You must measure wire rope diameter with accuracy and attention to detail. This process ensures safety and equipment compatibility in demanding applications such as cranes, construction sites, and elevators.

An accurate diameter helps you achieve accurate socket positioning, which is essential for reliable performance and long-term safety. Powerful Machinery’s steel wire rope products meet strict international standards, including ISO 2414 and DIN 3054, guaranteeing durability, load-bearing strength, and corrosion resistance.

Standard | Description | Importance |

|---|---|---|

ISO 2414 | Ensures steel wire ropes can handle high stress. | Focuses on load-bearing and tensile strength. |

DIN 3054 | Specifies steel quality, ensuring corrosion resistance and durability. | Ensures material quality for long-term use. |

General | Quality standards ensure ropes can withstand intense stress and wear. | Indispensable for industrial safety. |

Common uses for wire rope diameter measurement include:

Cranes and hoists

Construction and infrastructure

Elevators and lifts

Accurate wire rope diameter measurement protects your team, your equipment, and your investment.

Key Takeaways

Accurate wire rope diameter measurement is crucial for safety and compliance in industrial settings. It helps prevent failures and ensures equipment compatibility.

Use certified tools like parallel-jawed calipers or digital gauges for precise measurements. Avoid using tape measures for critical checks.

Regularly monitor wire rope diameter to track wear and prevent premature failures. Keep detailed records to support maintenance and safety compliance.

Follow industry standards for measuring wire rope diameter. Compare your measurements to nominal values to ensure they meet safety requirements.

Choose high-quality wire ropes that resist corrosion and maintain a consistent diameter. This choice enhances performance and extends service life.

Importance of Wire Rope Diameter Measurement

Safety and Compliance

You must measure wire rope diameter with precision to maintain safety in industrial environments. Accurate measurement helps you avoid unsafe rope performance, increased wear, and potential catastrophic failures.

Failure to carry out any of the above could result in unsatisfactory and unsafe rope performance.

Unsafe rope performance

Increased wear

Potential catastrophic failures

International standards, such as ISO 4309:2017, specify the care, maintenance, and discard criteria for wire ropes used in cranes. These standards guide you in inspecting and maintaining wire ropes, including proper diameter measurement.

GB standards also apply to elevator ropes, requiring a minimum diameter of 8mm to meet safety requirements. Powerful Machinery’s steel wire ropes comply with these standards, ensuring you meet safety and regulatory demands in every application.

Equipment Compatibility

You must ensure the wire rope diameter matches your equipment specifications. Accurate measurement guarantees a proper fit with sheaves, winches, and other components. If you use an incorrect diameter, you may face improper winding on drums, increased wear on parts, and uneven load distribution.

These issues can compromise both safety and operational efficiency. Powerful Machinery designs steel wire ropes to fit a wide range of equipment, supporting seamless integration and reliable performance.

Maintenance and Record-Keeping

Regular measurement of wire rope diameter helps you determine load capacity and safety factors. You can prevent premature wear and failure by monitoring diameter reduction.

Accurate wire rope diameter measurement is essential for determining load capacity and safety factors, which helps prevent premature wear and failure.

Diameter reduction can lead to significant issues such as rope breakage, excessive abrasion, and corrosion, impacting long-term maintenance costs.

Regular measurement and monitoring of wire rope diameter can help in timely replacements, thus reducing operational costs associated with unexpected failures.

You should keep detailed records of diameter measurements to track rope condition over time. Powerful Machinery’s commitment to quality and international standards supports your maintenance routines and documentation needs, helping you extend the lifespan of your wire ropes and reduce operational costs.

Tools for Measuring Wire Rope Diameter

Calipers and Digital Gauges

You need precise tools for measuring rope diameter. Industry experts recommend parallel-jawed calipers and digital gauges for reliable results. These instruments help you avoid errors and ensure accurate dimension readings.

Here is a comparison of popular calipers and gauges:

Type of Caliper | Description |

|---|---|

Caliper gauge | Wide jaws prevent systematic errors and allow professional measuring of rope diameter. |

Muncy™ Quick Check Calipers | Long surface design ensures proper measuring, available in digital or dial readouts. |

INSIZE Large Measuring Face Digital Caliper | Wide jaw faces suit rope diameter measuring in manufacturing and quality control. |

You should select certified and calibrated calipers for all measuring techniques. Digital gauges provide quick and clear readings, making them ideal for routine inspections.

Powerful Machinery Steel Wire Rope Features

Powerful Machinery’s steel wire rope stands out for its non-rotating design and high tensile strength. These features support accurate measuring and stable dimension control. The rope resists abrasion and corrosion, which helps maintain a consistent rope diameter over time.

You benefit from multiple configurations, such as 35W×7 and 18×19, tailored for specific applications.

Tip: Using high-quality wire ropes from Powerful Machinery ensures that your measuring results remain consistent and reliable throughout the rope’s service life.

Alternative Methods

You may use tape measures or specialized diameter tapes for quick checks. These techniques work for basic inspections but lack the precision of parallel-jawed calipers. For critical applications, always rely on professional measuring tools.

Calibration and Inspection

Regular calibration keeps your measuring tools accurate. You should inspect and calibrate instruments before installation, during preventive maintenance, and at scheduled shutdowns.

Calibration procedures include:

Calibration Step | Purpose |

|---|---|

Thorough inspections | Ensures all components function correctly and safely. |

Testing overload protection systems | Verifies safety mechanisms to prevent accidents. |

Calibrating load sensors and indicators | Maintains accuracy in measuring loads. |

Checking and adjusting limit switches | Ensures safe operation and prevents overextension. |

Verifying brake functionality | Confirms safe stopping and holding of loads. |

Calibration typically occurs annually, but you may need more frequent checks in harsh environments. Always label calibration intervals and balance costs with the risk of inaccuracies.

Wire Rope Diameter Measurement Procedure

Preparation and Placement

Before you begin wire rope diameter measurement, you must prepare the rope and your tools. Select a clean, straight section of the rope that is free from bends, kinks, or visible damage. Avoid measuring near end fittings, splices, or areas that have been flattened.

Place the rope on a stable surface or keep it suspended with minimal tension. This step ensures you get the most accurate measured diameter and prevents errors caused by rope distortion.

Tip: Powerful Machinery’s non-rotating steel wire ropes make it easier to find undistorted sections, reducing the risk of inaccurate readings.

Measuring Steel Wire Ropes Accurately

To achieve precise results when measuring steel wire ropes, follow these steps:

Use a certified parallel-jawed caliper or a digital gauge. These tools provide the most reliable measured diameter.

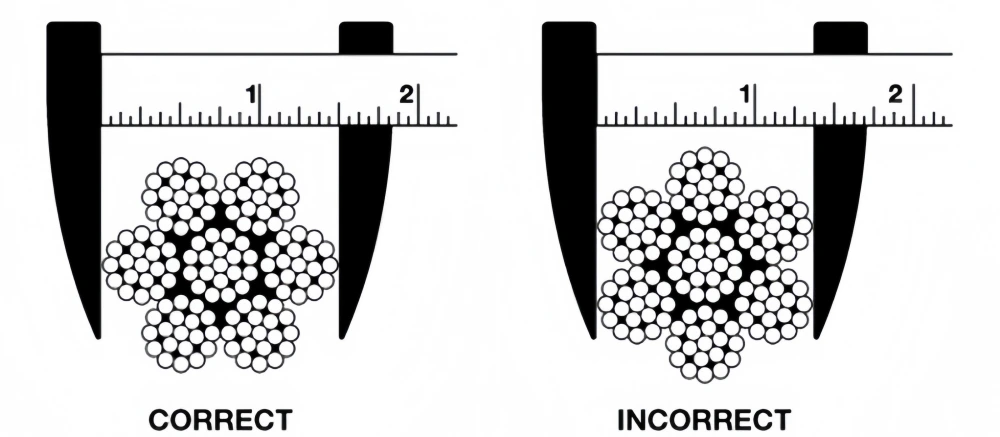

Open the caliper jaws and position them at a right angle to the rope’s axis. Make sure the jaws contact the outermost wires on opposite sides.

Gently close the jaws until they touch the rope without compressing it. Excessive force can distort the measured diameter.

Read the measured diameter directly from the caliper or digital display.

Record the measured diameter immediately for documentation and future reference.

You should always compare your measured diameter to the nominal wire rope diameter specified by the manufacturer. Powerful Machinery provides detailed product specifications, including nominal diameter and diameter tolerance, for every steel wire rope configuration.

Multiple Measurements and Averaging

Wire rope diameter measurement requires you to take several readings along the rope. Measure at three or more points, each spaced at least one meter apart. Rotate the rope slightly at each location to capture any variation in the measured diameter.

Write down each measured diameter and calculate the average. This method helps you identify local wear or deformation and ensures your results reflect the true nominal diameter.

Measurement Point | Measured Diameter (mm) |

|---|---|

1 | 15.2 |

2 | 15.1 |

3 | 15.3 |

Average | 15.2 |

Note: Averaging multiple measured diameter values helps you comply with industry standards and more stringent tolerances.

Off Tension vs. Under Tension

You must decide whether to measure the rope under tension or off tension. Most standards recommend measuring wire rope diameter when the rope is off tension, as tension can temporarily reduce the measured diameter.

However, some applications require you to check the measured diameter under working load to verify length tolerances and performance. Always follow the manufacturer’s guidelines and industry standards for your specific application.

Powerful Machinery’s steel wire ropes maintain a consistent measured diameter due to their robust construction and non-rotating design, even under load.

Common Mistakes to Avoid

Many technicians make errors during wire rope diameter measurement. You can avoid these mistakes by following best practices:

Do not measure flattened or bent sections. Always select undistorted rope areas.

Never use inappropriate tools. A caliper is required for accurate measured diameter.

Avoid starting measurements at the wrong point. Begin at the widest part of the rope cross-section.

Always account for manufacturing tolerance. Refer to the product’s diameter tolerance and industry standards.

Do not neglect the rope’s lay direction or construction. This is critical for matching existing systems or specifications.

Mistake | Solution |

|---|---|

Measuring flattened or bent sections | Always measure on undistorted rope sections. |

Using inappropriate tools | A caliper is required for diameter measurement. |

Not accounting for manufacturing tolerance | Refer to standards for acceptable limits. |

Neglecting the lay direction or construction | Critical for matching existing systems or specs. |

Remember: Powerful Machinery’s steel wire ropes are manufactured with more stringent tolerances, ensuring you receive consistent measured diameter and reliable performance in every application.

By following these steps and avoiding common mistakes, you ensure your wire rope diameter measurement meets industry standards. You also protect your equipment and personnel by maintaining accurate records of the measured diameter and diameter tolerance for every rope in service.

Standards, Tolerances, and Documentation

Nominal vs. Actual Diameter

You will often see two terms when measuring steel wire ropes: nominal diameter and actual diameter. The nominal diameter is the catalog value provided by the manufacturer. The actual diameter is what you measure on the rope, which can vary due to manufacturing tolerances and use.

Industry standards, such as EN and ISO, define these differences clearly. The table below shows how these values compare:

Aspect | Nominal Diameter | Actual Diameter (Range) |

|---|---|---|

Definition | Catalog value | Varies due to tolerances |

Reference Diameter | Larger than nominal | 22mm to 22mm + 5% |

Post-installation Change | Stated on certification | Changes after loading cycle |

You should always compare your measured diameter to the nominal value and check if it falls within the acceptable range.

Industry Standards for Measuring Steel Wire Ropes

You must follow recognized standards to ensure safety and reliability. EN, ISO, ASTM, and API standards all guide how to measure and interpret wire rope diameter. Powerful Machinery’s steel wire ropes meet or exceed these standards, including ISO9001, TUV Rheinland, and ASTM.

These certifications guarantee that you receive products with consistent quality and performance.

Tolerances and Permissible Differences

When you measure wire rope diameter, you need to understand the permissible tolerances. According to ASTM and API standards:

Manufacturers produce wire rope slightly larger than the nominal diameter.

Tolerances are positive when specified in inches.

The nominal diameter is the minimum allowed. The rope is not oversized unless it exceeds the maximum permissible diameter.

You should always check the manufacturer’s specifications for the exact tolerance range.

Documentation and Record-Keeping

Proper documentation is essential for compliance and safety. You should:

Measure the rope diameter at several points using a caliper.

Compare each measurement to the nominal diameter listed by the manufacturer.

Record all measurements and observations in a written log.

Keeping detailed records helps you track rope condition, meet industry requirements, and plan timely maintenance. Powerful Machinery supports your documentation needs by providing clear product specifications and compliance certificates.

Unit Conversion for Wire Rope Diameter

English to Metric Conversion

You often encounter wire rope specifications in both imperial and metric units. Accurate conversion ensures you select the correct rope for your equipment and comply with international standards.

To convert wire rope diameter from inches to millimeters, multiply the value by 25.4. For example, a 1/2 inch wire rope equals 12.7 mm. You can use the following table for quick reference:

Diameter (inches) | Diameter (mm) |

|---|---|

1/4 | 6.35 |

3/8 | 9.53 |

1/2 | 12.7 |

5/8 | 15.88 |

3/4 | 19.05 |

Tip: Always check the manufacturer’s specifications for the most accurate conversion.

Soft and Hard Conversion Methods

You may use two main methods for unit conversion: soft conversion and hard conversion. Soft conversion means you translate the measurement directly without changing the product’s physical dimensions. Hard conversion means you adjust the product to match the new unit system exactly.

For example, a wire rope with a nominal diameter of 1/2 inch (12.7 mm) remains unchanged with soft conversion. With hard conversion, you might round the diameter to 13 mm to fit metric standards.

Soft conversion: Keeps original dimensions, only changes units.

Hard conversion: Adjusts product to match the new unit system.

You should choose the method based on your project requirements and compliance needs.

Conversion Tables and Application

You need conversion tables for more than just diameter. Strength and weight also require accurate conversion. Use the following formulas:

Diameter: inches × 25.4 = millimeters

Strength: pounds × 0.4536 = kilograms

Weight: pounds per foot × 1.488 = kilograms per meter

Property | Imperial Value | Metric Value |

|---|---|---|

Diameter | 1/2 in | 12.7 mm |

Strength | 10,000 lbs | 4,536 kg |

Weight | 0.5 lbs/ft | 0.744 kg/m |

Note: When converting, always round to the nearest standard size. Follow industry tolerances to ensure safety and compatibility.

You improve accuracy and safety by applying these conversion methods and tables. Powerful Machinery provides detailed specifications in both imperial and metric units, helping you select the right steel wire rope for any application.

Conclusion

You ensure safety and compliance by measuring wire rope diameter with certified tools and following industry standards. Powerful Machinery’s Steel Wire Rope offers superior strength, corrosion resistance, and reliable performance in harsh environments.

Maintains flexibility under heavy loads

Resists rust and chemical corrosion

Performs well in extreme temperatures

Regularly measure and inspect your wire ropes. Follow manufacturer guidelines to prevent damage and extend service life. For expert support, consult Powerful Machinery’s team or review product specifications.

FAQ

How often should you measure wire rope diameter?

You should measure wire rope diameter during installation, after heavy use, and as part of regular inspections. Frequent checks help you detect wear early and maintain safety.

What tool gives the most accurate wire rope diameter measurement?

A certified parallel-jawed caliper provides the most accurate results. Digital gauges also work well for quick, reliable readings. Avoid using tape measures for critical measurements.

Why does the measured diameter sometimes differ from the nominal diameter?

Manufacturing tolerances and rope wear can cause slight differences. Always compare your measured value to the manufacturer’s specifications and industry standards.

What makes Powerful Machinery’s steel wire rope suitable for demanding applications?

You benefit from high tensile strength, a non-rotating design, and corrosion resistance. These features ensure reliable performance and long service life in harsh environments.