When you compare carabiner hooks vs snap hooks, you notice clear differences in design, locking mechanisms, and load capacity. Carabiner hooks often feature a secure gate, while snap hooks use a simple spring closure. Quick links provide a threaded option for semi-permanent connections.

Knowing these distinctions helps you choose the safest and most effective connector for your task. Powerful Machinery stands as a trusted partner, delivering certified lifting and rigging hardware built for demanding environments.

Key Takeaways

Carabiner hooks are designed for heavy loads and safety-critical tasks. They feature locking mechanisms for added security, making them ideal for climbing and industrial applications.

Snap hooks provide quick attachment and release, making them suitable for lighter loads and everyday use. They lack the locking features of carabiners, so they should not be used for climbing or rescue work.

Quick links offer a semi-permanent connection, ideal for rigging and joining chains or ropes. Their threaded design ensures a secure fit, making them reliable for heavy-duty tasks.

Always check the load ratings and certifications of connectors before use. This ensures safety and reliability in demanding environments.

Regularly inspect your connectors for wear and damage. Proper maintenance extends the life of your equipment and ensures safety during use.

Overview of Carabiner Hooks vs Snap Hooks

What Are Carabiner Hooks?

You often see carabiner hooks in climbing, construction, and safety systems. These connectors feature an elongated shape with a spring-loaded gate that closes automatically. Carabiners play a vital role in fall protection, connecting you to safety lines and reducing the risk of injury.

You also use them to organize gear during camping or hiking. Many carabiners include locking mechanisms and corrosion-resistant finishes to meet strict safety standards like EN 12275 and UIAA. Their design supports high loads, making them essential for both recreational and professional use.

Tip: Always check for certification markings on carabiners before using them in safety-critical applications.

Key Features of Carabiner Hooks:

Elongated shape with a spring-loaded gate

Engineered for significant loads

Locking options for added security

Used in climbing, construction, and safety harnesses

What Are Snap Hooks?

Snap hooks provide a quick and reliable way to secure loads or gear. You find them in many settings, from industrial rigging to outdoor recreation. Their wider, rounded shape and spring-loaded or hinged gate allow for fast attachment and release.

Snap hooks excel when you need strength and ease of use, such as in military gear, pet leashes, or marine equipment. In industrial environments, you rely on snap hooks to secure tools and manage rigging systems efficiently.

Feature/Application | Description |

|---|---|

Design | Spring-loaded or hinged gate for secure closure and easy access |

Outdoor and Recreational Activities | Secures gear like backpacks and harnesses |

Pet Enclosures | Keeps pets safely attached to leashes |

Marine Uses | Secures sails and equipment, often corrosion-resistant |

Industrial Applications | Critical for safety harnesses and equipment |

What Are Quick Links?

Quick links serve as versatile connectors in rigging, climbing, and safety systems. You recognize them by their looped metal body and threaded nut, which you screw closed for a secure connection. Made from steel or other durable metals, quick links come in various sizes and strengths.

You use them to connect ropes, chains, or cables, and to attach equipment to fixed anchors. Quick links offer a semi-permanent solution, making them ideal for situations where you need a strong, reliable link that you can still remove when necessary.

Feature/Use | Description/Details |

|---|---|

Design | Metal connector with looped end and threaded nut |

Materials | Steel or other metals, available in multiple sizes |

Typical Applications | Rock climbing, caving, industrial rigging, connecting ropes and chains |

Ease of Use | Quick to attach or detach from equipment |

Safety Considerations | Choose correct size and inspect regularly for wear |

Powerful Machinery stands out as a trusted provider of certified rigging hardware. You can rely on their expertise and product range for industrial and heavy-duty applications, ensuring safety and performance in every connection.

Design and Gate Mechanisms

Carabiner Hook Design

You notice that carabiner hooks come in a variety of shapes and materials, each affecting performance and safety. Most carabiners use aluminum, steel, or plastic. Aluminum carabiners feel light and work best for climbing and outdoor activities.

Steel carabiners weigh more but deliver unmatched strength and durability, making them ideal for rescue work and commercial settings. Plastic carabiners suit light-duty, non-climbing uses.

Material | Characteristics | Applications |

|---|---|---|

Aluminum | Lightweight, corrosion-resistant | Climbing, outdoor activities |

Steel | Heavy, extremely strong and durable | Industrial, rescue, heavy-duty |

Plastic | Light, not for load-bearing | Keychains, gear organization |

Shapes also matter. Oval carabiners share the load equally, while D-shaped and Offset-D carabiners transfer force to the spine, the strongest part. Pear or HMS shapes offer a wide gate opening, perfect for belaying and rappelling.

Powerful Machinery engineers carabiners with precision, using only certified materials and advanced designs to ensure you get maximum safety and reliability in every application.

Snap Hook Mechanism

Snap hooks feature a simple, spring-loaded gate. You can attach or detach them quickly, which makes them popular for tasks that require speed and convenience. Unlike carabiners, snap hooks do not usually have complex locking systems. This design gives you fast access but less security for critical loads.

You often use snap hooks for pet leashes, marine gear, or light industrial work where ease of use matters most.

Snap hooks allow for quick attachment and detachment.

Carabiners use locking gates for higher security, but snap hooks focus on convenience.

Quick Link Construction

Quick links use a threaded nut to open and close the connector. You twist the nut to secure the link, creating a semi-permanent connection. Most quick links use steel for strength and durability.

You rely on quick links when you need a strong, removable connector for chains, ropes, or cables. The simple construction makes them easy to inspect and maintain.

When you choose connectors from Powerful Machinery, you benefit from a commitment to quality, safety, and certified engineering. Every product meets strict international standards, giving you confidence in demanding environments.

Carabiners Strength and Load Ratings

Carabiner Load Capacity

When you select a carabiner, you need to understand its strength and load capacity. Carabiners used in climbing and industrial settings display their ratings in kilonewtons (kN).

These ratings show how much force the carabiner can handle before it fails. Most modern climbing carabiners are rated to at least 20 kN along the major axis with the gate closed. This means they can support heavy loads safely.

You will often see three sets of arrows on a carabiner. Each set shows the strength when the carabiner is pull tested in different ways: gate closed long axis, gate open long axis, and gate closed short axis. Here is a quick reference:

Condition | Strength Rating (kN) |

|---|---|

Closed, end-to-end | 23-24 |

Cross-loaded (minor axis) | 7-8 |

Gate open | 6-9 |

These numbers help you choose the right carabiner for your needs. Always check the markings before using a carabiner for critical applications.

Snap Hooks Strength

Snap hooks offer reliable strength for many tasks. You find heavy duty snap hooks made from stainless steel, aluminum, or strong plastic. These materials give you superior resistance to corrosion and wear. For example, an aluminum double locking snap hook has a working load limit of 600 lbs.

Its tensile strength reaches up to 6,000 lbs. (27 kN). This makes snap hooks suitable for both industrial and recreational uses where strength and load capacity matter.

Heavy duty snap hooks provide excellent strength for securing equipment.

You can trust them for tasks that require quick attachment and release.

Quick Links Durability

Quick links give you a strong and durable connection for lifting and rigging. Manufacturers rate a 3/8″ chain quick link with a working load limit of 3,500 lbs. This high load capacity makes it ideal for demanding environments.

Quick links also resist corrosion, so you can use them outdoors or in marine settings without worry. Here is a table showing typical load capacities for different sizes:

Size | WLL (lb) | Breaking Strength (lb) |

|---|---|---|

1/8″ | 200 | N/A |

5/16″ | 2,000 | 8,800 |

3/8″ | 3,500 | N/A |

You should always match the quick link size to your load requirements. Regular inspection ensures you maintain safety and reliability in every application.

Tip: Always choose connectors with certified strength and load capacity ratings for your specific task. This helps you avoid accidents and ensures long-term performance.

Carabiner Hooks vs Snap Hooks: Key Differences

Shape and Security

When you compare carabiner hooks vs snap hooks, you notice clear differences in both shape and security features. Carabiner hooks have an elongated, oval, or D-shaped body. This design directs force along the strongest axis, which increases safety during heavy-duty activities.

You open a carabiner hook by pushing the gate away from the loop, which helps prevent accidental opening. Many carabiner hooks include a threaded locking sleeve for extra security, especially in climbing or industrial settings.

Snap hooks, on the other hand, feature a rounded or slightly curved body. You open them by pushing the spring gate toward the loop, which allows for quick attachment but less resistance to accidental release.

Some snap hooks include a swivel, which helps prevent tangling but does not add significant security. You typically use snap hooks for lighter loads, such as attaching gear or securing items on boats.

Here is a quick comparison:

Feature | Carabiner Hooks | Snap Hooks |

|---|---|---|

Release Mechanism | Pressure inwards towards the spine | Downwards pressure on a knob |

Use | Professional climbing equipment | Household and boating uses |

Gate Mechanism | Spring-loaded, releases with inward pressure | Spring-loaded, releases with downward pressure |

Weight Bearing | Designed for heavier loads, tested with kN rating | Suitable for lighter items only |

Security Features | May have a threaded locking sleeve | Some have a swivel |

OSHA Standards | Must be tested in all directions to 16 kN | N/A |

Note: Carabiner hooks are more robust and suitable for climbing or securing heavier weights. Snap hooks are ideal for clipping lighter items only.

Ease of Use

You often choose between carabiner hooks vs snap hooks based on ease of use. Snap hooks excel when you need speed and convenience. You can attach or detach them with one hand, which makes them popular for pet leashes, keychains, or marine gear.

Their simple gate mechanism allows you to secure items quickly, saving time during repetitive tasks.

Carabiner hooks offer a balance between ease and security. While you can operate most carabiner hooks with one hand, the locking sleeve on some models adds a step. This extra action increases safety but may slow you down in situations where you need rapid access.

For heavy-duty activities, you benefit from the added protection, even if it takes a moment longer to secure the connection.

When you compare carabiner hooks vs snap hooks for ease of use, consider your environment and the importance of speed versus safety.

If you need to secure heavy loads or protect against accidental opening, a carabiner hook provides peace of mind. If you value quick attachment and release, a snap hook offers unmatched ease.

Reliability Over Time

Reliability over time is a critical factor when you evaluate carabiner hooks vs snap hooks. Carabiner hooks, especially those made from steel or high-grade aluminum, maintain their strength and function even after repeated use.

Their robust construction and locking mechanisms help prevent wear and accidental opening, which is essential for climbing, rescue, or industrial work.

Snap hooks, while convenient, may show signs of wear more quickly. The spring gate can weaken with frequent use, especially if exposed to harsh environments.

You should regularly inspect snap hooks for signs of corrosion or reduced tension in the gate. For applications where long-term reliability and safety are priorities, carabiner hooks remain the preferred choice.

Tip: Always inspect your connectors before each use. Replace any hook that shows signs of damage or wear to ensure ongoing safety and performance.

Advantages and Disadvantages

Carabiner Pros and Cons

Carabiner hooks give you flexibility and reliability in many situations. You can organize gear, secure equipment, or use them for light utility tasks. Many carabiners feature SlideLock options for extra security.

Stainless steel construction resists corrosion, so you can trust them outdoors or in harsh environments. You also find a wide range of sizes and colors to match your needs.

However, you should know that not all carabiners are rated for climbing or heavy loads. Some models have limited load capacity and work best for light-duty use. SlideLock sliders can detach if forced, and gates may snag compared to Keylock designs. Always check the rating before using a carabiner for safety-critical tasks.

Advantages | Disadvantages |

|---|---|

Versatile dual gates for easy organization | Not rated for climbing or load-bearing safety use |

SlideLock option adds security | SlideLock sliders may detach if forced |

Durable stainless steel resists corrosion | Gates may snag (not Keylock design) |

Multiple sizes and colors available | Limited load capacity for light utility |

Affordable and widely available | Occasional shipping or sizing issues |

Snap Hooks Pros and Cons

Snap hooks help you secure loads quickly and safely. You benefit from their self-closing gates, which reduce the risk of accidental drops. Many users appreciate the added safety, especially after experiencing equipment failures. Snap hooks also keep loads from slipping due to outside factors.

You may notice that snap hooks cost more than standard hooks and feel heavier. Some users find them cumbersome at first, but most adjust over time and value the safety features.

Advantages | Disadvantages |

|---|---|

Reduces risk of load falling out | More expensive than standard hooks |

Always closed when attached to a load | Heavier than standard hooks |

Less risk of load slipping | More cumbersome to open and close in some uses |

Many users find self-closing hooks awkward at first, but you will likely appreciate the safety benefits with experience.

Positive feedback often comes from those who have seen accidents prevented by these safety features.

Quick Links Pros and Cons

Quick links offer you a strong, semi-permanent connection. You can install them easily and rely on their durability for heavy-duty tasks. Over time, quick links prove cost-efficient, especially in industrial or outdoor settings.

You should consider that quick links have some pressure limitations and may wear with heavy use. Material constraints can affect performance in certain environments, so always choose the right type for your application.

Advantages | Disadvantages |

|---|---|

High durability and reliability | Limitations in pressure handling |

Easy and quick installation | Material constraints in some uses |

Cost efficiency over the long term | Potential for wear in heavy-duty use |

Tip: Always match your connector choice to your specific task and inspect regularly for signs of wear or damage.

Best Use Cases for Carabiners and Snap Hooks

Climbing and Safety Applications

You rely on carabiners and snap hooks for critical climbing and mountaineering applications. These connectors play a vital role in your climbing safety systems, where the gate mechanism and weight capacity must meet strict standards.

Carabiners with a spring-loaded gate and locking sleeve help prevent accidental opening during high-load applications. Snap hooks also feature a spring-loaded gate, but you should only use them in climbing if they meet the minimum tensile strength of 5,000 lbs and have a corrosion-resistant finish.

Type | Description | Standards and Ratings |

|---|---|---|

Snaphooks | Common connectors with a spring-loaded gate, typically 5-6 inches long. | Must have a minimum tensile strength of 5,000 lbs; should not connect directly to webbing or other snap hooks. |

Carabiners | Versatile connectors with a C-shape and spring-loaded gate. | Must maintain a minimum of 5,000 lbs (22.2kN) along the major axis; look for ANSI Z359.12 stamp. |

Note: In climbing and mountaineering, always check for ANSI or EN certification and avoid connecting snap hooks directly to webbing or other connectors.

Industrial and Rigging Uses with Powerful Machinery

In industrial settings, you depend on carabiners and snap hooks for lifting, securing, and rigging applications. These connectors must meet specific weight capacities and certifications to ensure safety.

Powerful Machinery provides certified hardware that exceeds international standards for high-load applications. Carabiners are essential for telecom rigging, utility work, and arborist applications. You can trust their gate mechanism and construction for reliable performance.

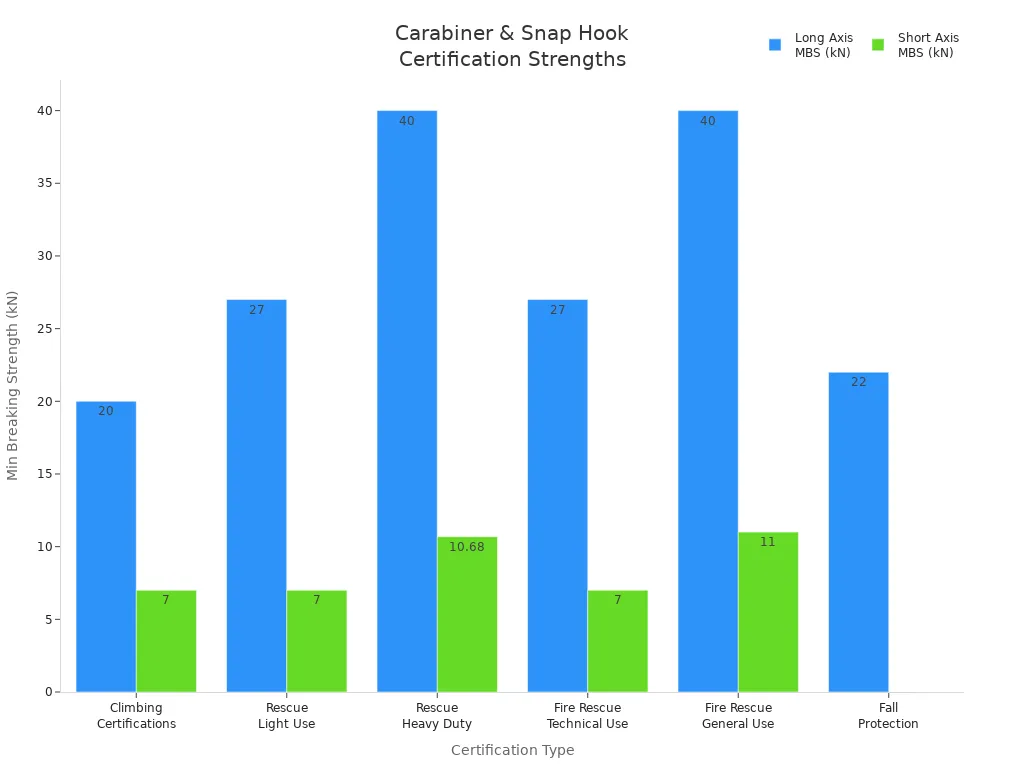

Certification Type | Minimum Breaking Strength (MBS) Long Axis | Minimum Breaking Strength (MBS) Short Axis |

|---|---|---|

Climbing Certifications | 20 kN | 7 kN |

Rescue Certifications (Light Use) | 27 kN | 7 kN |

Rescue Certifications (Heavy Duty) | 40 kN | 10.68 kN |

Fire Rescue (Technical Use) | 27 kN (gate closed) | 7 kN (gate open) |

Fire Rescue (General Use) | 40 kN (gate closed) | 11 kN (gate open) |

Fall Protection | 22 kN | N/A |

Powerful Machinery ensures every connector meets or exceeds these requirements, giving you confidence in demanding environments.

Recreational and Everyday Uses

You experience the versatility of carabiners and snap hooks in many recreational and daily applications. Outdoor activities like hiking, fishing, and travel benefit from these connectors. You use them to attach water bottles, organize gear, or secure fishing tackle.

In industrial use, they help secure tools and equipment on construction sites. The climbing community values carabiners for their reliability and ease of use in both sport and utility settings.

Outdoor activities: Connect gear or attach essentials to backpacks.

Fishing: Secure lures and rods.

Travel: Organize bags and accessories.

Industrial use: Attach tools for safety.

Semi-Permanent Connections

Quick links offer a solution for semi-permanent applications where you need a strong, removable connector. You use them to join chains, ropes, or cables in both climbing and industrial settings.

Their threaded gate mechanism provides extra security and supports specific weight capacities. Quick links excel in high-load applications where you require durability and easy inspection.

Tip: Always match the connector’s weight capacity to your application and inspect regularly for wear.

Choosing the Right Connector

Assessing Your Needs

You should start by identifying the demands of your application. Consider the environment, the weight you need to support, and how often you will use the connector. If you work in industrial or rescue settings, steel carabiners offer superior strength and durability.

Aluminum carabiners provide a lighter option, which is ideal for climbing or when you need to move quickly. The table below helps you compare key factors:

Factor | Steel Carabiners | Aluminum Carabiners |

|---|---|---|

Strength | Superior strength and durability | Good balance of strength and weight |

Weight | Heavier, best for stationary setups | Lighter, ideal for mobility |

Load Rating | Up to 70 kN | Typically 22-27 kN |

Locking Mechanism | Great for heavy-duty applications | Auto-locking for quick use |

Applications | Industrial, rescue scenarios | General use, climbing, rescue |

Tip: Always match the connector’s load rating and locking mechanism to your specific task.

Safety and Certification

You must prioritize safety when selecting connectors. Look for products that clearly state their working load limit (WLL) and minimum breaking strength (MBS). Pay attention to the size, gate type, material, and finish.

Reliable connectors meet international standards such as EN 362, EN 12275, ANSI/ASSE Z359.1, or DIN 5299C. Certifications from recognized bodies like CE or UIAA confirm that the connector has passed rigorous testing.

Choose connectors that meet or exceed industry and regional regulations.

Verify certifications from trusted organizations.

Select suppliers with strong quality management systems, such as ISO 9001.

Request material certifications for critical jobs.

Note: Powerful Machinery provides certified connectors that comply with global safety standards, giving you peace of mind in demanding environments.

Maintenance and Replacement

You should inspect your connectors before and after every use. Look for cracks, deformations, or any signs of wear. Clean the connectors regularly to keep the locking mechanism working smoothly. If you notice any resistance or damage, do not use the connector. Ignoring visible wear can put you at risk.

Visually inspect for cracks or deformation before each use.

Clean connectors to maintain durability and function.

Check the locking mechanism for smooth operation.

Replace any connector showing signs of damage or excessive wear.

Regular maintenance extends the life of your equipment and ensures your safety on every job.

Conclusion

You now understand the key differences between carabiner hooks, snap hooks, and quick links. The table below highlights their unique features and best uses:

Feature | Carabiner Hooks | Snap Hooks | Quick Links |

|---|---|---|---|

Design | Spring-loaded, robust | Lever, compact | Threaded, semi-permanent |

Load Ratings | High | Moderate | Versatile, high |

Applications | Climbing, heavy loads | Light gear, keychains | Swings, dog leashes |

For climbing or industrial work, choose carabiners with certified strength. Snap hooks suit light, everyday tasks. Quick links excel in semi-permanent setups. Always match your connector to your needs. Powerful Machinery delivers certified, high-performance solutions for every application.

FAQ

What is the main difference between a carabiner and a snap hook?

You use carabiners for heavy loads and safety-critical tasks. Carabiners feature locking gates for extra security. Snap hooks provide quick attachment and release. Snap hooks work best for light gear or everyday use.

Can you use snap hooks for climbing or rescue work?

No, you should never use snap hooks for climbing or rescue. Snap hooks lack the strength and locking features required for safety. Always choose certified carabiners for these applications.

How do you know if a connector is certified for industrial use?

Look for markings such as EN, ANSI, or CE on the connector. Certified products display load ratings and standards. Powerful Machinery provides connectors that meet or exceed international safety certifications.

When should you choose a quick link over a carabiner or snap hook?

You should select a quick link when you need a semi-permanent, strong connection. Quick links excel in rigging, chain joining, or situations where you do not need frequent attachment or removal.