When you secure cargo for transport, you face a choice between lever binders and ratchet binders. The main differences lie in their mechanism, safety, ease of use, and speed. Lever binders use a simple lever for quick tightening, while ratchet binders combine a lever with a screw thread for controlled tensioning.

The table below highlights how ratchet binders vs lever binders compare in key areas:

Feature | Lever Binders | Ratchet Binders |

|---|---|---|

Mechanism | Lever to increase force, locks after 180° rotation | Lever and screw thread multiply force |

Safety | Quick release may cause kickback | Controlled tensioning, safer take-up |

Ease | Fewer moving parts, easy install | Steadier loading and unloading |

Speed | Quick to secure and release | Takes longer due to ratcheting |

Powerful Machinery delivers high-quality load binders you can trust for safety and reliability in every application.

Key Takeaways

Lever binders allow for quick cargo securement with a simple lever action, making them ideal for time-sensitive jobs.

Ratchet binders provide precise tension control, enhancing safety and reducing the risk of sudden kickback during use.

Choose lever binders for lighter loads and fast installations; opt for ratchet binders when securing heavy or sensitive cargo.

Regular inspection and maintenance of load binders ensure safe operation and extend their lifespan.

Consider your cargo type and environment when selecting between lever and ratchet binders for optimal performance.

Load Binders Overview

Purpose and Types

You rely on load binders to achieve safe and effective securement of cargo during transportation.

A load binder serves as a mechanical device that tightens chains, keeping your load stable and preventing movement. This tool plays a vital role in logistics, construction, and freight industries, where securement is essential for safety and compliance.

Powerful Machinery offers a comprehensive range of load binder solutions designed for different transportation environments. You can choose from several types, each tailored to specific applications. The table below highlights the primary types of load binders and their typical uses:

Product Type | Application |

|---|---|

Ratchet Type Load Binders | Railway |

Lever Type Load Binders | Highway |

Others | Waterway |

Selecting the right load binder ensures that your cargo remains secure, whether you transport goods by road, rail, or water.

How do They Work?

A load binder operates by creating tension in chains through mechanical advantage. This tension is critical for securement, as it prevents cargo from shifting or falling during transit. You benefit from two main mechanisms:

Lever-type load binders use a solid steel lever and hooks to apply tension efficiently. You pull the lever, which tightens the chain with minimal effort.

Ratchet-type load binders combine a lever with a screw thread, allowing you to adjust tension precisely and steadily.

Both mechanisms maximize tension while reducing the physical effort required. You achieve reliable securement and enhance safety for every load.

Powerful Machinery’s load binder products feature robust construction and advanced designs. You gain access to certified, high-performance options that meet international standards. These solutions help you maintain security in demanding conditions and support your operational needs.

Lever Binders

Mechanism

Lever binders use a straightforward mechanical design to tighten transport chains. You operate a lever binder by attaching the hooks to the chain and pulling the handle. This action multiplies your force, allowing you to create strong tension in the chain.

The lever binder stores energy in the handle, so you need to apply steady pressure when tightening or releasing. Lever binders require more physical strength than other types, but their simple construction means fewer moving parts and less maintenance.

You should avoid using extension handles or cheater bars, as these can increase the risk of sudden kickback.

Lever binders have a simple design for easy installation.

The lever mechanism increases the force applied to the chain.

The handle stores tensioning energy, which requires careful handling.

Advantages

You benefit from several advantages when using lever binders. Lever load binders allow you to secure cargo quickly and efficiently. Their heavy-duty steel construction ensures durability, even in tough environments.

Lever binders are more economical than other options, making them a cost-effective choice for many operators. You can easily loosen the chain when unloading, which saves time on the job. Lever load binders also require minimal maintenance due to their simple design.

Tip: Lever load binders provide precise tensioning, which helps you keep your cargo secure throughout the journey.

Disadvantages

Lever binders come with some important safety considerations. The energy stored in the handle can cause a dangerous kickback if you lose your grip. Lever load binders require more strength to operate, which may not suit every user.

Using tools like cheater bars to increase leverage can lead to recoil injuries. You must always handle lever binders with care to avoid accidents.

Lever binders can store significant energy in the handle.

Built-up tension may cause kickback if mishandled.

Using extension handles increases the risk of injury.

Best Uses

You will find lever load binders most effective in the trucking industry, especially for securing cargo on flatbed trailers. Their design allows you to tighten chains quickly, making them ideal for highway transportation.

Lever-type binder models from Powerful Machinery offer robust construction and reliable performance, ensuring your load stays secure during transit. Choose lever binders when you need a simple, fast, and economical solution for heavy-duty cargo securement.

Ratchet Binders

Mechanism

You operate a ratchet binder by turning a geared handle that tightens the chain incrementally. This mechanism gives you a mechanical advantage, making it easier to achieve high tension with minimal effort.

The ratchet binder uses a screw thread and internal gears, allowing you to apply consistent pressure and maintain securement throughout transit. You rotate the handle repeatedly, which helps you fine-tune the tensioning and avoid sudden movements.

This design reduces the risk of recoil and provides better control over the load.

Advantages

Ratchet binders offer several benefits that make them popular in the transportation industry:

You experience increased safety because the ratcheting mechanism prevents sudden kickback.

Ratchet load binders allow for precise adjustments, so you can achieve optimal chain tensioning.

You need less physical effort to operate ratchet binders compared to lever types.

The continuous tensioning process gives you better control, especially when securing sensitive or irregularly shaped cargo.

Newer ratchet load binders from Powerful Machinery feature advanced safety designs and high-quality materials, meeting strict industry standards.

Tip: Ratchet load binders help you avoid over-tensioning, reducing the risk of damage to your cargo and equipment.

Disadvantages

While ratchet binders provide many advantages, you should consider a few limitations:

Ratchet binders generally take longer to tighten and release than lever binders.

The loading and unloading process is slower and steadier, which may not suit time-sensitive jobs.

Ratchet load binders are heavier and bulkier due to their internal gear system.

You may find that the slower operation is a trade-off for increased safety and control.

Best Uses

You will find ratchet load binders most effective in situations that demand strong tensioning and precise control. These binders excel in securing heavy loads for transportation, construction, logging, and agriculture. You can rely on ratchet binders for oilfield applications, flatbed trailers on long hauls, and rough roads.

In agriculture, ratchet load binders help you secure tractors and equipment on uneven terrain. Powerful Machinery’s ratchet load binders deliver reliable performance and precision tensioning, making them a trusted choice for demanding environments.

Ratchet Binders vs Lever Binders

When you compare ratchet binders vs lever binders, you see clear differences in how each tool secures cargo. The right choice depends on your priorities for safety, speed, ease of use, cost, and long-term value. Below, you will find a detailed breakdown to help you select the best binder for your needs.

Mechanism

The main difference between ratchet binders vs lever binders lies in their tensioning style. Ratchet load binders use a ratcheting handle to tighten the chain step by step. Lever load binders rely on a single, quick lever action to secure the load. This difference affects how you apply force and control tension.

Feature | Ratchet Load Binder | Lever Load Binder |

|---|---|---|

Tensioning Style | Step-by-step with a ratcheting handle | Single quick lever action |

Mechanical Advantage | High uses gears | Moderate, uses leverage |

Control | Precise, incremental | Fast, less precise |

Note: Ratchet binders give you more control over the tensioning process, while lever binders let you secure loads quickly.

Safety

Safety is a top concern when choosing between ratchet binders vs lever binders. Ratchet binders reduce the risk of sudden handle movement or kickback. The ratcheting mechanism stores less energy in the handle, making it safer for you during both tightening and release.

Lever binders, on the other hand, store significant energy in the handle. If you lose your grip, the handle can snap back, which may cause injury.

Ratchet binders: Safer, less risk of handle snapback.

Lever binders: Higher risk of sudden handle movement, requires careful handling.

Ease of Use

Ease of use matters, especially if you secure loads frequently. Ratchet binders allow you to tighten chains with less physical effort. You turn the handle in small increments, which reduces strain and makes the process manageable even for heavy loads.

Lever binders work faster but require more strength and control. You must pull the handle with enough force to achieve proper tension, which can be challenging for some operators.

Ratchet binders: Provide a mechanical advantage, easier on your body.

Lever binders: Faster to use, but they demand more physical strength.

Speed

Speed can influence your choice of tie-down methods. Lever binders secure loads in one quick motion, making them ideal for jobs where time is critical. Ratchet binders take longer because you must turn the handle repeatedly to reach the desired tension.

This slower process, however, gives you more control and precision.

Binder Type | Speed to Secure | Control Level |

|---|---|---|

Lever Binder | Fast | Moderate |

Ratchet Binder | Slower | High |

Tip: Choose lever binders for quick jobs and ratchet binders when you need precise tensioning.

Cost

Cost and long-term value play a role in your decision. Lever binders are typically more economical upfront. Ratchet binders cost slightly more due to their complex mechanism, but they may offer better long-term dependability because of their safer operation and reduced wear on chains.

Binder Type | Average Price (5/16″) |

|---|---|

Lever Binder | $31.89 |

Ratchet Binder | $35.19 |

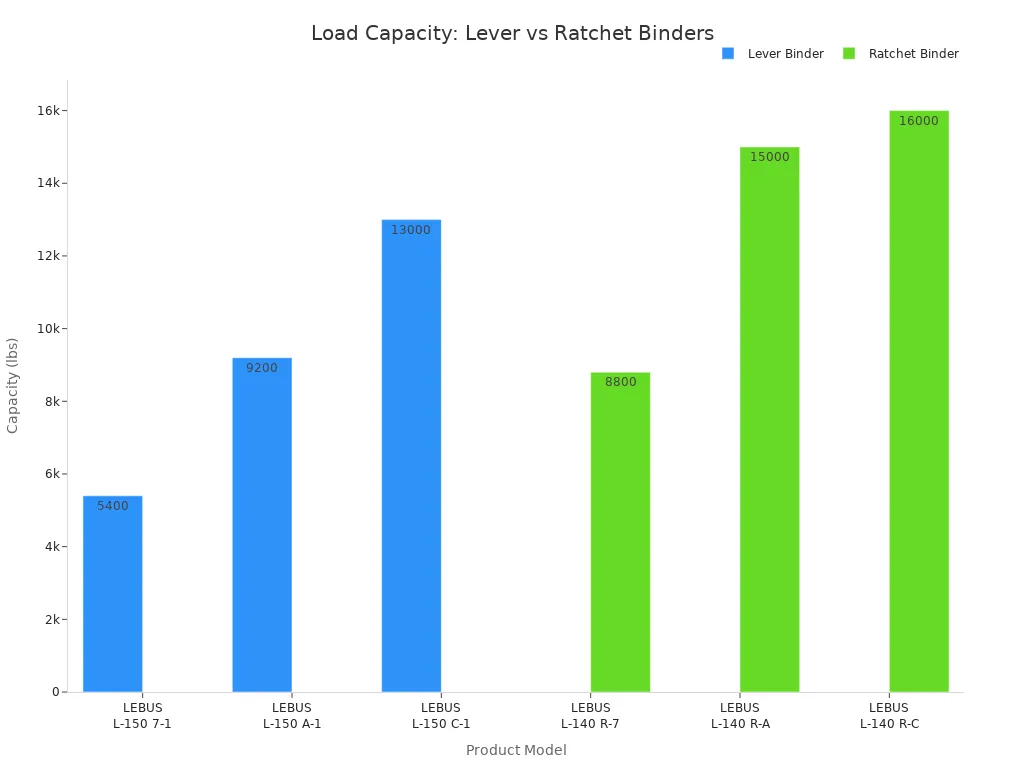

Load Capacity

Both ratchet load binders and lever load binders offer high load capacity, but specific models may differ. Ratchet binders often provide higher-rated capacities for the same chain size, giving you more flexibility for heavy-duty applications.

Type | Product ID | Description | Capacity |

|---|---|---|---|

Lever Binder | 1048128 | LEBUS L-150 5/16″ – 3/8″ Standard Lever Type | 5,400 lbs |

Lever Binder | 1048146 | LEBUS L-150 A-1 3/8″ – 1/2″ Standard Lever | 9,200 lbs |

Lever Binder | 1048164 | LEBUS L-150 C-1-1/2″ – 5/8″ Standard Lever | 13,000 lbs |

Ratchet Binder | 1048404 | LEBUS L-140 R-7 5/16″ – 3/8″ Standard Ratchet | 8,800 lbs |

Ratchet Binder | 1048422 | LEBUS L-140 R-A 3/8″ – 1/2″ Standard Ratchet | 15,000 lbs |

Ratchet Binder | 1048440 | LEBUS L-140 R-C 1/2″ – 5/8″ Standard Ratchet | 16,000 lbs |

Applications

You will find ratchet binders vs lever binders used in different industries based on their strengths. Ratchet load binders are common in heavy-duty transport, construction, and situations where safety and precision matter most.

Lever load binders are often chosen for lighter loads, quick installations, and jobs where speed is the priority.

Type | Mechanism | Safety Features | Typical Applications |

|---|---|---|---|

Ratchet Binders | Ratcheting mechanism for tension | Safer, less energy in handling | Heavy-duty transport, construction |

Lever Binders | Leverage to tighten the chain | Stores energy in the handle, needs strength | Lighter loads, quick installations |

Best for: Use ratchet binders when you need precision, safety, and reduced strain. Choose lever binders for quick jobs and lighter loads.

When you evaluate ratchet binders vs lever binders, consider your specific cargo, operator experience, and the environment. Both options deliver reliable performance, but your priorities for safety, speed, load capacity, and long-term dependability will guide your decision.

Safety

General Tips

You must prioritize safety when securing cargo with load binders. Regular inspection of both binders and chains helps you prevent accidents and maintain reliability. Lay out chains on a flat surface to check for visible defects.

Measure chain links against manufacturer specifications to identify wear or elongation, removing any that exceed 3% of their original length. Look for rust or corrosion, as even minor surface rust can signal deeper problems.

Before each use, check all rigging components for signs of damage or defects. Remove any damaged equipment from service immediately to avoid hazards.

Tip: Consistent inspection and maintenance of your equipment ensures safe operation and extends the lifespan of your load binders.

Lever Binder Safety

Lever binders require careful handling due to their mechanical design and stored energy. You should inspect the lever binder before each use and avoid using it if you notice any bending or cracking. Operate the binder alone, standing securely on the ground with a firm footing.

Never use a cheater bar or extender; always tighten by hand in a downward direction. Use gloves to maintain grip and protect your hands. Exercise caution when releasing the load to prevent injury. Stay clear of the line of fire in case you lose your grasp.

Safety Tip | Description |

|---|---|

Regular Inspection | Check for wear, bending, or cracks before each use. |

Single Operator Use | Operate alone, never with more than one person. |

Safe Positioning | Stand on the ground, not on the load. |

Avoid Cheater Bars | Tighten by hand, avoid extenders. |

Caution with Release | Be alert when releasing tension. |

Use of Gloves | Wear gloves for grip and protection. |

Ratchet Binder Safety

Ratchet binders offer enhanced safety and ease of use, but you must still follow best practices. Distribute cargo weight evenly, placing heavier items lower and centered over the axles. Use edge protectors to prevent damage to cargo and straps.

Inspect ratchet binders and straps for wear, cuts, abrasions, or UV damage before each use. Clean straps with mild detergent and store them in a cool, dry place away from sunlight.

Note: Powerful Machinery’s load binders meet strict safety standards, including ISO 9001 and LEEA certifications. You can trust their products for reliable performance and safety considerations in every application.

Choosing a Binder

Assessing Needs

You must evaluate your cargo and environment before selecting a load binder. The right choice depends on several factors that affect safety and efficiency. Consider these points when deciding between lever binders and ratchet binders:

Tension Control: Ratchet load binders give you precise tension control, which suits a wide range of cargo types.

Speed and Efficiency: Lever load binders work faster, making them ideal for time-sensitive jobs.

Cargo Sensitivity: Ratchet binders excel with delicate cargo because you can adjust tension incrementally.

Safety: Ratchet binders often include extra safety features, increasing cargo security.

Load Type and Size: Always match the binder to the size, weight, and shape of your load.

Tip: Powerful Machinery offers both lever and ratchet load binders, so you can select the best option for your specific transportation needs.

Operator Experience

Your experience level plays a key role in safe and effective binder use. Skilled operators focus on proven results and follow strict safety standards. This approach reduces the risk of accidents and injuries during cargo securement.

Evidence | Description |

|---|---|

Operator Experience | Experienced professionals prioritize validated results for safety and performance. |

Risk Reduction | Diligence in operation lowers the chance of accidents and injuries. |

You should also follow these safety practices:

Inspect the binder for wear before each use.

Avoid using binders with visible bending or cracks.

Operate lever binders alone, never with more than one person.

Stand on solid ground for a secure footing.

Never use a cheater bar to tighten or release the load.

Wear gloves to protect your hands.

Matching Binder and Chain

You need to pair the correct binder and chain for your cargo. This step ensures safe transport and compliance with industry standards.

Chain Grade: Select the grade based on your load. Grade 70 works well for general transport. Grade 80 and 100 suits heavier loads.

Chain Size: Larger diameters increase working load limits. For example, a 5/16″ Grade 70 chain supports about 4,700 lbs.

Working Load Limit (WLL): Choose a chain with a WLL greater than your load weight divided by the number of tie-downs.

End Fittings: Adjust grab hooks to fit your anchor points.

Note: Powerful Machinery provides expert support and custom-engineered solutions. You can consult their team to ensure you select the right binder and chain combination for your project.

Conclusion

You now understand the main differences between lever binders and ratchet binders. Lever load binders offer fast operation and simple design, while ratchet binders provide safer, more controlled tensioning.

When you select lever load binders or ratchet binders, always consider your cargo type and safety requirements. Powerful Machinery delivers certified products and expert support for every application.

For reliable cargo securement, consult Powerful Machinery. You get trusted advice and high-quality lever load binders and ratchet binders for your needs.

FAQ

What is the main difference between lever binders and ratchet binders?

Lever binders use a single lever action for quick tensioning. Ratchet binders use a ratcheting handle for gradual, controlled tightening. You get faster operation with lever binders and more precise control with ratchet binders.

How do I choose the right load binder for my cargo?

You should consider your cargo weight, chain size, and desired tension control. Ratchet binders work best for heavy or sensitive loads. Lever binders suit quick jobs with lighter cargo. Always match the binder to your chain and load requirements.

Are the Powerful Machinery load binders certified for safety?

Yes. Powerful Machinery load binders meet international safety standards, including ISO9001 and TUV Rheinland. You can trust their products for reliable performance and certified quality in demanding environments.

Can I use load binders in harsh weather conditions?

You can use Powerful Machinery load binders in various weather conditions. Their corrosion-resistant coating and robust construction ensure durability and performance, even in extreme environments.