columns.

You find them in various designs to suit different load capacities and mounting needs.

They work well as semi-permanent lifting points in rigging.

You can use them as hoisting anchors or for positioning beams during welding.

High-quality beam clamps use materials like alloy steel, carbon steel, or stainless steel. Manufacturers use precision welding, forging, and machining to ensure durability and reliability.

Powerful Machinery’s beam clamps feature welded alloy steel bodies, proof-tested safety, and RFID tracking for easy maintenance. You get a product that stands up to demanding environments and meets international safety standards.

Types of Beam Clamps

When you select beam clamps for lifting, you need to understand the main types available and how each design fits your application. Manufacturers like Powerful Machinery offer a wide range of options, including custom features to meet specific project requirements.

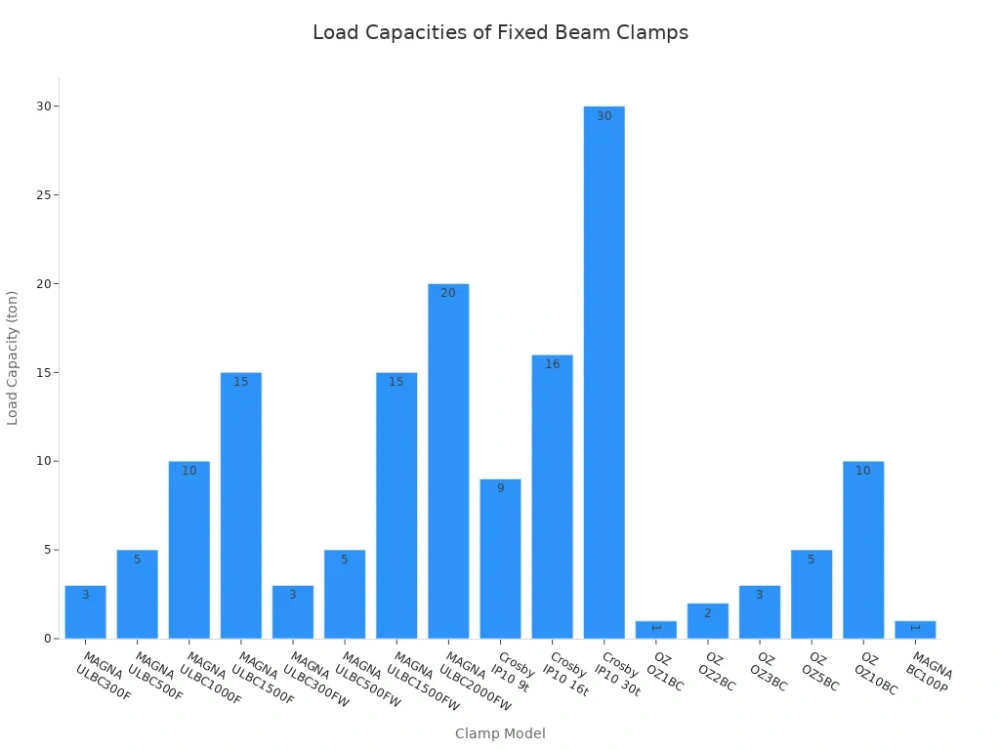

Fixed Beam Clamp

A fixed beam clamp provides a secure, stationary anchor point on an I-beam or girder. You use this type of beam clamp for overhead lifting solutions, pipe support systems, and temporary lifting points in mobile work areas.

Fixed beam clamps work well for attaching equipment to overhead beams, supporting electrical conduit, and installing HVAC ductwork. You benefit from their robust construction and reliable grip, which makes them ideal for rigging and lifting operations.

Clamp Type | Load Capacity |

|---|---|

Powerful Machinery Beam Clamp (TBC/TBE) | 1T – 10T |

MAGNA Universal Lifting Beam Clamp | 3T – 15T |

OZ Lifting Beam Clamp | 1T – 10T |

Note: Powerful Machinery’s fixed beam clamps are proof-tested to twice their Working Load Limit and come with RFID tracking for easy maintenance.

Adjustable Beam Clamp

An adjustable beam clamp gives you flexibility on the job site. You can fit it securely on a wide range of flange widths and beam sizes. The adjustable threaded mechanism allows you to use the clamp as a semi-permanent lifting point, hoisting anchor, or positioning tool for welding.

You can use adjustable beam clamps for vertical or horizontal rigging operations, and they work with both manual and powered hoists.

Feature | Description |

|---|---|

Adjustable jaw opening | Fits tapered or flat flanged beams |

Multidirectional screw spindle | Ensures a secure grip |

Versatile application | Suitable for lifting, pulling, or anchoring |

Powerful Machinery offers adjustable beam clamps with reinforced jaw designs and customization options, so you can match the clamp to your specific lifting needs.

Push Beam Trolley

A push beam trolley lets you move heavy loads smoothly along a fixed track. You attach the trolley to a beam clamp, then use its rolling wheels to transport equipment across the workspace. Push beam trolleys increase productivity and safety by reducing manual handling and streamlining operations.

You find features like adjustable height, anti-drop mechanisms, and ergonomic handles that help prevent injuries and ensure precise movement.

Advantage | Description |

|---|---|

Efficiency | Easy movement along the track boosts productivity |

Safety | Smooth rolling wheels, adjustable height, and anti-drop features |

Durability | Built for heavy loads and constant use |

Customization | Available in various sizes and configurations |

Tip: Powerful Machinery’s push beam trolleys integrate seamlessly with their beam clamps, providing a complete solution for overhead lifting and material handling.

You can choose from a variety of beam clamps and trolleys from Powerful Machinery, including custom-engineered options for unique lifting scenarios.

Whether you need a fixed anchor point, adjustable flexibility, or mobile lifting capability, you will find a solution that meets international safety standards and delivers reliable performance.

Beam Clamp Safety

Load Capacity and Compatibility

You must always respect the load capacity of beam clamps when performing any lifting operation. Manufacturers mark each beam clamp with a Safe Working Load (SWL) that you should never exceed.

The supporting structure, such as the beam flange, must also have enough yield strength and thickness to handle the intended load. For example, a flange with a yield strength of 40ksi and a thickness of 1/4 inch can support specific loads, but you should consult relevant codes like EN 1993-6 to confirm safety factors.

Tip: Align the suspension point of the beam clamp with the center line of the beam to ensure stability during lifting.

You need to use beam clamps only for vertical lifts and make sure they are securely attached. If you plan to replace any hardware, consult the supplier first. Only certified lifting equipment should be used, and a competent person must operate the beam clamps.

These steps help prevent accidents and ensure compatibility between the clamp and the supporting structure.

Never exceed the Work Load Limit marked on the product.

Use beam clamps as temporary anchorage points for lifting, not for direct load transfer.

Beam clamps work best in workshops and maintenance tasks.

Inspection and Maintenance

Regular inspection and maintenance keep your lifting operations safe and reliable. Before each use, inspect the mechanisms of beam clamps for proper function. Look for signs of structural cracking, deformation, grip surface wear, locking mechanism failure, pivot pin wear, and corrosion.

These issues can lead to sudden failure or loss of grip, putting your team and equipment at risk.

Inspection Type | Normal Service | Heavy Service | Severe Service | Special Service |

|---|---|---|---|---|

Every Lift Inspection | Before each use | Before each use | Before each use | Before each use |

Frequent Inspection | Monthly | Weekly to Monthly | Daily to Weekly | As recommended |

Periodic Inspection | Yearly | Semiannually | Quarterly | As recommended |

You should schedule frequent inspections monthly for normal service, weekly to monthly for heavy service, and daily to weekly for severe service. Plan periodic inspections yearly for normal use and quarterly for heavy-duty applications.

If you repair a beam clamp, test it according to applicable laws before returning it to service.

Before using beam clamps for lifting, proof testing must be performed under qualified supervision. The test load should reach up to 125% of the rated load unless the manufacturer specifies otherwise. After testing, a written inspection report should be generated.

Powerful Machinery beam clamps are proof-tested to twice their Working Load Limit and come with a unique serial number and test certificate for traceability.

RFID technology in Powerful Machinery beam clamps enables you to track inspection dates, maintenance records, and working load limit history. This system ensures each clamp meets safety standards and is managed effectively throughout its lifecycle.

Using Proper Lifting Equipment

You need to use certified lifting equipment for every lifting operation. Only products that meet international safety standards should be trusted for critical tasks. Powerful Machinery provides beam clamps and lifting equipment that are fully certified and proof-tested, giving you confidence in demanding environments.

Use only certified equipment for lifting.

Ensure all operators are trained in lifting operations and equipment use.

Never use beam clamps for loads beyond their rated capacity.

Note: Each Powerful Machinery beam clamp features RFID tracking and a test certificate, making it easy for you to maintain compliance and safety.

You protect your team and assets by following these safety protocols. Proper selection, inspection, and use of beam clamps and lifting equipment help you achieve safe and efficient lifting operations every time.

Applications of Beam Clamps

Construction and Industrial Use

You rely on beam clamps for a wide range of construction and industrial applications. These tools help you secure piping, HVAC systems, and cable trays to structural beams. You can mount heavy machinery, support ceiling grids, and install lighting fixtures with confidence.

Beam clamps also play a key role in bridge and tunnel construction, where you need to secure structural components during assembly. In safety-critical environments, you use them to attach fall protection equipment and safety rails.

Marine and offshore projects benefit from beam clamps when mounting equipment on ships and rigs. You can even use them for sound and vibration dampening by attaching specialized equipment.

Powerful Machinery’s beam clamps deliver the strength and reliability you need, with proof-tested designs and RFID tracking for efficient maintenance.

Structural support for piping, HVAC, and cable trays

Heavy equipment mounting and suspension

Bridge and tunnel assembly

Ceiling and lighting system support

Safety and fall protection attachment

Marine and offshore equipment mounting

Sound and vibration dampening

In shipyards, power plants, and refineries, you use beam clamps to hoist and position structural beams. They serve as anchor points for hoists, making maintenance tasks safer and more efficient. This adaptability ensures you maintain high safety standards in demanding industrial settings.

Manufacturing and Warehousing

In manufacturing and warehousing, you depend on beam clamps to create secure attachment points on overhead beams. These clamps enhance safety and efficiency in your daily operations. You can install them temporarily or semi-permanently without drilling or welding, which saves time and reduces disruption.

Beam clamps support HVAC components, electrical wiring, and water pipes, making them essential for facility upgrades and routine maintenance. Powerful Machinery offers a range of beam clamps with various load capacity options, ensuring you always have the right tool for your lifting needs.

Entertainment and Maintenance

You find beam clamps in the entertainment industry, where they provide safe rigging points for lighting and sound equipment. Adjustable models mount flush under I-beams, allowing you to set up overhead rigging quickly with simple tools.

This makes them ideal for direct loads, bridles, and hitches during concerts or theater productions. In maintenance operations, you use beam clamps to secure steelwork without creating dust or debris, which is vital in sensitive environments like food processing plants.

The cam system in some designs ensures stability under vibration and allows for easy realignment during equipment servicing. When you choose Powerful Machinery’s lifting equipment, you gain the versatility and safety required for both routine and specialized lifting tasks.

Tip: Always select beam clamps that match your application’s load capacity and safety requirements. Powerful Machinery’s certified products help you meet industry standards across all sectors.

Conclusion

You can achieve safe and effective lifting when you use beam clamps correctly and within their rated capacity. Always follow these best practices:

Inspect clamps for wear, clear markings, and secure hardware before each use.

Never exceed the Safe Working Load and maintain proper installation.

Choose certified products and document regular inspections.

Professional Tip | Recommendation |

|---|---|

Consult lifting specialists | Seek expert advice for complex lifts and equipment selection. |

Use reliable equipment | Select certified beam clamps from trusted brands for every project. |

For complex lifting operations, consult professionals and invest in reliable, certified equipment to ensure safety and compliance.

FAQ

What is the maximum weight you can lift with a beam clamp?

You must check the Working Load Limit (WLL) marked on your beam clamp. Powerful Machinery beam clamps support loads from 1 to 10 metric tons. Always verify the rating before lifting and never exceed the specified capacity.

How do you install a beam clamp safely?

Position the clamp on the beam flange. Tighten the adjustment screw or locking mechanism. Attach your lifting sling or hoist. Inspect the clamp for secure attachment before starting any lift. Always follow the manufacturer’s instructions for installation.

How often should you inspect beam clamps?

You should inspect beam clamps before each use. Schedule frequent inspections monthly for normal service and weekly for heavy use. Perform periodic inspections yearly or quarterly, depending on your application. Use RFID tracking to monitor inspection dates and maintenance records.

Can you use beam clamps outdoors?

You can use beam clamps outdoors if they feature corrosion-resistant coatings. Powerful Machinery beam clamps are designed for harsh environments. Always check for rust or damage before each use to maintain safety and reliability.

What certifications should you look for in beam clamps?

You should select beam clamps certified to international standards like ISO9001, TUV Rheinland, and OSHA. Powerful Machinery provides proof-tested clamps with unique serial numbers and test certificates. Certified products help you meet safety requirements and industry regulations.