You use a chain hoist by selecting the right model, preparing your work area, operating with care, and maintaining the equipment for longevity.

Powerful Machinery delivers reliable chain hoists trusted in manufacturing, construction, warehousing, and shipbuilding. Safety and efficiency matter most in lifting operations.

Common applications include:

Manufacturing: Moving machinery parts

Construction: Lifting building materials

Warehousing: Organizing storage

Shipbuilding: Handling large components

Key Takeaways

Select the right chain hoist model based on your lifting needs. Manual hoists are portable and cost-effective, while electric hoists are ideal for heavy-duty tasks.

Always perform a thorough pre-use inspection of your chain hoist. Check for damage, ensure the load does not exceed capacity, and confirm all components are functioning properly.

Follow safety protocols during operation. Keep the area clear, communicate effectively with your team, and never exceed the hoist’s rated capacity.

Regular maintenance is crucial for safety and longevity. Clean, lubricate, and inspect your hoist frequently to prevent issues and ensure reliable performance.

Understand the specific lifting techniques for different loads. Use proper methods for awkward loads and coordinate multiple hoists for complex operations.

Chain Hoist Basics

What Is a Chain Hoist?

A chain hoist is a mechanical device that helps you lift and lower heavy loads with ease. You operate it by applying a small force to a hand chain or by using an electric motor. The device uses gears and a lifting chain to multiply your effort, making it possible to move objects that would otherwise be too heavy to handle.

This principle of mechanical advantage, similar to a fixed pulley, allows you to work efficiently and safely. Powerful Machinery, a global leader in lifting solutions, designs chain hoists that deliver reliable performance in demanding environments.

Types of Chain Hoists

You will find two main types of chain hoists: manual and electric. Manual hoists are simple and portable. They do not require electricity, so you can use them in remote locations or during maintenance tasks. These hoists have a lower initial cost and suit infrequent lifts.

Electric hoists, on the other hand, use a motor to lift loads quickly and with minimal effort. They are ideal for high-volume lifting tasks, such as production lines or busy construction sites. Powerful Machinery offers both manual and electric models, ensuring you have the right tool for every job.

The benefits of chain hoists include increased productivity, reduced operator fatigue, and enhanced safety.

Key Components

A chain hoist consists of several essential parts that work together for safe lifting:

Load Chain: Carries the weight of the load.

Hand Chain or Motor: Provides the input force, either manually or electrically.

Gears and Mechanism: Multiply your input force for efficient lifting.

Hooks: Secure the load and anchor the hoist.

Brake System: Holds the load in place when you stop lifting.

Housing: Protects internal components from damage.

Tip: Always inspect the chains, hooks, and mechanical parts before each use. Regular maintenance and proper setup help you avoid accidents and extend the life of your chain hoist.

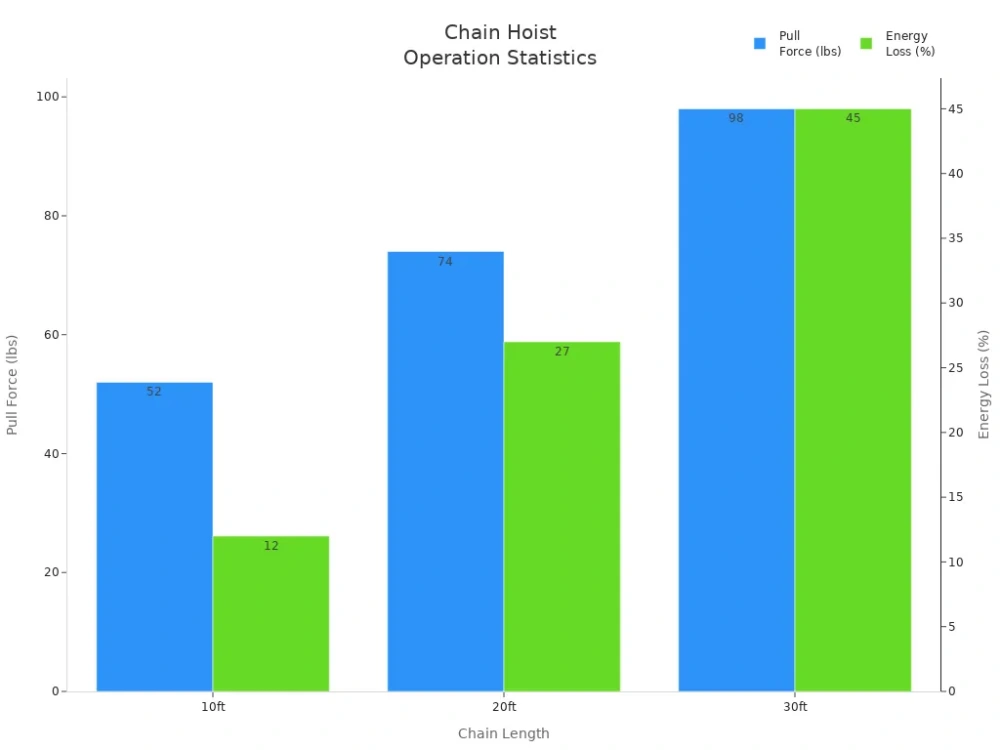

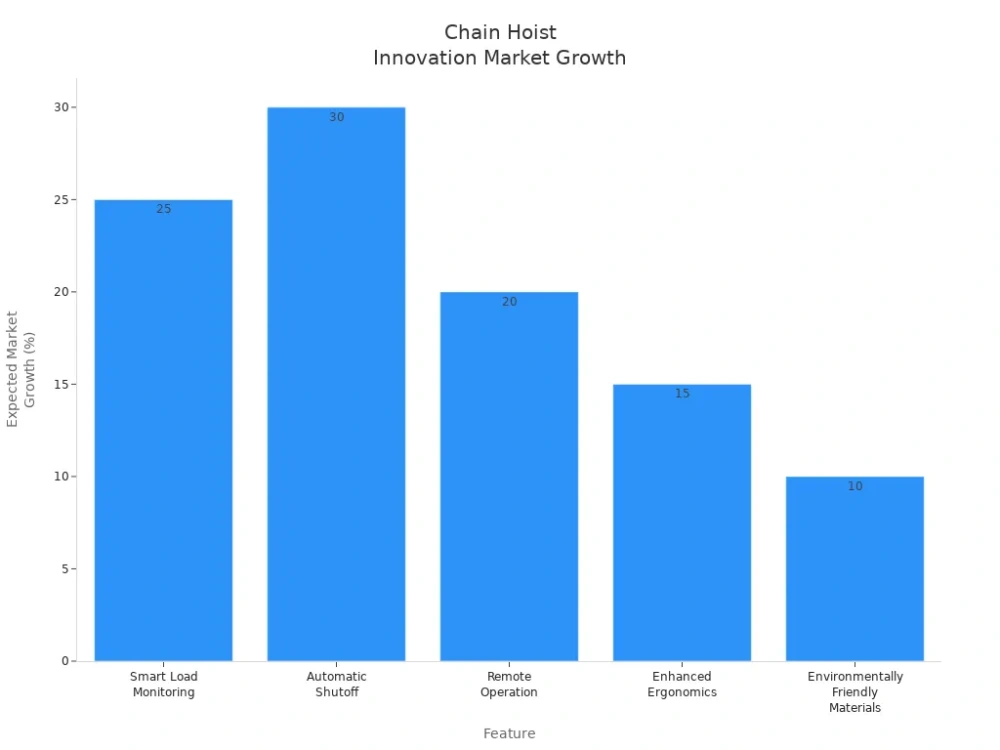

Feature | Description | Innovation Type | Safety Rating | Expected Market Growth (%) |

|---|---|---|---|---|

Smart Load Monitoring | Real-time analytics and load monitoring | Digital | A | 25 |

Automatic Shutoff | Prevents overloading with automatic shutoff | Mechanical | A+ | 30 |

Remote Operation | Control hoists from a safe distance | Digital | A | 20 |

Enhanced Ergonomics | Improved comfort for users | Design | B | 15 |

Environmentally Friendly | Sustainable and recyclable materials | Material | B+ | 10 |

Preparation and Inspection

Site Assessment

You must assess your worksite before operating a chain hoist. Start by checking for overhead obstructions, uneven flooring, and restricted access. Make sure the area is clear of unnecessary personnel and hazards. If you work outdoors or in hazardous locations, consider spark resistance and corrosion protection.

Flammable gases, dust, and harsh weather can affect the safety and integrity of your chain hoist. Use equipment that meets safety standards for these environments. Proper site assessment helps prevent accidents and ensures smooth lifting operations.

Tip: Always confirm that your anchor points are certified and capable of supporting the intended load.

Pre-Use Inspection

Inspect your chain hoist thoroughly before each use. Powerful Machinery recommends a detailed checklist to guarantee safe operation. Follow these steps:

Inspection Step | Details |

|---|---|

Visual Scan | Look for fluid leaks, loose bolts, or missing components. |

Hoist Status | Verify the hoist is not tagged ‘Out of Service,’ and safety labels are clear. |

Nameplate Check | Ensure the nameplate is complete and legible. |

Operational Test | Run the chain hoist through its full range of motion without a load. |

Brake System Test | Confirm the brake holds securely and prevents drift. |

Limit Devices Check | Test limit devices to avoid over-traveling. |

Hook Inspection | Check hooks for cracks, deformation, or excessive wear. |

Load Chain Inspection | Inspect for nicks, gouges, kinks, or visible damage. |

Chain Reeving | Make sure the chain is properly reeved and free of twists. |

Corrosion Check | Look for corrosion or oil leakage. |

You should perform frequent visual inspections weekly to monthly, and periodic detailed inspections monthly to annually. If your chain hoist has not been used for a long time, inspect it before returning to service.

Load Assessment

Evaluate the load before lifting with a chain hoist. Identify the weight and confirm it does not exceed the manufacturer’s rated capacity. OSHA and ASME standards require you to inspect rigging before each shift and use only gear with clear identification and rated load markings.

Never use damaged or untagged equipment. Proof-test custom lifting accessories to 125% of their rated load before use. New or modified chain hoists should be load tested at 100% to 125% of their rated load. Maintain written reports for periodic load tests as required by industry guidelines.

Note: Accurate load assessment protects both your equipment and your team from unnecessary risks.

Step-by-Step Usage Guide

How to Use a Manual Chain Hoist?

A manual chain hoist gives you reliable control over heavy lifting tasks, especially in environments without electricity. Powerful Machinery’s SK Series manual chain hoist stands out for its portability, efficiency, and robust safety features. You must follow a clear process to use a chain hoist safely and effectively.

Step-by-step usage guide for a manual chain hoist:

Attach the hoist to the load

Secure the manual chain hoist to a certified anchor point. Inspect the anchor for stability and rated capacity. Use a strong overhead beam, trolley, or crane hook.Attach the hoist to the load

Connect the load securely to the hoist’s lower hook. Make sure the load is balanced, and the hook’s safety latch is engaged.Operate the hand chain

Pull the hand chain in a steady, controlled motion. The gears inside the manual chain hoist multiply your effort, allowing you to lift the load with minimal force.Lift the load

Raise the load slowly. Watch for any shifting or swinging. Stop if you notice instability.Lower the load

To lower the load, reverse the direction of the hand chain. Move slowly to maintain control.Follow safety precautions

Never exceed the rated capacity of your manual chain hoist. Inspect the chain, hooks, and brake system before each use. Only trained personnel should operate the hoist.

Tip: Always keep your hands and feet clear of the suspended load. Never stand under a lifted load.

Common mistakes to avoid when you use a chain hoist:

Using damaged equipment.

Overloading the hoist.

Ignoring manufacturer guidelines.

Failing to secure loads properly.

Choosing the wrong hoist mechanism for the task.

Allowing untrained personnel to operate the hoist.

A manual chain hoist requires minimal maintenance. Lubricate the chain regularly and check for signs of wear. Powerful Machinery’s SK Series manual chain hoists undergo rigorous testing, including a breaking load test of four times the rated capacity and a proof load test of 1.5 times, ensuring operational safety.

How to Use an Electric Chain Hoist

An electric chain hoist streamlines lifting operations in busy environments. Powerful Machinery’s HHSY electric chain hoist features a compact design, making it ideal for tight spaces. You must understand how to use a chain hoist with electric power to maximize efficiency and safety.

Steps for operating an electric chain hoist:

Attach the hoist to the load

Position the electric chain hoist directly above the load. Secure the load to the hoist’s hook, ensuring balance and proper attachment.Lift the load

Use the pendant control or remote to activate the hoist. Lift the load vertically. Avoid side pulling, which can damage the hoist and create hazards.Lower the load

Lower the load using the control system. Move slowly and monitor the load’s stability.Use limit switches

Rely on limit switches as a backup to prevent over-travel, but do not use them for routine stopping.Maintain clear communication

Establish signals or verbal commands among team members during the lifting operation.Emergency preparedness

Familiarize yourself with the emergency stop function. Conduct regular drills to ensure everyone knows what to do in case of a malfunction.

Safety features of Powerful Machinery electric chain hoists:

Feature | Benefit |

|---|---|

Limit Switches | Prevent over-travel of the chain hoist |

Real-time Monitoring | Alerts operators to potential issues |

Brake System | Holds the load securely when not lifting |

Durable Construction | Withstands demanding industrial environments |

Note: Regular maintenance is essential. Inspect the chain, lubricate moving parts, and check the brake system. Only authorized personnel should operate electric hoists.

Avoid these mistakes when you use a chain hoist:

Using damaged equipment.

Overloading the hoist.

Ignoring manufacturer guidelines.

Failing to secure loads properly.

Choosing the wrong hoist mechanism.

Allowing untrained personnel to operate the hoist.

You must match the hoist mechanism to your specific task. Electric chain hoists excel in repetitive, heavy-duty lifting operations. Manual chain hoists suit smaller loads and outdoor environments. Pneumatic hoists offer solutions for hazardous or explosive atmospheres.

Advanced Lifting Techniques

Complex lifting operations require advanced skills and careful planning. You can use a chain hoist for awkward loads, multi-hoist lifts, and precision positioning.

Working with awkward loads

Identify the center of gravity before you attach the hoist to the load. Use multiple attachment points if needed. Perform a test lift to check stability. Guide ropes help control swinging or rotation.Multiple hoist coordination

When you use more than one chain hoist, synchronize lifting speeds. Designate a lift coordinator to oversee the operation. Communicate clearly with all team members.Precision positioning methods

Use small control inputs to lift the load or lower the load with accuracy. Implement a spotter to guide placement. Mark reference points for repeated positioning.

Alert: Never use a chain hoist for side pulling or dragging loads. Always lift the load vertically to prevent damage and ensure safety.

Chain hoist handling best practices:

Inspect all equipment before each lifting operation.

Attach the hoist to the load securely.

Lift the load slowly and steadily.

Lower the load with care.

Store chain hoists in a dry, clean area after use.

Powerful Machinery chain hoists deliver reliable performance in every lifting operation. You can use a chain hoist for manufacturing, construction, warehousing, and marine applications. Follow this step-by-step usage guide to maximize safety and efficiency.

Chain Hoist Safety and Maintenance

Safety Protocols

You must always follow strict safety protocols during use to protect yourself and your team. Powerful Machinery chain hoists meet international standards, including CE and ISO9001:2000, which guarantee high safety and quality.

Certification/Standard | Description |

|---|---|

CE | Compliance with European safety standards |

ISO9001:2000 | Quality management system standard |

Before you operate a chain hoist, inspect the hoist for any damage or wear. Complete a pre-operation inspection and pre-use inspection every time. Prepare the load by checking its weight and confirming it does not exceed the hoist’s rated capacity.

Secure the load to a lifting sling and center and balance the load before lifting. Always keep the area beneath the load clear and maintain clear communication with your team. Safety considerations include keeping the load path free of obstructions and responding quickly to any instability.

Key safety protocols during use:

Inspect the hoist for damage or wear before each use.

Adhere to the manufacturer’s recommended weight limits.

Ensure operators are properly trained.

Secure the load to the hook and distribute it evenly.

Keep the area beneath the load clear.

Maintain clear communication among operators.

Avoid swinging loads and always lift vertically.

Familiarize yourself with emergency procedures.

Maintenance Tips

Regular maintenance keeps your chain hoist reliable and safe. You should inspect the hoist and check for signs of wear, especially on chains and gears. Clean the hoist after each use and lubricate moving parts to reduce friction. Always check the chain for kinks and replace any damaged links.

Conduct regular testing and inspection to catch problems early. Operator training is essential, so make sure everyone knows how chain hoists work and can recognize issues.

Evidence | Description |

|---|---|

Proactive inspections | Contribute to a longer lifespan by finding issues early. |

Regular inspections | Help prevent failures during critical tasks. |

Regular maintenance and inspection routines ensure your chain hoist remains safe and effective for years. This approach supports a strong safety culture and prevents costly downtime.

Storage Guidelines

Proper storage extends the life of your chain hoist. After use, clean and inspect the hoist before storing it. Lubricate moving parts as part of your post-use maintenance routine. Store the hoist in a dry, well-ventilated area to prevent rust.

Hang the hoist from a solid structure, making sure the chain hangs freely and does not touch the ground. Never store the hoist in a way that causes kinks or twists in the chain. Prepare the load for the next use by keeping all lifting accessories organized and ready.

Tip: Always prepare the load, inspect the hoist, and follow storage guidelines to ensure safe and efficient lifting operations every time.

Conclusion

You achieve safe and efficient lifting by preparing your site, operating your chain hoist correctly, and maintaining it regularly. Industry experts recommend you select certified equipment, inspect before each use, and match the hoist to your task. Powerful Machinery delivers certified lifting solutions for every environment.

Differentiate between vertical lifts and pulling tasks.

Confirm the Working Load Limit exceeds your load.

Choose corrosion-resistant materials for harsh settings.

Select hoists with overload protection and safety latches.

Maintain strict inspection and maintenance schedules.

Use electric hoists for frequent or heavy-duty lifting.

Resource Title | Description |

|---|---|

Safety Tips Sheet No. 15: Overhead Manual Chain Hoist | Provides workers with information on the safe operation of overhead manual chain hoists. |

Safety Tips Sheet No. 4: Hoist Operation | Describes what an operator should and should not do while operating a hoist. |

OSHA Cranes and Derricks Hazards | Includes a pre-operational equipment checklist for cranes and hoists. |

Always follow safety protocols and consult manufacturer guidelines for every lift.

FAQ

How do you choose the right chain hoist for your job?

You should check the weight of your load and the environment. Select a hoist with a rated capacity at least 25% higher than your load. Powerful Machinery offers manual and electric models for different lifting needs.

What safety checks should you perform before using a chain hoist?

You must inspect the chain, hooks, and brake system. Look for signs of wear or damage. Test the hoist without a load to confirm smooth operation. Always verify the rated capacity and secure all connections.

Can you use a chain hoist outdoors?

You can use manual chain hoists outdoors. Choose models with corrosion-resistant materials for harsh weather. Powerful Machinery’s SK Series manual chain hoist works well in outdoor settings, including construction sites and farms.

How often should you maintain your chain hoist?

You should clean and inspect your chain hoist after every use. Lubricate moving parts regularly. Schedule detailed inspections monthly. Replace worn components immediately to keep your equipment safe and reliable.

What is the difference between a manual and electric chain hoist?

Manual chain hoists require hand operation and suit areas without electricity. Electric chain hoists use a motor for faster lifting and work best in busy environments. Powerful Machinery provides both types for various applications.