You want to know how to cut heavy-duty chain with minimal effort and maximum safety. Selecting the right tool matters most. Powerful Machinery brings over 20 years of experience in lifting solutions, helping you make smart choices for industrial tasks.

For example, construction teams often use bolt cutters sized from 36″ to 42″ to shear grade-70 chains, while fire departments rely on titanium models for quick access. Always wear protective gear and inspect chains before cutting to ensure your safety.

Application | Bolt Cutter Size | Description |

|---|---|---|

Construction sites | 36″—42″ | Used for removing corroded rebar ties and shearing grade-70 transport chains |

Security teams | 18″ | Compact models with hardened jaws for bypassing tamper-proof padlocks |

Fire departments | Lightweight | Titanium bolt cutters for rapid entry through hurricane clips and security grilles |

Key Takeaways

Choose the right tool for cutting heavy-duty chains. Options include angle grinders, hydraulic cutters, and bolt cutters based on chain type and size.

Always wear protective gear, including goggles and gloves, to ensure safety while cutting chains. Inspect tools and chains before starting.

Prepare your workspace by securing the chain and clearing unnecessary items. Proper preparation leads to safer and more efficient cutting.

Inspect the chain after cutting for sharp edges or damage. Clean and lubricate the chain before returning it to service.

Consult professionals for cutting certified lifting chains. Expert advice ensures safety and compliance with industry standards.

How to Cut Heavy Duty Chain: Top Methods

When you need to know how to cut heavy-duty chain, choosing the right method makes all the difference. Powerful Machinery’s Lifting Chains, made from high-tensile alloy steel, set a high standard for strength and durability. You must select robust tools to handle these chains safely and efficiently.

Below, you’ll find a comparison of the top methods used in the field.

Angle Grinder Method

Angle grinders remain a popular choice for cutting heavy-duty chain. You should use an abrasive or cut-off wheel, especially for chain sizes like 3/8″ and 5/16″. Avoid carbide blades to prevent tool damage. This method works for most chain diameters, but it requires steady hands and full protective gear.

“I’ve chopped our 13mm chain a few times as it gets worn, twisty and rusty. 240v 4 inch grinder with cutoff wheel over the front, slow and steady, takes a few minutes.”

Pros:

Handles a wide range of chain sizes

Readily available in most workshops

Cons:

Generates sparks and debris

Requires two hands and careful control

Cutting wheels can disintegrate, posing injury risks

Hydraulic and Electric Cutters

Hydraulic and electric cutters offer a safer and more efficient solution for how to cut heavy duty chain. A portable powered chain cutter can sever a 5/8” link in just 6 seconds, while larger links take about 35 seconds.

Some models, like the Yale YCC-201, deliver up to 23 tons of cutting force, making them ideal for high-strength chains.

Pros:

Fast and precise cutting

Reduced physical effort

Lower risk of flying debris

Cons:

Higher upfront cost

Some models are limited to smaller chain sizes

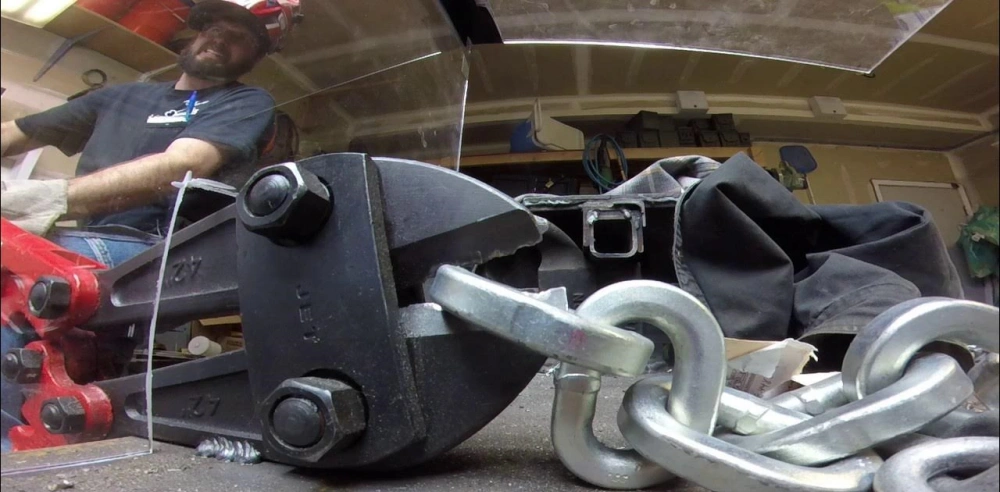

Bolt Cutters and Manual Tools

Bolt cutters provide a manual option for cutting heavy-duty chain, especially for smaller diameters and lower hardness levels. For example, a 24″ bolt cutter can handle up to 11mm diameter at 24 HRC or 8mm at 48 HRC.

Bolt Cutter Length | Maximum Diameter Cut | Material Hardness |

|---|---|---|

24″ | 11mm | 24 HRC |

24″ | 8mm | 48 HRC |

Pros:

No power source needed

Simple to use for lighter chains

Cons:

Limited effectiveness on high-grade or thick chains

Requires significant physical force

Tip: Always wear safety goggles and gloves, regardless of the method you choose. Inspect the chain and your tools before starting.

Cutting Heavy Duty Chain with Powerful Machinery

Tools and Safety Gear Needed

You need the right tools and safety gear before you start. Powerful Machinery Lifting Chains use high-tensile alloy steel, so you must select equipment designed for industrial-grade cutting.

Choose from angle grinders with cut-off wheels, hydraulic cutters, or heavy-duty bolt cutters rated for alloy steel. Always inspect your tools for damage or wear.

Recommended Safety Gear:

Safety goggles

Heavy-duty gloves

Protective clothing

Hearing protection

Steel-toe boots

Tip: Never skip safety gear. Flying debris and sparks can cause serious injuries.

Certifications for Powerful Machinery Lifting Chains:

Certification | Description |

|---|---|

ISO 9001 | International standard for quality management |

CE | Compliance with EU safety standards |

EN 818-7 | European standard for lifting chains |

ASME B30.9 | American standard for slings and lifting devices |

NACM 96/84 | National Association of Chain Manufacturers standards |

These certifications guarantee that Powerful Machinery chains meet strict safety and quality standards.

Preparation Steps

Proper preparation ensures a safe and efficient cutting process. You must inspect the chain and work area before you begin. Remove any dirt, grease, or rust from the chain. Confirm the chain is not under tension or load.

Preparation Checklist:

Select the correct cutting tool for the chain grade and diameter.

Clear the workspace of unnecessary items.

Secure the chain on a stable surface using a vise or clamps.

Measure and mark the exact link you need to cut.

Check chain tension. A chain that is too tight can overheat your tool, while a loose chain may slip and cause injury.

Confirm that all safety gear is in place.

Step | Description |

|---|---|

1 | Select high-strength steel bars |

2 | Hot roll or forge bars to the required dimensions |

3 | Cut bars to precise lengths |

4 | Punch and bend steel to form chain links |

5 | Inspect each link for accuracy |

Note: Proper chain tension ensures efficient power transfer. A loose chain can slip and cause instability. A tight chain increases friction and may damage your cutting tool.

Cutting Process Step-by-Step

Follow these steps to learn how to cut heavy duty chain with minimal effort and maximum safety. Powerful Machinery Lifting Chains require robust tools and careful technique.

Position the Chain: Place the chain securely in a vise or clamp. Make sure the link you want to cut is accessible.

Mark the Cut Point: Use chalk or a marker to identify the exact spot for cutting.

Check Chain Tension: Adjust the chain so it is stable but not overly tight.

Select the Tool: Choose an angle grinder, hydraulic cutter, or bolt cutter based on the chain’s grade and diameter.

Wear Safety Gear: Put on goggles, gloves, and other protective equipment.

Cut the Chain: Apply steady pressure with your chosen tool. For angle grinders, move slowly to avoid overheating. For hydraulic cutters, activate the device and let it do the work. For bolt cutters, use both hands and apply firm force.

Inspect the Cut: After cutting, check both ends of the chain for sharp edges or deformation.

Post-Cutting Inspection:

Inspect all repaired or replaced parts for proper installation and condition.

Clean and lubricate the chain and moving parts.

Test the brake system and adjust as needed.

Reassemble any equipment, ensuring all bolts and screws are secure.

Conduct a controlled load test to confirm smooth operation.

Have a qualified professional review and approve the chain for use.

⚠️ Always inspect the chain after cutting. Certified chains from Powerful Machinery offer durability, but you must confirm integrity before returning them to service.

You now know how to cut heavy-duty chain using certified lifting chains from Powerful Machinery. By following these steps, you ensure safety, efficiency, and compliance with industry standards.

Alternatives and Quick Reference

Manual vs. Powered Tools

You have several options when cutting heavy-duty chain. Manual tools, such as bolt cutters, work well for smaller or softer chains. Powered tools, like angle grinders and hydraulic cutters, handle thicker or hardened chains with less effort. Each method has unique advantages.

Manual tools require more physical strength but offer portability. Powered tools deliver speed and precision, especially for industrial-grade chains.

Alternative cutting methods include:

Torching

Angle grinders

Cut-off tools

Mechanical bolt cutters

Hydraulic chain cutter machines

Electric chain cutters

When selecting a tool, consider these factors:

Chain type

Pitch

Gauge

Cutter design

Application requirements

Suitability Table for Different Chains

Use the table below to match your chain type with the most suitable cutting tool. This quick reference helps you choose the right equipment for the job.

Chain Type | Recommended Tool | Suitability Level |

|---|---|---|

Standard steel chain | Bolt cutters | Good |

Hardened alloy chain | Angle grinder, hydraulic cutter | Excellent |

High-tensile lifting chain | Hydraulic or electric cutter | Best |

Rusted or corroded chain | Angle grinder, torch | Good |

Certified lifting chain | Hydraulic cutter | Best |

Tip: Always match the tool to the chain’s grade and diameter for safe, efficient results.

When to Seek Professional Help?

Some situations require expert intervention. If you work with certified lifting chains, such as those from Powerful Machinery, you should consult a professional for cutting or modification. Certified chains demand strict adherence to safety standards. Improper cutting can compromise load integrity and safety.

⚠️ If you feel unsure about the chain’s grade, certification, or the right cutting method, contact a qualified technician or reach out to Powerful Machinery for guidance. Your safety and equipment reliability depend on expert advice.

Conclusion

You now understand the most efficient and safest ways to cut heavy-duty chain. Always select the right tool for your chain type and wear proper safety gear. Choose certified, high-quality chains and cutting tools to ensure reliable results.

Use angle grinders or hydraulic cutters for tough jobs

Inspect your chain and tools before every cut

Follow each safety step closely

💡 For expert advice or custom lifting solutions, contact Powerful Machinery. You get trusted support from industry leaders.

FAQ

What is the safest way to cut a certified lifting chain?

You should use a hydraulic cutter and wear full safety gear. Secure the chain in a vise. Mark the link before cutting. Inspect the chain after the cut to confirm integrity.

Can you cut Grade 100 or Grade 120 chains with bolt cutters?

Bolt cutters cannot handle Grade 100 or Grade 120 chains. You need hydraulic or electric cutters for these high-tensile chains. Always check the chain’s grade before selecting your tool.

How do you know which tool to use for your chain?

Check the chain’s grade and diameter. Use bolt cutters for standard chains. Choose angle grinders or hydraulic cutters for hardened or certified lifting chains. Refer to the suitability table for guidance.

Do you need to inspect the chain after cutting?

Yes. You must inspect both ends for sharp edges, deformation, or cracks. Clean and lubricate the chain. Test the chain under load before returning it to service.

Where can you get expert advice for cutting heavy-duty chains?

Contact Powerful Machinery for expert guidance. You receive support from industry professionals who understand certified lifting chains and safe cutting practices.