You rely on an electric chain hoist to handle lifting heavy loads with precision and efficiency. This lifting equipment uses an electric motor to move a chain and hook, making it one of the most trusted lifting devices in the industry today. Electric chain hoists account for 40% of the electric hoist market, supporting a wide range of sectors.

Industry | Market Share |

|---|---|

Manufacturing | Significant |

Construction | Primary consumer |

Warehousing | Fast-growth |

Logistics | Fast-growth |

Mining | Notable user |

Oil and Gas | Notable user |

Public Works | Notable user |

Powerful Machinery stands out as a leader, providing certified solutions that ensure safety and reliability for your toughest lifting challenges.

Key Takeaways

Electric chain hoists improve efficiency by lifting heavy loads quickly, reducing physical strain, and increasing productivity.

Safety features like limit switches and emergency stops are essential for preventing accidents and ensuring reliable operation.

Regular inspections and maintenance extend the lifespan of electric chain hoists, ensuring they operate safely and effectively.

Choosing the right hoist involves evaluating load capacity, duty cycle, and environmental conditions to match your specific needs.

Powerful Machinery offers tailored electric chain hoist solutions, ensuring you find the right equipment for your industrial applications.

What Is an Electric Chain Hoist?

Definition and Purpose

You use an electric chain hoist to lift and lower heavy loads with the help of an electric motor. This device features a chain and a hook, which work together to move materials safely and efficiently. Electric chain hoists play a vital role in manufacturing, construction, and warehousing.

You can operate these hoists with a simple push-button pendant or remote control, making them easy to use and reducing physical strain. The main purpose of an electric chain hoist is to improve productivity and safety in environments where you need to move heavy objects regularly.

Tip: You can rely on electric chain hoists to handle repetitive lifting tasks, which helps prevent workplace injuries and increases operational efficiency.

Comparison to Manual and Pneumatic Hoists

You may wonder how electric chain hoists compare to manual and pneumatic hoists. Manual hoists require you to use physical force, which can be tiring and slow. Pneumatic hoists use compressed air, offering higher lifting capacities and faster speeds.

Electric chain hoists provide a balance between ease of use and lifting power. You get reliable performance for most industrial tasks.

Here is a comparison of maximum load capacities:

Hoist Type | Maximum Load Capacity |

|---|---|

Manual Hoists | Up to 10 tons |

Electric Chain Hoists | Up to 10 tons (often less than manual) |

Pneumatic Hoists | Up to 60 tons |

Electric chain hoists suit most daily lifting needs, while pneumatic hoists handle extremely heavy loads.

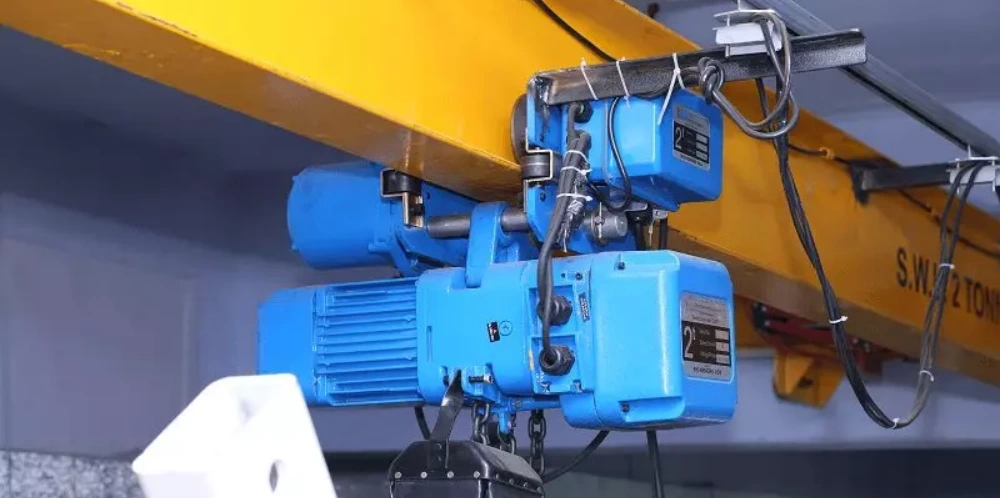

Integration with Overhead Cranes

You can integrate electric chain hoists with overhead cranes to streamline your material handling process. This combination allows you to move loads across large areas with minimal effort. You benefit from silent operation, versatility, and increased efficiency.

Electric chain hoists reduce the challenges of lifting and transporting heavy items, making your workflow smoother.

Advantages | Disadvantages |

|---|---|

Affordable, silent in operation, and versatile. | Risk of electrical shock due to careless operation. |

Durable for lifting heavy objects. | Dependency on electricity; power outages disrupt work. |

Reduces issues of lifting and moving heavy loads. | Limitations in lifting capacity and height. |

Increases production and reduces overhead costs. | |

Higher efficiency and capacity. | |

Easier transport between locations. |

You should always follow safety guidelines when using electric chain hoists with overhead cranes. This practice helps you avoid electrical hazards and ensures reliable operation.

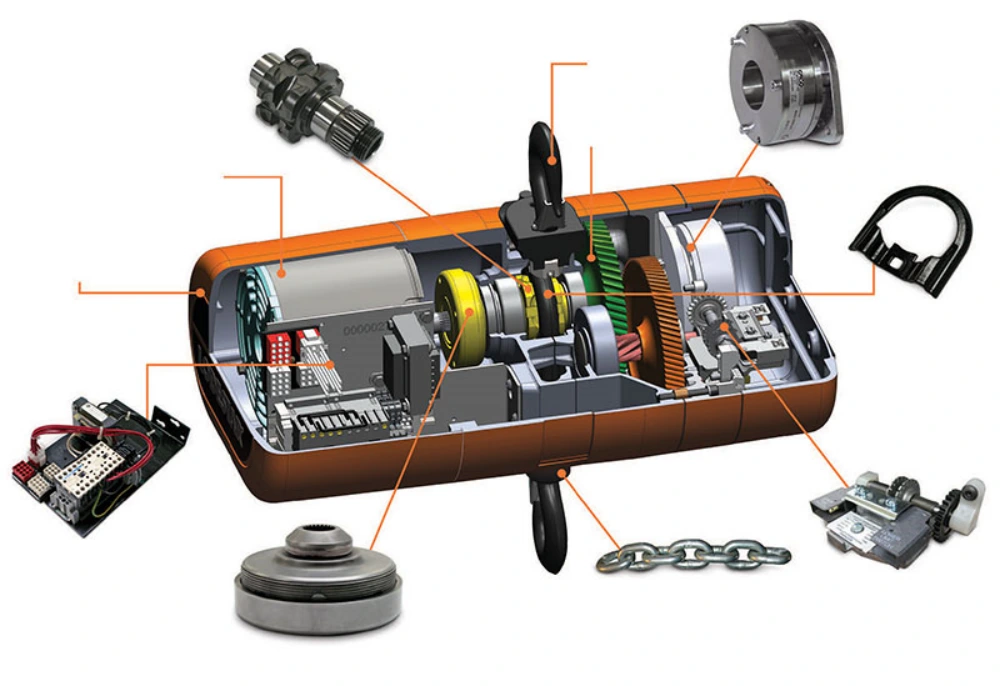

Main Components of Electric Chain Hoists

Understanding the key components of an electric chain hoist helps you operate your equipment safely and efficiently. Each part plays a vital role in the overall performance and reliability of your lifting system.

Motor and Gearbox

You rely on the motor-driven chain system to provide the power needed for lifting and lowering heavy loads. The motor converts electrical energy into mechanical force, while the gearbox manages speed and torque. High-quality motors ensure consistent performance, even under demanding conditions.

The gearbox works with the motor to deliver smooth and controlled movement, which is essential for precise load handling.

Note: A well-maintained motor and gearbox extend the lifespan of your electric hoist with remote control and improve lifting accuracy.

Load Chain and Hook

The load chain and hook serve as the core load-bearing components. Manufacturers use high-strength alloy steel for the chain, which resists stress and wear. You benefit from corrosion-resistant coatings like zinc plating, which enhance durability and maintain quality over time.

The hook, often made from heat-treated alloy grades, secures the load and ensures safe lifting.

Material Type | Description |

|---|---|

Load Chain | High-strength alloy steel, designed for stress |

Alloy Grades | Heat-treated high-tensile steels for enhanced strength |

Durability | Corrosion-resistant coatings like zinc plating |

Braking System

You depend on the braking system to keep loads secure during operation. The holding brake keeps the load stationary when the motor is not running. The controlled brake regulates the speed of lowering, preventing overload and enhancing safety. These features protect both the operator and the equipment.

Holding the brake keeps the load in place.

Controlled brake manages lowering speed for safe operation.

Controls and Limit Switches

You operate the electric hoist with remote control for convenience and safety. Controls allow you to lift, lower, and position loads with precision. Limit switches prevent overtravel, protecting both the hoist and the load.

Industry standards, such as OSHA and ASME, require overtravel limit switches and independent upper limit switches to prevent accidents.

Source | Requirement |

|---|---|

OSHA 1910.179(g)(5)(iv) | Over-travel limit switch in the hoisting direction |

ASME B30.2 and B30.16 | Prevent exceeding the upper limit of travel |

You should always check these components before each use to ensure safe and reliable operation. The features built into modern electric hoists with remote control make lifting tasks easier and safer, while maintaining high quality and performance.

How an Electric Chain Hoist Works?

Understanding how an electrical chain hoist works helps you operate your equipment safely and efficiently. You rely on a series of coordinated steps and specialized components to lift and lower heavy loads with precision. Let’s break down the process into clear stages.

Power Input and Activation

You start the operation by connecting the electric chain hoist to a suitable power supply. Most industrial models use single-phase or three-phase AC power. You must ensure the electrical requirements match the manufacturer’s specifications. Proper grounding of the hoist and trolley system protects you from electrical hazards.

Tip: Always inspect the power connections and grounding before activating the hoist to prevent accidents.

Once you connect the power, you activate the hoist using a pendant control or remote. When you press the “up” or “down” button, the electric motor receives the signal and begins to operate. The motor’s rotation passes through a gearbox, which reduces speed and increases torque.

This process provides the force needed for the lifting mechanism to move heavy loads smoothly.

Step-by-step activation process:

Mount the electric chain hoist securely to an overhead support structure.

Attach the load to the lower hook using proper rigging hardware.

Connect the hoist to the power supply and ground the system.

Adjust limit switches to prevent over-travel.

Test the brake system and controls for correct function.

Use the control device to activate the motor and begin lifting or lowering.

Lifting and Lowering Process

During the lifting process, you use the control pendant or remote to manage the direction and speed of the load. The electric motor powers the gearbox, which drives the chain sprocket. As the sprocket turns, it moves the load chain either upward or downward, depending on your input.

Component | Function |

|---|---|

Motor | Provides the mechanical force for lifting and lowering. |

Gearbox | Reduces motor speed, increases torque, and ensures smooth movement. |

Chain | Lifts and lowers the load securely, designed for specific applications. |

Hook | Attaches the load to the chain, providing a secure grip. |

Control Mechanism | Allows you to manage the hoist’s movement effortlessly. |

Chain Stripper | Prevents the chain from tangling or jamming. |

Chain Guide | Directs the chain’s movement for smooth operation. |

Suspension Method | Ensures stability and proper functioning of the hoist. |

Variable Frequency Drive | Regulates motor speed for precise control. |

Rotary Limit Switch | Stops the hoist at pre-set limits, preventing overloading. |

You benefit from features like chain guides and chain strippers, which prevent tangling and ensure a smooth lifting mechanism. The rotary limit switch automatically stops the hoist at preset points, protecting both the equipment and the load.

You should always keep the load path clear and never exceed the rated load limit during operation.

Note: Before lifting any load, perform a no-load test to check basic functions. You can also conduct static and dynamic load tests to verify strength and stability.

Braking and Load Holding

You depend on the braking system to maintain control and safety during operation. The brake system manages load lowering and positioning, preventing unintended movements.

Most electric chain hoists use electromagnetic brakes that engage automatically when you release the control button. This feature ensures the load remains securely held, even if you lose power or activate an emergency stop.

Key load-holding features:

The emergency stop button halts operation instantly.

The electromagnetic brake secures the load during power loss.

Fail-safe brake designs use DC for enhanced security.

You can trust the electric chain hoist to hold the load safely in place, even during unexpected interruptions. Regularly test the brake system and inspect all safety features to maintain reliable operation.

Safety Reminder: Always inspect the hoist before each use and follow manufacturer guidelines for maintenance. Proper operation and regular checks help prevent accidents and extend the lifespan of your equipment.

By understanding how an electric chain hoist works, you gain confidence in managing heavy loads with precision and safety. Each component plays a vital role in the lifting mechanism, ensuring smooth operation and secure load handling throughout every stage.

Safety Features of Electric Chain Hoists

Electric chain hoists deliver reliable lifting, but you must understand their safety features to ensure user safety and protect your investment. Powerful Machinery designs every hoist to meet strict safety and performance standards, giving you confidence in demanding environments.

Braking and Overload Protection

You depend on advanced braking systems to keep loads secure during operation. The holding brake automatically engages when you release the control, preventing accidental drops. Overload protection is another critical safety feature.

Modern electric chain hoists use several mechanisms to prevent equipment failure and maintain improved safety:

Mechanism Type | Function Description |

|---|---|

Automatic Stop | Stops the hoist when the load exceeds safe limits. |

Thermal Relay | Monitors the motor’s temperature to prevent overheating. |

Slip Clutch Mechanism | Disengages when the load is too heavy to prevent damage. |

These safety features work together to protect both the operator and the equipment. You should always follow safety protocols and never exceed the rated load.

Limit Switches and Emergency Stops

Limit switches serve as essential safety measures. They prevent the chain from moving beyond safe operational limits, reducing the risk of accidents. You should not rely on limit switches as the primary stopping mechanism. Instead, use them as a backup while manually controlling the hoist’s movement.

Emergency stop buttons allow you to halt operation instantly in unexpected situations. These features support user safety and help you respond quickly to emergencies.

Tip: Regularly test limit switches and emergency stops as part of your safety protocols.

Remote Operation and Operator Safety

Remote operation enhances safety features by allowing you to control the hoist from a safe distance. You reduce exposure to moving parts and hazardous areas. Powerful Machinery’s electric chain hoists include waterproof remote controls and trip switches, which further improve safety.

You should always inspect controls and cables before each use. Routine maintenance and inspection help you maintain safety and performance standards.

Certification | Region | Key Standards/Requirements |

|---|---|---|

ASME | North America | ASME B30.16 for Overhead Hoists includes design factors, hook requirements, braking systems, and markings. |

CE Mark | Europe | Compliance with EU safety directives requires a Declaration of Conformity. |

EAC Mark | Eurasian Economic Union | Mandatory conformity symbol for sthe afety of machinery and equipment. |

ISO | Global | Quality management systems, e.g., ISO 9001 for manufacturing processes. |

National Standards | Various | Standards like DIN (Germany) and BS (UK), harmonized with European standards. |

You should schedule regular inspections and maintenance to keep all safety features in optimal condition. This practice ensures your equipment continues to meet safety and performance standards.

Benefits of Electric Chain Hoists

Efficiency and Speed

You experience significant benefits when you use electric chain hoists for material handling. These devices deliver faster lifting and lowering speeds compared to manual alternatives. You save time on every lift, which increases productivity in your workspace.

You do not need to exert physical effort, so you minimize fatigue and reduce the risk of injury. Electric chain hoists excel in heavy and repetitive tasks, making them ideal for busy industrial environments. You gain precise control over load movement, which ensures smoother and more accurate positioning.

This efficiency is one of the main reasons why choose an electric chain hoist for your operations.

Electric chain hoists provide rapid lifting and lowering.

You avoid physical strain, which improves workplace safety.

You achieve consistent results, even with frequent use.

Tip: You can handle more tasks in less time, which helps your business stay competitive.

Precision and Safety

You benefit from advanced features that enhance precision and safety. Electric chain hoists often include integrated load beam scales, which allow you to weigh payloads accurately. Adjustable mechanical brakes give you multi-level stopping points, so you can position loads exactly where you need them.

Monitoring electrical limits prevents overheating and overload, protecting both you and your equipment. Magnetic overload relays and emergency stop switches add extra layers of safety, ensuring immediate response in critical situations.

Feature | Benefit |

|---|---|

Integrated load beam scales | Accurate payload weighing for precise load handling. |

Adjustable mechanical brakes | Multi-level stopping points for exact positioning. |

Monitoring electrical limits | Prevents overheating and overload, improving safety. |

Magnetic overload relay | Protects equipment and users from overheating. |

Emergency stop switch | Immediate power cut-off for worker safety. |

You see why choose an electric chain hoist when you need reliable performance and enhanced safety in your lifting operations.

Cost Savings and Durability

You realize long-term benefits with electric chain hoists due to their durability and cost-effectiveness. Although the initial purchase price may be higher, you save money over time. Electric chain hoists reduce labor costs because they operate quickly and efficiently.

You also benefit from lower maintenance costs, as these hoists are built to last and require fewer repairs. Less downtime means you keep your operations running smoothly.

Higher-quality electric chain hoists offer better value over their lifespan.

You spend less on maintenance and repairs.

You reduce labor expenses by streamlining lifting tasks.

Note: The average lifespan of an electric chain hoist often exceeds other hoist types, making it a smart investment for your business.

You gain multiple benefits when you choose electric chain hoists, including efficiency, precision, safety, and cost savings. These advantages make electric chain hoists a preferred solution for modern industrial environments.

Industrial Applications of Electric Hoist

Manufacturing and Warehousing

You see electric hoist systems at the heart of industrial material handling in manufacturing and warehousing. These industries that rely on electric chain hoists demand reliable lifting for raw materials, components, and finished goods.

You use electric hoist equipment to move parts through production lines and maintain machinery.

In warehousing, electric hoist solutions streamline logistics, improve throughput, and maximize storage capacity. You benefit from user-friendly controls, which reduce training time and minimize errors. The speed of operation allows you to lift heavy loads quickly, enhancing workflow and safety.

Industrial Sector | Applications | Specific Requirements |

|---|---|---|

Manufacturing | Lifting raw materials and components | Must be mounted securely, equipped with limit switches, and have thermal overload protection. |

Automotive Assembly | Assembling vehicle parts | Requires precise control and safety features to prevent accidents during operation. |

Logistics | Moving goods in warehouses | Needs to be compatible with overhead trolley systems for efficient horizontal movement. |

Maintenance | Repairing heavy machinery | Should have emergency stop controls and easy access for maintenance and lubrication. |

Electric hoist systems enhance safety by reducing manual labor.

You improve efficiency and reduce material damage with precise lifting.

You organize storage areas and facilitate loading and unloading tasks.

Construction and Mining

You encounter unique challenges when using electric hoist equipment in construction and mining. These industries that rely on chain electric hoists require robust solutions for lifting building materials, machinery, and ore. You must address noise levels, load capacity limits, and the need for skilled technicians.

Electric hoist models built for harsh environments withstand dust, moisture, and extreme temperatures. You follow manufacturer guidelines to avoid mechanical failure and invest in training programs to ensure safe operation.

Challenge | Description | Solution |

|---|---|---|

Noise During Operation | It can exceed 85 decibels, risking hearing damage. | Invest in noise reduction measures or protective gear for workers. |

Limited Load Capacity | Can handle up to 20 tons, but less than wire rope hoists. | Strict adherence to manufacturer guidelines to avoid mechanical failure. |

Complexity of Repairs | Requires specialized knowledge for troubleshooting. | Ensure access to trained technicians to minimize downtime. |

Dependence on Electrical Power | Requires a consistent power supply, unsuitable for remote locations. | Some models offer battery backups at an added cost. |

Skilled Labor Shortages | Operation and maintenance require trained personnel. | Address labor shortages through training programs to ensure safety and efficiency. |

Durability in Harsh Conditions | Built with robust materials to withstand dust, moisture, and temperature. | Use specialized equipment designed for harsh environments to enhance durability. |

Note: Electric hoist systems in foundries have a 20% longer lifespan than pneumatic alternatives, according to ASME.

Marine, Transportation, and Cargo Handling

You rely on electric hoist technology for industrial material handling in the marine, transportation, and cargo sectors. These industries that rely on electric chain hoists use electric hoist systems to move containers, ship components, and heavy goods. You operate maritime cranes daily to load and unload cargo at ports and shipyards.

On ships, electric hoist equipment helps you transfer goods and place equipment on the seabed. You depend on robust construction and waterproof controls to ensure safe operation in challenging environments.

Application Area | Description |

|---|---|

Marine and Shipbuilding | Electric hoists are used to handle cargo, containers, and ship components in shipyards and ports. |

On-Ship Cranes | These cranes assist in moving heavy goods around the ship or to another vessel. |

Shipyard Operations | Towering cranes in shipyards are essential for moving cargo to and from ships. |

You improve workflow and safety with electric hoist systems in marine and transportation.

You handle cargo efficiently, reducing downtime and increasing productivity.

You meet the demands of modern industry with reliable electric hoist solutions.

Powerful Machinery Electric Chain Hoist Solutions

You need reliable lifting equipment for demanding industrial environments. Powerful Machinery stands out as an electric hoist manufacturer with over 20 years of experience. You benefit from certified products, advanced engineering, and tailored solutions for your specific needs.

HHSY Electric Chain Hoist

You choose the HHSY Electric Chain Hoist when you need efficient lifting in tight spaces. This model features high-quality components that ensure durability and superior performance. Modern technology reduces maintenance costs and boosts efficiency.

You operate the hoist easily with a user-friendly control panel. Safety features include overload protection, an emergency stop button, and limit switches to prevent accidents. The compact design saves floor space and improves workspace efficiency.

Drop forged steel suspension and load hooks receive heat treatment for extra strength.

The energy-saving motor uses an asbestos-free brake system.

Alloy steel chain is surface hardened for strength and wear resistance.

Limit switch devices prevent the load chain from running out.

You trust this electric hoist manufacturer to deliver solutions that fit your workspace and safety requirements.

Electrical Chain Hoist (DHS Series)

You rely on the DHS Series for heavy-duty lifting in factories, warehouses, and construction sites. This model offers advanced technology, including a disc brake motor and planetary gearboxes for enhanced performance. The sturdy design supports high load capacity and durability in harsh environments.

Safety features like limit switches and robust construction protect your team and equipment.

Hoist Series | Load Capacity | Design Type | Suitable Applications | Performance Features |

|---|---|---|---|---|

DHS | Heavy-duty | Sturdy | Factories, warehouses, construction sites | Advanced technology, disc brake motor, planetary gearboxes |

You select this electric hoist manufacturer for reliable performance in demanding settings.

Chain Electric Hoist (DHP Series)

You use the DHP Series when you need a versatile and compact lifting solution. This model suits various industries and offers easy installation. The lightweight design ensures durability and minimal wear. You operate the hoist remotely, improving workflow and safety.

Built-in safety features, such as trip switches and reliable braking systems, protect your operations.

Note: Powerful Machinery meets international safety and quality standards. You benefit from products certified by ISO, CE, and SGS.

Certification | Description |

|---|---|

ISO | International safety standards |

CE | European quality assurance |

SGS | Independent product testing |

You work with an electric hoist manufacturer that provides customization and supports diverse industry applications.

Selecting the Right Electric Hoist

When you start choosing the right hoist for your application, you need to evaluate several critical factors. Powerful Machinery offers expert support and customization services to help you make the best decision for your operational needs.

Load Capacity and Duty Cycle

You must determine the maximum weight you plan to lift. Select a hoist with a load capacity slightly above your heaviest load to ensure safety and efficiency. Consider the duty cycle, which indicates how long the hoist can operate without overheating.

If you run continuous or heavy-duty operations, choose a model with a higher duty cycle rating. This approach helps you avoid downtime and extends equipment life.

Identify the heaviest load you will lift.

Choose a hoist with a duty cycle suitable for your lifting frequency.

Match the hoist’s load capacity to your operational intensity.

Lift Height and Headroom

You need to measure the vertical distance between the lifting point and the highest position the hoist must reach. In areas with limited headroom, select a compact hoist design. Powerful Machinery’s HHSY Electric Chain Hoist is ideal for tight spaces.

Always check for obstructions such as HVAC systems or lighting fixtures that may affect installation.

Factor | Recommendation |

|---|---|

Lift Height | Measure the required vertical distance |

Headroom | Choose compact models for low spaces |

Obstructions | Inspect for overhead barriers |

Power Supply and Controls

Verify that the hoist matches your facility’s voltage and phase requirements. You should select controls that enhance precision and safety, such as pendant or remote options.

Waterproof remote controls and advanced safety features are available from Powerful Machinery. Always confirm power compatibility before installation.

Check voltage and phase compatibility.

Select control options that suit your workflow.

Prioritize integrated safety features.

Environmental and Installation Factors

Assess your operating environment. For outdoor or harsh conditions, choose hoists with high IP ratings and weather-resistant enclosures. Consider optional rain covers or heaters for humid or cold climates.

Match the hoist to your support structure, such as I-beams or gantry cranes, and verify beam capacity. Routine inspection and maintenance help ensure longevity.

Tip: Powerful Machinery provides custom-engineered solutions for specialized environments. You can request tailored features to meet unique installation challenges.

Buyer’s Checklist

When choosing the right hoist for your application, use this checklist:

Confirm load capacity and duty cycle.

Measure lift height and headroom.

Verify power supply and control options.

Assess environmental and installation needs.

Consult Powerful Machinery for customization and support.

Conclusion

You now understand how an electric chain hoist operates, from its motor and chain system to advanced safety features. Choosing the right model boosts efficiency, safety, and cost savings in your operations. Powerful Machinery offers certified, reliable solutions for every industry.

Take the next step: Review your lifting needs and contact Powerful Machinery for expert guidance. Visit qdpowerful.com to explore tailored electric chain hoist options.

FAQ

What is the typical lifespan of an electric chain hoist?

You can expect a high-quality electric chain hoist to last 10 to 15 years with proper maintenance. Regular inspections and timely repairs help extend its service life.

How often should you inspect your electric chain hoist?

You should inspect your hoist before each use. Schedule a thorough inspection every three months. Always follow the manufacturer’s maintenance guidelines for best results.

Can you use an electric chain hoist outdoors?

Yes, you can use an electric chain hoist outdoors. Choose a model with weather-resistant features and proper IP ratings. Always protect electrical components from rain and moisture.

What should you do if your hoist stops working during operation?

First, check the power supply and control connections. Inspect the emergency stop and limit switches. If the issue persists, contact a qualified technician for assistance.