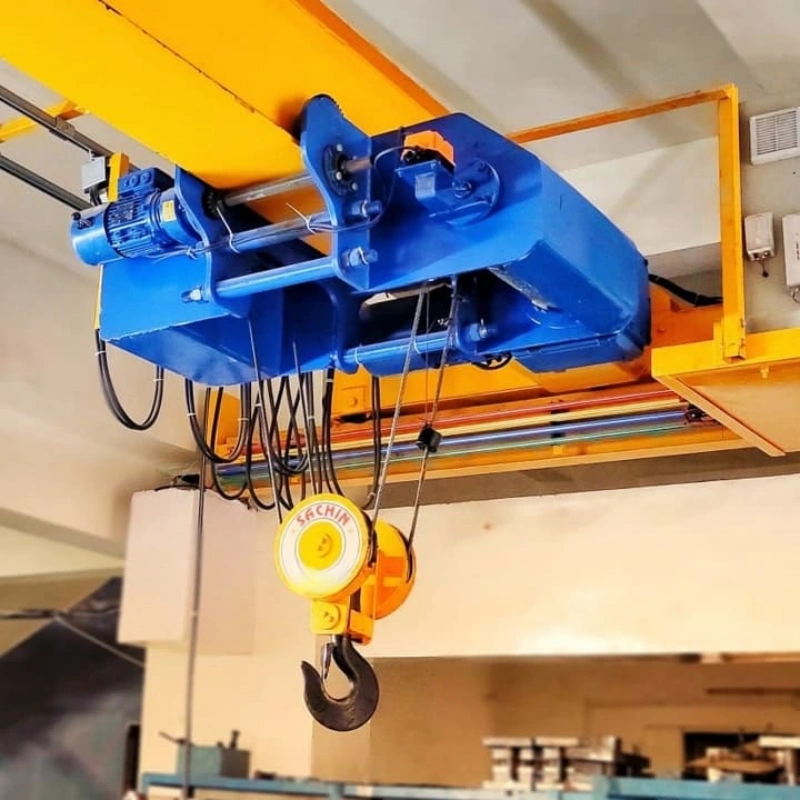

When your come along tool stops working, you need answers fast. You trust the Powerful Machinery Come Along Tool for its strength and durability, but even the best equipment needs attention. Spotting damaged parts early and using safe, step-by-step repair methods keeps your tool reliable.

If you want to know how to fix a come-along and keep it performing at its best, use these maintenance tips with confidence. You have the skills to handle common repairs and keep your projects moving.

Key Takeaways

Inspect your come-along tool before and after each use. Look for visible damage like frayed cables or bent hooks to catch issues early.

Use certified replacement parts from Powerful Machinery for repairs. This ensures safety and reliability in your tool’s performance.

Regularly clean and lubricate the ratchet mechanism. This simple maintenance step can extend the tool’s life by up to 20%.

Follow a systematic approach for repairs. Always release tension, inspect components, and test the tool after reassembly to ensure proper function.

Wear appropriate personal protective equipment during repairs. Safety gear like gloves and goggles reduces the risk of injury.

How to Fix a Come Along: Quick Solutions

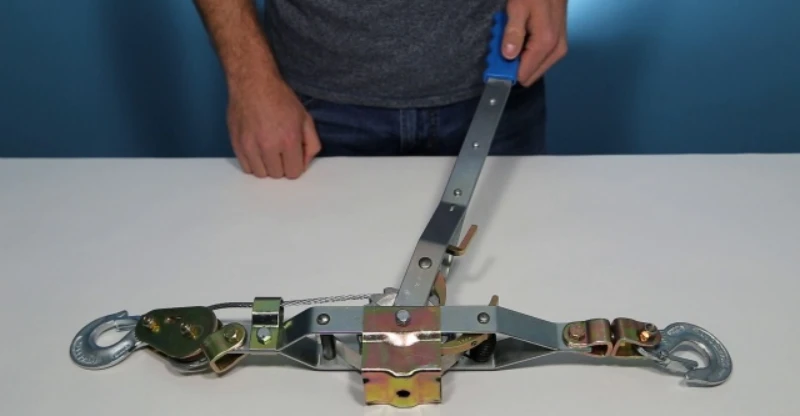

Cable and Hook Issues

You rely on the Powerful Machinery Come Along Tool for its robust design and consistent performance. When you encounter cable and hook problems, you need to act quickly to keep your project on track. Many users report common issues that can affect the tool’s operation:

Items repaired or modified through welding

Shackles with the wrong size or improperly rated pins

The hoist ring bolts locked up due to overload

Missing or illegible identification tags on rigging equipment

Improper setup and anchor points

Overloading the cable puller

Wrong cable or rope selection

Overlooking regular maintenance

Inadequate training and safety measures

Common mistakes when using cable pullers

If you notice a cable snapped or a hook that does not secure properly, you should follow a systematic approach. Here are immediate troubleshooting steps to resolve cable and hook malfunctions:

Release the drive-pawls by sliding the pawl spring hook from the bottom to the top of the drive-pawl slot.

Swing the handle all the way to the other side until you feel resistance, then push a bit harder until you hear a ‘clunk’ sound. This means the stop-pawl is released.

Repeat the process by swinging the handle and relaxing it to gradually release tension on the cable.

Once most tension is released, hold the stop-pawl trigger with your thumb while swinging the handle back. This allows the ratchet wheel to spin freely and quickly retracts the cable.

Tip: Always inspect the cable and hooks for visible damage before starting any come along repair. Replace any worn or damaged parts with certified components from Powerful Machinery to maintain safety and reliability.

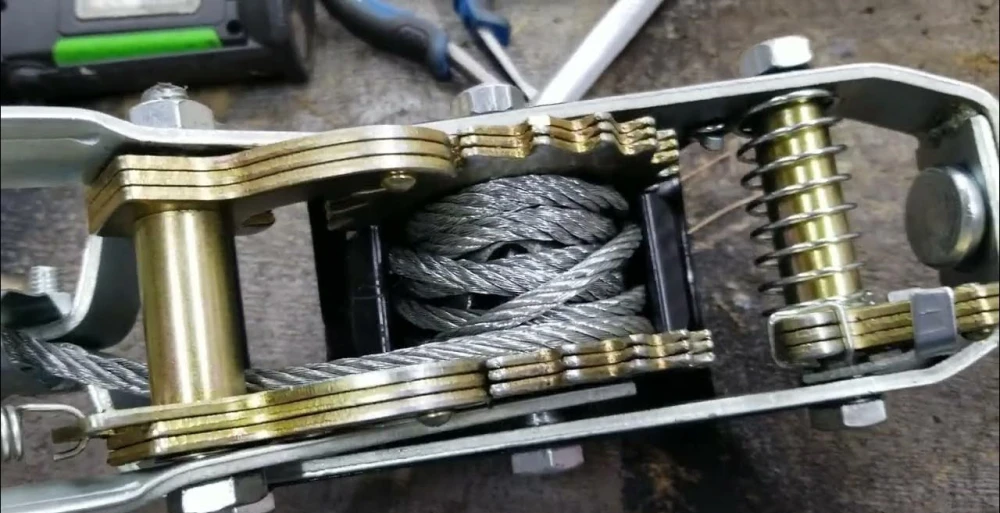

Fastener and Ratchet Problems

Fastener and ratchet issues can disrupt your workflow and compromise safety. You may encounter problems such as:

Jammed ratchet mechanism caused by rust or corrosion

Dirt and debris obstructing pawl movement

Overloading that leads to damage or malfunction

You can address these problems with proven quick fixes. The table below summarizes effective techniques for fastener and ratchet repairs:

Technique | Description |

|---|---|

Lubrication | Extends tool life by up to 20%. Use an appropriate lubricant for tools. |

Cleaning | Regular cleaning helps maintain functionality and prevents fastener issues. |

Double-Socket Technique | Saves up to 50% time by minimizing socket changes, which can help in quick adjustments. |

Two-Pronged Approach | Recommended for rusted or stripped fasteners; involves greasing threads to loosen bonds. |

Alternative Methods | Use locking pliers for damaged bolts and studs when the socket grip fails. |

You should clean and lubricate the ratchet mechanism regularly. If you find rust or debris, remove it before reassembling the tool. For stripped or damaged fasteners, try the two-pronged approach or use locking pliers for a secure grip.

These steps help you maintain the reliability and strength of your Powerful Machinery Come Along Tool.

If you want to know how to fix a come-along quickly, always start with a thorough inspection and use certified replacement parts. You can resolve most issues with simple tools and careful attention to detail. This approach ensures your equipment remains safe and ready for heavy-duty tasks.

Identifying Come Along Repair Needs

Inspecting for Damage

You need to check your Powerful Machinery Come Along Tool before and after every use. Start with a visual scan of the entire tool. Look for cracks, bends, or any signs of stress on the frame. Examine the cable for fraying, kinks, or broken wires. Inspect the hooks for deformation or worn latch springs.

Check the ratchet and fasteners for rust, corrosion, or missing parts. Use a flashlight to see inside tight spaces. If you spot any damage, remove the tool from service right away and tag it for repair. Assigning a dedicated safety lead for daily checks ensures that no tool gets overlooked.

Consistent cleaning and inspection help you catch small issues before they become major problems.

Tip: Always inspect your personal protective equipment along with your tools. Damaged gloves, helmets, or safety glasses can be just as dangerous as faulty machinery.

Recognizing Faulty Parts

You can recognize malfunctioning parts by following a simple routine. Use this checklist to stay organized:

Inspect the tool at the start and end of every shift. Quick checks catch loose bolts, frayed cords, or worn parts before they become bigger issues.

Follow a maintenance schedule. Regular servicing prevents breakdowns during critical tasks.

Immediately report any tool that shows signs of wear or failure. Remove it from service and tag it for repair.

Assign a dedicated person to handle daily inspections. This step ensures every tool receives attention.

Check your PPE and safety gear, along with your come-along tool.

If you notice any part that does not move smoothly or looks different from normal, do not use the tool. Replace damaged components with certified parts from Powerful Machinery. This approach keeps your equipment safe and reliable for every project.

Step-by-Step Troubleshooting and Repair

Tools and Materials Required

You need the right tools and materials to complete any troubleshooting and repair task on your Powerful Machinery Come Along Tool. Gather these items before you start:

Certified replacement cables

Heavy-duty hooks

Adjustable wrench

Screwdrivers (flathead and Phillips)

Lubricant (approved for lifting equipment)

Wire brush

Safety gloves and goggles

Clean cloths

Manufacturer’s manual

Tip: Always use certified parts from Powerful Machinery. This practice ensures your tool meets safety standards and performs reliably.

Safe Removal and Replacement

You must follow a systematic process to remove and replace damaged components. Begin by disconnecting the tool from any load. Place the tool on a stable surface. Wear your safety gloves and goggles.

Inspect the cable and hooks for visible damage.

Release tension from the cable using the ratchet handle. Make sure the cable is slack before proceeding.

Use the adjustable wrench to loosen fasteners securing the cable and hooks.

Remove the damaged cable and hooks. Set them aside for proper disposal.

Clean the ratchet mechanism and attachment points with a wire brush and cloth.

Install the replacement cables and new hooks. Align them according to the manufacturer’s guidelines.

Tighten all fasteners securely. Check for proper fit and alignment.

Alert: Never reuse damaged parts. Always install new certified components to maintain safety and reliability.

Reassembly and Testing

You must reassemble the tool carefully. Follow these steps to ensure proper function:

Reattach the ratchet handle and check its movement.

Apply lubricant to the ratchet mechanism. Use only approved products.

Inspect all connections and fasteners. Make sure everything is secure.

Test the tool without a load. Operate the ratchet and cable to confirm smooth movement.

Attach a test load within the tool’s rated capacity. Observe the cable, hooks, and ratchet for any signs of malfunction.

Record the repair in your maintenance log. Note the date, parts replaced, and results of the test.

Note: Always follow the manufacturer’s instructions for Powerful Machinery products. This step ensures your troubleshooting and repair process meets industry standards.

You can keep your Powerful Machinery Come Along Tool in top condition by following these steps. Regular maintenance and careful attention to detail help you avoid unexpected breakdowns. Use only certified replacement parts and always consult the official manual for guidance.

Repair or Replace Your Come-Along Tool?

Assessing Tool Condition

You need to evaluate your Powerful Machinery Come Along Tool carefully before deciding on your next step. Start by checking for visible wear, such as frayed cables, cracked cases, or bent hooks. These signs often point to deeper problems that may not be fixable with a simple come-along repair.

If your tool is relatively new, within its expected lifespan, and the damage is minor, a repair usually makes sense. Replacement parts from Powerful Machinery are readily available, so you can restore performance quickly if the issue is small.

Use this table to guide your decision:

Criteria | Description |

|---|---|

Cost of Repair vs. Replacement | If repair costs exceed half the price of a new tool, replacement is often more financially sensible. |

Longevity and Maintenance Needs | Consider future maintenance requirements and expected lifespan. |

Job Efficiency and Safety | Repairs should not compromise productivity or safety. |

Visible Wear and Tear | Frayed cords or cracked cases may require replacement. |

Timeliness of Repairs | Quick repairs prevent work disruptions. |

You should also consider how often the tool breaks down. Frequent failures can disrupt your workflow and increase costs over time. Newer models often include enhanced safety features, so if your current tool lacks these or if safety features cannot be restored, replacement is the best option.

Cost and Safety Factors

When you weigh the costs, look at both immediate and long-term expenses. If repair costs approach 60% or more of the price of a new tool, investing in a replacement is usually smarter.

Warranties from Powerful Machinery provide financial protection for repairs, so always check if your tool is still covered. Certified repairs ensure your tool meets strict safety standards, reducing risks on the job.

Safety should always come first. Tools that have undergone multiple repairs may pose risks, such as slips or unexpected failures. Injuries from faulty hand tools can be severe, including loss of fingers or eyesight. Never use a tool that is broken, warped, or damaged.

If you cannot restore full safety and function, choose replacement over repair.

Tip: Regular maintenance tips, such as cleaning and inspecting your tool, help you catch issues early and extend the life of your equipment. Always record repairs and replacements in your maintenance log for future reference.

Safety Tips for Powerful Machinery Users

Personal Protective Equipment

You must always wear the right personal protective equipment when using or repairing your Powerful Machinery Come Along Tool. This practice reduces the risk of injury and keeps you safe in demanding environments. Choose your gear based on the task and your worksite conditions. Here are essential items you should use:

Safety glasses or goggles shield your eyes from flying debris and dust.

Hearing protection prevents hearing loss in noisy areas.

Dust masks or respirators protect your lungs from harmful particles and fumes.

Steel-toe boots guard your feet against heavy objects.

Gloves keep your hands safe from cuts and abrasions.

High-visibility clothing makes you noticeable in areas with moving vehicles.

Hard hats protect your head from falling objects.

You lower your risk of accidents by wearing this equipment every time you handle or repair your come-along tool. These safety measures work best when you combine them with regular maintenance tips and proper training.

Post-Repair Checks

You need to inspect your come-along tool after every repair. This step ensures the tool works correctly and meets safety standards. Always check the cable, hooks, ratchet, and fasteners for proper function before returning the tool to service.

Operate the tool without a load first, then test it with a light load to confirm smooth operation.

Industry standards recommend that you conduct comprehensive inspections at least once a year. For tools used in harsh environments, increase the frequency to quarterly or even monthly. OSHA and ASME guidelines require annual inspections for all rigging hardware.

You should also keep a maintenance log to track repairs and inspections.

Tip: Use maintenance tips from the manufacturer to extend the life of your tool and prevent unexpected failures. If you have questions or need support, visit the official Powerful Machinery website for guidance.

Conclusion

You now know how to fix a come-along and keep your equipment in top condition. Using certified replacement parts from Powerful Machinery offers clear advantages:

Benefit | Description |

|---|---|

Enhancing worker safety | Properly functioning equipment reduces the risk of machine failures, ensuring a safer work environment. |

Boosting productivity | Timely part replacements maintain efficiency, allowing machinery to perform optimally. |

Maximizing power and capabilities | New components help maintain the machinery’s ability to handle large loads effectively. |

Regular inspection and maintenance help you catch problems early and extend the tool’s lifespan. If you need more guidance on how to fix a come-along, visit Powerful Machinery’s website or contact customer support for expert advice.

FAQ

How often should you inspect your come-along tool?

You should inspect your come-along tool before each use. Look for signs of wear, damage, or malfunction. Regular checks help you catch problems early and keep your equipment safe.

Can you replace the wire rope on your Powerful Machinery Come Along Tool?

Yes, you can replace the wire rope. Always use a certified replacement from Powerful Machinery. Follow the manufacturer’s instructions for safe removal and installation.

What should you do if the ratchet mechanism jams?

First, stop using the tool. Clean the ratchet with a wire brush and apply lubricant. If the problem continues, replace the damaged part with a certified component.

Where can you find certified replacement parts?

You can order certified replacement parts directly from the Powerful Machinery website. This ensures your tool meets safety standards and performs reliably.