You often face the decision between chain hoists and come-alongs when handling heavy materials. The main difference centers on their intended use. You use chain hoists for vertical lifting, while come-alongs focus on pulling or moving loads horizontally.

This distinction makes the choice clear in many work situations. Powerful Machinery stands as a trusted provider, offering the reliable Come Along Tool and Chain Hoist for your lifting and pulling needs. Understanding chain come-alongs vs chain hoists helps you make the right choice for every project.

Key Takeaways

Chain hoists are ideal for vertical lifting tasks, making them perfect for construction sites and warehouses.

Come-alongs excel at pulling and positioning loads, offering flexibility for various tasks in tight spaces.

Safety features like automatic brakes and overload protection are essential for both tools, ensuring safe operation.

Consider the environment and task requirements when choosing between a chain hoist and a come-along for optimal efficiency.

Regular inspections and maintenance of your lifting equipment enhance safety and prolong tool life.

Come Alongs vs Chain Hoists: Differences

Intended Use

You need to understand the intended use before choosing between chain come-alongs vs chain hoists. Chain hoists serve as the primary tool for vertical lifting. You use them to raise and lower heavy loads in a controlled manner.

This makes them ideal for construction sites, warehouses, and manufacturing plants where you must lift materials straight up and down.

Come-alongs, on the other hand, excel at pulling, stretching, and positioning loads. You use them for moving objects horizontally or at an angle. They work well for tasks like securing cargo, tensioning fences, or dragging equipment into place.

The versatility of chain come-alongs allows you to operate them in various positions, including both horizontal and vertical orientations.

Tip: If your main task involves lifting heavy objects vertically, a chain hoist is your best choice. For pulling or adjusting loads in multiple directions, you should consider a chain come-along.

Mechanisms

The mechanical differences between chain come-alongs vs chain hoists play a crucial role in their operation. Chain hoists use a hand chain and a lifting chain system. You pull the hand chain, which turns gears and lifts the load with minimal effort.

This mechanism transforms a small input force into a much larger lifting force, making it possible for you to handle heavy weights safely.

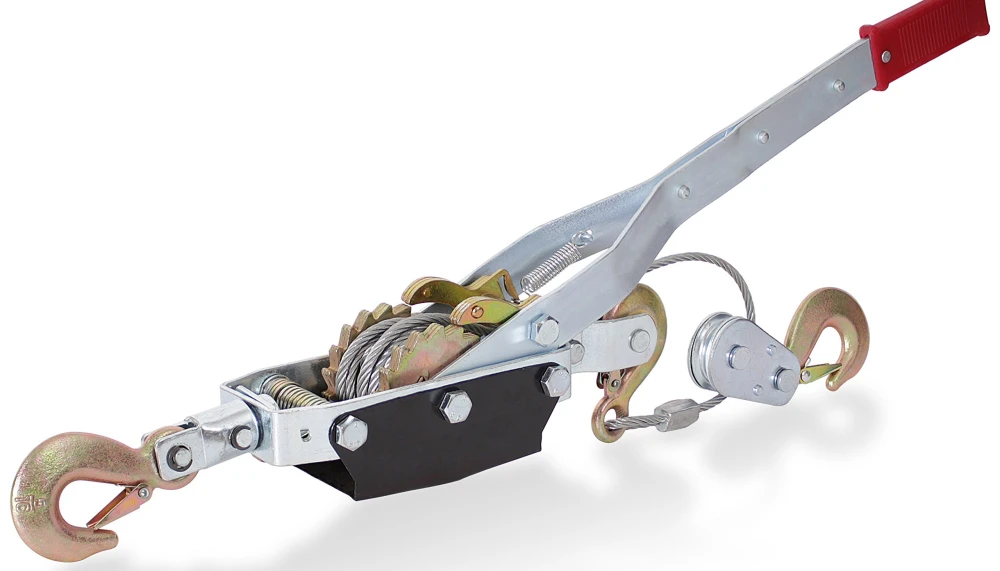

Come-alongs, also known as lever hoists, operate with a ratchet and pawl system. You move a lever back and forth to pull or lift the load. This design gives you precise control over the movement and allows you to set the tool to a neutral position for manual adjustments.

The table below summarizes the main mechanical differences:

Feature | Chain Hoist | Chain Come Along |

|---|---|---|

Operation Mechanism | Hand chain pulled to lift/lower load | Lever operated to lift/lower the load |

Direction Control | Up/Down via hand chain | Up/Down via lever operation |

Neutral Position | Not applicable | Can be set to neutral for manual pull |

You will find that chain hoists are best for repetitive lifting tasks, while chain come-alongs offer flexibility for pulling and positioning.

Portability and Efficiency

Portability and efficiency often influence your decision when comparing chain come-alongs vs chain hoists. Chain hoists, especially manual models, are robust and designed for stationary use. You typically install them in fixed locations such as warehouses or workshops.

Their higher load capacity makes them suitable for lifting large and heavy items, but their size and weight limit mobility.

Come-alongs stand out for their portability. You can easily carry them to different job sites or use them in tight spaces where a chain hoist would not fit. Their compact design and lighter weight make them ideal for fieldwork, outdoor projects, and emergencies. The table below highlights these differences:

Feature | Chain Hoist | Lever Hoist (Chain Come Along) |

|---|---|---|

Portability | Less portable, best for stationary use | Highly portable, ideal for tight spaces |

Versatility | Primarily vertical lifting | Can lift and pull in multiple directions |

Load Capacity | Handles larger loads | Generally, for smaller loads (0.5 to 6 tons) |

Use Cases | Fixed locations like warehouses | Mobile tasks, outdoor projects, rescues |

Application in Tight Spaces | Not suitable for tight spaces | Compact design suits tight spaces |

When you evaluate come-alongs vs chain hoists, consider the environment and the nature of your tasks. If you need a tool for heavy lifting in a fixed location, choose a chain hoist from Powerful Machinery. If you require mobility and versatility, the Come Along Tool offers the flexibility and control you need.

Come Along vs Chain Hoist: Working Principle

You need to understand how each tool works before you select the right equipment for your project. The Come Along Tool from Powerful Machinery uses a ratchet and lever system. You move the handle back and forth to pull or lift the load. This action gives you precise control and allows you to adjust tension easily.

The Chain Hoist operates with a hand chain and gear mechanism. You pull the hand chain, which turns internal gears and lifts the load vertically. This system multiplies your input force, making it possible to lift heavy objects with minimal effort.

Both tools offer features that improve your experience and safety. You benefit from compact designs that make transportation and setup simple. The durable construction ensures reliable performance, even in tough environments.

You can operate these tools with minimal training because Powerful Machinery designs them for straightforward use.

Note: Safety remains a top priority. You will find automatic brakes and overload protection on both the Come Along Tool and Chain Hoist. These features help prevent accidents and keep your work environment secure.

The ergonomic design of each tool reduces fatigue and improves comfort. You handle lightweight aluminum bodies that resist corrosion and last for years. Reinforced handles and aluminum alloy hand wheels make the operation smooth and portable. Non-slip nuts add another layer of safety during use.

Here is a summary of key operational and ergonomic features:

Feature | Description |

|---|---|

Portability | Compact, easy to transport, usable in many locations |

Durability | Built to last under tough conditions |

Ease of Use | Simple operation, minimal training required |

Safety Mechanisms | Automatic brakes, overload protection, and non-slip nut |

Ergonomic Design | Lightweight aluminum body, reinforced handle, easy handling |

High-Efficiency | Low hand pull needed, reduces operator fatigue |

You can rely on Powerful Machinery’s Come Along Tool and Chain Hoist for safe, efficient, and comfortable lifting or pulling tasks. Each tool combines advanced safety features and ergonomic design to help you work smarter and safer.

Applications in Industry and DIY

Chain Hoist Use Cases

You rely on chain hoists for lifting loads in demanding environments. These tools excel at lifting heavy loads on construction sites, moving materials in warehouses, and supporting manufacturing operations. Chain hoists also play a vital role in shipbuilding, mining, and rail transport.

You use them for lifting jobs that require precision and safety. The following table shows the most common industrial applications for chain hoists:

Application |

|---|

Construction & Infrastructure |

Manufacturing |

Warehousing & Logistics |

Oil & Gas / Petrochemicals |

Mining |

Agriculture |

Shipbuilding & Marine |

Rail & Transport |

Aerospace & Defense |

Chain hoists help you optimize space with their low-headroom design. You improve operational efficiency and reduce manual labor. You also enhance safety by minimizing the risk of injury when lifting heavy loads.

Tip: When you need to lift loads vertically and maintain control, chain hoists from Powerful Machinery deliver reliable performance.

Come Along Use Cases

You use a chain come-along for pulling loads and positioning objects in both professional and DIY settings. This tool is perfect for lifting a car engine, installing HVAC units, and positioning steel beams during renovations.

You also find it useful for garage door installations, heavy cabinet placement, and overhead storage systems. The table below highlights typical DIY and home use cases for chain come along:

Use Case | Description |

|---|---|

Motorcycle Lifts | Lifting motorcycles onto workbenches in garage workshops. |

HVAC Unit Installations | Positioning HVAC units on rooftops and maneuvering ductwork through tight spaces. |

Steel Beam Positioning | Positioning steel beams during basement renovations. |

Transmission Removal | Removing transmissions from full-size trucks with precision. |

Heavy Cabinet Positioning | Positioning heavy cabinets during kitchen remodels. |

Garage Door Installations | Lifting and placing heavy garage doors. |

Engine Removal | Lifting a car engine with control and safety. |

Overhead Storage Systems | Installing overhead storage systems in garages. |

Shop Equipment Movement | Lifting and positioning heavy shop equipment like table saws or milling machines. |

You benefit from the chain come along’s versatility. You can use it for lifting loads, pulling heavy loads, and handling tasks in tight spaces.

Powerful Machinery Product Value

You choose Powerful Machinery for reliability and peace of mind. Both chain hoists and chain come-along tools meet CSA c/us and CSA Mark certifications, ensuring quality and safety. You receive a warranty of one year or 2,500 operational hours, with 24/7 support for defects.

Spare parts are always available, and customer service responds quickly.

Powerful Machinery achieves customer satisfaction rates up to 98%.

You trust their service and support for lifting jobs in critical industries.

Many users recognize Powerful Machinery as a top manufacturer for lifting and pulling heavy loads.

Note: When you select Powerful Machinery, you invest in certified products that deliver consistent performance and long-term value.

Selection Guide: Choosing the Right Tool

Criteria for Selection

You face many choices when selecting between a chain hoist and a chain come-along. You must consider the nature of your task, the environment, and the specific requirements for lifting or pulling. You want to ensure that you choose the right tool for safety, efficiency, and reliability.

Safety: You should always select equipment that meets international safety standards. Look for products with built-in safety features such as overload protection and secure locking mechanisms. Powerful Machinery’s chain hoist and come-along tool both comply with recognized certifications, giving you peace of mind.

Efficiency: You need to understand the weight, shape, and character of the load. If you plan to lift heavy objects vertically, a chain hoist is the best choice. If you need to pull or tension loads horizontally or from different angles, a chain come-along offers greater flexibility.

Suitability: You must decide if manual operation or electric power fits your project. Manual chain hoist models from Powerful Machinery provide precise control and are ideal for environments where power sources are limited. The come-along tool excels in mobile and field applications due to its portability.

Environment: You should assess the working conditions. Chain hoists perform best in clean environments and fixed locations. Chain come-alongs are more versatile and can operate in dusty, outdoor, or tight spaces.

Maintenance: You need to consider how often you can inspect and maintain your equipment. Chain hoists require regular lubrication and inspection. Chain come-alongs generally need less maintenance, making them suitable for quick jobs and remote sites.

The following table helps you compare the main features and suitability of each tool:

Feature | Chain Hoists | Chain Come Alongs |

|---|---|---|

Primary Use | Lifting tasks | Pulling and tensioning tasks |

Environment Suitability | Requires clean environments, sensitive to dust | Versatile, suitable for various applications |

Portability | Heavier, less flexible | Portable, can be used in tight spaces |

Maintenance | Requires regular lubrication and inspection | Generally, lower maintenance needs |

You should remember that chain hoists are designed for vertical lifting and offer high load capacities. You use them in warehouses, factories, and construction sites. Come-alongs allow you to pull loads from any angle, making them ideal for fieldwork, rescue operations, and DIY projects.

You benefit from the portability and compact design of the come-along tool, especially when working in confined spaces.

Tip: If you need to lift loads straight up and down, choose a chain hoist. If you need to move or tension loads horizontally or at an angle, select a chain come-along.

Safety and Performance

You must prioritize safety and performance when choosing lifting equipment. You want to ensure that your chain hoist or come-along tool meets all regulatory requirements and operates reliably under demanding conditions.

International Standards: You should verify that your equipment complies with standards such as ASME B30.21 for lever hoists and ASME B30.16 for chain hoists. Powerful Machinery’s products meet these standards, ensuring safe construction, inspection, and operation.

Regulatory Compliance: You need to check for certifications like ISO 4301-1, IEC 60204-32, EN 14492-2, and the Machinery Directive 2006/42/EC. These standards cover overload protection, emergency lowering devices, and electrical safety. Powerful Machinery’s chain hoist and come-along tool carry CE marking and other certifications for global use.

Inspection Intervals: You must follow recommended inspection schedules to maintain safety. Frequent inspections should occur daily to monthly, while periodic inspections range from one to twelve months. You should visually inspect hooks and chains daily and certify them monthly.

Inspection Type | Interval |

|---|---|

Frequent Inspection | Daily to monthly intervals |

Periodic Inspection | 1 to 12-month intervals |

Visual Inspection for Hooks | Daily, Monthly, with certification |

Visual Inspection for Chains | Daily, Monthl,y with certification |

Performance Features: You should look for ergonomic designs that reduce operator fatigue. Powerful Machinery’s chain hoist features a lightweight handle and a smooth lifting mechanism. The come-along tool offers a comfortable grip and precise ratchet control. Both tools include automatic brakes and overload protection for added safety.

Load Capacity: You must select a chain hoist or come-along tool with a load capacity that matches your requirements. Powerful Machinery offers chain hoist models ranging from 250 kg to several tons. The come-along tool supports up to 3 tons, making it suitable for most pulling and lifting tasks.

Standard | Description |

|---|---|

ISO 4301-1 | Classification of lifting appliances, duty cycles, and service conditions |

IEC 60204-32 | Electrical safety requirements for hoists |

EN 14492-2 | Overload protection, emergency lowering devices |

ASME B30.16 | Safety devices and operational practices for chain hoists |

Machinery Directive 2006/42/EC | CE marking, conformity with harmonized standards in the EU |

GB/T 3811 | Design rules for cranes in China |

You should always follow manufacturer guidelines and safety standards. You need to inspect your chain hoist and come-along tool regularly. You must ensure that all operators receive proper training. You can rely on Powerful Machinery for certified products, comprehensive support, and spare parts availability.

Note: You improve workplace safety and efficiency by choosing the right tool and maintaining it according to international standards.

You make the best decision by considering your task requirements, environment, and safety needs. You can trust Powerful Machinery’s chain hoist and come-along tool to deliver reliable performance and meet the highest safety standards.

Conclusion

You now understand the key differences between chain hoists and come-alongs. Chain hoists excel at vertical lifting, while come-alongs offer flexibility for pulling and positioning. Choosing the right tool impacts your safety and efficiency.

Safe lifting tools reduce injuries and physical strain.

Proper equipment boosts productivity and morale.

Certified products ensure compliance with safety regulations.

Trust Powerful Machinery for reliable, certified lifting solutions that keep your workplace safe and productive.

FAQ

What is the main difference between a chain hoist and a come-along?

You use a chain hoist for vertical lifting. You use a come-along for pulling or positioning loads. The come-along gives you flexibility for pulling tasks. The chain hoist focuses on lifting heavy objects straight up.

Can you use a come-along for lifting as well as pulling?

You can use a come-along for both lifting and pulling. The come-along works well for lifting smaller loads and pulling objects in different directions. You get precise control with the ratchet mechanism. Always check the load rating before lifting.

How do you choose the right come-along for your project?

You should consider the weight of your load, the direction of pulling, and the environment. The come-along from Powerful Machinery supports up to 3 tons. You can use it for lifting, pulling, and securing loads in many settings.

What safety features should you look for in a come-along?

You need to check for automatic brakes, overload protection, and secure hooks. The come-along from Powerful Machinery includes these features. You get safe lifting and pulling every time. Always inspect your come-along before each use.

How often should you inspect your come-along and chain hoist?

You should inspect your come-along and chain hoist before every use. Look for wear, damage, or loose parts. Regular inspection ensures safe lifting and pulling. You keep your equipment in top condition by following a maintenance schedule.

Tip: You improve safety and performance by using the right come-along for lifting and pulling tasks. Always follow manufacturer guidelines.