Safe operation is crucial when you use a ratchet cable puller. Every year, thousands of injuries occur due to improper handling of lifting equipment.

Over 36,000 lifting-related injuries happen annually in the United States, showing the risks involved with tools like cable winches and similar devices.

Choosing certified equipment makes a significant difference, especially for beginners and DIY users. Powerful Machinery ratchet cable pullers deliver reliability through advanced features and international certifications:

Feature | Benefit |

|---|---|

Compliance with ISO 9001:2015 and ANSI/ASME B30.16 | Meets global safety standards and reduces accident risk. |

Overload protection and fail-safe locks | Prevents mishaps during use, even in demanding conditions. |

Dual-gear ratchet mechanisms | Improves control and makes the operation safer and more efficient. |

You must always prioritize safety during Wire rope winch and cable puller usage.

Key Takeaways

Always inspect your ratchet cable puller and cables for wear or damage before each use. This step helps prevent accidents and ensures safe operation.

Choose the right equipment based on your project needs. Consider the load weight and environment to select a cable puller that meets safety standards.

Use a secure anchor point for your cable puller. Ensure it can support the load and is free from rust or damage to maintain safety during operation.

Engage the ratchet mechanism carefully. Apply force gradually and monitor the load to avoid sudden jerks that can lead to equipment failure.

Follow proper tension release steps after use. Gradually unwind the cable and store the equipment correctly to extend its life and maintain reliability.

Wire Rope Winch and Cable Puller Usage Overview

Tool Functions and Applications

You rely on wire rope winch and cable puller usage for lifting, pulling, and securing heavy loads in both industrial and DIY settings. Wire rope winches offer exceptional strength and durability, making them ideal for demanding tasks.

You see these tools in action across many industries, from construction to marine operations. Their high strength-to-weight ratio improves safety and productivity.

Industry | Application Description |

|---|---|

Cranes and Hoists | Integral in lifting operations, handling significant weight while maintaining flexibility. |

Construction and Infrastructure | Used for suspending bridges, supporting structures, and operating machinery. |

Marine and Shipping | Essential for mooring, towing, and rigging operations, resistant to harsh conditions. |

Mining and Drilling | Supports underground operations, lifting materials, and drilling rigs. |

Elevators and Lifts | Used in vertical transportation systems requiring strength and controlled movement. |

Logging and Forestry | Utilized for pulling logs and securing loads with heavy-duty winches. |

In everyday scenarios, wire rope winch and cable puller usage includes vehicle recovery, rock climbing assists, anchoring ships, supporting fishing operations, and handling loads on construction sites.

When to Use a Wire Rope Winch or Cable Puller?

You choose between a wire rope winch and a cable puller based on the task requirements. Wire rope winches handle larger loads and offer versatility in lifting or pulling in any direction. Cable pullers work best for lighter loads and horizontal pulling. The following table highlights their differences:

Feature | Wire Rope Hoist | Cable Puller |

|---|---|---|

Versatility | Can lift/pull in any direction | Limited to horizontal pulling |

Capacity | Can handle larger loads | Suitable for lighter loads |

Length of Cable | Can pull any length of cable | Limited by the internal drum diameter |

Practical Applications | Wide range of tasks | Primarily for load tensioning |

Safety | Generally safer for heavy lifting | Less safe for heavy loads |

Wire rope winch and cable puller usage depends on your project’s needs. You select the right tool to maximize safety and efficiency.

Safety Considerations with Powerful Machinery Products

You must follow basic safety principles during wire rope winch and cable puller usage. Powerful Machinery provides certified products that meet international standards, ensuring reliability. Always wear gloves, helmets, and protective glasses. Inspect the winch and cable before use.

Choose a secure anchor point and confirm all connections. Avoid overloading and keep a safe distance during operation. If you notice any abnormality, stop immediately and use emergency procedures.

Tip: Powerful Machinery’s certified equipment helps you maintain safety and performance in every wire rope winch and cable puller usage scenario.

Preparation and Inspection Steps

Selecting Powerful Machinery Equipment

You must select the right ratchet cable puller for your project. Start by evaluating your task requirements. Consider the weight of the load, the distance you need to pull, and the environment where you will work.

Powerful Machinery offers a range of certified cable pullers designed for different capacities and applications. Use the following table to guide your selection:

Criteria | Description |

|---|---|

Project Requirements | Assess the type of cables, distances, and environment to determine the machine’s capacity needs. |

Machine Specifications | Evaluate pulling force, speed, and weight to ensure suitability for the specific tasks at hand. |

Durability and Reliability | Choose machines made from high-quality materials and consider maintenance needs and support services. |

You should always check the product certifications. Powerful Machinery equipment meets international standards, which ensures safety and reliability for every job.

Inspecting Tools and Accessories

Before you begin, inspect all tools and accessories. Look for visible signs of wear, such as frayed cables, bent hooks, or damaged slings. Examine the ratchet mechanism for smooth operation. Test the locking system to confirm it engages securely.

If you find any defects, replace the part immediately. You should also check that all components are clean and free from oil or debris. Clean equipment reduces the risk of slippage and improves safety.

Tip: Regular inspection extends the life of your equipment and helps prevent accidents.

Choosing a Secure Anchor Point

A secure anchor point is essential for safe operation. You must attach the wire rope to a stable structure that can handle the load. Look for anchor points that do not move or shift under tension. Avoid using weak or corroded fixtures. Make sure the anchor point sits directly in line with the pulling direction to prevent side loading.

Attach the wire rope to a stable anchor point to maintain security during operation.

Confirm the anchor point can support the full load without deformation or failure.

Inspect the anchor area for rust, cracks, or other weaknesses before use.

You protect yourself and your team when you follow these preparation and inspection steps.

How to Use a Cable Puller: Setup and Operation

Learning how to use a cable puller safely starts with proper setup and careful operation. You must follow each step to ensure the load moves securely and the equipment functions as designed.

Powerful Machinery cable pullers offer advanced safety features and reliable performance, but your attention to detail remains essential.

Disengaging and Releasing the Cable

Begin by disengaging and releasing the cable. This step prepares the puller for attachment and prevents accidental tension. Follow these steps:

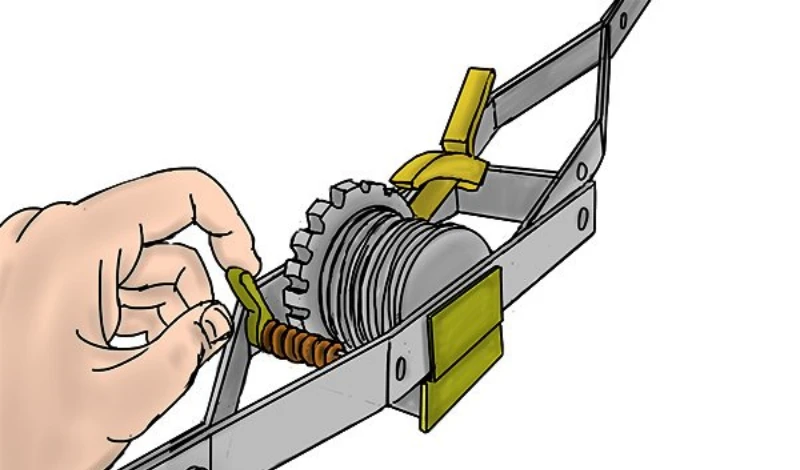

Slide the spring’s hook from the bottom of the drive-pawl slot to the top. This action releases the drive-pawls.

Swing the handle all the way over to the opposite side until you feel resistance.

Push a little harder until you hear a distinct ‘clunk.’ This sound means the stop-pawl has disengaged.

Move the handle back and forth to gradually release tension. Continue until the cable feels loose.

If you need to reel in the cable quickly, swing the handle back and hold the stop-pawl trigger with your thumb. This allows the ratchet wheel to spin freely.

Tip: Always keep your hands and clothing away from moving gears during this process. Powerful Machinery designs its ratchet mechanisms for smooth operation, but you must remain alert to avoid injury.

Attaching Hooks and Positioning the Load

Next, attach the hooks and position the load. Proper attachment prevents accidents and ensures the load remains secure throughout the operation.

Safety Precaution | Description |

|---|---|

Proper Hook Usage | Support the load with the hook, not the latch. |

Work Load Limit | Never exceed the hook’s Work Load Limit (WLL) rating. |

Inspection | Check hooks for wear or damage before every use. |

Avoid Overloading | Do not use hooks for lifting people or overload them. |

Securement | Use a masterlink or bolt-type shackle with a cotter pin for suspension systems. |

You must inspect the hooks and cables for damage before attaching. Position the load so the cable runs straight, avoiding side pulls or angled loads. Keep the cable neatly wound to prevent kinks or overlapping. Never overload the puller or use it for lifting people.

Note: Powerful Machinery hooks and shackles meet strict international standards. You can trust their durability, but regular inspection remains your responsibility.

Engaging the Ratchet and Pulling Safely

Once you attach the hooks and position the load, engage the ratchet mechanism. This step allows you to apply controlled force and move the load safely.

Move the handle back and forth to engage the ratchet. The dual-gear system in Powerful Machinery cable pullers provides smooth, incremental movement.

Monitor the cable as you pull. Keep hands, tools, and clothing away from the ratchet and gears.

Apply force gradually. Avoid sudden jerks or rapid movements.

Watch for any signs of cable wear, hook deformation, or abnormal noises. Stop immediately if you notice anything unusual.

Safety Tip: Always check the load capacity before operation. Ignoring load limits can cause equipment failure and serious injury.

Monitoring Operation and Securing the Load

During operation, you must monitor key indicators to ensure the load remains secure and the cable puller functions correctly.

Indicator | Description |

|---|---|

Line Tension Indicator | Shows the pulling force applied, helping you keep the load secure. |

Pull Load Indicator | Displays the pulling load on a dial gauge, allowing you to track performance. |

You should check these indicators regularly. If the tension or load exceeds safe limits, stop and adjust. Once the load reaches its destination, secure it with additional restraints if needed. Rewind the cable neatly to prevent damage.

Reminder: Plan for emergency situations. Keep a clear path around the work area and know how to disengage the puller quickly if needed.

Common Mistakes to Avoid

Many users make mistakes during setup and operation. You can avoid these errors by following best practices:

Choosing the wrong cable puller for the job

Skipping regular inspections

Improper installation

Ignoring load limits

Using damaged or incompatible cables

Improper storage and maintenance

Failing to plan for emergencies

Powerful Machinery cable pullers help reduce risks with certified components and robust safety features. Your attention to detail and adherence to guidelines ensure safe and efficient operation every time.

Releasing Tension and Post-Use Safety

Safe Tension Release Steps

You must release tension from your ratchet cable puller with care. Sudden releases can cause the cable to snap back, leading to injury or equipment damage. Begin by checking that the area around the puller is clear. Grip the handle firmly and slowly move it to disengage the ratchet mechanism.

Allow the cable to unwind gradually. Never let go of the handle until all tension is gone. If your puller features a stop-pawl, use it to control the release. Always keep your hands and body away from the cable path. You should wear gloves and safety glasses during this process.

Tip: Controlled tension release protects both you and your equipment. Powerful Machinery designs its ratchet systems for smooth, predictable operation, but your attention remains essential.

Rewinding and Storing Equipment

Proper storage extends the life of your cable puller. After use, inspect the rope and hooks for any signs of wear. Clean all components to remove dirt, moisture, or oil. Coil the rope carefully onto the drum or frame, making sure there are no twists.

Avoid placing the equipment on the floor, as this can lead to corrosion or accidental damage. Use a suitable rack or shelf for storage.

Procedure | Description |

|---|---|

Cleanliness | Ensure the equipment is dry and clean before storage to prevent corrosion. |

Coiling of Rope | Carefully coil the rope onto a suitable drum or frame, avoiding any twists. |

Proper Storage | Store machines and ropes on a suitable rack, not on the floor to prevent damage. |

You maintain equipment reliability when you follow these steps. Regular cleaning and proper coiling prevent premature wear and keep your cable puller ready for the next job.

Technical Support from Powerful Machinery

You may encounter questions or need assistance with your cable puller. Powerful Machinery provides comprehensive technical support for all users. You can access product manuals, troubleshooting guides, and expert advice through their official website.

If you need help with maintenance, repairs, or selecting the right equipment, their support team responds promptly. You benefit from decades of experience and a commitment to customer satisfaction.

Note: Reliable support ensures you operate your ratchet cable puller safely and efficiently every time.

Conclusion

You improve safety and efficiency by following essential steps when using a ratchet cable puller:

Inspect cables and pullers for wear or damage before every use.

Avoid rusted or frayed cables to prevent failure.

Use a dampener for added protection.

Never exceed rated working load limits.

Practice with lighter loads to build confidence.

Powerful Machinery equipment meets ISO 9001, ASME, and OSHA standards. Advanced features like locking mechanisms, non-slip grips, and safety latches enhance your protection:

Safety Feature | Benefit |

|---|---|

Locking Mechanisms | Prevent accidental release under tension |

Non-Slip Grips | Improve handling and control |

Safety Latches | Add extra security during operation |

Consult experts if you encounter rust, debris, or overloading issues. You ensure safe operation and extend equipment life by seeking professional support.

FAQ

How often should you inspect your ratchet cable puller?

You should inspect your ratchet cable puller before every use. Look for frayed cables, bent hooks, or damaged parts. Regular checks help you prevent accidents and extend the life of your equipment.

Can you use a ratchet cable puller for vertical lifting?

You should not use a standard ratchet cable puller for vertical lifting. These tools work best for horizontal pulling. For vertical lifts, choose certified lifting equipment from Powerful Machinery.

What should you do if the cable gets stuck during operation?

Stop using the puller immediately. Release tension slowly and check for kinks or debris. Never force the handle. If you cannot fix the issue, contact Powerful Machinery technical support for guidance.

How do you choose the right capacity for your cable puller?

Check the weight of your load. Select a cable puller with a rated capacity higher than your load. Powerful Machinery provides clear capacity ratings on every product for your safety.

Where can you find technical support or replacement parts?

You can visit Powerful Machinery’s official website for manuals, support, and replacement parts. Their expert team responds quickly to your questions and helps you keep your equipment in top condition.