Choosing the right pallet truck size for your pallets and workspace protects you from injuries and prevents equipment damage. When you match the truck’s load capacity and fork size to your pallets, you keep operations stable and efficient.

You avoid overloading and make maneuvering safer, especially in tight warehouse aisles. Powerful Machinery’s Pallet Trucks feature ergonomic handles and durable construction, which help you move heavy loads comfortably and reliably in any environment.

Key Takeaways

Choose the right pallet truck size to prevent injuries and equipment damage. Matching the truck’s load capacity and fork size to your pallets ensures safe operations.

Regularly inspect your pallet truck before use. Daily checks on the hydraulic system, wheels, and forks help prevent accidents and maintain safety.

Select pallet trucks based on your warehouse layout. Measure aisle widths and pallet dimensions to ensure smooth maneuverability and avoid collisions.

Use ergonomic handles on pallet trucks to reduce operator fatigue. This feature enhances control and comfort during heavy lifting and transport.

Train operators on safe handling techniques. Proper training improves safety and efficiency, ensuring everyone knows how to use pallet trucks correctly.

Why Pallet Truck Size Selection Matters?

Safety Risks of Incorrect Sizing

You face serious risks when pallet truck size selection does not match your pallets or workspace. Using a truck that is too large or too small for your pallets can cause instability during transport.

Loads may tip over, or pallets may break under weight, leading to injuries and damaged goods. Acute injuries can happen to you or nearby workers if the truck is overloaded or hard to control.

Chronic injuries, such as musculoskeletal disorders (MSDs), often develop from repeated strain. These MSDs range from mild pain to permanent disabilities.

Tip: Always check that your pallet truck size selection fits the pallet dimensions and load requirements to prevent accidents.

Employers must comply with health and safety regulations. You need to ensure that pallets are not damaged and are the correct size for the truck. This reduces the risk of workplace accidents and keeps everyone safe, especially in narrow warehouse aisles where maneuvering is more difficult.

Incorrect use of pallet trucks can lead to:

Acute injuries for operators and nearby workers

Chronic injuries, including musculoskeletal disorders

Increased risk of load instability and tipping

Benefits of the Right Pallet Truck

Choosing the right pallet truck for your pallets and environment improves safety and boosts productivity. When you select the correct pallet truck size, you streamline weighing processes and enhance inventory accuracy. You reduce manual hassles and save time by combining weighing and transporting into one process.

Improvement Type | Description |

|---|---|

Efficiency Boost | Streamlines weighing processes, enhances inventory accuracy, and reduces manual hassles. |

Safety and Compliance | Ensures workplace safety, complies with regulations, and optimizes shipping processes with precise weight measurements. |

Time Savings | Combines weighing and transporting into one process, reducing downtime and increasing productivity. |

You also lower operational costs. The table below shows how different pallet truck types affect your workflow:

Type of Pallet Truck | Pros | Cons |

|---|---|---|

Single Pallet Truck | Cost-Effective, Versatile, Simple Operation | Limited Load Capacity, Lower Efficiency |

Double Pallet Truck | Increased Efficiency, Reduced Labor Costs, Better for Bulk Handling | Larger Size, Higher Initial Investment |

Pallet truck size selection helps you avoid overloading and makes it easier to maneuver in narrow warehouse aisles. You protect your team and your goods, and you keep your operations running smoothly. When you focus on choosing the right pallet truck, you create a safer and more efficient workplace.

Pallet Types and Standard Sizes

Understanding pallet types and their standard sizes helps you choose the right pallet truck for your warehouse. Each region and industry uses specific pallets, and these differences impact your equipment needs.

Euro Pallets

You often find Euro pallets in European warehouses. These pallets measure 1200 x 800 mm. Their standard size ensures compatibility with most warehouse systems and forklifts. You can optimize space in transport vehicles and storage areas with these pallets. They also make loading processes more efficient.

Euro pallets have standard dimensions of 1200 x 800 mm.

They fit most warehouse racking and pallet trucks.

You gain 15-25% more transportation efficiency compared to non-standardized alternatives.

Metric | Value |

|---|---|

Total EUR-pallets in circulation | Approximately 675 million |

Transportation efficiency gains | 15-25% |

UK Pallets

UK pallets differ from Euro and US pallets in size. The standard UK pallet measures 100 x 120 cm. This size affects how you select pallet trucks, especially when you handle mixed pallet types.

Pallet Type | Dimensions (cm) |

|---|---|

Euro Pallet | 80 x 120 |

Standard UK Pallet | 100 x 120 |

US Pallet | 121.9 x 101.6 |

US Pallets

In the US, the 48 x 40-inch pallet is the most common. This size fits through standard truck and container doors. You also see 42 x 42 inch pallets in retail and pharmaceuticals, and 48 x 48 inch pallets in construction and manufacturing.

The dimensions of US pallets determine the fork length and width you need for your pallet truck. The Grocery Manufacturers Association specifies the 48 x 40-inch pallet, which makes up over 30% of all pallets in the US.

The 48 x 40-inch pallet fits standard doorways and trucks.

The 42 x 42-inch pallet is common in retail and pharmaceuticals.

The 48 x 48-inch pallet offers stability for heavy loads.

Printers and Small Pallets

You may encounter smaller pallets in logistics, especially for printers or compact goods. These pallets vary by region:

Region | Standard Pallet Size (inches) | Description |

|---|---|---|

North America | 40 x 48 | Used in the grocery and retail industries |

Europe | 39.37 x 47.24 | Known as Euro pallets, for international transport |

Asia | 43.3 x 43.3 / 39.37 x 47.24 | Space-saving for smaller goods |

Australia | 45.9 x 45.9 | Standard for domestic logistics |

You need to match your pallet truck to these smaller sizes for safe and efficient handling.

Custom and Mixed Pallets

Some industries use custom or mixed pallets for specialized needs. You see these in food distribution, chemical, and automotive sectors. Food distributors prefer hygienic pallets that are easy to clean. Chemical industries use pallets with plastic-coated edges to resist spills.

Automotive companies rely on heavy-duty reinforced wood core pallets for machinery. Custom pallets require you to check dimensions and select the right pallet truck for stability and safety.

Note: Always verify pallet types and sizes in your warehouse before choosing a pallet truck. This step ensures safe and efficient operations.

Key Dimensions for Pallet Truck Size Selection

Selecting the right pallet truck dimensions is essential for safe and efficient material handling. You must evaluate several requirements before making your choice. Each dimension affects stability, maneuverability, and stacking performance in your warehouse.

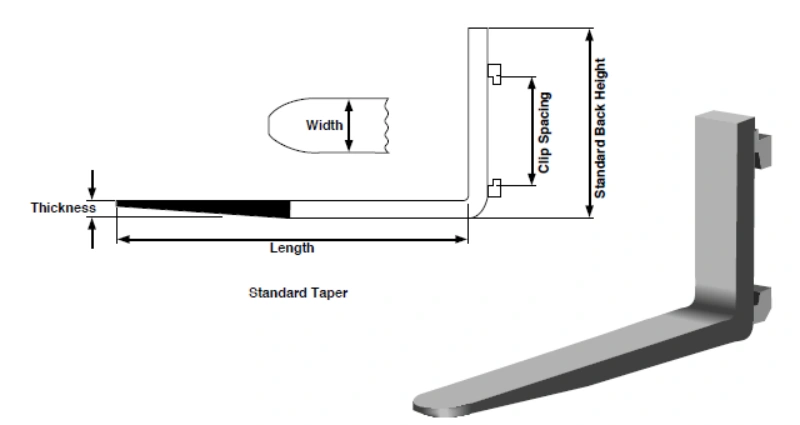

Fork Width and Length

You need to match the pallet truck length and pallet truck width to your specific pallet types. Standard fork length is 48 inches, which supports most standard pallets. If you operate in tight spaces, you can choose shorter forks, such as 36 inches.

The common fork width is 27 inches, allowing easy entry into standard pallets. For smaller pallets, narrower options like 20.5 inches are available.

Fork Length: Standard is 48 inches; shorter options, like 36 inches, suit compact areas.

Fork Width: Common width is 27 inches; 20.5 inches fits smaller pallets.

Lowered Height: Usually around 3 inches for easy access under pallets.

Raised Height: Typically between 7 and 8 inches for safe transport.

The stated capacity of a pallet truck only applies when the load is centered at the specified position. If you increase the load center distance, you risk tipping and instability.

Using a fork length that is too short can cause the load to tip or the pallet to break during stacking. Excessively long forks may protrude, creating hazards in confined areas.

You should ensure the fork length matches or slightly exceeds the pallet length for stability. Avoid forks that are too short or too long to maintain safety and maneuverability.

Fork extensions can help manage wider loads but may affect stability and capacity.

Keep the load center close to the backrest to minimize tipping risk.

The inside width of the extension must not exceed the fork width by more than 1/2 inch.

The length of the fork extension cannot exceed 1½ times the fork length.

Each extension must support three times its rated capacity when mounted.

Lift Height and Ground Clearance

Lift height and ground clearance are critical requirements for stacking and moving pallets. Standard pallet jacks lift between 6 and 8 inches, which is ideal for horizontal transportation and loading or unloading trucks. High-lift pallet jacks can reach 20 to 32 inches, supporting advanced stacking needs.

Type of Pallet Jack | Lift Height Range |

|---|---|

Standard Pallet Jacks | 6 to 8 inches |

High-Lift Pallet Jacks | 20 to 32 inches |

You must check ground clearance to ensure smooth movement over uneven floors or ramp transitions. Adequate ground clearance helps you avoid scraping and damage, especially at the center of the wheelbase.

Aspect | Explanation |

|---|---|

Ground Clearance | The vertical distance from the ground to the lowest point of the pallet truck body (excluding forks). Proper clearance allows navigation over uneven surfaces and ramps. |

Load Capacity

Load capacity is a vital requirement for safe stacking and transport. Hand pallet trucks typically support loads from 1,000 kg to 5,000 kg. Manual models can bear between 5,000 and 6,000 pounds, while electric models handle up to 8,000 pounds or more.

You must select a pallet truck based on your handling needs and the types of pallets you use.

Hand pallet trucks: 1,000 kg to 5,000 kg capacity.

Manual pallet trucks: 5,000 to 6,000 pounds.

Electric models: Up to 8,000 pounds.

Exceeding the maximum load capacity can damage the pallet truck and compromise safety. Overloading affects several components:

Component | Effect of Overloading | Consequence |

|---|---|---|

Forks | Can bend or break under excessive weight. | Unsafe operation and costly replacements. |

Frame | Stress from extra weight can cause cracks or structural damage. | Compromised stability and increased accident risk. |

Wheels | Excessive weight leads to faster wear, such as flat spots or uneven tread. | Difficult maneuverability and potential failure. |

Steering | Becomes less responsive due to added weight, requiring more force to steer. | Increased operator fatigue and collision risk. |

Stability | Overloading reduces stability, increasing the risk of tipping over. | Serious injury risk for the operator. |

You must always check the requirements for load capacity before stacking or moving heavy pallets.

Wheel and Tire Types

Wheel and tire selection impacts pallet truck performance, especially on different floor surfaces and during stacking. You can choose from several types, each with unique characteristics:

Wheel Type | Characteristics | Suitability for Floor Surfaces |

|---|---|---|

Polyurethane Wheels | Lower rolling resistance, quieter, less likely to mark floors, susceptible to corrosion | Ideal for soft floors like laminated and polished tile |

Nylon Wheels | Better suited for harsh environments, good chemical resistance, and can support heavier loads | Best for cold storage, wet, or rough floors |

Poly tread with nylon hub | Non-marking, rolls easily, quiet, susceptible to flat spots | Ideal for display floors, carpeting, and warehouses |

Ultra-poly tread on aluminum hub | Non-marking, longer-lasting, rolls more easily | Suitable for various surfaces, less likely to shatter |

Solid nylon | Best for cold storage, ideal for grated floors, likely to mark floors | Suitable for refrigerated transport trucks and rough pavement |

Solid steel | Best for factories, suitable for rough asphalt, noise is not an issue | Ideal for environments with metal or hard debris |

If you operate in wet or uneven environments, traction tires with deeper treads enhance grip and prevent slippage. Pneumatic tires, filled with air, absorb shocks and allow smoother movement over rough terrain. You must select wheels and tires based on your specific requirements for stacking, maneuverability, and safety.

Tire Type | Features | Benefits for Wet/Uneven Surfaces |

|---|---|---|

Forklift Traction | Deeper treads and complex designs. | Prevents slippage, enhances load control, and improves safety. |

Pneumatic Tires | Air-filled for shock absorption, suitable for rough terrain. | Provides a smooth ride on uneven surfaces, ideal for outdoor use. |

You must consider all pallet truck dimensions and requirements before choosing a model. Proper selection ensures safe stacking, efficient transport, and long-lasting equipment performance.

Matching Pallet Truck to Pallet Type

Standard Pallet Truck Sizes

You need to match your pallet truck to the pallets you handle every day. Standard pallet trucks fit the most common pallet sizes used in logistics and warehousing. These trucks make pallet transport smooth and safe during loading and unloading. The right size helps you avoid jams and keeps your workflow efficient.

Here is a table showing the most common pallet sizes and their uses:

Pallet Size (inches) | Common Uses |

|---|---|

40-by-48 | Grocery products, general industries |

42-by-42 | Telecommunications equipment |

48-by-48 | Transporting oil and liquids |

48-by-42 | Chemical and beverage industries |

40-by-40 | Dairy industry, food safety |

48-by-45 | Automotive industry, bulky parts |

44-by-44 | Chemicals in 55-gallon drums |

36-by-36 | Beverages like soda and water |

48-by-36 | Beverages, shingles, paper goods |

40-by-24 | Retail displays in narrow aisles |

You should check the pallet truck load width and overall width before choosing a model. Standard pallet trucks work best for routine pallet transport, loading, and unloading tasks.

Hand Pallet Truck Size Options

Hand pallet trucks come in many sizes and models. You can select a truck based on your loading needs and the type of pallets you use. Some models offer high lift pallet trucks for stacking, while others provide low lift pallet trucks for simple pallet transport.

Manufacturers like Toyota and Linde offer models with ergonomic designs and special features for easier handling.

Model Type | Description | Weight Capacity | Fork Dimensions |

|---|---|---|---|

Standard Hand Pallet Truck | Light to medium-duty applications | Varies by model | Standard dimensions |

Heavy Duty Hand Pallet Truck | Handles substantial weight | Higher than standard | Standard dimensions |

Weighing Scale Hand Pallet Truck | Integrated scale for weight determination | Varies by model | Standard dimensions |

Semi-Electric Hand Pallet Truck | Battery-powered lifting mechanism | Varies by model | Standard dimensions |

Fully Electric Hand Pallet Truck | Battery-powered lifting and movement | Varies by model | Standard dimensions |

Low/Ultra-Low Profile | Handles low-profile pallets | Standard capacity | Low-profile dimensions |

4-Way Entry/Low Profile | Moves four-way-entry pallets in all directions | Standard capacity | Low-profile dimensions |

You can choose high lift pallet trucks for stacking pallets or low lift pallet trucks for quick loading and unloading. Always match the truck to your handling needs.

Pallet Jack Sizes and Measurements

Pallet jack sizes affect how you move pallets during pallet transport, loading, and unloading. You must consider the overall width, fork length, and load capacity. Most pallet jacks have a load capacity between 2,000 and 5,000 pounds.

Heavy-duty models handle up to 10,000 pounds. Standard fork width is 27 inches, which fits most pallets. Adjustable options let you handle different pallet sizes.

Load capacity ranges from 2,000 to 5,000 pounds.

Fork width is usually 27 inches.

Fork length is often 48 inches.

Overall width is important for navigating tight spaces.

Maximum lift height varies by model.

You should select pallet truck sizes that match your pallets and warehouse layout. High lift pallet trucks help with stacking, while low lift pallet trucks work best for simple pallet transport and loading. Always check the measurements before you start handling pallets.

Tip: Measure your pallets and check your warehouse aisles before choosing a pallet truck. The right fit improves safety and efficiency during loading and unloading.

Adapting to Warehouse Environments

Aisle Width and Maneuverability

You need to measure aisle widths in your warehouse before selecting a pallet truck. Proper aisle width ensures safe operation and prevents collisions. You should account for the largest equipment, add safety clearance, and consider pallet overhang.

The formula for calculating aisle width is simple: W = L + R + S. W stands for aisle width, L is the maximum load size, R is the minimum turning radius of your pallet truck, and S is the safety clearance.

Forklift Type | Recommended Aisle Width (meters) |

|---|---|

Electric Pallet Truck | 2.4 – 2.7 |

Counterbalance Forklift | 3.5 – 4.0 |

Reach Truck | 2.7 – 3.0 |

Very Narrow Aisle (VNA) Forklift | 1.8 – 2.2 |

Measure the largest piece of equipment used in your warehouse.

Add at least 36 inches of safety clearance.

Account for pallet overhang, usually 3 to 6 inches.

Review racking systems to optimize space.

Consider workflow needs to avoid bottlenecks.

You improve maneuverability by choosing a pallet truck that fits your aisle width. This step reduces the risk of accidents and keeps your workflow efficient.

Floor Type and Wheel Selection

You must evaluate your warehouse floor type before choosing pallet truck wheels. Polyurethane wheels work well on smooth, polished floors. Nylon wheels suit cold storage and rough surfaces.

Solid steel wheels handle heavy loads in factories. Pneumatic tires absorb shocks on uneven terrain. Select wheels that match your floor type to prevent damage and ensure smooth movement.

Tip: Use polyurethane wheels for quiet operation and floor protection in retail or office environments.

Wheel selection affects how easily you move loads and how long your equipment lasts. The right wheels reduce wear and improve safety.

Shelf Height and Door Clearance

You should measure shelf heights and door clearances in your warehouse. The lift height of your pallet truck must match the highest shelf you need to reach. Standard pallet trucks lift pallets to 7.5 inches.

High-lift models reach up to 32 inches. Check door clearance to ensure your pallet truck and load fit through all entryways. This step prevents delays and protects your goods from damage.

Measure shelf heights for proper stacking.

Confirm door clearance for easy transport.

Choose pallet trucks with adjustable lift heights for flexibility.

You create a safer and more efficient warehouse by adapting your pallet truck selection to these environmental factors.

Powerful Machinery Pallet Trucks: Features and Advantages

Product Specifications and Versatility

You need equipment that adapts to your daily demands. Powerful Machinery’s pallet trucks deliver a wide range of specifications to fit your unique requirements. You can choose from models with load capacities between 2,000 and 5,500 pounds.

Fork lengths typically measure 48 inches, while fork widths reach 27 inches, making these trucks compatible with most standard pallets. If you handle smaller or custom pallets, you can select narrower or shorter fork options.

Tip: Use the standard 48-inch fork for Euro and US pallets. Choose a shorter fork for tight warehouse spaces.

You benefit from a hydraulic pump system that ensures smooth lifting and lowering. Polyurethane wheels provide excellent maneuverability and protect your floors. The compact design allows you to navigate crowded aisles with ease.

Feature | Specification Range |

|---|---|

Load Capacity | 2,000 – 5,500 lbs |

Fork Length | 36 – 48 inches |

Fork Width | 20.5 – 27 inches |

Lift Height | Up to 7.5 inches |

Wheel Material | Polyurethane |

Safety and Ergonomics

You protect your team and your goods when you choose equipment designed for safety. Powerful Machinery’s pallet trucks feature ergonomic handles that reduce operator fatigue. The handle design gives you a comfortable grip and precise control, even during long shifts.

You also benefit from a robust hydraulic system that prevents sudden drops. The trucks include safety features such as overload protection and smooth braking. These elements help you avoid accidents and injuries in busy warehouse environments.

Ergonomic handle reduces wrist and back strain.

Overload protection keeps you within safe limits.

Smooth braking system enhances load control.

Note: Regularly train your operators on safe handling techniques to maximize these safety features.

Durability and Cost-Effectiveness

You invest in equipment that lasts. Powerful Machinery builds pallet trucks with high-grade steel, ensuring long-term durability. The hydraulic system requires minimal maintenance, which saves you time and money. Polyurethane wheels resist wear and tear, even on rough surfaces.

You lower your operational costs because these trucks do not need electricity or fuel. The simple design means fewer parts to replace, reducing downtime. You can rely on Powerful Machinery’s pallet trucks for consistent performance year after year.

Advantage | Benefit to You |

|---|---|

Steel Construction | Long service life |

Low Maintenance | Reduced repair costs |

No Power Needed | Lower operating expenses |

Versatile Design | Adapts to many applications |

Choose Powerful Machinery for reliable, cost-effective pallet handling in any warehouse environment.

Quick Guide to Right Pallet Truck Size Selection

Selecting the right pallet truck size keeps your operations safe and smooth. Use this quick-reference table to match your needs with the best pallet truck option:

Factor | What to Check | Your Best Choice |

|---|---|---|

Pallet Type | Standard, Euro, Custom, or Small | Match fork length and width |

Load Capacity | Maximum weight per pallet | Choose a truck rated above the max load |

Floor Surface | Smooth, rough, or uneven | Select wheels for your floor type |

Aisle Width | Narrow or wide aisles | Compact or standard truck as needed |

Operation Frequency | Occasional or frequent use | Manual for light, electric for heavy |

Environment | Indoors, outdoors, or cold storage | Durable or specialized materials |

Tip: Always measure your pallets and aisles before making a decision. This step prevents costly mistakes and improves warehouse efficiency.

Follow these steps to select the right Powerful Machinery Pallet Truck for your operation:

Determine the average and maximum weight of your pallets. Pick a truck with a load capacity that exceeds your heaviest load.

Measure your pallet dimensions. Standard pallets need 48-inch forks, while smaller or custom pallets may require shorter or narrower forks.

Assess your workspace. If you work in tight aisles, select a compact model with a tight turning radius.

Check your floor surface. Polyurethane wheels suit smooth floors, while nylon or steel wheels work better on rough or cold surfaces.

Decide how often you will use the truck. Manual models fit occasional use, while electric models handle frequent, heavy-duty tasks.

Review your budget and consider long-term maintenance costs to ensure the best value.

You can always consult Powerful Machinery’s experts for tailored advice. The right choice will boost safety and productivity in your warehouse.

Safe Operation Tips for Pallet Trucks

You improve safety and efficiency when you follow best practices for pallet truck use. Start each day by inspecting your equipment. Check the hydraulic system, wheels, and forks for signs of wear. You prevent accidents when you spot issues early.

Tip: Always use the ergonomic handle on Powerful Machinery pallet trucks. This feature reduces wrist strain and gives you better control during pallet handling.

You should use proper lifting techniques. Keep your back straight and bend your knees when you move heavy loads. Grip the handle firmly and use smooth, steady motions. Avoid sudden jerks or sharp turns. You protect yourself and your coworkers when you use safe movement patterns.

You must use the correct truck for each pallet type. Match the fork length and width to the pallet size. This step keeps loads stable and prevents tipping. You should use trucks with overload protection to avoid exceeding weight limits.

Follow these steps for safe daily use:

Inspect the pallet truck before each use.

Use the ergonomic handle for every movement.

Check the load capacity and never overload.

Use smooth motions when lifting and transporting.

Keep aisles clear for safe operation.

Use proper posture and lifting techniques.

Park the truck in a safe area after use.

Regular maintenance keeps your equipment reliable. Clean the hydraulic pump and wheels after each use. Lubricate moving parts monthly. Replace worn components promptly. You extend the life of your pallet truck when you use a consistent maintenance schedule.

Operator training is essential. You should use training sessions to teach safe use and emergency procedures. Review safety guidelines often. You create a safer workplace when everyone knows how to use pallet trucks correctly.

Safety Tip | Benefit |

|---|---|

Daily inspection | Prevents accidents |

Ergonomic handle use | Reduces fatigue |

Proper lifting technique | Protects your health |

Extends equipment life | |

Operator training | Improves overall safety |

You maximize safety and efficiency when you use Powerful Machinery pallet trucks for every pallet handling operation.

Conclusion

You maximize safety and efficiency when you select the right pallet truck for your needs. Always check pallet dimensions and review your warehouse layout before making a decision.

Powerful Machinery’s pallet trucks help you handle materials safely and reliably. Regularly assess your equipment and environment. If you need expert advice or a custom solution, reach out to Powerful Machinery for support.

FAQ

What pallet truck size should you choose for Euro pallets?

You should select a pallet truck with 48-inch forks and a 27-inch width. This size fits Euro pallets securely and allows safe movement in most warehouse environments.

How often should you inspect your pallet truck for safety?

You need to inspect your pallet truck daily before use. Check the hydraulic system, wheels, and forks for wear or damage. Regular inspections help prevent accidents.

Can you use Powerful Machinery pallet trucks outdoors?

You can use Powerful Machinery pallet trucks outdoors on smooth surfaces. Polyurethane wheels work best indoors, while nylon or steel wheels handle rougher outdoor conditions.

What is the maximum load capacity for Powerful Machinery pallet trucks?

You can handle loads up to 5,500 pounds with Powerful Machinery pallet trucks. Always check your model’s specifications and never exceed the rated capacity.