When you compare chain hoist vs hydraulic lift, your choice depends on the specific task. If you need to lift heavy loads with precision in tight spaces, a chain hoist offers reliability and control. For larger, vertical movements, a hydraulic lift delivers power and speed. Selecting the right equipment matters for several reasons:

You improve productivity by moving materials faster.

You enhance safety, reducing injury risks on your job site.

You save costs by avoiding damage and downtime.

Powerful Machinery stands as your trusted source for advanced hoist and lift solutions. Always match your lifting needs with the right tool for the job.

Key Takeaways

Choose a chain hoist for precise vertical lifting in tight spaces. It offers reliability and control, making it ideal for construction and logistics.

Select a hydraulic lift for larger, repetitive movements. It provides power and speed, suitable for manufacturing and warehousing tasks.

Both chain hoists and hydraulic lifts include essential safety features. Regular inspections and maintenance ensure safe operation and prevent accidents.

Evaluate lifting capacity based on your project needs. Chain hoists can lift to 20 tons, while hydraulic lifts can handle over 100 tons.

Consider cost and maintenance when choosing equipment. Chain hoists are cost-effective with low maintenance, while hydraulic lifts may require more servicing.

Chain Hoist vs Hydraulic Lift: Quick Comparison

Main Differences

When you compare a chain hoist vs hydraulic lift, you notice several fundamental distinctions in how each system operates and where you can use them. The table below highlights the main technical differences:

Feature | Chain Hoists | Hydraulic Lifts |

|---|---|---|

Movement and Access | Limited to vertical movement, requires direct positioning above the load | Greater versatility can extend to hard-to-reach areas |

Installation and Mobility | Easily erected and relocated on-site with a tower crane | Often, permanent installations with mobility features |

Power Sources | Can operate manually, electrically, hydraulically, or pneumatically | Primarily use hydraulic pressure or electric power with pulley systems |

Classification | Material hoists for tools and supplies, personnel hoists for crews | Includes aerial lifts, articulating boom lifts, telescopic boom lifts, and scissor lifts |

You will find that chain hoist vs hydraulic lift systems serve different roles. Chain hoists excel in precise, vertical lifting, especially when you need to position loads directly overhead.

Hydraulic lifts offer more flexibility for reaching elevated or awkward spaces. These fundamental distinctions help you decide which equipment fits your project best.

Key Similarities

Despite their differences, chain hoist vs hydraulic lift systems share important safety and operational features. Both types of equipment include built-in safety mechanisms to protect you and your team. The table below summarizes these shared features:

Safety Feature | Chain Hoists | Hydraulic Lifts |

|---|---|---|

Overload Protection | Yes, stops operation if the load exceeds | Yes, stops operation if the load exceeds |

Safety Brakes | Yes, activates on malfunction | Yes, activates on malfunction |

Operator Procedures | Strict adherence required | Enclosed cabins for safety |

Both systems are designed to prevent load slippage.

They ensure safe lifting operations through critical safety mechanisms.

Regular inspection and maintenance are essential for operational safety.

When you evaluate chain hoist vs hydraulic lift options, you see that both prioritize safety and reliability. This focus on protection gives you confidence, no matter which lifting solution you choose.

What Is a Chain Hoist?

How Does a Chain Hoist Work?

You use a chain hoist to lift and move heavy objects vertically. The lifting mechanism relies on a strong alloy steel chain, which passes through a system of gears and pulleys.

When you pull the hand chain or activate the motor, the gears multiply your input force, allowing you to raise loads that would otherwise be impossible to move manually.

The brake system holds the load securely in place, preventing accidental drops. Mechanical engineering literature highlights the importance of each component in the hoist. The hoisting mechanism and brake system work together to ensure efficient and safe load handling.

Manufacturers optimize these parts using computer-aided design, which improves performance and cost-effectiveness.

Material strength plays a critical role in the reliability of a chain hoist. For example, link chains made from AISI 8622 steel offer a yielding strength of 805 MPa and an ultimate strength of 1204 MPa.

These properties allow the hoist to perform under demanding conditions without failure. You will find different types of hoists available, each designed for specific applications and load capacities.

Powerful Machinery Chain Hoist Features

Powerful Machinery designs chain hoists for professionals who demand safety, versatility, and reliability. You benefit from a compact and lightweight design, which makes installation and transport easy. The high-strength steel construction ensures durability, while the alloy steel chain resists wear and corrosion.

You operate the hoist with an ergonomic handle, reducing fatigue during long shifts. The secure locking mechanism prevents accidental release, keeping your team safe.

Tip: Regular inspection and minimal lubrication keep your Powerful Machinery chain hoist performing at its best.

You can choose from models with capacities ranging from 250 kg to several tons. Each hoist meets strict international safety standards, giving you peace of mind in critical environments. Powerful Machinery chain hoists carry certifications that reflect their commitment to quality:

Certification/Standard | Description |

|---|---|

CE | Compliance with European safety standards |

ISO9001:2000 | Quality management system standard |

You rely on Powerful Machinery for lifting solutions that excel in construction, manufacturing, marine, and cargo handling. The chain hoist stands out as a cost-effective, low-maintenance tool that delivers consistent performance in every application.

What Is a Hydraulic Lift?

How Hydraulic Lifts Work?

You rely on a hydraulic lift when you need to move heavy objects with minimal effort. This machine uses the science of fluid mechanics to create a powerful lifting action. The system contains a hydraulic cylinder filled with oil. When you activate the electric motor, it powers a pump that pushes oil into the cylinder.

The pressure from the oil moves a piston, which raises the platform or load.

Hydraulic lifts use incompressible liquids, so the volume stays the same under pressure.

When you apply force to the fluid, the pressure spreads equally in all directions.

Pascal’s Principle allows a small force on a small area to create a much larger force on a bigger area.

The piston rises as the oil pressure increases, lifting the load smoothly and safely.

You see hydraulic lifts in many industries because they offer reliable vertical transportation for both people and materials.

Note: Regular maintenance of the hydraulic system ensures smooth operation and extends the life of your equipment.

Common Uses

Hydraulic lifts play a vital role in modern industry. You find them in settings where safe and efficient lifting is essential. The table below highlights the most common application areas and their descriptions:

Application Area | Description |

|---|---|

Aerospace | Provides access to elevated areas for aircraft maintenance, repair, and manufacturing. |

Warehousing | Handles materials and stacks goods, improving efficiency in tight spaces. |

Oil and Gas | Supports safe and efficient lifting in harsh environments. |

Mining | Handles lifting and material transport tasks in mining operations. |

Utilities | Assists with various lifting tasks in utility work. |

Industrial Sector | Used in manufacturing and construction for material handling and machinery maintenance. |

Logistics and Transport | Tail lifts on trucks make loading and unloading faster and safer. |

You benefit from hydraulic lifts in aerospace, warehousing, mining, and logistics. These machines help you move heavy loads, reach high places, and improve workplace safety.

Chain Hoist vs Hydraulic Lift: Detailed Comparison

Lifting Capacity

You need to consider lifting capacity when choosing between a chain hoist and a hydraulic lift. Powerful Machinery chain hoists offer a wide range of load capacity options, making them suitable for many industrial tasks. You can select a manual chain hoist with a capacity from 1/4 ton up to 20 tons.

Hydraulic lifts also provide impressive lifting power, often designed for larger loads in manufacturing and heavy industry.

Type of Hoist | Lifting Capacity Range |

|---|---|

Manual Chain Hoists | 1/4 to 20 tons |

Hydraulic Lifts | 1 ton to 100+ tons |

You should match the load capacity of your equipment to the demands of your project. Construction hoists from Powerful Machinery give you reliable performance for heavy-duty lifting, while hydraulic lifts excel in environments where you need to move extremely large items.

Operation and Control

You operate a chain hoist using a manual or powered mechanism. The design allows you to lift loads vertically with precise control. Powerful Machinery chain hoists feature ergonomic handles and smooth gear systems, which help you position materials accurately.

Hydraulic lifts use fluid pressure and electric motors to raise platforms or objects. You control these lifts with push-button panels or remote systems, making them ideal for repetitive tasks in manufacturing.

Chain hoists give you direct feedback and control, especially in tight spaces. Hydraulic lifts provide automated movement and can handle larger vertical distances. You should choose construction hoists when you need hands-on control and flexibility.

Hydraulic lifts work best when you require automated lifting for high-volume operations.

Applications

You find chain hoists and hydraulic lifts in different industries and tasks. Construction hoists from Powerful Machinery are popular in construction and logistics. Hydraulic lifts dominate manufacturing, mining, and automotive sectors.

Industry | Preferred Equipment |

|---|---|

Construction | Chain Hoists |

Manufacturing | Hydraulic Lifts |

Mining | Hydraulic Lifts |

Automotive Manufacturing | Hydraulic Lifts |

Metal Fabrication | Hydraulic Lifts |

Oil & Gas | Hydraulic Lifts |

Logistics | Chain Hoists |

You use construction hoists for a variety of tasks:

Construction and infrastructure projects: You lift steel beams and concrete blocks with hydraulic chain hoists, especially outdoors, where electrical tools may not be safe.

Manufacturing and assembly lines: You move heavy parts with chain hoists, improving productivity and accuracy.

Maintenance and repair operations: You lift machinery for repairs in confined spaces, using chain hoists for precise control.

Hydraulic lifts handle bulk material movement, vehicle assembly, and large-scale maintenance. You should select construction hoists for versatile lifting in changing environments. Hydraulic lifts suit fixed installations and high-capacity tasks.

Safety Aspects

You must prioritize safety when operating lifting equipment. Powerful Machinery chain hoists include automatic brakes and overload protection. These features ensure safe operation even in challenging conditions. The hoists meet international standards such as EN 13157, CE, and ISO9001:2000.

Certification/Standard | Description |

|---|---|

EN 13157 | Safety requirements for manually operated hoisting devices |

CE | European safety compliance |

ISO9001:2000 | Quality management system standard |

You benefit from reliable safety mechanisms in both chain hoists and hydraulic lifts. Hydraulic lifts often include emergency stop buttons and enclosed operator cabins. Construction hoists from Powerful Machinery provide peace of mind with robust safety features and strict compliance.

Tip: Always inspect your lifting equipment before use. Regular maintenance and adherence to safety protocols reduce risks and improve performance.

Cost and Maintenance

You need to consider cost and maintenance when selecting lifting equipment. Powerful Machinery chain hoists offer a cost-effective solution for many industries. You benefit from low maintenance requirements and durable construction.

Hydraulic lifts require more frequent servicing due to complex hydraulic systems and moving parts.

Chain hoists have fewer components, which means less downtime and lower operational costs. You can easily transport and install construction hoists, making them ideal for temporary or changing job sites.

Hydraulic lifts provide high lifting capacity but may involve higher initial investment and ongoing maintenance expenses.

You should evaluate your budget, maintenance resources, and project needs before making a decision. Construction hoists from Powerful Machinery deliver long-term value and reliability for heavy-duty lifting tasks.

Choosing the Right Lifting Solution

When to Choose a Chain Hoist

You should select a chain hoist when you need precise vertical lifting, especially in environments with limited space or changing job sites. Chain hoists serve distinct purposes in manufacturing, construction, and logistics. They offer strong weight capacity, advanced safety features, and flexibility for various lifting scenarios.

You can rely on Powerful Machinery Chain Hoists for heavy-duty tasks, as they use mechanical advantage to lift loads efficiently and safely. These hoists require minimal maintenance and provide cost-effective solutions for your business.

Advantages of Chain Hoists in Manufacturing Plants:

Advantage | Description |

|---|---|

Strong Weight Capacity | Handles heavy loads efficiently |

Modern Safety Features | Protects users with advanced mechanisms |

Flexibility | Adapts to different lifting scenarios and environments |

Productivity | Enables quick lifting and placement |

Cost-Effectiveness | Affordable and low maintenance |

Maintenance teams in power plants and factories use motorized chain hoists to reduce downtime and improve safety during equipment repairs.

When to Choose a Hydraulic Lift?

You should choose a hydraulic lift for applications that require ergonomic lifting, precise load positioning, or frequent vertical movement over greater distances. Hydraulic lifts excel in manufacturing and warehousing, where you need to move heavy materials quickly and safely.

These machines include emergency lowering systems and anti-drop valves, which enhance safety. You benefit from reliable performance and robust lifting capabilities in demanding industrial environments.

Key Factors to Consider:

Factor | Description |

|---|---|

Duty Cycles | Match the equipment to your usage frequency |

Maximum Weight Requirements | Include the total weight of the load and lifting device |

Lift Speed | Choose the right speed for your workflow |

Amount of Lift | Calculate the required height difference |

Maximum Headroom | Ensure the equipment fits your workspace |

Power Supply | Select the correct voltage for your site |

Environmental Conditions | Consider temperature, moisture, and corrosive elements |

Practical Scenarios

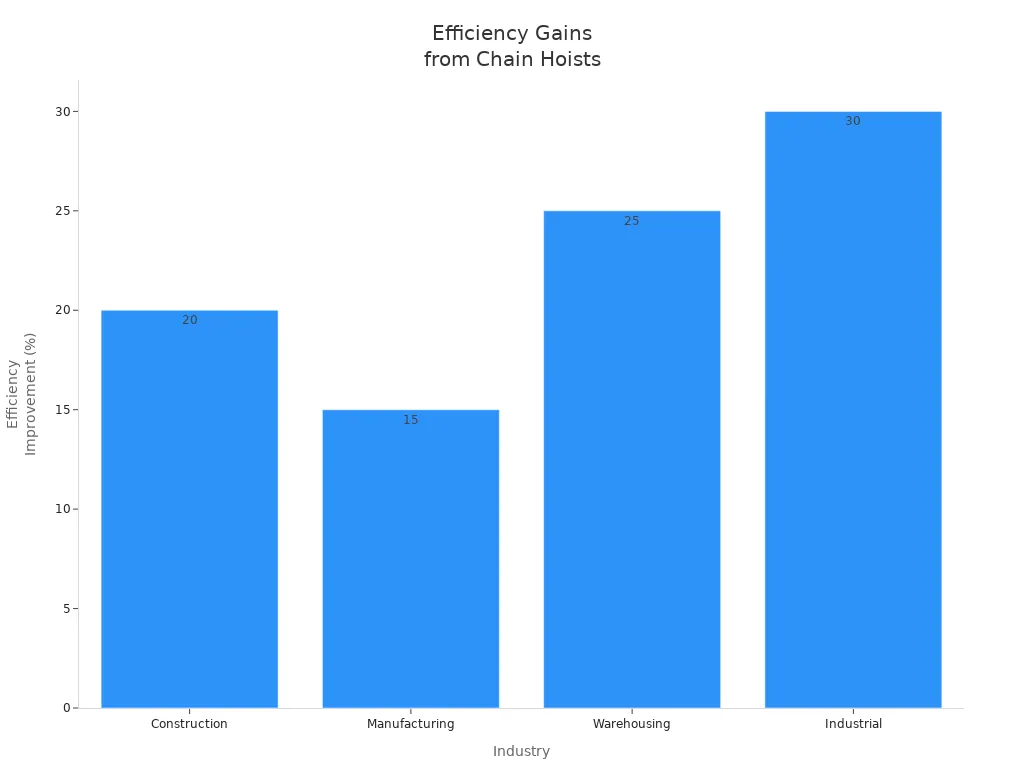

You can see the impact of choosing the right equipment in real-world settings. Many companies have switched from hydraulic lifts to chain hoists and achieved measurable improvements in efficiency and safety.

In construction, a mid-sized firm reduced setup time by 20% after adopting Powerful Machinery Chain Hoists.

A car manufacturer saw a 15% decrease in downtime by using chain hoists for assembly line tasks.

Logistics companies improved throughput by 25% with chain hoists for bulky goods handling.

Energy plants and emergency services reported faster maintenance and response times.

You should evaluate your lifting needs, work environment, and safety requirements before making a decision. Powerful Machinery Chain Hoists deliver reliable performance for heavy-duty and versatile lifting tasks across industries.

Conclusion

You see clear differences between chain hoists and hydraulic lifts. Chain hoists give you precise, vertical lifting and low maintenance. Hydraulic lifts handle larger, repetitive movements. For high-frequency, heavy-load operations, electric chain hoists and manual hydraulic tongs stand out:

Equipment Type | Description |

|---|---|

Electric Chain Hoists | Handle heavy loads in many industries with efficiency and safety. |

Manual Hydraulic Tongs | Ideal for demanding lifting tasks, ensuring operator safety. |

Powerful Machinery chain hoists deliver proven reliability. Many companies in automotive, aerospace, and manufacturing trust them for critical lifting. Before you choose, assess your load, environment, and safety needs. Consult Powerful Machinery for expert, custom solutions.

FAQ

What is the main advantage of using a chain hoist over a hydraulic lift?

You gain precise control and easy portability with a chain hoist. This equipment works well in tight spaces and requires minimal maintenance. You can quickly set it up for different tasks, making it ideal for changing job sites.

How often should you inspect your lifting equipment?

You should inspect your lifting equipment before each use. Schedule a thorough inspection at least once every three months. Regular checks help you spot wear, damage, or safety issues early.

Tip: Keep a logbook to track inspection dates and findings for each device.

Can you use a chain hoist outdoors?

Yes, you can use a chain hoist outdoors. Choose a model with corrosion-resistant materials for harsh environments. Always protect the hoist from excessive moisture and debris to extend its lifespan.

What certifications should you look for in lifting equipment?

Look for certifications such as CE, ISO9001, and EN 13157. These standards ensure your equipment meets international safety and quality requirements. Powerful Machinery chain hoists carry these certifications for your peace of mind.