Wire Rope Hoists

Powerful Machinery builds wire rope hoists for real lifting jobs. You get compact design, stable control, and long service life straight from the manufacturer. Ask Powerful Machinery for a wire rope hoists quote and move your loads with confidence.

You get wire rope hoists built for heavy duty cycles, smooth lifting control, and stable operation in demanding industrial environments.

You rely on wire rope hoists tested to international standards, with proven braking systems and safety features that protect loads and operators.

You work with a true manufacturer that controls materials, machining, and assembly to ensure consistent quality and on-time delivery.

You receive tailored wire rope hoists, technical guidance, and long-term spare support to match your crane systems and applications.

Powerful Machinery - Your Reliable Wire Rope Hoist Manufacturer

We supply work provide dependable wire rope hoists for industry leaders.

WIRE ROPE HOIST

Our wire rope hoists support lifting and rigging operations across diverse applications. Our selection includes:

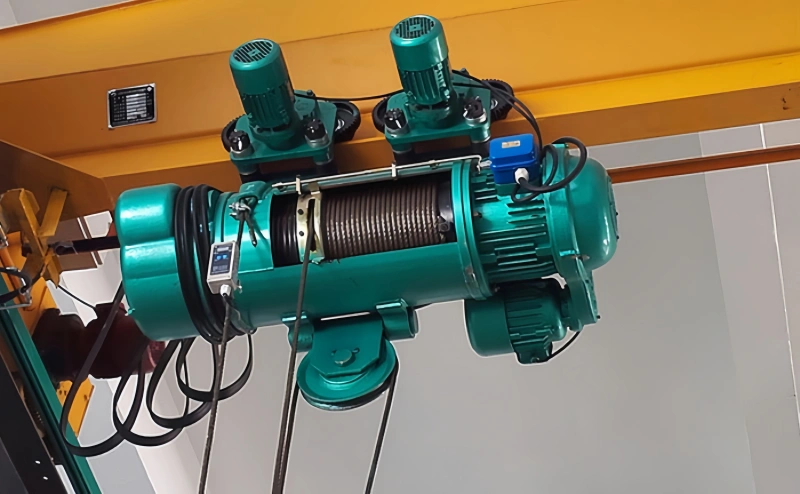

Electric Wire Rope Hoist

An electric wire rope hoist uses a motor-driven system for fast, stable lifting. It supports heavy loads, high duty cycles, and precise control for demanding industrial operations.

A manual wire rope hoist operates by hand or lever to deliver stable lifting without electricity. It fits maintenance work, light-duty lifting, and sites with limited or no power access.

Monorail Wire Rope Hoist

A monorail wire rope hoist moves along straight or curved tracks to deliver smooth lifting and travel. The compact design handles 1t to 16t loads for efficient material handling lines.

Double Girder Overhead Wire Rope Hoists

Double girder overhead wire rope hoists lift heavy loads with strong stability on two-rail crane systems. The crab unit design delivers precise, reliable performance in demanding operations.

Low Headroom Wire Rope Hoist

Low headroom wire rope hoist increases lifting height in spaces with limited ceiling clearance. The compact structure minimizes hook-to-beam distance for efficient crane use.

Pneumatic Wire Rope Hoist

Pneumatic wire rope hoists lift loads using compressed air, providing safe, reliable operation in hazardous or specialized industrial environments without electrical power.

NEED HELP WITH YOUR WIRE ROPE HOIST ORDER?

Let us help! Reach out today and get recommendations on materials and sizing from our experts.

Guide to Wire Rope Hoist

Our guide to wire rope hoists helps you understand shackle types, applications, and selection tips so you can choose safe, reliable lifting equipments.

Wire Rope Hoist vs Chain Hoist: What's the Difference?

Wire rope hoists handle heavier loads, longer lift heights, and frequent operation better than chain hoists. You get:

Smooth lifting for long distances

Reduced wear and extended rope life

Higher stability for overhead crane systems

Compatibility with industrial plants, ports, and energy sectors

Chain hoists remain cost-effective for light-duty applications, but wire rope hoists give consistent, long-term performance in demanding industrial operations. Contact us for guidance on the right choice.

Advantages of Wire Rope Hoists

Wire rope hoists provide unmatched lifting speed, precision, and reliability. You benefit from:

Robust steel ropes and drums for high durability

Advanced braking systems for safe operation

Long lift heights for overhead cranes, jib cranes, and monorails

Adaptability in harsh or continuous-duty environments

Selecting wire rope hoists ensures operational efficiency, fewer maintenance intervals, and compliance with industrial safety standards. Reach out to discuss custom options for your facility.

Wire Rope Hoist Maintenance

Proper maintenance maximizes hoist life and performance. You should:

Inspect ropes, hooks, drums, and gears for wear

Check brake efficiency and electrical/pneumatic connections

Lubricate ropes and gear systems regularly with manufacturer-approved oils

Track operating hours and service intervals

Following these steps prevents downtime, ensures consistent lifting performance, and keeps your hoist compliant with safety standards. Request a maintenance schedule from our team.

How to Choose the Right Wire Rope Hoist?

Selecting a wire rope hoist requires careful assessment. You should:

Define load capacity, lift height, and duty cycle

Evaluate headroom, workspace, and power supply

Match hoist speed, rope grade, and safety features to your operations

Consider integration with cranes, monorails, or jib systems

Correct selection ensures precise lifting, operational efficiency, and long-term reliability. Contact us for personalized recommendations.

Common Wire Rope Hoist Applications

Wire rope hoists serve critical industrial tasks. You can use them for:

Lifting machinery in steel, metal, and fabrication plants

Handling cargo in ports, shipyards, and logistics facilities

Moving components in energy, power generation, and mining operations

Continuous-duty tasks in production workshops

Choosing a manufacturer with flexible models ensures your hoist adapts to space, load, and safety requirements. Request application-specific guidance today.

Wire Rope Hoist Installation Guide

Safe installation is essential for efficiency. You should:

Verify beam capacity and track alignment

Mount hoist securely on single or double girder cranes

Connect electrical or pneumatic controls per manufacturer diagrams

Test limit switches, brakes, and no-load operation before use

Proper installation prevents structural stress, enhances lift accuracy, and ensures compliance. Ask us for installation support and load charts for your project.

Wire Rope Hoist Safety Tips

Safety reduces risks and maintains uptime. You should:

Confirm load limits, brake function, and rope condition before each lift

Ensure hooks are properly latched and travel paths are clear

Train operators and enforce proper handling procedures

Conduct regular inspections and follow manufacturer guidelines

Implementing these practices protects personnel, maintains regulatory compliance, and extends hoist life. Contact us for safety audit checklists.

Wire Rope Hoist Troubleshooting

Quick troubleshooting minimizes downtime. You should:

Check power supply, control wiring, and emergency stops

Inspect drum rotation, hook condition, and rope alignment

Verify brakes, limit switches, and overload protection

Replace worn components with manufacturer-approved parts

Systematic checks restore lifting performance, prevent damage, and keep your operations running smoothly. Reach out for technical support from our engineers.

Upgrading or Customizing Wire Rope Hoists

Customization maximizes performance for specific applications. You can:

Add VFDs for precise speed control and micro-lifts

Choose low headroom or extended lift designs

Select galvanized ropes, heat-resistant finishes, or modular components

Integrate with overhead, jib, or monorail cranes

Manufacturer-backed customization ensures compliance, efficiency, and reliability. Contact us to design a hoist tailored to your operations.

Have More Questions of Wire Rope Hoists?

Have more questions about wire rope hoists? Access our guides or contact Powerful Machinery for expert advice, technical support, and custom industrial lifting solutions.