You want to trust every anchor point when lifting or securing loads in concrete. Choosing the right equipment makes all the difference in safety. Powerful Machinery provides certified solutions that help you avoid costly failures.

Eye bolts and concrete hook anchors installation demands precision and the right materials. You protect people and property when you use products that meet strict standards. Rely on proven methods and quality hardware for lasting results.

Key Takeaways

Choose the right eye bolt material. Use stainless steel for outdoor or harsh environments to ensure durability and corrosion resistance.

Select the correct size and load rating for eye bolts. Match the diameter and anchor type to the expected load for safety.

Prepare the installation area thoroughly. Clean the surface and mark precise locations to ensure accurate anchor placement.

Maintain vertical alignment during installation. Proper verticality prevents bending forces that can compromise load capacity.

Conduct regular inspections and maintenance. Check for wear and ensure all anchors remain secure to uphold safety standards.

Select Eye Bolt and Concrete Hook Anchors

Types and Materials

Choosing the right eye bolt for concrete applications starts with understanding the materials and types available. You will find two main materials: carbon steel and stainless steel. Carbon steel offers strength and cost-effectiveness for mild environments.

Stainless steel provides superior corrosion resistance, especially in harsh or outdoor concrete applications. For marine or chemical settings, stainless steel eye bolts, such as those from Powerful Machinery, deliver long-term durability.

Material | Properties |

|---|---|

Carbon Steel | Cost-effective, strong, often coated for mild environments |

Stainless Steel | Superior corrosion resistance, especially Type 316, for harsh environments |

You should always use rated concrete anchors when installing eye bolts in concrete. Expansion anchors or wedge anchors work well for heavy-duty concrete applications where vibration or dynamic loads are present.

Tip: Stainless steel bolts outperform galvanized bolts in concrete environments. The zinc coating on galvanized bolts can wear off, but stainless steel resists corrosion even in extreme conditions.

Load Ratings and Sizing

Selecting the correct size and load rating ensures safety in all concrete applications. You must match the eye bolt diameter and anchor type to the expected load. The table below shows industry-recommended load ratings for common eye bolt sizes:

Diameter | Straight Pull (lbs) | 45° Pull (Shoulder Only) (lbs) |

|---|---|---|

1/4″ | 500 | 125 |

5/16″ | 900 | 225 |

3/8″ | 1,300 | 325 |

7/16″ | 1,800 | 450 |

Proper installation is critical. For concrete applications, ensure the anchor provides enough thread engagement. Use at least 1.5 times the bolt diameter for steel, and always follow safety standards like ASME B30.26 and OSHA 1910.184.

Powerful Machinery Product Options

Powerful Machinery offers a full range of certified eye bolts and anchors for concrete applications. You can choose from stainless steel eye bolts, ring eye bolts, and lifting eye nuts. Each product meets international standards, including DIN 580 and JIS 1168.

These eye bolts provide reliable performance in construction, marine, and industrial concrete applications. You can trust Powerful Machinery for products that deliver strength, safety, and compliance with global regulations.

Standard | Description |

|---|---|

OSHA 1926.74c | Compliance for lifting applications |

ASME B30.26 | Rigging hardware for below-the-hook lifting devices |

DIN 580 / JIS 1168 | International eye bolt standards |

Note: For critical or overhead lifting in concrete, always select eye bolts and anchors that display clear load ratings and certifications.

Prepare for Installing Eye Bolts in Concrete

Tools and Safety Gear

You must gather the correct tools before you begin installing eye bolts in concrete. The right equipment ensures accuracy and protects you from injury. For this task, you need a hammer drill and masonry bit, a wrench set, a vacuum or brush, and a measuring tape.

Handling power tools with care is essential for your safety and for achieving a secure installation.

Personal protective equipment is non-negotiable. Always wear:

Safety glasses to shield your eyes from flying debris

Gloves to protect your hands from sharp edges and rough surfaces

A dust mask to avoid inhaling concrete dust

Marking and Cleaning

Pre-installation preparation starts with marking the exact spot for each eye bolt. Use a pencil or chalk to make clear, visible marks on the concrete. Accurate marking prevents misalignment and ensures the anchor points line up with your load requirements.

Cleaning the surface is just as important as marking. Remove all objects from the area and sweep away loose dirt. For large surfaces, pressure washing works best. For smaller spots, scrub with detergent or use natural cleaners like vinegar. Always follow the manufacturer’s instructions for any cleaning products.

Clean surfaces help the anchor grip the concrete, which increases holding strength. If you see cracks or damage, fill them before proceeding.

Test Condition | Load-Bearing Capacity | Failure Type |

|---|---|---|

Reinforced | Enhanced | Cone Failure |

Unreinforced | Reduced | Splitting Cracks |

Thorough cleaning and preparation improve the performance of every eye bolt you install.

Drilling Pilot Holes

Drilling accurate pilot holes is the next step. Use the correct tools for this process. Select a masonry bit that matches the diameter of your anchor. Drill to the recommended depth for your anchor type. Deeper embedment increases the load-bearing capacity of the anchor.

Embedment Depth (inches) | Load Increase (%) |

|---|---|

2″ | Base Load |

3″ | +25% |

4″ | +50% |

5″ | +75% |

Vacuum or brush out all dust from the hole before inserting the anchor. Clean holes ensure maximum grip and prevent slippage. Careful pre-installation preparation sets the foundation for a safe and reliable installation.

Install Eye Bolts and Concrete Hook Anchors

Anchor Selection and Placement

You must approach eye bolts and concrete hook anchors installation with careful planning. Start by selecting the right anchor for your application. Powerful Machinery’s stainless steel eye bolts offer unmatched durability and corrosion resistance, making them ideal for both indoor and outdoor concrete environments.

When you choose anchor placement, consider several factors to ensure a safe and effective installation. Use the table below to guide your decisions:

Factor | Description |

|---|---|

Load Requirements | Determine the safe working load (SWL) and ultimate breaking load (UBL) for your application. |

Environmental Considerations | Assess exposure to moisture, chemicals, or temperature extremes that may affect anchor longevity. |

Concrete Condition | Inspect the concrete for cracks, voids, or weak aggregate before proceeding with installation. |

Proper anchor spacing is essential for distributing forces evenly. If you place anchors too close together, stress cones can overlap and weaken the concrete. Adequate spacing allows each anchor to perform at its best and prevents cracking or progressive failures.

Tip: Always position anchors away from edges and corners. This practice reduces the risk of splitting and ensures the full strength of your installation.

Ensuring Verticality

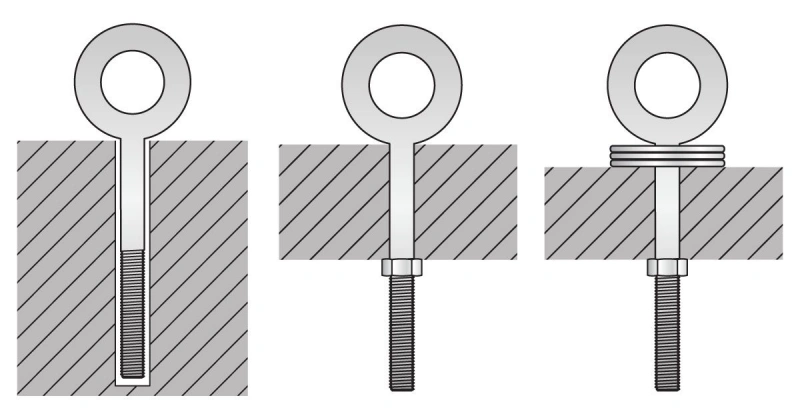

Maintaining vertical alignment during eye bolts and concrete hook anchors installation is critical for safety and performance. If you tilt an eye bolt, you introduce bending forces that can reduce its load-bearing capacity and increase the risk of failure.

You must keep each eye bolt perfectly vertical to avoid deformation and damage to both the bolt and the surrounding concrete.

Use these methods to achieve proper verticality:

Method Description | Details |

|---|---|

Orientation | Align the eye bolt with the direction of the load to prevent side loading. |

Washer Packing | Insert washers between the shoulder and the concrete surface for a snug fit and correct torque. |

Shoulder Installation | Seat the shoulder at a right angle to the hole axis for full contact. |

Use of Spreader Bar | Employ a spreader bar to maintain a 90° lift angle when needed. |

Washer or Spacer Use | If alignment is difficult, use a steel washer or spacer, but keep it within one thread pitch in thickness. |

Always check that the eye and shank are free from bends or distortions.

Apply the load in line with the plane of the eye.

Confirm that the shoulder sits flush against the concrete surface.

Alert: Improper verticality can compromise the entire installation. A tilted eye bolt may fail under load, causing accidents or equipment damage.

Gradual Tightening

You must secure each anchor with the correct tightening technique. For eye bolts and concrete hook anchors installation, gradual tightening helps distribute the load evenly and prevents overstressing the anchor or the concrete.

Use a wrench to bring the eye bolt to a snug, tight condition unless your project engineer specifies a torque value.

Gradual tightening offers several benefits:

It reduces the risk of anchorage creep, which can weaken the installation over time.

It allows the anchor to settle into the concrete, improving long-term performance.

It ensures that the eye bolt remains secure, even under dynamic or fluctuating loads.

When securing eye bolts with anchors, avoid sudden or excessive force. Tighten the bolt incrementally, checking alignment and seating after each adjustment. This method helps you achieve a reliable and durable installation.

Note: After tightening, inspect each anchor for full engagement and proper seating. Recheck verticality and make final adjustments as needed.

By following these steps, you ensure that eye bolts and concrete hook anchors installation meets the highest standards for safety and reliability. Powerful Machinery’s certified products provide the foundation for secure and long-lasting anchor points in any concrete application.

Safety Measures for Eye Bolt Installation

Personal Protection

You must prioritize your well-being before starting any installation. Wearing appropriate safety gear protects you from flying debris, sharp edges, and dust. Always use safety glasses, gloves, and a dust mask. Steel-toed boots and a hard hat add another layer of protection, especially on construction sites.

These safety measures during installation help prevent injuries and keep you focused on the task.

Tool Handling

You should handle all tools with care and attention. Inspect your hammer drill, wrenches, and other equipment before use. Check for cracks, deformation, or visible damage. Make sure each tool operates smoothly and fits the job requirements.

When you drill or tighten, keep a firm grip and maintain control at all times. Never force a tool beyond its intended use. Proper tool handling reduces the risk of accidents and ensures a secure anchor for every load.

Workspace Safety

A clean and organized workspace supports safe and efficient installation. Remove unnecessary items from your area to prevent tripping hazards. Sweep away dust and debris before you begin. Good lighting helps you see clearly and avoid mistakes.

Always keep emergency exits clear and know the location of first aid supplies. You should also verify that the shoulder of each eye bolt is fully seated, the threads are engaged, and the load direction aligns with the anchor.

Tip: Follow all manufacturer instructions and industry standards for every installation. Look for markings such as the manufacturer’s logo, working load limit, and material grade on your eye bolts. These details confirm product quality and traceability.

Standard | Description |

|---|---|

ASME B30.26 | Rigging hardware for below-the-hook lifting devices |

OSHA 1910.184 | Slings and rigging hardware regulations |

ASME B18.15 | Forged eyebolts dimensional and strength standards |

Federal Spec FF-B-575E | Bolt, hook, and forged eyebolt specifications |

You build a safer environment when you follow these guidelines and use certified products from Powerful Machinery.

Post-Installation Safety and Inspection

Anti-Loosening Methods

After installing eye bolts in concrete, you must reinforce each anchor to prevent loosening over time. Vibrations, temperature changes, and repeated loading can cause movement. You can use several anti-loosening measures to maintain security:

Use two nuts to create a locking effect. This method prevents rotation and loosening, even under vibration.

Apply specialized locking adhesives for exceptional locking performance. These adhesives work well in severe vibration environments and suit various materials and sizes.

Consider jammed thread techniques. This approach eliminates relative motion between nuts and ensures consistent preload, making it one of the most reliable options.

You should always select the method that matches your application and environment. Proper application of these techniques ensures a stable and reliable joint in concrete.

Final Inspection

You must perform a thorough inspection after installation. This step confirms the safety and reliability of your anchor points. Follow these steps for a complete final inspection:

Reconfirm the verticality of each eye bolt. Misalignment can reduce load capacity and increase risk.

Apply a test load using a lightweight. Observe the eye bolt and the surrounding concrete for any movement or abnormalities.

Check the concrete surface for cracks or damage. If you find a tilted eye bolt that cannot be adjusted, remove it immediately.

Inspect the threaded hole in the base material. Repair or relocate the eye bolt if necessary.

You should conduct periodic inspections for signs of wear or damage. Prolonged use of tilted or damaged eye bolts poses a serious safety hazard.

Load Testing

You must verify the safety of your installation through load testing. International standards such as EN795 and BS 7883:2019 provide guidelines for anchor devices. For lifting and rigging, follow ASME B30.26, OSHA 1910.184, and ASME B18.15. These standards ensure your anchors meet industry requirements.

Risk Level | Inspection Frequency |

|---|---|

High-risk structures | every 6 months |

Medium-risk structures | at least once a year |

Low-risk structures | every 2 years |

Regular monitoring and inspection keep your anchors safe. Clean and tighten each eye bolt at least once a year. Check alignment during every inspection, especially after environmental changes. If you notice any issues, consult a professional or contact Powerful Machinery for expert support.

Tip: Ongoing monitoring and maintenance protect your investment and ensure long-term safety in all concrete applications.

Professional Advice and Compliance

Consulting Experts

You should always seek professional guidance when planning to install eye bolts in concrete, especially for load-bearing or safety-critical applications. Consulting a structural engineer helps you assess the load requirements and environmental conditions unique to your project.

Structural engineers also ensure your installation meets local building codes and industry standards. Their expertise becomes essential for complex or high-risk projects.

A structural engineer evaluates load requirements and environmental factors.

They confirm compliance with local building codes.

You receive tailored advice for your specific application.

The correct anchor bolt selection impacts foundation stability and structural integrity.

Experts consider both load requirements and installation environment.

If you feel uncertain, consulting an expert prevents costly mistakes.

Tip: When in doubt, always consult a qualified professional. Their input can save you time, money, and help you avoid safety hazards.

Building Codes

You must follow all relevant building codes when installing eye bolts and concrete anchors. These codes protect both people and property by setting clear requirements for installation, inspection, and documentation. The following table summarizes key code references and their requirements:

Code Reference | Requirement |

|---|---|

2024 IBC | Contract documents must specify installation and inspection parameters for concrete anchorage. |

ACI 318-19 | Compliance is required for anchor installation; adhesive anchors must be installed by certified personnel. |

Chapter 19A Concrete | Specifies testing requirements for post-installed anchors, including proof testing percentages. |

ACI 318-19 Chapter 26 | Details compliance for anchor installation, including proper positioning and qualified installers. |

You should review these codes before starting your project. Proper documentation and certified installation help you pass inspections and maintain long-term safety. Always use certified products, such as those from Powerful Machinery, to ensure compliance with these standards.

Conclusion

You ensure safe and reliable results when you follow each step for installing eye bolts in concrete. Select certified hardware from Powerful Machinery to maximize load-bearing performance. Always review every safety warning before starting your project.

Consult a professional for complex installations. Proper installation protects people and property. Your attention to detail keeps every anchor point secure for years to come.

FAQ

What type of eye bolt should you use for outdoor concrete installations?

You should use stainless steel eye bolts. These resist corrosion and provide long-term durability in outdoor or marine environments. Powerful Machinery’s stainless steel options meet international standards for safety and performance.

How do you determine the correct load rating for your application?

Check the expected load weight and match it to the eye bolt’s rated capacity. Always select an eye bolt with a higher load rating than your maximum expected load. Refer to manufacturer charts for guidance.

Can you reuse eye bolts after removal from concrete?

You should not reuse eye bolts removed from concrete. Removal can damage threads or reduce holding strength. Always install a new, certified eye bolt for each application to ensure safety.

How often should you inspect installed eye bolts?

Inspect eye bolts at least once a year. For high-risk or critical applications, increase inspection frequency to every six months. Look for signs of wear, corrosion, or loosening.

Where can you find certified eye bolts for concrete applications?

You can find certified eye bolts at Powerful Machinery’s official website. The company offers a full range of products that meet international safety standards.