You know how critical manual pallet jack repair becomes when your warehouse depends on reliable equipment. A small issue with a pallet jack can slow down an entire operation. You need to identify problems quickly and use a targeted manual pallet jack repair approach.

Regular manual pallet jack repair keeps every pallet jack functioning at peak performance. You reduce downtime and improve workflow each time you complete a manual pallet jack repair.

Powerful Machinery supports your efforts with trusted pallet jack solutions. With a focus on safety, you protect your team and your investment through consistent manual pallet jack repair.

Key Takeaways

Regular inspections of your pallet jack can prevent major issues and extend its lifespan. Check for wear and tear weekly.

Proper lubrication of moving parts reduces friction and prevents breakdowns. Make lubrication a part of your maintenance routine.

Always use manufacturer-recommended parts for repairs. This ensures safety and reliability in your pallet jack’s operation.

Train all operators on basic inspection and maintenance. This practice helps catch problems early and keeps everyone safe.

Schedule professional inspections at least once a year. This step helps identify hidden issues and ensures compliance with safety standards.

Common Pallet Jack Issues

Manual pallet jacks play a vital role in your warehouse, but even the best equipment faces problems over time. Understanding common pallet jack issues helps you spot trouble early and keep your operation running smoothly.

Hydraulic Problems

Hydraulic problems often top the list of common pallet jack issues. You may notice a drop in lifting capacity or a stiff, unresponsive hydraulic system. These symptoms usually point to worn seals, low hydraulic fluid, or trapped air in the system.

If your pallet jack struggles to lift loads or lowers too quickly, check the hydraulic fluid level and inspect for leaks. Regular maintenance prevents most hydraulic failures.

Mechanical Failures

Mechanical failures can disrupt your workflow and pose safety risks. The most common pallet jack issues in this category include squeaky wheels, stiff steering, and difficulty lifting loads.

Fork misalignment and fork rollover also occur, making it hard to insert the forks into pallets. Wheel lockup and uneven lifting are other common causes of downtime. You should inspect moving parts and tighten loose bolts to avoid these problems.

Wheel and Seal Issues

Wheels and seals take a beating in busy warehouses. Uneven or flat tires lead to vibrations and reduced traction. Jammed or stuck forks often result from debris or pallet damage.

Damaged seals allow hydraulic fluid to leak, which affects performance. You should check the wheels for wear and replace damaged seals to keep your pallet jack in top shape.

Tip: Inspect wheels and seals weekly to catch small issues before they become big problems.

Lubrication and Wear

Lack of lubrication causes excessive wear on moving parts. Dry or dirty components increase friction and shorten the life of your pallet jack. You should apply lubricant to pivot points, axles, and the hydraulic pump as part of your regular maintenance routine.

Clean and lubricate your pallet jack to prevent breakdowns and extend its service life.

Manual Pallet Jack Repair Inspection

Weekly Checklist

You keep your operation running smoothly when you follow a consistent pallet jack inspection routine. A weekly checklist helps you catch small issues before they become major problems. Use this step-by-step process for effective pallet truck inspection:

Remove all foreign material from the pallet jack with a stiff brush.

Wipe the equipment with a damp cloth and let it dry completely.

If the pallet jack is very dirty, use a pressure washer carefully, especially around wheels and moving parts, then allow it to air dry.

Always follow the manufacturer’s recommendations for repairs and service.

Replace any worn parts using only manufacturer-recommended components.

Grease bushings and bearings as needed, following the manufacturer’s guidelines.

Fill hydraulic oil as necessary, using the correct procedures.

Repaint areas to prevent rust, but avoid painting wheels or moving parts.

Test the pallet jack to ensure all parts function correctly, it holds weight, and it rolls freely.

Tip: A thorough pallet truck inspection each week reduces downtime and extends the life of your equipment.

Annual Specialist Check

You should schedule a professional pallet truck inspection at least once every twelve months. Industry standards, including OSHA and ASME, require periodic inspections to ensure safety and compliance. In harsher work environments, you may need to increase the frequency to quarterly or even monthly.

Factors such as how often you use the pallet jack, the type of loads you handle, and the conditions in your facility all influence the ideal inspection schedule.

Annual inspections by a qualified specialist help you identify hidden issues.

More frequent inspections may be necessary for heavy use or tough environments.

Regular professional checks support your overall maintenance plan.

Operator Training

Proper operator training plays a key role in maintaining and repairing your pallet jack. You should train every team member to perform a basic pallet truck inspection before each shift. This habit helps you spot problems early and keeps your equipment safe to use.

Training also ensures that everyone understands the correct procedures for maintenance and repair, which reduces the risk of accidents and equipment failure.

Troubleshooting Guide for Pallet Jacks

Manual pallet jacks are reliable, but even the best equipment can develop issues. This troubleshooting guide gives you a step-by-step guide for diagnosing and repairing the most common problems. Always follow safety precautions and use Powerful Machinery’s recommended tools and parts for every repair.

Not Lifting

When you face a pallet jack not lifting, you need to act quickly. This problem can stop your workflow and create safety risks. Use this step-by-step guide to identify and fix the issue:

Check Hydraulic Fluid Level

Inspect the hydraulic fluid. Low fluid often causes a pallet jack not to lift. Top up with the manufacturer’s recommended fluid if needed.Inspect for Leaks

Examine hydraulic hoses and connections. Look for visible leaks. Replace or repair damaged parts.Test the Control Handle

Move the handle through all positions. Make sure it engages and releases properly. If the handle feels loose or unresponsive, you may need to adjust or replace it.Look for Air in the System

Air trapped in the hydraulic system can cause a pallet jack not lifting. Bleed the system according to the manual.Check for Fault Lights or Error Codes

Some advanced models display error codes. Refer to the manual for guidance.

Tip: Always keep your feet away from under the machine during troubleshooting. Wear gloves and safety shoes for protection.

Not Lowering

If your pallet jack does not lower, you need to follow a step-by-step guide to restore normal operation:

Inspect the Release Lever

Check if the release lever moves freely. Dirt or debris can block movement. Clean and lubricate the lever.Check Hydraulic Fluid

Low or contaminated fluid can prevent lowering. Top up or replace the fluid as needed.Examine the Control Linkage

Inspect the linkage between the handle and the hydraulic valve. Bent or broken parts can stop the pallet jack from lowering. Replace damaged components.Test Without Load

Remove any load and try lowering again. Sometimes, an overloaded jack will not lower for safety reasons.

Note: Never exceed the weight-bearing capacity of your pallet jack. Always inspect the equipment before use.

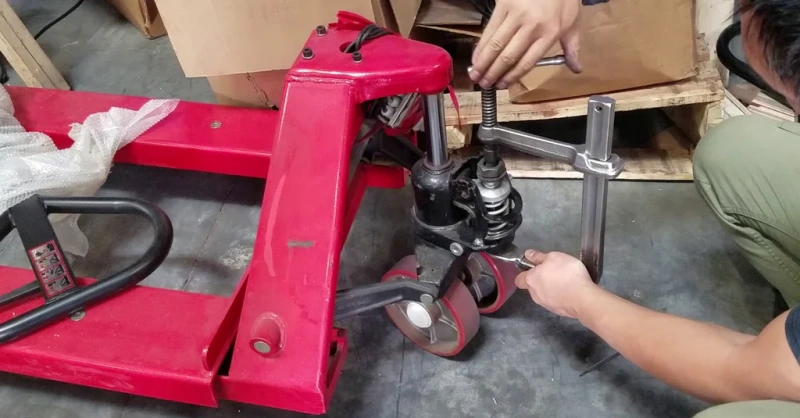

Pallet Jack Wheel Repair

Stuck or damaged wheels can make your pallet jack hard to move. Use this step-by-step guide for simple repairs:

Inspect Wheels for Debris

Remove any string, plastic, or debris wrapped around the wheels.Check for Flat Spots or Cracks

Examine the wheels for visible damage. Replace wheels that show signs of wear or cracks.Lubricate Axles and Bearings

Apply lubricant to the axles and bearings. This reduces friction and helps the wheels turn smoothly.Test Movement

Push and pull the pallet jack to ensure the wheels roll freely.

Alert: Always clear your path of obstacles before moving a loaded pallet jack. Inspect wheels regularly to prevent accidents.

Hydraulic Leaks

Hydraulic leaks can cause a pallet jack not to lift and reduce performance. Follow this step-by-step guide for repairing leaks:

Identify the Leak Source

Wipe down the hydraulic system and look for wet spots or drips.Tighten Connections

Use the correct tools to tighten any loose fittings or connections.Replace Damaged Seals or O-Rings

If you find worn or damaged seals, replace them with manufacturer-approved parts.Refill Hydraulic Fluid

After repairs, refill the hydraulic fluid to the recommended level.Test for Leaks

Pump the handle and check for further leaks.

Safety Reminder: Use personal protective equipment and keep hands clear of pinch points when repairing hydraulic systems.

By following these step-by-step instructions, you can resolve most pallet jack not lifting issues and other common problems. This troubleshooting guide helps you perform simple repairs and maintain safe, efficient operations.

Hydraulic Repair and Maintenance

Proper hydraulic repair and maintenance keep your pallet jack running smoothly and safely. You need to address issues quickly to avoid costly downtime and ensure reliable pallet truck service. This section covers the most important steps for keeping your hydraulic system in top condition.

Bleeding Air

Air trapped in the hydraulic system can cause poor lifting performance and inconsistent operation. You may notice the pallet jack struggles to lift loads or feels spongy when pumping.

To bleed air, lower the forks completely, then pump the handle several times. This process forces air out of the system and restores normal function. Always check for air pockets if you experience low lift pressure.

Tip: Bleed the system after any hydraulic system repair or fluid replacement to prevent future problems.

O-Ring and Seal Replacement

Worn or damaged seals and O-rings often lead to leaks and reduced hydraulic performance. You should inspect these components during every service interval. If you see fluid around the pump or cylinder, replace the seals immediately. Use only manufacturer-approved parts for every repair to maintain safety and reliability.

Regular seal replacement prevents hydraulic fluid leaks and supports smooth operation.

Hydraulic Fluid Service

Hydraulic fluid plays a critical role in your pallet jack’s performance. Dirty or low fluid can cause internal valve failure, difficulty lifting, and even damage to the pump. Most manufacturers recommend changing the hydraulic fluid after every 1,000 hours of operation.

During each service, check the fluid level and quality. Top up or replace the fluid as needed to keep your equipment in peak condition.

Common causes of hydraulic failure include:

Insufficient hydraulic fluid

Air trapped in the system

Worn or damaged seals

Dirty or contaminated fluid

Clogged release valve

Pallet Jack Pump Repair

If your pallet jack still struggles after basic service, you may need pump repair. Signs include difficulty lifting loads, leaking fluid, or a pump that feels weak. Disassemble the pump carefully and inspect for worn-out parts or bent components.

Replace damaged parts with genuine replacements to restore full function. Always test the pallet jack after any hydraulic system repair to confirm safe operation.

Note: Schedule regular maintenance and professional pallet truck service to catch pump issues early and extend equipment life.

Pallet Truck Repair with Powerful Machinery

Product Features and Advantages

You want your pallet truck repair process to be efficient and reliable. Powerful Machinery designs pallet trucks with heavy-duty steel frames and ergonomic handles. These features help you move heavy loads with less effort. The hydraulic system lifts smoothly and lowers with precision.

Polyurethane wheels protect your floors and roll quietly in busy warehouses. You can trust these trucks to last through daily use. Each model meets strict international safety standards, so you know your equipment is safe.

Tip: Choose a manual pallet truck from Powerful Machinery for simple operation and low maintenance.

Model-Specific Tips

You need to match your pallet truck repair approach to the model you use. Standard models work well for most warehouse tasks. If you handle oversized pallets, select a wide-fork version. For narrow aisles, use a compact model. Some trucks have built-in scales for weighing loads.

Always check your user manual before you start any repair. This step helps you avoid mistakes and keeps your equipment in top condition.

Model Type | Best Use Case | Special Feature |

|---|---|---|

Standard | General warehouse | High load capacity |

Wide-Fork | Large pallets | Extra fork width |

Compact | Tight spaces | Easy maneuverability |

Scale-Equipped | Shipping/receiving | Built-in scale |

Sourcing Genuine Parts

You protect your investment when you use genuine parts for pallet truck repair. Powerful Machinery offers certified replacement parts for every model. You can order seals, wheels, handles, and hydraulic components directly from the official website.

Genuine parts fit perfectly and meet all safety standards. This choice reduces downtime and extends the life of your equipment. If you need help, contact Powerful Machinery’s support team for expert advice.

Alert: Never use unapproved parts for repair. Only genuine components guarantee safe and reliable operation.

Safety in Manual Pallet Jack Repair

Required Tools and Gear

You need the right tools and gear to ensure safety during every pallet jack repair. Always wear protective gloves and safety shoes to protect your hands and feet from injury. Safety glasses shield your eyes from debris or hydraulic fluid.

Use a sturdy wrench set, a hydraulic fluid pump, and a grease gun for most maintenance tasks. Keep a clean rag and a flashlight nearby for inspections. When you use the correct tools, you reduce the risk of accidents and improve safety in the workplace.

Safe Handling Practices

You protect yourself and your team by following safe handling practices. Start each day by inspecting your pallet jack for cracks, loose bolts, and damaged wheels. Distribute weight evenly on the forks to keep the load stable. Plan your route before moving a load, and keep aisles clear to avoid obstacles.

Use mirrors or signals in blind spots and move at a controlled speed. The table below outlines essential maintenance tasks and their recommended frequency:

Maintenance Task | Frequency | Description |

|---|---|---|

Inspect the hydraulic fluid | Daily | Check levels to ensure proper operation. |

Check wheels | Daily | Ensure wheels are in good condition to prevent accidents. |

Clean pallet jack | Daily | Remove dirt and debris to maintain equipment performance. |

Lubricate moving parts | Weekly | Apply lubricant to pivot points and wheel bearings to ensure smooth operation. |

Check the hydraulic fluid | Monthly | Verify levels and replace if necessary to maintain functionality. |

Basic repairs | As needed | Replace worn wheels or fix minor hydraulic leaks; seek professional help for complex issues. |

Tip: Regular inspections and cleaning help you spot problems early and maintain a high level of safety.

When to Call a Professional?

You should call a professional when you notice issues beyond basic repair. If the braking system feels tight or responds slowly, seek expert help. Low hydraulic fluid or difficulty lowering the handle may signal a deeper problem.

Complex repairs, such as adjusting release valves or fixing major leaks, require specialized knowledge. Timely professional service prevents sudden breakdowns and supports ongoing safety. Regular maintenance and inspections by qualified technicians keep your pallet jack reliable and safe for daily use.

Preventive Maintenance for Pallet Jacks

Cleaning and Lubrication

You keep your pallet jack running smoothly when you focus on cleaning and lubrication. Dirt and debris can build up on moving parts, causing friction and wear. Regular cleaning removes these hazards and helps you spot early signs of damage.

Lubricate all pivot points, axles, and the hydraulic pump to reduce friction and extend the life of your equipment. Effective cleaning and lubrication routines prevent larger issues, saving you time and money. These simple steps also create a safer workspace and help you avoid unexpected repair needs.

Tip: Stick to a cleaning and lubrication schedule to catch minor problems before they become major repair jobs.

Routine Inspections

Routine inspections form the backbone of pallet truck maintenance. You should check your equipment at least once a month. In busy warehouses or tough environments, inspect more often. Tailor your inspection schedule to your operation’s needs.

During each inspection, look for visible damage, check wheels and rollers, and make sure safety labels are intact. Test the hydraulic system for leaks and verify fluid levels. Operate the lifting mechanism and steering to ensure everything works smoothly. Finish by cleaning the pallet jack and documenting any issues.

Pre-operational inspection: Look for damage and check wheels.

Hydraulic system inspection: Test the pump and check for leaks.

Operational checks: Test lifting, movement, and brakes.

Post-operational inspection: Clean and report any defects.

Professional Servicing

Professional servicing adds another layer of protection to your pallet truck maintenance plan. Schedule a qualified technician to inspect your pallet jack at least once a year. A professional can spot hidden issues and perform advanced repairs that go beyond basic maintenance.

Timely professional service ensures your equipment meets safety standards and operates at peak efficiency. You reduce downtime and extend the lifespan of your pallet jack with proper maintenance and expert care.

Note: Preventive maintenance, including regular inspections and professional servicing, keeps your pallet jack reliable and safe for daily use.

Cost and Replacement Considerations

Repair vs Replacement

You face a key decision when your pallet jack breaks down: should you repair it or replace it? The answer depends on cost and long-term value. On average, you spend about 15-30% of the original purchase price each year on repair and maintenance.

If the cost of repair climbs above 50-65% of the price of a new pallet jack, replacement becomes the smarter choice. Timely repairs help you avoid expensive breakdowns and keep your equipment running longer. Always weigh the cost of ongoing maintenance against the benefits of investing in a new unit.

Annual repair costs: 15-30% of purchase price

Replace if repair costs exceed 50-65% of the new unit price

Tip: Track your repair expenses over time. This helps you decide when replacement is more cost-effective.

Finding the Right Parts

You need high-quality parts to keep your pallet jack safe and reliable. Sourcing the right components ensures smooth operation and reduces downtime. Several trusted suppliers offer a wide range of replacement parts for manual pallet jacks. The table below highlights two reputable sources:

Source Name | Description | Link |

|---|---|---|

Helmar Parts | Offers a wide range of replacement parts for manual pallet jacks, including wheels, hydraulic pumps, and more. | Visit Helmar Parts |

Fast Lift Parts | Provides a variety of manual pallet jack parts, including diagrams and kits, suitable for various brands. | Visit Fast Lift Parts |

You can also order genuine parts directly from Powerful Machinery for guaranteed compatibility and performance.

Pallet Jacks Repair and Sales

You want reliable channels for both repair and purchasing new pallet jacks. Look for providers that offer efficient maintenance solutions, fast parts delivery, and flexible service options.

Dedicated customer support helps you resolve issues quickly. Many companies provide tailored service plans, preventative maintenance programs, and OEM parts installation. The table below outlines common service types:

Service Type | Description |

|---|---|

Preventative Maintenance | Scheduled programs, fluid checks, tire inspections, and more |

Hydraulic & Lift System Repairs | Cylinder rebuilds, hose replacements, diagnostics |

Battery & Electrical Diagnostics | Battery testing, charger troubleshooting, wiring repairs |

CSA/MOL Safety Inspections | Annual inspections, compliance documentation, and onsite reporting |

OEM Parts Installation | Installation of genuine parts for safety and performance |

Note: Choose a provider with quick response times and comprehensive service solutions. This ensures your pallet jack stays in top condition and supports your daily operations.

Conclusion

You protect your team and equipment when you prioritize regular inspection, safe operation, and systematic troubleshooting. Annual inspections, as recommended by European FEM guidelines, help you catch leaks and damaged parts early:

Benefit | Description |

|---|---|

Enhanced Safety | Identify issues before accidents or failures occur. |

Reduced Downtime | Prevent unexpected breakdowns and keep operations efficient. |

Compliance with Regulations | Maintain a safer work environment and meet safety standards. |

Rely on Powerful Machinery for certified pallet jacks, genuine parts, and expert support. Follow your repair checklist, stay proactive, and reach out to professionals for complex repairs.

FAQ

How often should you inspect your manual pallet jack?

You should inspect your manual pallet jack before each shift. Weekly and monthly checks help you catch wear and tear early. Schedule a professional inspection at least once a year for the best results.

What hydraulic fluid should you use for pallet jacks?

Always use the hydraulic fluid recommended by your pallet jack’s manufacturer. Using the wrong type can damage seals and reduce performance. Check your user manual or contact Powerful Machinery for guidance.

Can you repair a leaking hydraulic system yourself?

You can fix minor leaks by replacing seals or tightening connections. For major leaks or if you feel unsure, contact a professional technician. Safety always comes first.

How do you know when to replace your pallet jack?

Replace your pallet jack if repair costs exceed half the price of a new unit. Frequent breakdowns, major frame damage, or persistent hydraulic issues also signal it is time for a replacement.

Where can you find genuine replacement parts?

You can order genuine parts directly from Powerful Machinery’s official website. Genuine parts ensure safety, compatibility, and long-term performance.