To measure chain link size, start by identifying your chain type and focus on the wire diameter, which is the most important measurement. You can use calipers for the best accuracy, but a ruler or tape measure also works for basic checks.

Powerful Machinery supplies certified chains and accessories, making it easier to match your measurements. Always consult standard tables and calibration systems for reference. Accurate chain measurement and cutting help ensure compatibility with replacement chains and accessories.

Here are some common aspects to check:

Measurement Aspect Description Overall width of the chain The total width of the chain links. Diameter and width of roller The size of the roller components. Thickness of the plate The thickness of the chain’s plates. Overall height of the chain The total height of the chain links. Chain pitch Distance from the center of one pin to the next.

Key Takeaways

- Identify your chain type before measuring. Each type has unique features that affect measurement points.

- Use a digital caliper for the most accurate measurements of wire diameter, link width, and length.

- Always clean the chain before measuring to ensure accurate readings and remove any debris.

- Follow international standards like ISO 1704 for reliable measurements and compatibility with accessories.

- Consult with experts at Powerful Machinery for personalized advice and certified products to ensure safety and efficiency.

Chain Types

When you measure a chain, you first need to identify its type. Each chain type has unique features and measurement points. Here are the main types you will encounter, including those from Powerful Machinery:

- Standard Roller Chains

You often see these in machines and conveyors. They transfer power and come in many sizes. Their tensile strength ranges from 1,000 to 150,000 pounds. You measure the pitch, roller diameter, and width between inner plates. - Engineering Class Chains

These chains handle heavy loads and tough conditions. You find them in construction, mining, and marine industries. Powerful Machinery’s log boom chains fall into this group. For these, you measure the link diameter, length, and width. - Stud Link Chains

You use these in marine and offshore applications. Each link has a central stud for extra strength. Powerful Machinery’s marine stud link chains meet ISO 1704 standards. Measure the diameter of the link, the length, and the width. The stud in the middle affects how you measure the inside width. - Studless Anchor Chains

These chains do not have a central stud. They are flexible and easy to handle. Powerful Machinery’s studless anchor chains work well for anchoring ships. You measure the wire diameter, link length, and width. The absence of a stud makes the inside width easier to check. - Leaf Chains

These chains have interlocking plates. You see them in lifting equipment. Measure the plate thickness, width, and pin diameter. - Plastic Chains

These chains are lightweight and rustproof. Powerful Machinery’s plastic chains help with marking off areas or crowd control. You measure the link thickness, length, and width.

Tip:

Always check which measurement points matter most for your chain type. For example, stud link chains need careful measurement of the stud area, while plastic chains focus on link thickness and width.

| Chain Type | Key Measurement Points |

|---|---|

| Roller Chain | Pitch, roller diameter, inner width |

| Stud Link Chain | Link diameter, length, stud width |

| Studless Anchor Chain | Wire diameter, link length, and width |

| Log Boom Chain | Link diameter, length, width |

| Leaf Chain | Plate thickness, width, and pin diameter |

| Plastic Chain | Link thickness, length, width |

Understanding your chain type helps you measure it correctly and choose the right replacement or accessory. Powerful Machinery offers certified options for every application, ensuring you get the right fit every time.

Chain Dimensions

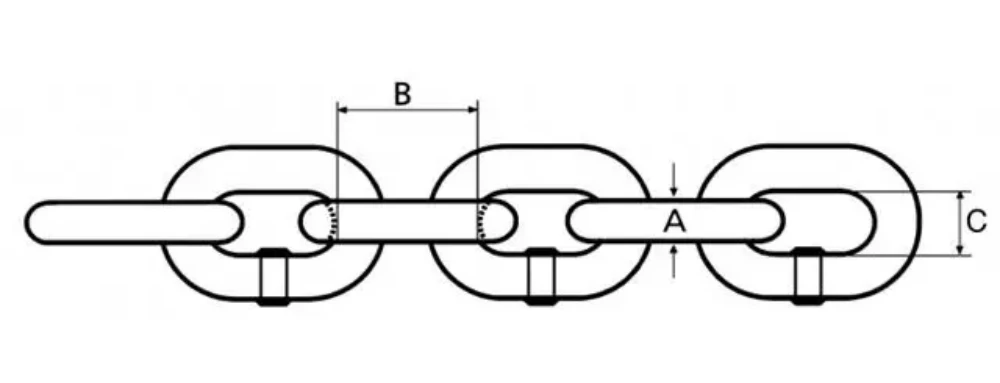

Understanding chain dimensions helps you select the right chain and ensures safe operation. You need to measure three main aspects: wire diameter, link width, and link length. Each chain type may require a slightly different approach, but the basic steps remain the same.

Wire Diameter

Wire diameter is the most important measurement for most chains. You measure this by finding the thickness of the metal used to form each link. Use a digital caliper or micrometer for the best accuracy. Before you measure, clean the chain to remove any coatings or debris.

Place the caliper across the thickest part of the wire and record the reading. Take measurements at several points along the chain to check for consistency.

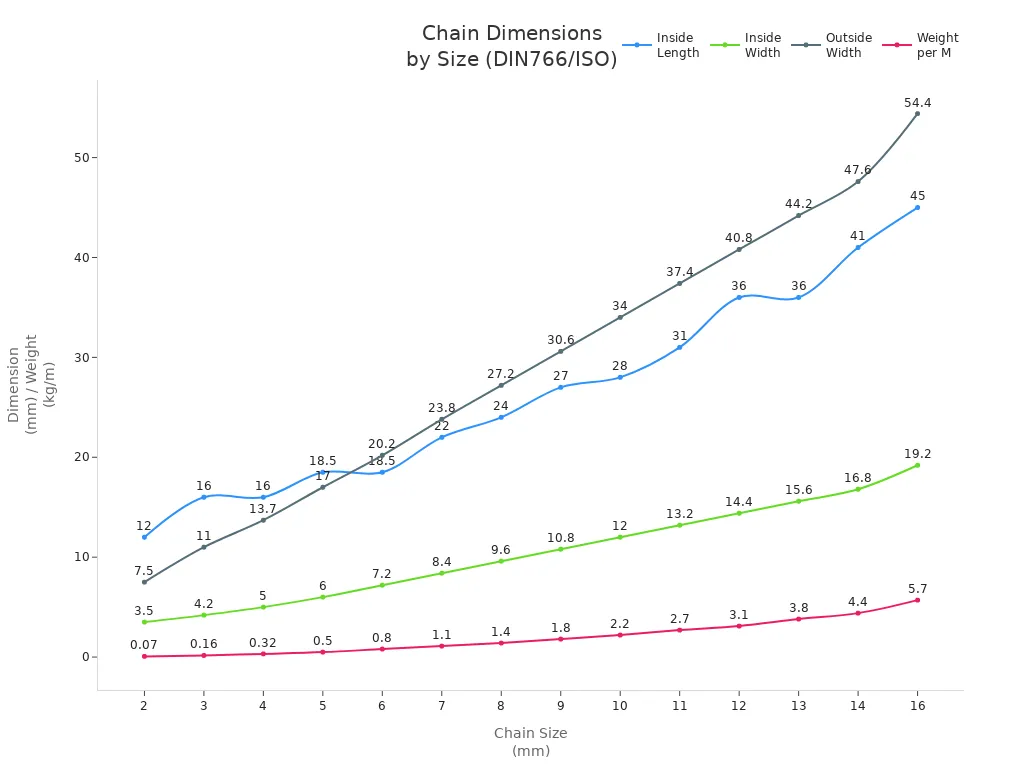

For example, Powerful Machinery’s studless anchor chains and stud link chains follow international standards like DIN 766 and ISO 1704. These standards define exact wire diameters for each chain size. The table below shows typical dimensions according to DIN 766 and ISO standards:

| SIZE | INSIDE LENGTH (mm) | INSIDE WIDTH (mm) | OUTSIDE WIDTH (mm) | WEIGHT PER M (kg) |

|---|---|---|---|---|

| 2 | 12 | 3.5 | 7.5 | 0.07 |

| 3 | 16 | 4.2 | 11 | 0.16 |

| 4 | 16 | 5 | 13.7 | 0.32 |

| 5 | 18.5 | 6 | 17 | 0.5 |

| 6 | 18.5 | 7.2 | 20.2 | 0.8 |

| 7 | 22 | 8.4 | 23.8 | 1.1 |

| 8 | 24 | 9.6 | 27.2 | 1.4 |

| 9 | 27 | 10.8 | 30.6 | 1.8 |

| 10 | 28 | 12 | 34 | 2.2 |

| 11 | 31 | 13.2 | 37.4 | 2.7 |

| 12 | 36 | 14.4 | 40.8 | 3.1 |

| 13 | 36 | 15.6 | 44.2 | 3.8 |

| 14 | 41 | 16.8 | 47.6 | 4.4 |

| 16 | 45 | 19.2 | 54.4 | 5.7 |

You can also see how these dimensions change with size in the chart below:

Tip: Always follow the standards for your chain type. This ensures your chain measurement and cutting process matches industry requirements.

Link Width

Link width tells you how wide each link is from side to side. You measure this by placing your caliper or ruler across the widest part of the link. For stud link and studless anchor chains, measure the inside width and the outside width.

For log boom chains, measure the width at the thickest point. For plastic chains, measure the width of the flat or round section.

Industrial standards define link width in several ways:

- Pitch: Distance from the center of one pin to the next.

- Side Plate Height: Measured inside and outside the chain.

- Thickness: Overall thickness of the link.

- Pin Diameter: Useful for non-standard chains.

- Roller Diameter: For roller chains, measure the bushing if there is no roller.

- Inner Width: Distance between the link plates.

- Overall Chain Width: Full width of the master link.

You often find that the width is about 5/8 of the chain pitch. For roller links, add twice the plate thickness to the nominal width to get the maximum width.

Note: Accurate link width measurement helps you choose compatible accessories and ensures smooth operation.

Link Length

Link length is the distance from one end of a link to the other, measured along the longest axis. For most chains, you measure the inside length. For stud link and studless anchor chains, measure from the inside edge of one end to the inside edge of the other. For log boom chains, measure the full length of the link.

For plastic chains, measure the straight distance from one end to the other.

ISO 1704 and similar standards set clear rules for measuring link length:

- Measure after applying and reducing the proof load to 10%.

- Select five links for every 27.5 meters of chain and measure their length.

- The maximum tolerance is +2.5%. If any group exceeds this, check the entire chain in overlapping groups of five links.

Tip: Always use the same method for every link to keep your chain measurement and cutting process consistent.

Special Considerations

Each chain type may need special attention:

- Studless Anchor Chains: Measure wire diameter, link width, and length. The absence of a stud makes the inside width easier to check. Powerful Machinery’s studless anchor chains meet ISO standards and are certified by RINA and BV.

- Stud Link Chains: Measure the diameter, length, and width. The central stud affects the inside width, so measure carefully around the stud. These chains follow ISO 1704 and are ideal for marine use.

- Log Boom Chains: Measure the diameter, width, and length at the thickest points. These chains are proof-tested and certified for safety.

- Plastic Chains: Measure the thickness, width, and length of each link. Use heavy-duty scissors or bolt cutters for cutting. These chains are non-load-bearing but perfect for marking and crowd control.

Powerful Machinery provides certified products that follow DIN766, ISO4565, and ISO 1704 standards. You can trust their chains for accurate sizing and reliable performance.

Always use the right tools and follow the standards for chain measurement and cutting. This ensures your chains fit perfectly and work safely in any application.

Chain Measurement and Cutting

Tools for Measurement

You need the right tools to get accurate results during chain measurement and cutting. The most reliable tool is a digital caliper. It gives you precise readings for wire diameter, link width, and length.

A micrometer also works well for measuring wire thickness. If you do not have these, a steel ruler or a tape measure can help with basic checks, but they may not match the accuracy of calipers.

- Digital Calipers: Offer high precision for all chain dimensions.

- Micrometers: Best for measuring wire diameter.

- Steel Rulers/Tape Measures: Useful for quick checks or when you need to measure longer chains.

- Chain Wear Tools: Quick and easy, but less accurate than calipers or the hanging method.

Tip: Remove the chain from the equipment for the most accurate measurement. Use a calibrated tape measure to check the full length. This method gives you the best results, though it may take more time.

Environmental factors can affect your measurements. High temperatures or humidity may change the size of metal links or cause condensation on your tools. Always measure in a stable environment and clean the chain before you start.

Measurement Techniques

You can follow a step-by-step process to ensure accurate chain measurement and cutting. Start by checking for any size markings on the side plates. If you see a stamped number, use it to identify the chain size. If not, measure the key dimensions yourself.

- Clean the chain to remove dirt or grease.

- Use a caliper to measure the wire diameter at several points.

- Measure the inside width by placing the caliper’s jaws between the inner sides of the link.

- Measure the link length from one end to the other, along the longest axis.

- For roller chains, measure the pitch by zeroing the caliper at the pin and checking the distance between two pins.

- Compare your measurements with the catalog or standard tables to confirm the chain size.

- For weldless chains, include any twists in your measurements.

Note: Always measure past the last usable link if you plan to cut the chain. This ensures you do not end up with a damaged or unusable link.

You should also check the chain’s condition. Look for signs of wear, corrosion, or deformation. These issues can affect both the measurement and the performance of the chain.

Cutting Chains

Cutting chains safely is an important part of chain measurement and cutting. The right tool depends on the chain’s material and grade. For most steel chains, you can use an angle grinder.

This tool cuts through almost any chain, including hardened steel. Always wear safety glasses and gloves when using power tools. Secure the chain before you start to prevent movement.

- Angle Grinders: Fast and effective for tough chains, but noisy. Use in a safe area.

- Hacksaws: Good for smaller or softer chains. They work well in quiet environments.

- Chain Breakers: Designed for bicycle or light-duty chains. They make clean cuts without damaging the links.

- Hydraulic Cutters: Best for industrial or very thick chains. These tools provide clean cuts with less effort.

Safety Reminder: Always stabilize the chain before cutting. Keep bystanders away from your work area.

The way you cut the chain affects its durability. Smooth cuts reduce surface roughness and help prevent cracks. This improves the fatigue life of the remaining links. If you need a custom length or special finish, Powerful Machinery offers chain measurement and cutting services.

Their products are built for durability and can be tailored to your needs.

You can trust Powerful Machinery for certified chains that meet international standards. Their team can help you select the right chain and provide guidance on safe cutting methods. Customization options ensure you get the perfect fit for your project.

Accessories and Support

Chain Markers

Chain markers help you identify and manage chains in industrial settings. You can use metal safety tags, colored links, or engraved plates to display important information.

These markers prevent misidentification and support workplace safety. Metal tags show critical safety details, which help your team follow regulations and avoid accidents. Durable tags stay readable over time, reminding everyone about safety protocols.

Metal safety tags warn workers and the public about hazards. They are required by law in many industries. You can use them to label hazardous areas or equipment, which reduces the risk of injuries.

Here is a table showing common chain types and their marker materials:

| Chain Type | Material | Applications |

|---|---|---|

| High Test Boomer Chain | Grade 43 Steel | Logging, binding, towing |

| Transport Chains | Grade 70 Steel | Tie-down loads on trucks |

| Stainless Steel Chains | Grade 43 Steel | Construction, trucking |

| Alloy Steel Chains | Grade 80 Steel | Overhead lifting |

| Grade 100 Chains | Grade 100 Steel | Heavy-duty lifting |

You can also find markers for roller chains, specialty chains, agricultural chains, engineering class chains, and leaf chains. These markers make chain management easier and safer.

Compatibility

You need accurate measurements to select compatible accessories and replacement chains. Matching the chain’s wire diameter, link width, and length ensures a proper fit. Always check the manufacturer of your chain and accessories.

If you use mixed systems, align the chain with the cassette and rear derailleur. Some chains have unique designs, so choose accessories that match your chain’s specifications.

- Match the manufacturer for best results.

- Check chain speed and number of cogs.

- Align the chain and accessories for mixed systems.

- Watch for proprietary designs that may not fit other brands.

Accurate measurements help you avoid compatibility issues and keep your equipment running smoothly.

Personalized Advice

You can get expert support from Powerful Machinery to help with chain selection and maintenance. Their customer care teams offer tailored assistance for your specific needs. You may receive on-site visits for direct support and quick solutions.

Parts warehouses near large job sites provide fast access to necessary components. The integrated digital ecosystem makes it easy to find and order the right parts online.

| Type of Support | Description |

|---|---|

| Dedicated Customer Care Teams | Experts provide tailored help for your needs. |

| On-Site Visits | Direct support at your location. |

| Strategically Placed Parts Warehouses | Quick access to parts near jobsites. |

| Integrated Digital Ecosystem | Seamless online experience for finding parts and services. |

| Personalized Online Experience | Interactions based on your preferences. |

Expert advice helps you evaluate chain specifications, consider environmental conditions, and plan for preventive maintenance. You can rely on Powerful Machinery for solutions that improve reliability and safety. If you have questions, reach out for personalized guidance and support.

Conclusion

Measuring and cutting chains starts with identifying your chain type, using accurate tools, and referencing standard tables. You reduce errors and improve safety by following calibration systems and regular inspection routines. Certified products from Powerful Machinery ensure reliable performance.

| Benefits of Certified Tools | How It Helps You |

|---|---|

| Traceable measurements | Early error detection, better accuracy |

| Calibration to standards | Reliable, consistent chain performance |

Stay proactive with maintenance and reach out to Powerful Machinery for expert support and certified solutions. Explore their full range to keep your operations safe and efficient.

FAQ

How do you measure the wire diameter of a chain link?

Use a digital caliper. Place it across the thickest part of the wire. Record the reading. Clean the chain first for accuracy. Repeat at several points to check for consistency.

What tools work best for measuring chain links?

Digital calipers give you the most accurate results. You can also use a micrometer for wire diameter. Steel rulers or tape measures help with quick checks, but they are less precise.

Why should you follow international standards when measuring chains?

International standards like ISO 1704 and DIN 766 ensure your measurements match industry requirements. You get reliable performance and safety. These standards help you choose compatible accessories and replacement chains.

Can Powerful Machinery help you select the right chain size?

Yes! You can contact Powerful Machinery for expert advice. Their team helps you match chain measurements to certified products. You get support for custom solutions and safe installation.