You use a ratchet chain binder by following several key steps: inspect your binder and chain, select the right equipment, attach the chain, tighten with the ratchet mechanism, lock the handle, check for secure tension, remove after transport, and maintain the binder regularly.

Prioritizing ratchet chain binder safety means choosing certified products like Powerful Machinery Load Binders and meeting industry regulations.

The table below outlines common regulatory requirements for commercial cargo transport:

Requirement | Description |

|---|---|

Good Working Condition | Tie-down equipment must be free from cracks, excessive wear, or deformities. |

Minimum Working Load Limit | Requirements must be met based on the weight of the cargo. |

Number of Tie-Downs | Determined by the length and weight of the load. |

Secure Attachment | All tie-downs must be secured to prevent loosening or detachment during transport. |

Focusing on safety and compliance helps you prevent accidents and ensure secure cargo transport.

Key Takeaways

Inspect your ratchet chain binder and chain before each use to ensure safety and reliability.

Choose certified equipment that meets industry standards for safe cargo transport.

Tighten the chain gradually using the ratchet mechanism to avoid over-tightening and potential damage.

Lock the binder securely and double-check all connections to prevent accidental release during transport.

Regularly maintain your equipment by cleaning, lubricating, and replacing any damaged components.

Ratchet Chain Binder Basics

What Is a Ratchet Chain Binder?

You use ratchet chain binders to secure and tighten chains around heavy cargo. These tools play a vital role in transportation and material handling. Powerful Machinery specializes in certified lifting and securing solutions, offering load binders that meet strict industry standards for safety and reliability.

Ratchet chain binders feature a gear and pawl mechanism. This design allows you to tighten chains with less force and greater control. The locking mechanism prevents chains from loosening during transit. Reduced built-up tension enhances safety for operators.

The table below outlines the main components and mechanical principles:

Component/Principle | Description |

|---|---|

Gear and Pawl Mechanism | Tightens chains with less force and more control |

Locking Mechanism | Keeps chains secure during transport |

Reduced Built-up Tension | Improves safety during use |

Industry standards, such as WSTDA T-6, guide the design and manufacturing of ratchet chain binders. Powerful Machinery ensures every product meets or exceeds these requirements, giving you confidence in demanding environments.

High-quality load binders from Powerful Machinery provide durability and ease of use. You reduce the risk of accidents and ensure cargo remains secure throughout the journey.

Common Uses in Cargo Securement

You rely on ratchet chain binders for a wide range of cargo securement tasks. These binders excel in situations where you need to stabilize heavy loads. Common applications include:

Securing heavy machinery and construction materials

Transporting industrial equipment and high-value cargo

Use in logistics, agriculture, and construction

Fastening heavy loads to flatbeds, trailers, and other transport vehicles

Holding steel coils, concrete products, and other dense cargo in place

Ratchet chain binders offer advantages over lever binders. You experience reduced risk of sudden kickback and require less physical effort. The table below compares key features:

Feature | Ratchet Binders | Lever Binders |

|---|---|---|

Safety | Lower risk of handle snapback | Higher risk of snapback |

Ease of Use | Less physical effort is required | More strength needed |

Speed | Slower, more controlled tension | Faster, less precise |

You achieve secure cargo transport by choosing certified ratchet chain binders and matching them with the right chains. Powerful Machinery’s products help you meet regulatory standards and maintain safety on every job.

Equipment Selection and Inspection

Choosing Load Binders and Chains

Selecting the right equipment is the foundation of safe cargo securement. You must choose the appropriate binder and chain for your load. Powerful Machinery offers a wide range of certified load binders and chains designed for heavy-duty applications.

Always match the binder and chain to the weight and type of cargo you plan to transport.

Tip: Use only chains and binders that meet DOT and industry standards. Certified products ensure compliance and safety.

The following table summarizes the key standards and requirements you should consider:

Standard/Requirement | Description |

|---|---|

DOT Approval | Equipment must meet federal standards for materials, construction, and testing. |

Working Load Limit | Permanent, legible WLL marking required. |

Chain Grade | Grade 70 transport chain is DOT-approved for commercial tie-downs. |

Testing Compliance | Proof load testing at 2.5 times the working load limit. |

Safety Factor | Breaking strength minimum 3:1 ratio to working load limit. |

Manufacturer Certification | DOT compliance documentation required. |

You should select a chain with a working load limit greater than the load weight divided by the number of tie-downs. Grade 70 is the most common choice for transport, but Powerful Machinery also supplies Grade 80 and Grade 100 chains for specialized needs.

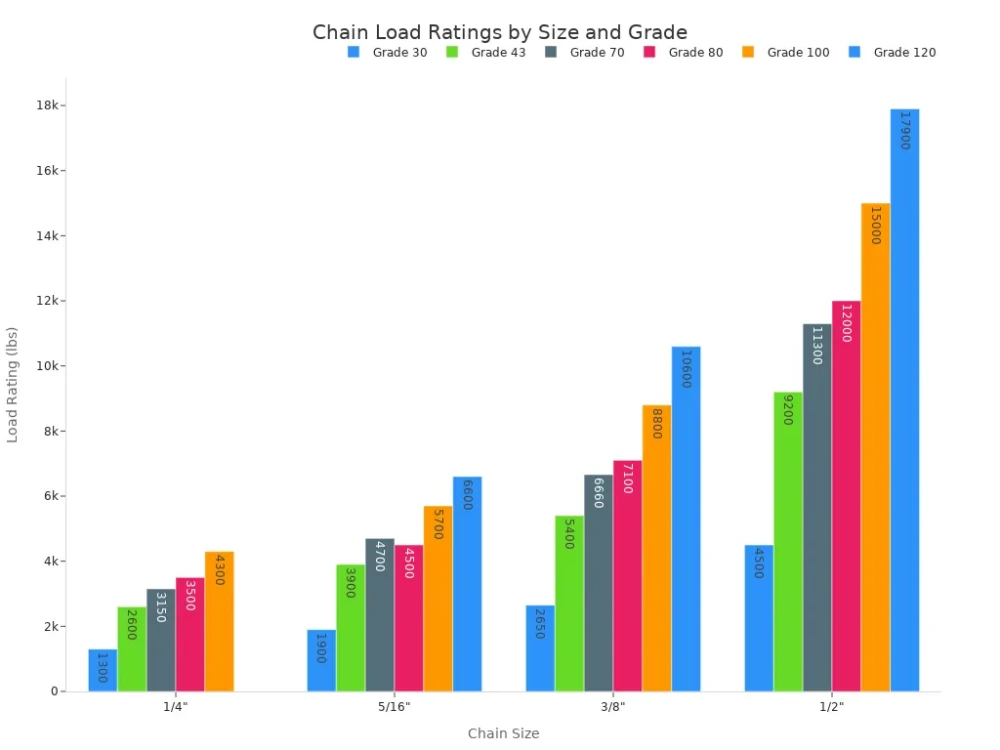

The chart below compares load ratings for different chain sizes and grades:

Pre-Use Inspection Steps

Before you tighten the chain or ratchet the binder, inspect the chain and binder thoroughly. You must inspect and recheck every component to prevent accidents and ensure reliability.

Follow these steps before each use:

Check for deformation, cracks, nicks, or gouges on the binder.

Inspect for stretched or bent links, cracks, or gouges in the chain.

Examine hooks and connectors for damage or malfunction.

Remove any damaged chains or binders from service immediately.

The table below highlights common signs of wear or damage and the required action:

Damage Type | Description | Required Action |

|---|---|---|

Stretched or Bent Links | Links elongated or bent due to excessive load | Replace the chain immediately |

Cracks and Gouges | Cracks or gouges at stress points | Replace the chain immediately |

Hook and Connector Damage | Deformation or latch malfunction | Replace the damaged part |

You maintain safety and compliance by inspecting equipment before every job. Powerful Machinery’s certified products help you meet these standards and keep your cargo secure.

How to Use Ratchet Chain Binders Safely?

Ratchet chain binder safety begins with a disciplined approach to every step of the process. You must follow safety guidelines and the manufacturer’s instructions to secure cargo loads and prevent accidents.

Powerful Machinery Load Binders offer reliability and ease of use, making them an excellent choice for load securement in demanding environments.

Attaching and Positioning the Chain

You start by positioning the chain and binder for optimal load restraint. Follow these steps to ensure secure chains and proper operation:

Attach one end of the chain to a solid anchor point on your trailer.

Connect the other end to the cargo’s tie-down location, keeping the chain straight and free of twists or kinks.

Place the ratchet binder on the chain section between the cargo and anchor point. Hook the binder to separate chain links, ensuring the hooks are not twisted.

Confirm the chain is taut but leaves enough slack for the binder to engage.

Inspect the setup for pitted rust, deformed links, or worn gear teeth. Replace any damaged components immediately.

Tip: Always use certified equipment like Powerful Machinery Load Binders for maximum safety and reliability.

Ratcheting and Tensioning

Proper tensioning is critical for ratchet chain binder safety. You must apply tension gradually and check for secure loads throughout the process. Use these steps to achieve effective load securement:

Engage the ratchet mechanism by pumping the handle back and forth. Tighten the chain slowly until it is taut.

Avoid over-tightening, which can damage equipment or cargo.

Position your body safely to prevent injury if something slips or breaks. Solid footing or kneeling helps protect against slippage.

Take your time and do not rush. Check the chain and binder after each adjustment.

Distribute binders evenly across the cargo to maintain balanced load restraint.

Risk Type | Description |

|---|---|

Binder breakage | Can lead to loss of load control and safety. |

Load slippage | Increases the risk of accidents and injuries. |

Equipment damage | Can result in costly repairs and downtime. |

Workplace injuries | Potentially fatal incidents can occur. |

Safety Precautions: Always follow the manufacturer’s instructions and use a load bar with a hook-type end for easier removal. Never use damaged or incompatible equipment.

Locking and Double-Checking

Securing the binder and performing a final check ensures your cargo is securely fastened for transport. You must lock the binder and double-check every connection:

Lock the ratchet mechanism to prevent accidental release.

Position the lever arm horizontally to avoid movement during transit.

Perform a visual inspection for tightness and security. The chain should have no slack, twists, or kinks.

Conduct a tug test to confirm the load is immovable.

Recheck all binders and chains before departure. Document the condition for compliance and tracking.

Note: Common mistakes include choosing the wrong binder type, ignoring the safe working load limit, rushing the process, and neglecting basic safety precautions. Always wear protective gear and inspect equipment before use.

Ratchet chain binder safety depends on your attention to detail and adherence to safety guidelines. Powerful Machinery Load Binders help you secure loads and maintain compliance with industry standards. You protect cargo, equipment, and personnel by following these procedures for load securement.

Regulatory Compliance and Maintenance

Load Securement Regulations

You must comply with strict regulations when securing cargo with ratchet chain binders. Regulatory bodies in North America, such as OSHA and FMCSA, set standards for load capacity and equipment durability.

European countries implement stringent safety rules that promote the use of high-quality securing solutions. The following table summarizes key regulations across regions:

Region | Regulatory Body | Key Regulations | Standards |

|---|---|---|---|

North America | OSHA, FMCSA | Strict safety standards for load capacity and durability criteria | ANSI, ASTM |

Europe | Various | Implementation of stringent safety regulations promoting high-quality solutions | N/A |

You must use equipment with clear markings and proper documentation. Unmarked or improperly marked chain binders violate federal regulations and can result in fines or failed inspections. Damaged or worn-out equipment increases the risk of failure during transport.

Improper positioning of binders may lead to inadequate securement. You should familiarize yourself with FMCSA regulations and state-specific guidelines. Regular training and the use of structured checklists help ensure compliance. The table below outlines best practices for documenting compliance:

Procedure/Practice | Description |

|---|---|

Use of Checklists | Structured checklist for securement steps |

Regular Training | Ongoing staff training on securement techniques |

Equipment Inspection | Routine inspection of securement devices |

Tip: Regulatory compliance is crucial for safe cargo transport. Agencies enforce standards that require specific load capacity and promote sustainable manufacturing practices.

Maintenance and Replacement

You maintain safety and reliability by inspecting and servicing your ratchet chain binders regularly. Before each use, inspect binders for wear and damage. Clean binder chains after every use to prevent corrosion.

Lubricate moving parts on a regular schedule to reduce friction and prevent seizing. The table below shows recommended maintenance intervals:

Maintenance Task | Frequency | Benefits |

|---|---|---|

Inspect binders for wear/damage | Before each use | Ensures safety and prevents equipment failure |

Clean binder chains | After each use | Prevents corrosion and wear |

Lubricate moving parts | Regularly | Reduces friction and prevents seizing |

Apply a light lubricant to the moving parts of your binder. Avoid over-lubrication, as excess oil attracts dirt and debris. Use a silicone-based lubricant or penetrating oil for the ratchet mechanism and pivot points. Periodic lubrication keeps your load binder working smoothly and extends its lifespan.

You should replace any binder or chain showing signs of damage, excessive wear, or malfunction. Powerful Machinery’s certified products meet international safety standards, giving you confidence in every application.

🛠️ Note: Regular inspection and maintenance protect your equipment and help you avoid costly downtime or regulatory violations.

Conclusion

You achieve safe and effective cargo securement by following each step with care and attention. Certified ratchet chain binders, such as Powerful Machinery Load Binders, offer key benefits:

Maintain tension securely for efficient load restraint

Allow precise, controlled tightening with reduced risk of snapback

Require less physical effort, making them easier to use

Regular maintenance—cleaning, inspecting for wear, lubricating moving parts, and replacing damaged components—keeps your equipment reliable. Prioritize safety, compliance, and ongoing training to protect your cargo and ensure every transport meets industry standards.

FAQ

How do you use a ratchet chain binder on flatbed trailers?

You attach the chain to anchor points on your flatbed trailers, then hook the ratchet chain binder between chain links. Pump the handle to tighten the chain. Lock the binder and check for secure tension before starting transportation.

What makes a ratchet chain binder safer for trucking?

You gain safety with a ratchet chain binder because its mechanism allows gradual tensioning. This reduces the risk of sudden release. You avoid snapback injuries, which are common with lever binders. Always inspect your equipment before securing loads on trucks.

Can you use a ratchet chain binder for different types of trailers?

You can use a ratchet chain binder on various trailers, including flatbed and enclosed types. Always match the binder and chain to the cargo weight. Certified binders help you meet transportation safety standards and keep your loads secure.

How often should you inspect your ratchet chain binder during transportation?

You should inspect your ratchet chain binder before every trip and periodically during transportation. Check for wear, rust, and proper tension. Regular inspections help you prevent accidents and ensure safe cargo delivery in trucking operations.

What chain grade works best with a ratchet chain binder for trucks?

You should use Grade 70 or higher chains with a ratchet chain binder for trucks. These grades meet industry standards for transportation and provide reliable strength. Powerful Machinery offers certified chains for secure cargo restraint on flatbed trailers.