You master plate clamp safety at work by using only certified, high-quality lifting clamps and following strict safety tips during lifting operations. Choosing plate clamps from trusted brands like Powerful Machinery reduces risks and keeps you compliant with the latest safety regulations.

Reliable lifting tools help you avoid accidents and improve efficiency. You see fewer injuries and smoother workflows when you inspect equipment and select the right clamp for each job.

Certified plate clamps lower manual handling risks.

These products help you meet industry safety standards.

High-quality clamps increase operational efficiency in lifting operations.

Key Takeaways

Always use certified plate clamps to ensure safety and compliance with industry standards.

Inspect your clamps before each use to identify any signs of wear or damage.

Choose the right type of clamp based on the load’s weight and orientation for safe lifting.

Communicate effectively with your team to enhance safety during lifting operations.

Follow strict safety protocols to prevent accidents and ensure smooth workflows.

Plate Clamp Safety Basics

What Are Plate Clamps?

You use plate clamps to lift and move heavy steel plates in industrial settings. These tools grip the edge or surface of a plate, allowing you to handle materials safely and efficiently. Plate clamps play a vital role in construction, manufacturing, and shipping.

You can rely on them to reduce manual handling risks and improve workplace safety. When you select the right lifting clamps, you make your lifting operations smoother and more secure.

Tip: Always check the clamp’s compatibility with the plate’s size and weight before starting any lift.

Powerful Machinery Plate Clamp Features

Powerful Machinery designs plate clamps with your safety in mind. Each clamp uses high-strength steel for durability and a long service life. You benefit from a secure locking mechanism that prevents accidental release during lifting. The smooth surface finish protects your plates from scratches or damage.

Powerful Machinery stands out for its rigorous safety testing and strict adherence to international standards. This commitment makes the brand a dependable choice in the lifting clamps sector. You can trust that every clamp meets ASME B30.20 certification, ensuring safe operation and compliance with industry regulations.

Feature | Benefit to You |

|---|---|

High-strength steel | Long-lasting performance |

Safety lock mechanism | Prevents accidental release |

Smooth finish | Protects plate surfaces |

Certified to ASME B30.20 | Meets safety requirements |

Types: Vertical vs Horizontal

You will find two main types of plate clamps: vertical plate lifting clamps and horizontal plate lifting clamps. Vertical clamps allow you to lift plates upright, which is ideal for moving plates from a stack or standing them on edge.

Horizontal clamps let you lift plates flat, making them perfect for transporting plates across a floor or onto a machine. You should always follow safety tips for each type to avoid accidents and ensure a secure grip. Choosing the correct clamp type for your application keeps your team safe and your workflow efficient.

Choosing the Right Plate Clamp

Assessing Load and Application

You need to select the right plate clamp by carefully assessing your load and application. Start by identifying the weight of the plate you plan to lift. Always choose a clamp with a working load limit (WLL) that matches or slightly exceeds the weight of your load.

Next, check the thickness of the plate and make sure the clamp’s jaw opening fits the material. Consider the orientation of the lift—vertical or horizontal—and the environment where you will use the clamp. Material hardness and the attitude of the lift also play a role in safe lifting.

Review the manual and inspect the clamp before every use.

Load weight: Match the clamp’s WLL to your plate.

Plate thickness: Ensure the jaw opening fits the material.

Clamping force: Use the correct jaw capacity for a secure grip.

Object orientation: Decide if you need vertical or horizontal lifting.

Environment: Check for temperature extremes or special conditions.

Tip: Never lift more than one plate at a time and always keep a safe distance during lifting and lowering.

Powerful Machinery Product Selection

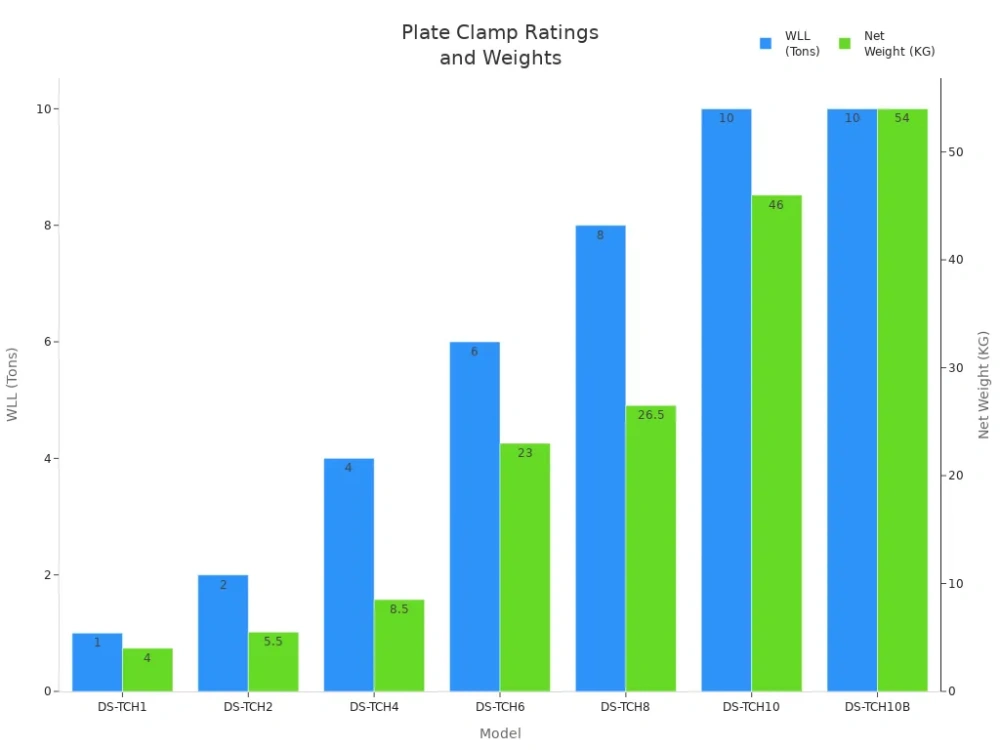

Powerful Machinery offers a wide range of plate clamps designed for different applications. You can find models that handle loads from 1 ton up to 10 tons, with jaw openings suitable for various plate thicknesses. Each clamp features a robust locking mechanism and high-strength steel construction.

These lifting clamps are suitable for use in construction, manufacturing, and shipping. Powerful Machinery’s certified products help you meet strict safety requirements and deliver reliable performance in demanding environments.

Model | WLL (Tons) | Jaw Opening (MM) | Net Weight (KG) |

|---|---|---|---|

DS-TCH1 | 1 | 0-50 | 4 |

DS-TCH2 | 2 | 5-32 | 5.5 |

DS-TCH4 | 4 | 5-50 | 8.5 |

DS-TCH6 | 6 | 5-75 | 23 |

DS-TCH8 | 8 | 5-75 | 26.5 |

DS-TCH10 | 10 | 5-100 | 46 |

DS-TCH10B | 10 | 50-150 | 54 |

Manufacturer Ratings and Standards

You should always check that your plate clamps meet industry standards. Powerful Machinery’s products comply with ASME inspection standards. Each clamp undergoes operational and load tests to ensure safety and functionality.

New or repaired clamps must pass tests by a qualified person, confirming that all moving parts and locking mechanisms work correctly. Load tests verify that clamps can handle 125% of their rated load. These standards guarantee that you use safe, reliable equipment for every lift.

Suitable for lifting steel plates with a maximum hardness of 37 HrC.

Usable in normal atmospheric conditions, from -40℃ to +100℃.

Avoid overloading and jerking the load.

Use the full jaw depth when loading.

Never allow anyone under the load during operation.

Note: Always follow the manufacturer’s guidelines and perform regular inspections to maintain safety.

Plate Clamp Safety Inspection

Exterior and Internal Checks

You must inspect your plate clamps before every use. This process keeps your team safe and ensures reliable lifting operations. Start with an initial inspection when you receive a new clamp or after repairs. For each lift, check the clamp’s condition.

Schedule frequent inspections at set intervals, and perform periodic checks to meet safety standards.

Follow these steps for a thorough inspection:

Examine the clamp for any distortion or bending.

Look for visible cracks or signs of corrosion on all surfaces.

Inspect suspension points, wheels, shackles, gears, pivots, pins, bolts, threads, and springs for wear.

Test the locking mechanism to confirm it works smoothly and holds securely.

Check that the Work Load Limit, serial number, and other markings are clear and readable.

Review inspection records to ensure all checks and tests are up to date.

Tip: Always use only undamaged, clean clamps for every lift. This is one of the most important safety tips for plate clamp safety.

Signs of Wear and Damage

You need to recognize the warning signs that show a clamp is unsafe. Remove any clamp from service if you find these issues:

Cracks anywhere on the clamp.

Permanent deformation, such as a spread jaw, bent frame, or elongated holes.

Excessive wear on teeth or cams, especially if they fall below the manufacturer’s limits.

Heavy corrosion or pitting, especially on gripping faces.

Locking mechanism that fails to engage or disengage, or broken springs.

Illegible nameplate or missing Work Load Limit or serial number.

If you spot any of these problems, do not use the clamp. Replace or repair it according to the manufacturer’s instructions. You protect your team and equipment by acting quickly.

Alert: Never ignore these signs. Immediate action prevents accidents and supports your plate clamp safety program.

Cleaning and Maintenance

You extend the life of your lifting clamps by following a regular cleaning and maintenance routine. Clean the clamp after each use to remove dirt, grease, and debris. Lubricate moving parts as recommended by the manufacturer. Store clamps in a dry, secure place to prevent rust and accidental damage.

Here is how proper maintenance benefits your operation:

Maintenance Practice | Benefit |

|---|---|

Regular Maintenance | Ensures integrity and reliability |

Performance Checks | Reduces the risk of failures |

System Optimization | Optimizes lifespan |

Proper Care | Ensures long-lasting performance |

Safety Checks | Improves operational safety |

Routine Inspections | Prevents wear and tear |

Cleanliness Practices | Maintains accuracy |

Timely Repairs | Extends lifespan |

Note: Consistent cleaning and maintenance help you avoid unexpected breakdowns and keep your plate clamp safety standards high. Make these steps part of your daily routine for the best results.

Safe Lifting Practices

Vertical Plate Clamp Safety Tips

You must follow strict safety tips when using vertical plate lifting clamps. Start by inspecting the clamp before every lift. Check for clear markings, a secure latch, and a clean jaw. Make sure the clamp body and hardware show no signs of damage. Always position the clamp at the plate’s center of gravity.

This step keeps the load stable and prevents tipping.

Apply the load slowly. This action helps the clamp engage properly and reduces shock. Maintain a vertical pull at all times. Angled pulls can weaken the grip and increase the risk of accidents. Lower the plate gently and wait until it is fully supported before removing the clamp.

Tip: Never sideload a vertical clamp or try to lift more than one plate at once. For long plates, use two clamps with a spreader bar to minimize swinging. Avoid lifting plates that are extremely hot, as high temperatures can affect clamp integrity.

Keep the Working Load Limit in mind. Never exceed it. Do not use clamps on oily or slippery surfaces. Avoid making any unauthorized changes to the clamp. These steps form the foundation of plate clamp safety and help you prevent common mistakes.

Horizontal Plate Clamp Safety Tips

Horizontal lifting clamps require a different approach. Always use the correct number of clamps for the plate’s length and weight. Place the clamps evenly along the plate’s edge to distribute the load. Make sure the clamps grip the plate securely before lifting.

Lift the plate slowly and keep it level. Sudden movements can cause the plate to slip or swing. Never allow anyone to stand under a suspended load. Lower the plate onto a stable surface before releasing the clamps.

Check that the clamps match the plate’s thickness and weight.

Inspect the jaw and locking mechanism before each use.

Use a spreader beam if needed to keep the plate balanced.

Avoid jerking or sudden stops during lifting and lowering.

Alert: Always follow the manufacturer’s guidelines for horizontal lifting. Proper positioning and load calculation are key to safe operation.

Team Communication

Effective team communication plays a vital role in plate clamp safety. You need to make sure everyone understands the safety protocols before starting any lift. Hold a quick briefing to review the plan and assign roles. Encourage open dialogue about potential hazards.

This approach helps your team spot risks early and address them before accidents happen.

Clear signals and verbal commands keep everyone on the same page during lifting operations. If you see something unsafe, speak up right away. Training programs that cover the use of lifting clamps, load selection, and safe lifting practices build a strong safety culture.

When your team communicates well, you reduce the risk of mistakes and create a safer work environment.

Note: Safety awareness grows when you share information and support each other. Make communication a daily habit for every lifting task.

Common Plate Clamp Mistakes

Overloading and Sideloading

You face serious risks when you overload or sideload plate clamps. Manufacturers design lifting clamps for specific weights and orientations. If you exceed the rated capacity, you increase the chance of clamp failure. Using the wrong clamp type can cause catastrophic accidents.

Always check the clamp’s condition before each lift. Wear and misuse can reduce the rated capacity, making the clamp unsafe. Shock loading also puts extra stress on the clamp, so you must avoid sudden movements during lifting. These safety tips help you prevent dangerous situations and protect your team.

Exceeding rated capacity

Using the wrong clamp type

Ignoring shock loading

Not considering clamp wear

Remember, the rated capacity applies only when the clamp is in new or like-new condition. Always size the clamp for the plate and application.

Ignoring Inspections

You must never skip regular inspections. These checks help you spot wear patterns, loose components, and other issues before they become hazards. Neglecting inspections leads to equipment breakdowns and increases the risk of workplace accidents.

Regular inspections keep your lifting clamps reliable and safe. Make inspection part of your daily routine and follow all safety tips for plate clamp use.

Identifying wear and tear

Spotting loose or damaged parts

Preventing equipment failures

Reducing workplace accidents

Consistent inspections support a safer work environment and extend the life of your equipment.

Improper Use and Positioning

Improper use and positioning of plate clamps create multiple hazards. You must always lift one plate at a time unless the manufacturer approves otherwise. Overloading or underloading the clamp can cause slippage or instability. Center the clamp above the plate’s center of gravity to prevent side stress.

Wind can make loads swing, so expand the fall-zone when lifting plates to elevated areas. Never drag the load or lift over workers. Avoid lifting from the side with vertical clamps.

Safety Guideline | Description |

|---|---|

Lift one plate at a time | Plate clamps must only lift one plate at a time, except for specific approved cases. |

Avoid overloading | Plate clamps must never be overloaded; always calculate the plate weight and size the clamp appropriately. |

Prevent under-loading | Plate clamps are vulnerable to slippage when lifting less than 50% of the WLL, which can lead to accidents. |

Center above the center of gravity | Always center the clamp directly above the plate’s center of gravity to prevent side stress and slippage. |

Be cautious with the wind | When lifting steel plates to elevated areas, wind can cause the load to swing uncontrollably, necessitating an expanded fall-zone. |

Avoid shock-loading | Just like any other lift, avoid shock-loading when using plate clamps. |

Do not lift over workers | Lifting over workers increases the risk of injury in case of load failure. |

Do not lift from the side | Lifting from the side with a vertical clamp can lead to instability and accidents. |

Do not drag the load | Dragging the load using the plate clamp can compromise safety and control. |

Following these safety tips reduces mistakes and keeps your lifting operations efficient and secure.

Conclusion

You master plate clamp safety by following a clear process. Select the right lifting clamps for your job. Inspect your equipment before every use. Follow all safety protocols and communicate with your team. Powerful Machinery stands behind every product with a strong commitment to quality and safety.

Choose certified solutions and stay alert to keep your workplace safe every day.

FAQ

What is the maximum load a Powerful Machinery plate clamp can handle?

You can find plate clamps from Powerful Machinery with working load limits ranging from 1 ton up to 10 tons. Always check the model’s specifications and never exceed the rated capacity for safe operation.

How often should you inspect your plate clamps?

You should inspect your plate clamps before every use. Schedule more thorough inspections at regular intervals, such as monthly or quarterly, depending on usage frequency and workplace conditions.

Can you use one clamp for both vertical and horizontal lifting?

No, you must use the correct clamp type for each application. Vertical clamps lift plates upright. Horizontal clamps move plates flat. Using the wrong type increases the risk of accidents.

What should you do if you find damage on a plate clamp?

Remove the clamp from service immediately. Do not attempt to use or repair it yourself. Contact a qualified technician or the manufacturer for proper evaluation and repair.

Are the Powerful Machinery plate clamps certified for international safety standards?

Yes. Powerful Machinery plate clamps meet or exceed major international safety standards, including ASME B30.20. You can trust their certification for use in demanding industrial environments.