You can complete pallet jack adjustment by carefully modifying the handle position and checking the lift height to match your operational needs. Proper adjustment ensures you maintain safety and efficiency every time you use the equipment.

Always follow the manufacturer’s instructions and use the right tools for every adjustment. Powerful Machinery recommends that you inspect your pallet jack regularly to keep it reliable and easy to operate.

Key Takeaways

Adjust your pallet jack regularly to ensure safe and efficient operation. Monthly checks help catch issues early.

Use the right tools for adjustments, including wrenches and screwdrivers. Proper tools make the process easier and more effective.

Prioritize safety by wearing protective gear and ensuring a clear workspace. This reduces the risk of accidents during adjustments.

Follow step-by-step instructions for handling and lift height adjustments. Clear guidance helps maintain optimal performance.

Regular maintenance, like lubrication and inspections, extends the life of your pallet jack and prevents costly repairs.

Tools for Pallet Jack Adjustment

Essential Tools List

You need the right tools to adjust your pallet jack efficiently. For most handle and lift height adjustments, gather these items:

Adjustable wrench

Flathead and Phillips screwdrivers

Pliers

Measuring tape

Lubricating oil

These tools help you tighten bolts, adjust the handle, and set the correct lift height. You may also need a clean rag to wipe away dirt or grease from moving parts. If you use a Powerful Machinery pallet jack or truck, you will notice that maintenance is straightforward.

The advanced technology and durable materials in these models mean you spend less time on upkeep. You can expect fewer repairs and less frequent adjustments compared to other brands. This design focus allows you to keep your equipment running smoothly with minimal effort.

Tip: Always keep your tools organized in a toolbox. This practice saves time and reduces the risk of losing important items during maintenance.

Safety Gear and Preparation

Before you begin any adjustment, prioritize safety. Wear protective gloves to shield your hands from sharp edges or pinch points. Safety glasses protect your eyes from debris or hydraulic fluid. Choose sturdy footwear to prevent injuries if you drop a tool or part.

Make sure the pallet jack sits on a flat, stable surface before you start. Clear the area of obstacles and ensure good lighting. Disconnect the hydraulic system if your model allows, and never work under a raised load. These steps help you avoid accidents and keep your workspace secure.

Note: Powerful Machinery’s pallet jacks and trucks are built to withstand heavy use, but following proper safety procedures ensures long-term reliability and operator well-being.

Step-by-Step Pallet Jack Adjustment

Proper pallet jack adjustment ensures your equipment operates safely and efficiently. You can follow these step-by-step instructions to adjust the handle and set the pallet truck lift height for optimal performance.

Powerful Machinery’s ergonomic design and advanced hydraulic system make these adjustments straightforward, even for new operators.

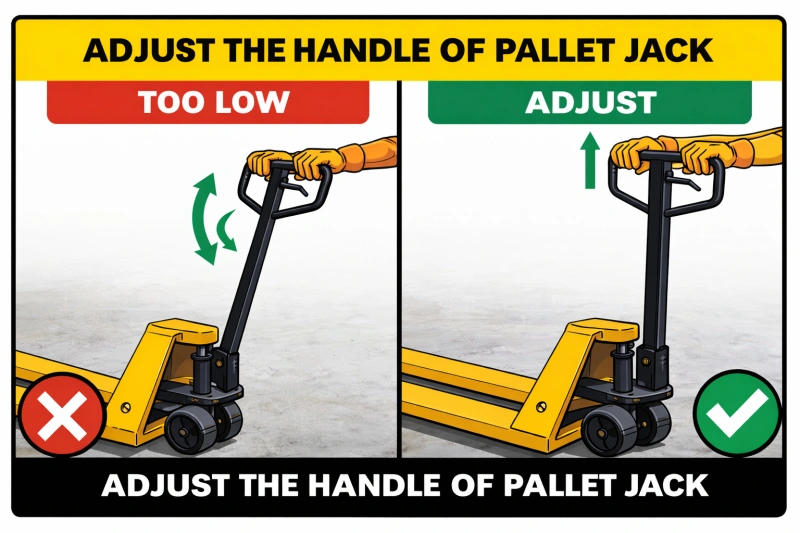

Adjust the Handle

You need to adjust the handle to maintain smooth operation and reduce operator fatigue. Powerful Machinery’s pallet jacks feature adjustable handles and easy-to-use controls, which help you work comfortably during long shifts. Follow these steps to adjust the handle:

Gather your tools: hammer, Phillips screwdriver, flathead screwdriver, pin punch, pliers, and a 10mm wrench.

Place the pallet jack on a flat surface. Make sure the forks are lowered and the area is clear.

Locate the adjustment points near the base of the handle and the release pedal.

Loosen the 10mm lock nut on the adjustment screw found on the release pedal.

Back out the set screw until it no longer touches the release pin.

Move the handle lever to the pump position (lever down). Lightly pump the handle to raise the jack.

Pull the lever into the neutral position. Turn the set screw while pumping the handle until it stops.

Tighten the jam nut with your wrench to lock the adjustment in place.

Set the handle lever to the lower position and pump the handle to lower the jack.

Return the handle to the neutral position. Pump the handle to confirm the jack does not lower in neutral.

Tip: Adjustable handles on Powerful Machinery pallet jacks help reduce strain and improve comfort. The 3-position control handle allows for versatile operation, making it easier to adapt to different tasks.

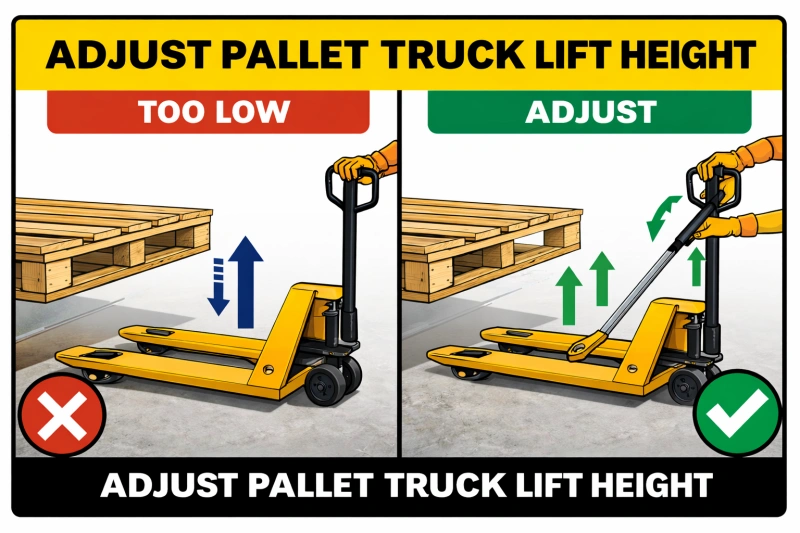

Pallet Truck Lift Height

Setting the correct pallet truck lift height is essential for safe and efficient material handling. The hydraulic system in Powerful Machinery pallet jacks provides smooth and controlled lifting, making height adjustments simple. Use these steps to achieve the optimal lift height:

Safety comes first. Wear gloves and safety glasses. Place the pallet truck on a stable, flat surface and engage the brakes.

Inspect the hydraulic pump and cylinders located under the forks. These components control the lift height.

Identify the adjustment points. Look for bolts or nuts that regulate the hydraulic lift mechanism.

Use your wrenches to loosen or tighten these adjustment points. Adjust until the forks reach your desired lift height.

Measure the height that the forks can be raised. Confirm the lift height matches your operational requirements.

Test the lift by raising and lowering the forks several times. Check for smooth operation and listen for unusual noises.

Inspect the hydraulic system for leaks or signs of wear. Make sure all adjustment points are secure.

Repeat the process if you need to fine-tune the lift height for specific pallets or tasks.

Note: Powerful Machinery offers customization options for hand pallet trucks. You can request larger or longer forks to achieve the optimal lift height for your unique needs.

Safety and Training Reminders

Keep your feet away from under the pallet jack to prevent injuries.

Never exceed the recommended lift height or load capacity.

Move loads slowly and always check for obstacles in your path.

Inspect the wheels and hydraulic system before each use.

Provide regular training for all staff responsible for pallet jack adjustment and maintenance.

Course Title | Description |

|---|---|

Manual Pallet Jacks Safety: Best Practices Training Course | Covers operation, maintenance, and safety guidelines for manual pallet jacks. |

Beginner Pallet Jack Training: Step-by-Step Safety Guide | Focuses on safe operation, equipment inspection, and OSHA compliance. |

Pallet Jack Safety Training and Certification | Online course for certification covering safe operating procedures and accident prevention. |

By following these steps, you ensure your pallet jack adjustment process is safe, efficient, and tailored to your workplace. Powerful Machinery’s ergonomic handle design and advanced hydraulic system make every adjustment easier, helping you achieve the optimal lift height for any job.

Troubleshooting and Maintenance

Common Issues and Solutions

You may encounter several common issues during pallet jack adjustment or daily operation. Addressing these problems quickly helps you maintain safe and efficient performance.

Inconsistent lifting capacity often results from wear in the hydraulic system. This can make it difficult to lift heavy loads to the correct height.

Fork misalignment may occur after continuous use, making it hard to insert the forks at the right height into pallets.

Uneven or flat tires can cause vibrations and reduce traction, affecting your ability to lift and move loads smoothly.

A stiff or unresponsive hydraulic system usually points to low fluid levels or leaks, which can prevent the forks from reaching the desired height.

Jammed or stuck forks may result from debris or pallet damage, disrupting your workflow.

Excessive noise during lift or lowering often signals mechanical wear or a need to lubricate moving parts.

If the lift mechanism does not work properly, check the hydraulic pump for air bubbles or failure.

Wheels that do not move smoothly may have debris or misalignment, making it hard to reach the correct height.

When you notice hydraulic leaks, follow these steps for effective solutions:

Identify the source of the leak by visually inspecting the jack and removing the cover plate.

Check the bleeder valve, filler cap, screws, and pump handles for signs of leakage.

Replace damaged seals or O-rings to prevent further leaks.

Flush the system and refill with clean hydraulic fluid to restore optimal lift performance.

Tip: Addressing these common issues early prevents further damage and keeps your equipment operating at the correct height.

Maintenance Tips for Powerful Machinery Products

Regular maintenance ensures your Powerful Machinery pallet jacks and trucks deliver reliable lift performance and long service life. You should follow a structured schedule to maximize efficiency and safety.

Maintenance Practice | Description |

|---|---|

Daily Inspections | Check for visible damage, test the handle, and verify the hydraulic system. |

Lubrication | Lubricate moving parts weekly to reduce friction and wear. |

Brake and Wheel Checks | Inspect brakes and wheels to ensure smooth lift and safe operation. |

Seasonal Deep Maintenance | Clean pivot points and check the hydraulic system for leaks or wear. |

Proper Storage | Store in dry areas to protect the hydraulic system and maintain height. |

You should perform daily inspections before each shift. Every six months, inspect critical components, including the handle and hydraulic system. Schedule annual servicing with trained technicians for a comprehensive check. This routine helps you maintain the correct lift height and prevents unexpected breakdowns.

Manual pallet jacks from Powerful Machinery can last 10-15 years or more with regular maintenance. Electric models typically last 7-10 years, with battery replacements every 3-5 years. Always check the hydraulic system and lubricate moving parts to extend the lifespan of your equipment.

Note: Consistent maintenance reduces the risk of accidents, optimizes lift performance, and lowers repair costs. Make regular maintenance part of your safety culture.

Sourcing Parts and Support

Quality Parts from Powerful Machinery

When you need replacement parts for your pallet jack, always choose OEM components from Powerful Machinery. These parts fit your equipment perfectly and help maintain top performance.

Using OEM parts ensures that every component matches the original design, which boosts reliability and extends the life of your pallet jack. You avoid compatibility issues and keep your equipment running smoothly in busy warehouse environments.

You should regularly inspect your pallet jack for signs that a part needs replacement rather than repair. Look for these indicators:

Wear, leaks, or loose components on forks, wheels, or wiring

Chips, cracks, or debris on wheels

Hydraulic leaks or damage in the system

Bends, cracks, or deformities in the forks

Worn hydraulic seals

Damaged or worn wheels

Powerful Machinery offers a wide range of certified parts and accessories. The company holds global certifications such as ISO9001, TUV Rheinland, and OSHA, which means you can trust the quality and safety of every product.

You also benefit from an 18-month warranty on many models, covering the frame, hydraulic pump, forks, and handle mechanisms.

The availability of spare parts from Powerful Machinery helps you minimize downtime. You keep your operations running efficiently by having the right parts on hand and reducing maintenance delays.

Explore more about Powerful Machinery’s products and support:

When to Seek Professional Help?

Some issues require expert attention. If you notice persistent problems during pallet jack adjustment or operation, contact a certified technician. The table below highlights common scenarios where professional help is necessary:

Common Issue | Description |

|---|---|

Stuck Wheels | Wheels jam due to debris, worn bearings, or misalignment. |

Leaking Hydraulics | Damaged seals or faulty hydraulic parts need skilled repair. |

Malfunctioning Pump Handle | The faulty release valve affects the handle operation. |

Uneven Lifting | Hydraulic valve or piston misalignment causes uneven fork movement. |

You should also seek help if the lift mechanism does not work properly, such as difficulty raising or lowering loads. Professional support ensures safe repairs and keeps your equipment in peak condition.

Powerful Machinery’s customer support team stands ready to assist you with troubleshooting, parts sourcing, and technical guidance.

Conclusion

You can keep your pallet jack in top condition by adjusting the handle and setting the correct lift height. Regular maintenance and troubleshooting help you avoid costly repairs and extend equipment life.

Clean and lubricate moving parts to prevent wear.

Inspect wheels and tires often for best performance.

Use the handle correctly to ensure safe operation.

Powerful Machinery’s website offers checklists, inspection guides, and expert support for all your pallet jack needs.

FAQ

How often should you adjust your pallet jack?

You should check and adjust your pallet jack every month or after heavy use. Regular inspections help you catch issues early and keep your equipment safe and efficient.

What signs indicate your pallet jack needs adjustment?

Look for uneven lifting, difficulty moving the handle, or hydraulic leaks. If you notice the forks do not reach the correct height, adjustment is necessary.

Can you adjust the lift height on all pallet jacks?

Most manual pallet jacks allow lift height adjustment. Always check your user manual or consult Powerful Machinery’s support team for model-specific guidance.

Where can you find genuine replacement parts for Powerful Machinery pallet jacks?

You can order certified OEM parts directly from Powerful Machinery’s official website. This ensures compatibility and maintains your equipment’s performance.

Tip: Using genuine parts helps you avoid unexpected breakdowns and extends the life of your pallet jack.