Choosing between chain hoists vs wire rope hoists depends on your facility’s load requirements, operating environment, budget, and safety priorities. You will see wire rope hoists in 55% of industrial facilities, while chain hoists account for 40%.

Selecting the right hoist improves operational efficiency and reduces safety risks. Overloading equipment, poor rigging, and ignoring manufacturer guidelines often lead to accidents. You should consider both immediate needs and future growth, and consult with experts for complex projects.

Hoist Type | Market Share (%) |

|---|---|

Wire Rope Hoists | 55% |

Chain Hoists | 40% |

Key Takeaways

Evaluate your facility’s lifting needs. Consider load capacity, frequency of use, and environmental conditions to choose the right hoist.

Understand the differences between chain hoists and wire rope hoists. Chain hoists are cost-effective for lighter loads, while wire rope hoists excel in heavy-duty applications.

Prioritize safety and compliance. Regular inspections and adherence to safety standards are crucial for safe hoist operation.

Consider the total cost of ownership. Look beyond the initial purchase price to include maintenance, repairs, and lifespan in your decision-making.

Consult with experts for complex projects. Specialists can provide tailored solutions and ensure your equipment meets safety and operational standards.

Chain Hoists vs Wire Rope Hoists Overview

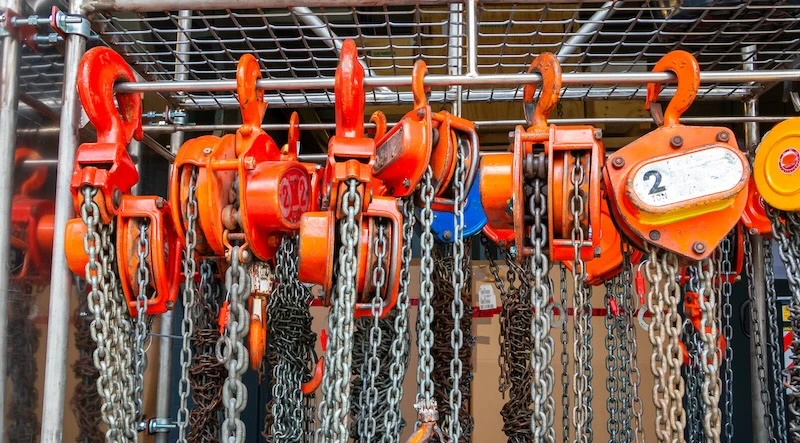

What Is a Chain Hoist?

A chain hoist gives you a compact and reliable way to lift heavy loads. You operate it manually or with electric power, making it suitable for vertical lifts and precise positioning. Chain hoists work well for pushing or pulling loads in construction, manufacturing, and logistics.

You benefit from their lower initial cost and simple design. These hoists use high-tensile chains and robust steel housings, which help them resist wear and corrosion. Powerful Machinery’s chain hoist models meet strict international safety standards, including CE and ISO9001:2000.

You can trust their certified quality and ergonomic features to improve safety and reduce operator fatigue.

Tip: Never modify a chain hoist in the field. Removing safety latches or changing components can compromise safety and equipment integrity.

What Is a Wire Rope Hoist?

A wire rope hoist offers you advanced lifting capabilities for demanding environments. You find wire rope hoists in facilities that require faster operation and higher lifting capacities. These hoists use a wire rope wound around a drum, powered by electric or pneumatic motors.

You can lift loads to 80 tons with standard models and up to 250 tons with special designs. Wire rope hoists excel in heavy-duty applications, such as marine, transportation, and large-scale construction. Powerful Machinery’s wire rope hoists feature components that resist wear and provide long-term durability.

Their products carry certifications like ASME 30.5, OSHA 1926.1400, and ANSI/ASME 30.2, ensuring you meet global safety and quality standards.

Certification/Standard | Description |

|---|---|

CE | Meets EU safety standards. |

ISO9001:2000 | Ensures quality management. |

ASME 30.5 | Mobile crane safety. |

ASME 30.4 | Pedestal and portal crane safety. |

ANSI/ASME 30.2 | Overhead and gantry crane safety. |

OSHA 1926.1400 | Construction crane safety. |

When you compare chain hoists vs wire rope hoists, you see clear differences in lifting mechanisms, speed, and load capacity. Chain hoists are more compact and cost-effective for lighter loads.

Wire rope hoists deliver greater versatility, faster lifting speeds, and higher capacities for intensive use. Each hoist type has unique advantages, so you should match your choice to your facility’s specific needs.

Wire Rope Hoist vs Chain Hoist: Construction and Design

Chain Hoist Structure

You will find that a chain hoist uses a simple yet robust design. The main components include a load chain, a lifting mechanism, hooks, and a steel housing. Powerful Machinery’s chain hoist features high-tensile alloy steel chains, which deliver excellent strength and wear resistance.

The housing, made from high-strength steel, protects the internal gears and ensures long-term reliability. You benefit from a secure locking mechanism that prevents accidental load release. The ergonomic handle allows for smooth and precise lifting, reducing operator fatigue.

High-tensile chains play a key role in safety and performance. Their strength helps prevent accidents and load failures, especially in demanding industrial settings. When you follow a regular maintenance schedule, you can extend the lifespan of your sling by up to 35% and reduce equipment-related downtime by 40%.

Note: High-tensile chains not only improve safety but also help you achieve zero rigging-related safety incidents when paired with proper inspections.

Material Type | Description | Impact on Durability |

|---|---|---|

Grade 80 Alloy Steel | Provides a balance of strength, toughness, and wear resistance. | Standard for overhead lifting; good durability. |

Grade 100 Alloy Steel | Higher strength-to-weight ratio; offers increased safety and durability. | Suitable for demanding applications. |

Galvanized Steel | Coated with zinc for corrosion resistance. | Protects against rust, enhancing longevity in harsh climates. |

Stainless Steel | Superior corrosion resistance but different strength characteristics. | Ideal for extreme environments but at a higher cost. |

Wire Rope Hoist Structure

A wire rope hoist uses a different approach to lifting. You will see a drum that winds the wire rope, a powerful motor, and a sturdy frame. The wire rope itself is made from high-tensile steel strands, which provide flexibility and superior load-bearing capacity.

Powerful Machinery’s wire rope hoists use precision-engineered drums and gears to ensure smooth operation. The wire rope resists wear and corrosion, making it ideal for heavy-duty and outdoor applications. You can rely on these hoists for consistent performance in the marine, construction, and transportation industries.

High-tensile wire ropes are essential for safety, as they reduce the risk of dropped loads and extend equipment life. When you implement a structured maintenance program, you improve operational efficiency and keep your facility running smoothly.

Load Capacity and Duty Ratings

Chain Hoist Capacity

You rely on a chain hoist for versatile lifting equipment in many applications. Manual chain hoists typically lift loads between 0.5 and 20 tons. Electric chain hoists expand your options, handling loads from 0.125 tons up to 50 tons, with specialized models reaching 100 tons.

Powerful Machinery’s chain hoists meet strict international standards, ensuring reliable performance and safety. You use these hoists for heavy lifting in manufacturing, construction, and logistics.

The compact design allows you to position loads precisely, making chain hoists ideal for applications that require accuracy and control. You benefit from certified lifting capacity, which helps you avoid overloading and equipment failure.

Chain Hoist Type | Typical Load Capacity (tons) |

|---|---|

Manual | 0.5 – 20 |

Electric | 0.125 – 50+ |

Specialized Models | Up to 100 |

Wire Rope Hoist Capacity

A wire rope hoist gives you high-capacity lifting equipment for demanding applications. You find wire rope hoists in environments where you need to move loads up to 80 tons with standard models. Some advanced wire rope hoists, such as the DH series, handle loads up to 220,000 pounds.

Powerful Machinery’s wire rope hoists deliver consistent performance for heavy lifting in marine, transportation, and large-scale construction. You choose wire rope hoists when your application requires high-capacity lifting and continuous operation.

These hoists meet international certifications, so you can trust their reliability in critical lifting equipment applications.

Wire Rope Hoist Model | Maximum Load Capacity |

|---|---|

DVR | Up to 80 tons |

DH | Up to 220,000 pounds |

Hoist Duty Ratings

Duty ratings help you select the right hoist for your application. Chain hoists work best for lighter, frequent lifting tasks. You use them in environments where contamination is a concern, thanks to their compact and easy-to-clean design. Wire rope hoists excel in high-duty cycles and continuous operation.

You rely on wire rope hoists for applications that demand consistent heavy lifting. High duty cycles in chain hoists can generate heat, leading to equipment downtime. Powerful Machinery’s certified hoists meet international standards, so you can operate safely and efficiently.

Always match the duty rating to your lifting equipment needs to maximize performance and lifespan.

Tip: Review duty ratings before selecting lifting equipment. Proper selection prevents overload and extends equipment life.

Suitability for Different Environments

Chain Hoist Suitability

You often choose a chain hoist when you need a compact and portable solution for lifting in diverse industrial settings. Chain hoists excel in environments where space is limited and loads are moderate.

You see them in automotive assembly lines, warehouses, oil and gas facilities, chemical plants, and mining operations. Their design makes them easy to install and maintain, which reduces downtime and operational costs.

Hoist Type | Common Environments | Advantages |

|---|---|---|

Chain Hoist | Automotive, warehouse, oil & gas, chemical, mining | Compact, portable, easy installation, low maintenance, cost-effective, ideal for lighter loads |

You benefit from the versatility of Powerful Machinery’s chain hoist in many application scenarios. For example, you use them on automated manufacturing lines to lift and position components. On construction sites, you rely on them for moving steel beams and concrete forms.

During maintenance and repair operations, you lift heavy machinery parts safely. In warehousing and logistics, you streamline the handling of bulky goods. Heavy equipment assembly, such as wind turbines, also depends on the precise control these hoists provide.

Note: Chain hoists offer reliable performance in both indoor and outdoor applications, making them a trusted choice for many industries.

Wire Rope Hoist Suitability

A wire rope hoist gives you the power and speed needed for heavy-duty applications and severe-duty environments. You find these hoists in production facilities, high-frequency lifting operations, and application scenarios that demand smooth operation and high lifting speeds.

Wire rope hoists handle greater capacities, often over 10 tons, and distribute weight efficiently across the load.

You use wire rope hoists in production environments where you need to move large volumes quickly. They are essential for heavy-duty applications in transportation, marine, and large-scale construction projects. Their robust construction ensures safety and reliability, even in the most demanding conditions.

When your ideal use cases involve continuous operation and high loads, a wire rope hoist delivers the performance you require.

Tip: For severe-duty or high-capacity lifting, wire rope hoists provide the durability and efficiency you need to keep your operations running smoothly.

Performance and Operation

Lifting Speed and Precision

You need to consider both speed and precision when selecting a hoist for your facility. Chain hoists typically operate at slower speeds, which makes them suitable for congested areas and tasks that do not require exact load placement.

Wire rope hoists deliver faster lifting speeds, especially over longer distances, and provide better control for precise positioning. This difference becomes important in manufacturing environments where you must align parts or handle heavy-duty tasks.

Hoist Type | Lifting Speed | Precision |

|---|---|---|

Chain Hoist | Generally slower in congested areas | Suitable for general lifting without exactness |

Wire Rope Hoist | Can achieve faster speeds over longer distances | Better control for exact load placement |

You should use wire rope hoists for tasks that demand precise load placement, such as aligning components on a production line. Chain hoists work best for general lifting tasks where precision is less critical.

Electric chain hoist models from Powerful Machinery offer smooth operation and accurate control, which helps you position loads safely and efficiently.

Chain hoists are ideal for lighter loads and simpler operations.

Wire rope hoists excel in heavy-duty tasks with higher lifting capacities.

For exact load positioning, wire rope hoists provide better control.

Manual vs Electric Hoist

You have two main options for hoist operation: manual and electric. Manual chain hoists require physical effort and are best for occasional lifting or environments without power access. Electric chain hoists and wire rope hoists offer automated operation, which increases speed and reduces operator fatigue.

Powerful Machinery integrates ergonomic controls and safety features into every hoist. You benefit from clearly labeled controls at comfortable heights, robust safety interlocks, and easy maintenance access. These features improve operator performance and reduce risks during operation.

Feature | Description |

|---|---|

Ergonomic Controls & Layouts | Controls are placed for comfort and safety, reducing strain during operation. |

Guarding & Safety Interlocks | Systems shut down under unsafe conditions, protecting you and your team. |

Easy Maintenance Access | Service doors and clear sightlines make inspections and repairs safer and faster. |

You should choose electric chain hoist models for frequent lifting tasks and environments that require consistent performance. Manual hoists remain valuable for simple, low-volume operations.

Powerful Machinery’s focus on ergonomic design and advanced safety features ensures you achieve reliable operation and optimal lifting performance in every application.

Maintenance and Lifespan

Chain Hoist Maintenance

You need to keep your chain hoist in top condition to ensure safe and efficient operation. Daily visual inspections help you spot wear or damage on chains, hooks, and other components before each use. Monthly inspections focus on critical parts and usage frequency.

You should follow three levels of inspection: Level I every month, Level II every three months, and Level III every six months. An annual comprehensive safety inspection confirms that your hoist meets all operational standards.

Powerful Machinery designs its chain hoist for low maintenance, so you spend less time on upkeep and more time on productive work.

Daily visual inspections for wear or damage

Monthly, three-month, and six-month component checks

Annual comprehensive safety inspection

Tip: Regular maintenance reduces downtime and extends the lifespan of your equipment.

Wire Rope Hoist Maintenance

Wire rope hoist maintenance requires careful attention to detail. You must inspect the wire rope, drum, and motor before each use. Monthly and annual inspections help you identify issues early and prevent costly repairs. You should check for fraying, corrosion, and proper tension.

Keeping the wire rope clean and lubricated improves performance and safety. Powerful Machinery’s wire rope hoist uses high-tensile steel strands, which resist wear and corrosion, making maintenance easier and less frequent.

Hoist Durability

You want equipment that lasts. Powerful Machinery’s products meet strict international certifications, including CE and ISO standards. Customers praise the reliability and long lifespan of these hoists, even in demanding environments. The table below highlights key attributes from satisfied clients:

Product Name | Company Name | Key Attribute |

|---|---|---|

High Quality Fixed Type Electric Chain Hoist 1 Ton 2 Ton 3 Ton | Henan Shuang’an ‘Crane Co., Ltd. | CE ISO Certified |

High Quality Electric Chain Hoist 1 Ton 2 Ton 3 Ton 5 Ton | Henan Weihua Heavy Machinery Co., Ltd. | 5-Ton Capacity |

Heavy Duty 50 Ton Electric Chain Hoist | Wuhan Vohoboo Import & Export Trade Co., Ltd. | 50-Ton Capacity |

You can trust Powerful Machinery to deliver hoists that stand up to daily use and harsh conditions. Regular maintenance and certified quality ensure your equipment remains reliable for years.

Cost Considerations

Purchase Price

You want to make a smart investment when choosing a hoist for your facility. The purchase price for a chain hoist is usually lower than for a wire rope hoist. Chain hoists offer a cost-effective solution for light to moderate lifting tasks.

Wire rope hoists cost more upfront because they handle heavier loads and offer advanced features. Powerful Machinery provides both options with certified quality, so you can select the right equipment for your budget and operational needs.

Hoist Type | Typical Purchase Price Range | Best Use Case |

|---|---|---|

Chain Hoist | Lower | Light to moderate lifting |

Wire Rope Hoist | Higher | Heavy-duty, frequent lifting |

Note: You should always consider the total value, not just the initial price, when selecting hoists for your facility.

Total Cost of Ownership

You need to look beyond the initial purchase price. The total cost of ownership includes maintenance, repairs, downtime, and lifespan. Chain hoists require less maintenance and have fewer moving parts, which helps you save on long-term costs.

Wire rope hoists may need more frequent inspections and specialized servicing, especially in high-duty environments. Powerful Machinery designs hoists for durability and reliability, reducing unexpected expenses over time.

Chain hoists: Lower maintenance costs, simple repairs, long lifespan.

Wire rope hoists: Higher maintenance needs, advanced servicing, suited for continuous heavy lifting.

You benefit from choosing equipment that matches your workload and environment. This approach helps you control costs and maximize productivity.

Training and Installation

Proper training and installation ensure safe and efficient operation of hoists. You should enroll your team in expert-led programs that cover hoist use, maintenance, and inspection. Classes teach the basics of equipment care and repair techniques. Certification programs qualify individuals as professional hoist technicians.

The safe operation of wire rope hoists is governed by stringent safety standards and regulations, which are essential for guiding the manufacturing, installation, operation, and maintenance of these hoists.

You need frequent inspections, including daily visual checks and operational tests. Periodic inspections by qualified professionals help you identify wear and prevent failures.

Powerful Machinery supports your facility with training resources and installation guidance, making sure your hoists meet all safety and performance standards.

Decision Guide for Hoist Selection

Assessing Load and Frequency

You need to start by evaluating your facility’s lifting requirements. The type and frequency of lifting tasks play a major role in determining the right equipment. Manual chain hoists work best for temporary or infrequent lifting jobs.

Powered chain hoists offer faster operation and ergonomic benefits for heavy-duty cycles. Wire rope hoists handle larger loads and suit environments where you lift heavy items less frequently but require higher capacity.

Hoist Type | Load Requirements | Frequency of Use |

|---|---|---|

Chain Hoist | 0.5–10 tons (light loads) | Frequent, light lifts |

Wire Rope Hoist | 1–250 tons (heavy loads) | Infrequent, heavy lifts |

You should match the hoist’s duty cycle classification to your operational intensity. Chain hoists excel in clean environments and frequent use. Wire rope hoists perform better in harsh conditions and for infrequent, heavy lifts. Always calculate the maximum load your hoist will need to lift and consider how often you will use it.

Tip: Accurate load calculation and understanding your lifting frequency help prevent equipment overload and extend service life.

Evaluating Space and Suitability

Space constraints often affect your choice of lifting equipment. Chain hoists have a compact profile, making them ideal for facilities with limited vertical space. You can utilize vertical space more efficiently with a chain hoist.

Wire rope hoists require more headroom due to their drum and motor design. In low-ceiling factories, this can be a limitation. Low-headroom versions of wire rope hoists exist, but they tend to cost more.

Consider environmental factors such as temperature, dust, and moisture. Chain hoists work well in clean, controlled environments. Wire rope hoists are designed for harsh conditions and outdoor use.

You should also review the control methods available, such as pendant control or wireless remote control, to ensure safe and efficient operation.

Note: Evaluate your facility’s space and environmental conditions before selecting lifting equipment. This step helps you avoid costly modifications and ensures optimal performance.

Budget and Safety

Budget and safety standards are critical in your decision-making process. Focusing only on the initial purchase price can lead to poor long-term investment decisions. A hoist represents a long-term capital investment.

The true cost is determined by its total cost of ownership over its service life. Chain hoists generally have lower maintenance costs and simple repairs. Wire rope hoists may require more frequent inspections and specialized servicing.

Safety is governed by laws, regulations, and technical standards. Compliance with safety standards protects operators and ensures operational integrity. Look for essential safety mechanisms like limit switches and braking systems. Partner with a supplier known for quality manufacturing and robust after-sales support.

Practical Checklist for Hoist Selection:

Power supply compatibility: Match the hoist’s motor to your facility’s electrical supply.

Control methods: Choose between a pendant or wireless remote control.

Safety features: Ensure the hoist includes limit switches and braking systems.

Load capacity: Calculate the maximum load for your lifting tasks.

Duty cycle: Select a hoist with a duty cycle that matches your operational needs.

Environmental factors: Consider temperature, dust, and moisture.

Space constraints: Assess vertical clearance and headroom.

Supplier quality: Work with a trusted supplier for reliable equipment and support.

Call Powerful Machinery for custom-engineered solutions. Their experts help you match hoist features to your facility’s unique requirements and ensure compliance with international safety standards.

Expert Recommendations

When to Consult a Specialist

You should consult a specialist when your project involves complex lifting requirements or large-scale operations. A hoist expert helps you navigate technical challenges and ensures your facility meets all safety standards. You need guidance if you face any of these situations:

You must comply with international, national, or local safety standards.

Your operators require specialized training or ongoing maintenance support.

You want to set up a rigorous inspection program, including pre-shift and periodic checks.

You need to understand the duty cycle classification to prevent premature wear.

A specialist from Powerful Machinery can assess your needs and recommend the right chain hoist or wire rope hoist for your application.

Custom Hoist Solutions

Every facility has unique operational challenges. You may need a custom solution for a non-standard lifting environment or a demanding schedule. Powerful Machinery offers tailored hoist solutions for complex projects. Their team evaluates your requirements and delivers equipment designed for reliability and efficiency.

You benefit from:

Custom-engineered hoists that match your project’s demands.

Equipment built for safety and performance in tough conditions.

Project consulting and support services that keep your work on track.

You can also access comprehensive rental packages and full-time operator support, which help you maintain safety and productivity.

Safety and Compliance

You must prioritize safety and compliance when installing or operating hoists. Regular inspections and tests should occur at least every three months. You need to keep certification records, including inspection dates and signatures. Protect hoistway entrances with sturdy gates or bars.

Before using any hoist, a competent person should supervise inspections and tests. Operators must follow the manufacturer’s specifications for every piece of equipment. Pre-operational safety checks help you spot potential issues before they cause incidents.

You ensure compliance with standards like the American National Standard A10.4–1963 by following these steps.

Tip: Partner with Powerful Machinery for expert guidance on safety, compliance, and ongoing support. Their team helps you maintain a safe and efficient facility.

Conclusion

You need to weigh lifting capacity, speed, flexibility, budget, and environment when selecting the right hoist. The table below highlights these decision factors:

Decision Factor | Chain Hoists | Wire Rope Hoists |

|---|---|---|

Lifting Capacity | Best for loads under 2,000 kg | Best for loads over 7,500 kg |

Speed | Fewer speed options | Greater speed options |

Flexibility of Hook | Advantageous for tight spaces | Precise horizontal positioning |

Budget | Lower cost, easier installation | Higher cost, more complex |

Application/Environment | Versatile, tight spaces | Heavy-duty, harsh environments |

Long-term investment in high-quality equipment improves safety and efficiency. Facilities that choose expert installation reduce energy and maintenance costs, while poor choices can lead to expensive repairs and downtime. Before consulting Powerful Machinery, you should:

Understand your relocation needs.

Conduct a feasibility study.

Assess risks and create a risk management plan.

Audit inventory and assets.

Maintain business continuity.

If you want professional advice or a custom quote, ask about experience with similar applications, equipment criteria, support, total cost of ownership, and longevity. Reach out to Powerful Machinery for tailored solutions that meet your operational goals.

FAQ

What is the difference between a chain hoist and a wire rope hoist?

You use a chain hoist for lighter loads and precise positioning. You choose a wire rope hoist for heavy-duty lifting and faster operation in demanding environments.

How often should you inspect your hoist?

You should inspect your hoist daily for visible damage. Schedule monthly and annual checks to ensure safe operation and compliance with safety standards.

Can you use a chain hoist outdoors?

You can use a chain hoist outdoors. Choose models with corrosion-resistant materials for harsh weather. Always follow manufacturer guidelines for maintenance.

What certifications should you look for in a hoist?

You should look for certifications like CE, ISO9001, and ASME. These standards guarantee safety, reliability, and quality in lifting equipment.

How do you choose the right hoist for your facility?

You assess load requirements, lifting frequency, available space, and safety needs. Consult with experts to match equipment features to your operational goals.

Tip: Always follow manufacturer instructions for installation and operation to maximize safety.