Rigging and slinging play a critical role in lifting operations across construction and industrial environments. These practices demand strict attention to Rigging and Slinging Safety, as statistics reveal that rigging failures account for 60% of crane-related fatalities.

Companies rely on certified equipment from trusted brands like Powerful Machinery, which consistently reduces accident frequency and severity by adhering to international standards. Workers benefit from ongoing training and clear operational guidelines that support safer workplaces and reliable outcomes.

Key Takeaways

Rigging and slinging are essential for safe lifting operations in construction and industry.

Proper training and ongoing education help workers recognize hazards and use equipment safely.

Daily inspections of rigging equipment prevent accidents and ensure reliability.

Selecting certified equipment reduces risks and supports compliance with safety standards.

Effective communication among team members is crucial for safe rigging and lifting operations.

Understanding load weights and sling configurations is vital for maintaining load stability.

A strong safety culture encourages workers to report hazards and prioritize safety.

Using modern tools and technology enhances monitoring and improves lifting outcomes.

What is Rigging and Slinging?

Rigging Explained

Rigging forms the foundation of safe material handling in industrial and construction settings. Industry standards define rigging as both the act of using equipment or gear to lift and support a load, and the equipment itself. Workers rely on rigging systems to move heavy objects efficiently and securely.

These systems include a variety of components such as hooks, chains, wire ropes, and other hardware. Rigging requires careful planning and precise execution to ensure that every load remains stable throughout the operation.

Term | Definition |

|---|---|

Rigging | The act of using equipment or gear to lift and support a load. |

The equipment or gear used to lift or support a load. | |

Slinging | Sometimes used interchangeably with ‘rigging’ in certain contexts. |

Slinging Explained

Slinging refers to the process of attaching and securing a load to the rigging equipment for lifting. Operators select slings based on the weight, shape, and nature of the load. Slings may consist of wire rope, chain, or synthetic materials, each designed for specific applications.

Proper slinging ensures that the load remains balanced and does not shift during movement. Workers must understand sling types and configurations to prevent accidents and maintain control over the load.

In some contexts, slinging and rigging overlap, but slinging focuses more on the connection between the load and the lifting gear.

Safety Significance

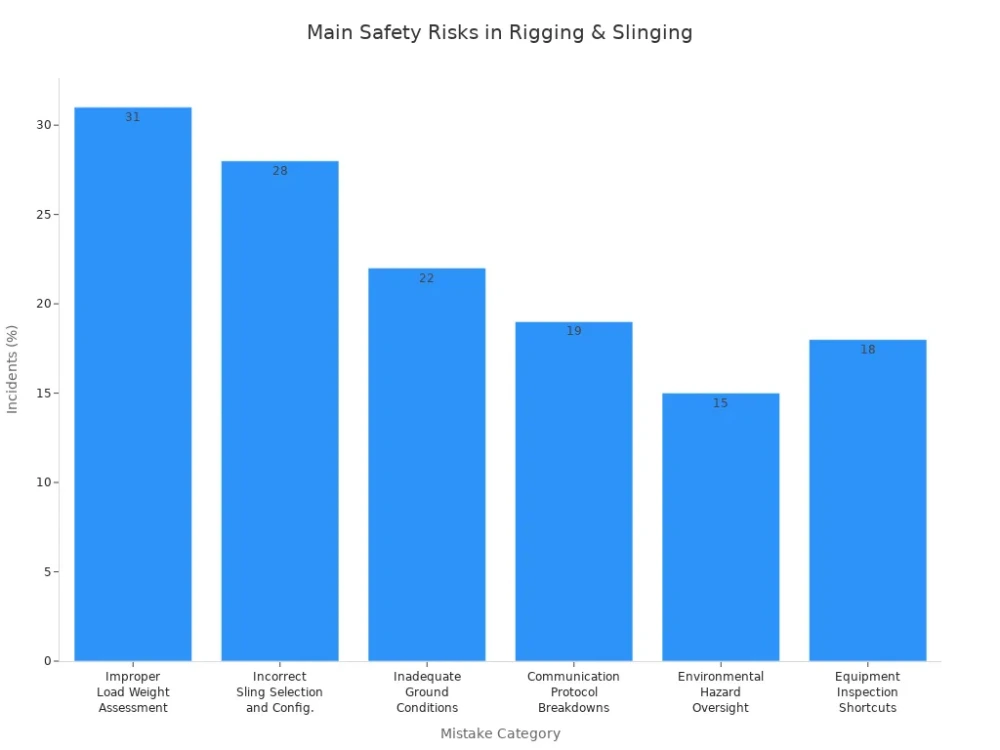

Rigging and slinging safety is critical in every lifting operation. Mistakes can lead to severe incidents, property damage, and injury. The following chart illustrates the main safety risks associated with improper rigging and slinging:

Several factors contribute to safe rigging and slinging practices:

Proper training ensures that workers recognize hazards and use equipment correctly.

Equipment inspection before each use prevents accidents caused by damaged gear.

Planning and preparation help identify risks and select the right equipment.

Following established procedures maintains load integrity and protects workers.

Compliance with safety guidelines from regulatory authorities supports a safe work environment.

Using personal protective equipment shields workers from potential hazards.

Continuous monitoring during rigging operations maintains safety and load stability.

Operators must always confirm the weight of the load and select equipment rated for the task. Calculating rigging angles and using standardized communication methods help prevent errors.

Standing under suspended loads poses a significant risk and should be strictly avoided. Rigging and slinging safety remains a top priority in every lifting scenario.

System Approach

A system approach in rigging and slinging operations establishes a structured framework for every lifting task. This method combines planning, coordination, and continuous monitoring to achieve safe and efficient outcomes.

Professional rigging teams design each operation with precision, considering every variable that could affect the lift.

Certified riggers play a vital role in this process. They follow strict standards set by organizations such as OSHA and NCCCO. These professionals complete extensive training that covers equipment inspection, safe load handling, and effective communication.

Their expertise helps identify hazards and implement controls before lifting begins.

Lift planning forms the backbone of the system approach. Teams calculate load weights, select appropriate equipment, and map out movement paths. They use modern tools like IoT sensors and load indicators to monitor conditions in real time.

These technologies provide instant feedback, allowing operators to adjust procedures and maintain safety throughout the operation.

Tip: Detailed lift plans include accurate load calculations, optimized movement paths, and clear safety protocols. This preparation reduces the risk of accidents and keeps projects on schedule.

A system approach also emphasizes risk assessment. Rigging teams evaluate potential hazards at every stage. They inspect equipment, review site conditions, and confirm that all gear meets required standards. This process ensures that only suitable equipment enters service, minimizing the chance of failure.

Key elements of a system approach include:

Certified riggers conduct thorough risk assessments and use proper equipment to prevent accidents.

Teams develop detailed lift plans with accurate calculations and optimized movement paths.

Modern tools such as IoT sensors and load indicators enhance monitoring and control.

Expert coordination ensures that every team member understands their role and follows safety protocols.

Professional rigging companies rely on this structured method to manage complex lifts. The system approach improves safety, reduces costs, and increases efficiency. By integrating planning, technology, and skilled personnel, organizations create a safer work environment and achieve reliable results.

Rigger Roles & Responsibilities

Key Duties

Riggers hold a central role in ensuring safe rigging practices during lifting operations. Their responsibilities extend across every phase of the job, from initial planning to final equipment breakdown. Industry guidelines highlight several essential duties:

Assessing the load’s weight and center of gravity before any movement.

Selecting and inspecting rigging equipment, following ASME B30 Series standards.

Confirming that the rated load of each piece of equipment matches the requirements for safe rigging.

Attaching rigging gear securely to hooks, shackles, or other devices.

Protecting rigging equipment from abrasion, cutting, or other damage during lifting.

Rigging loads to maintain balance and stability throughout the operation.

Understanding and using standard signals for equipment in use.

Installing tag lines when additional control is needed.

Inspecting and preparing loads for movement.

Setting, aligning, and leveling heavy machinery.

Monitoring and maintaining rigging equipment.

Ensuring compliance with safety procedures.

Communicating with the rigging and construction team.

Breaking down equipment and conducting post-operation inspections.

These duties require attention to detail and a commitment to safe rigging at every step.

Required Skills

Riggers must possess a diverse set of skills to perform their roles effectively and maintain safe rigging standards. Physical fitness is essential, including strength, endurance, flexibility, balance, and hand-eye coordination. Problem-solving ability allows riggers to assess situations quickly and adapt to changing conditions.

Teamwork is vital, as riggers often coordinate with other trades and support colleagues during complex lifts. Communication skills, such as clarity, assertiveness, and active listening, help prevent misunderstandings and ensure everyone follows the same plan.

Continuous learning keeps riggers updated on safety protocols and industry standards, supporting safe rigging practices in every environment.

Note: Riggers who invest in ongoing training and skill development contribute to safer lifting operations and reduce the risk of accidents.

Communication

Effective communication forms the backbone of safe rigging operations. Riggers use clear protocols to coordinate movements, prevent misunderstandings, and alert team members to hazards. The following table summarizes the importance of communication in rigging and lifting activities:

Description | Source |

|---|---|

Effective communication prevents misunderstandings and coordinates movements | Mastering Rigging Safety Through Knowledge and Technique |

Clear protocols ensure safe and efficient movement of loads | Successful Lifts Start with Safe Rigging Practices |

Standard signals help avoid distractions and injuries | Safety Tips for Safe Lifting |

Crew members communicate a plan before lifting begins | Best Lifting and Rigging Practices |

Riggers rely on agreed-upon signals and pre-lift planning to maintain safe rigging throughout every project. Communication ensures that each team member understands their role and responds quickly to changing conditions.

By prioritizing communication, riggers create a safer work environment and support successful lifting operations.

Hazard Awareness

Hazard awareness stands as a cornerstone of safe rigging operations. Riggers must recognize and address risks before, during, and after every lift. They rely on training and experience to identify potential dangers that could compromise safety or disrupt workflow.

Vigilance ensures that hazards do not go unnoticed, and proactive measures help prevent incidents.

Note: Rigging teams that prioritize hazard awareness reduce the likelihood of accidents and maintain a safer work environment.

Riggers encounter a range of hazards in lifting operations. Each hazard requires careful attention and specific controls. The following list outlines the most common risks that riggers must manage:

Inadequate Pre-Use Inspections

Riggers must inspect all equipment before use. Failure to detect wear, damage, or defects can lead to equipment failure and serious accidents.Lack of Communication and Coordination

Miscommunication between team members increases the risk of errors. Clear signals and coordinated actions help maintain control and prevent misunderstandings.Poor Load Control

Unstable or shifting loads pose significant dangers. Riggers must secure loads properly and monitor movement to avoid loss of control.Overloading Rigging Equipment

Exceeding the rated capacity of chains, slings, or hardware can cause catastrophic failure. Riggers must verify load weights and select equipment with appropriate ratings.Incorrect Sling Angles

Improper sling angles increase stress on rigging components. Riggers calculate angles carefully to ensure safe load distribution and minimize risk.Improper Storage of Rigging Equipment

Storing equipment in unsuitable conditions leads to corrosion, damage, and reduced performance. Riggers maintain proper storage practices to preserve equipment integrity.Electrical Hazards from Power Lines

Lifting operations near power lines present electrocution risks. Riggers assess site conditions and maintain safe distances from electrical sources.

Hazard awareness extends beyond recognizing risks. Riggers must implement controls and follow established procedures to mitigate dangers. They participate in regular safety meetings and review site-specific hazards before each lift.

Continuous education keeps riggers informed about new risks and evolving best practices.

Riggers also document hazards and report unsafe conditions to supervisors. This proactive approach supports a culture of safety and accountability. Teams that foster open communication about hazards create an environment where everyone feels responsible for safety.

Training programs reinforce hazard recognition skills. Riggers learn to identify warning signs, assess risk levels, and respond appropriately. Competency in hazard awareness empowers riggers to make informed decisions and protect themselves and their colleagues.

Hazard awareness remains an essential skill for every rigger. By staying alert and informed, riggers uphold safety standards and contribute to successful lifting operations.

Equipment & Selection

Rigging Equipment Types

Rigging operations depend on a wide range of equipment designed for strength, durability, and safety. Each type serves a specific purpose in lifting and securing loads. The following list highlights essential rigging equipment used in heavy lifting:

Chains: Provide exceptional strength for heavy or abrasive loads.

Wire rope slings: Known for durability and reliability in demanding environments.

Synthetic slings: Lightweight and flexible, ideal for sensitive or delicate items.

Chain rigging: Used for extremely heavy loads requiring robust support.

Shackles: Serve as connection points within rigging systems.

Hoists: Enable controlled lifting and lowering of heavy objects.

Accessories: Include turnbuckles for tension adjustment, pulleys and blocks for load movement, and load binders for securing cargo.

Operators select equipment based on the nature of the load and the requirements of the lifting task. Proper sling selection and inspection help prevent accidents and ensure safe operations.

Slings, Shackles, Hoists, Accessories

Slings, shackles, hoists, and accessories form the backbone of most rigging systems. Wire rope slings offer durability and strength for heavy lifting. Synthetic slings provide flexibility and reduce the risk of damage to fragile loads. Chain slings deliver unmatched performance for the most demanding applications.

Shackles connect various components, while hoists control the movement of loads. Accessories such as turnbuckles, pulleys, and load binders enhance the versatility and safety of rigging setups.

Tip: Regular inspection of slings, shackles, and hoists is essential for maintaining rated capacity and preventing equipment failure.

Selection Criteria

Load Ratings, Certification

Selecting the right rigging equipment requires careful consideration of several criteria. Operators must ensure that each component meets the safe working load for the intended application.

The rated capacity of chains, slings, and hardware determines the maximum weight that can be lifted safely. Understanding the working load limit helps prevent overloading and reduces the risk of accidents.

Certification plays a vital role in equipment selection. Certified rigging products have undergone rigorous testing to meet international safety standards. Using certified equipment assures reliability and performance.

Employers should verify that personnel handling rigging tasks are qualified, especially for complex lifts.

System Integration

System integration ensures that all rigging components work together seamlessly. Operators must match the rated capacity of each item to the overall requirements of the lifting system. The nature of the load, including its shape and fragility, influences the choice of materials and techniques.

Environmental conditions, such as temperature and humidity, also affect equipment performance. Selecting the right combination of chains, slings, and accessories creates a safe and efficient lifting system.

Powerful Machinery Solutions

Powerful Machinery delivers certified, high-performance rigging solutions for the most demanding industries. The company offers a comprehensive range of products designed to meet strict safety and quality standards. The table below showcases some of the specialized equipment available:

Product Type | Description |

|---|---|

Foundry Hooks & High-Temp Fittings | Specialized hooks engineered for high-temperature environments, maintaining structural integrity. |

High-Capacity Sling Components | Heavy-duty master links, couplers, and shackles for the heaviest lifting tasks. |

Below-the-Hook Lifter Components | Load-bearing shackles and eyebolts for plate clamps, coil tongs, and other specialized lifters. |

Heat-Treated Alloy Chains | Chains are designed to resist abrasion and thermal degradation in extreme conditions. |

IWRC Wire Ropes | Wire ropes are selected for superior strength and performance under challenging conditions. |

Powerful Machinery’s commitment to quality ensures that every product meets or exceeds international certification requirements. Operators benefit from reliable equipment that supports safe lifting practices and maximizes rated capacity.

The company’s solutions help organizations maintain compliance and achieve efficient, accident-free operations.

Inspection & Maintenance

Daily Checks

Rigging teams perform daily checks to maintain safety and reliability in lifting operations. Workers confirm the load weight before each lift. They inspect slings, ropes, and chains for visible signs of wear or damage. Shackles and hooks receive close attention to ensure proper function.

Hoists and cranes undergo inspection to verify operational readiness. Ground conditions are evaluated to prevent instability during lifting. A trained signal person is assigned to coordinate movements and maintain clear communication.

A standard daily inspection process includes:

Inspect slings for cuts, burns, broken wires, kinks, and missing tags.

Inspect shackles and pins for bent bodies, damaged threads, or mismatched pins.

Inspect hooks for deformation and confirm the latch closes securely.

Confirm the rigging matches the lift, including capacity, angle, and edge protection.

Ensure no one stands under the load at any time.

Companies that make daily checks a routine dramatically reduce the likelihood of accidents. Regular pre-lift inspection extends the life of industrial lifting equipment and helps avoid unnecessary repairs or replacements.

Synthetic Sling Risks

Synthetic slings offer flexibility and strength, but they present unique risks in lifting operations. Abrasion damage occurs when slings tighten around rough loads or scrape against sharp edges.

This weakness can lead to sling failure. High pressure can compromise the protective barrier of the sling, increasing the risk of failure during lifting. Employee oversight, such as a lack of training or supervision, often results in human error and lifting accidents.

Risk Type | Description |

|---|---|

Abrasion Damage | Occurs when slings tighten around rough loads or scrape against sharp edges, leading to weakness and potential failure. |

Pressure Levels | High pressure can compromise the protective barrier of the sling, increasing the risk of failure during lifting operations. |

Employee Oversight | Lack of proper training and oversight can lead to human error, which is a significant cause of lifting accidents. |

Operators must inspect synthetic slings regularly and remove any sling showing signs of damage. Training programs help workers recognize risks and follow safe handling procedures.

Maintenance Protocols

Maintenance protocols ensure rigging equipment remains safe and reliable throughout its service life. Teams implement a routine inspection program to assess components for wear and damage. Workers follow manufacturer guidelines and use safe rigging techniques to avoid conditions that could harm equipment.

Proper storage protects rigging components from environmental factors such as moisture and extreme temperatures.

Best practices for maintenance include:

Regular inspections and maintenance of all rigging components.

Use the correct equipment for each task based on load specifications.

Store rigging equipment properly to prevent environmental damage.

Powerful Machinery supports these protocols by providing certified products that meet international standards. Their commitment to quality and reliability helps organizations maintain safe lifting operations and minimize equipment failure.

Defect Management

Defect management stands as a critical process in rigging and slinging operations. Teams must identify, report, and address defects before they cause accidents or equipment failure. Rigging professionals follow strict procedures to ensure every piece of equipment meets safety standards.

Workers inspect all rigging gear before each use. They look for cracks, corrosion, bent components, and other visible defects. If they find damaged or defective slings, they remove them from service immediately. This action prevents unsafe lifts and protects workers from injury.

A systematic approach to defect management includes several key steps:

Select rigging equipment rated for the expected load and working conditions.

Inspect every item for defects such as wear, deformation, or corrosion.

Calculate the weight of each load to confirm it stays within the working load limit.

Train employees on inspection procedures and defect recognition.

Follow standards set by organizations like OSHA and ASME.

Teams must stop work at once if they suspect unsafe conditions or discover defects in any rigging component.

Clear communication supports effective defect management. Workers report problems to supervisors and document findings. Supervisors track equipment status and schedule repairs or replacements. This process ensures only safe gear enters service.

Rigging teams also maintain detailed inspection records. These logs help identify recurring issues and guide future maintenance. Regular reviews of inspection data improve safety and reduce downtime.

Powerful Machinery demonstrates a strong commitment to quality and reliability. The company designs products to withstand demanding environments and rigorous use.

Each item undergoes thorough testing to minimize the risk of defects. Clients trust Powerful Machinery to deliver certified equipment that meets international standards.

The following table summarizes best practices for defect management in rigging operations:

Practice | Benefit |

|---|---|

Immediate removal of defective gear | Prevents accidents and equipment failure |

Regular inspections | Detects defects early |

Comprehensive training | Improves defect recognition |

Documentation and reporting | Tracks issues and supports accountability |

Adherence to standards | Ensures compliance and safety |

Rigging teams must never ignore defects. They protect workers and property by removing unsafe equipment and following established procedures. Effective defect management keeps lifting operations safe and reliable.

Legal Standards & Compliance

Regulatory Bodies

Rigging and slinging operations must follow strict regulations set by recognized authorities. These organizations create and enforce rules that protect workers and ensure safe lifting practices. The main regulatory bodies include:

Regulatory Body | Role |

|---|---|

OSHA | Enforces safety regulations for workplaces in the U.S. |

ASME | Develops industry standards for lifting and rigging equipment. |

ISO | Establishes international guidelines for operational safety and efficiency in lifting and rigging. |

Other important organizations, such as CSA and ANSI, also contribute to the development of safety codes and best practices. Each body plays a unique role in shaping the legal framework for rigging and slinging safety.

CSA, ANSI, ASME

The Canadian Standards Association (CSA) sets safety standards for lifting equipment in Canada. The American National Standards Institute (ANSI) coordinates the development of safety guidelines in the United States.

The American Society of Mechanical Engineers (ASME) publishes the B30 series, which covers the design, inspection, and use of rigging hardware. These organizations work together to ensure that companies meet standard requirements and maintain safe operations.

Certification Requirements

Certification remains a critical part of compliance in rigging and slinging. Workers and equipment must meet specific criteria before participating in lifting operations. The following table outlines the main certification requirements:

Requirement Type | Details |

|---|---|

Rigger Eligibility | Must be at least 18 years old and have a high school diploma or GED. |

Rigger Training | Enroll in a rigger training program from a CCO-accredited organization. |

Rigging Examinations | Pass both written and practical rigger exams administered by a CCO-accredited organization. |

Professional rigging gear certification is essential for safety and compliance in the crane and heavy lift industry. Many organizations require extensive testing and technical documentation for rigging devices. These measures help ensure that only qualified personnel and certified equipment enter service.

Note: Certification processes help prevent accidents and support a culture of safety in every workplace.

Powerful Machinery Certifications

Powerful Machinery demonstrates a strong commitment to legal standards and compliance. The company’s products carry certifications from leading international bodies, including ISO9001, ISO14001, TUV Rheinland, EURO CERT, EAC, Geprüfte Sicherheit, OSHA, ASTM, China Classification Society, and Korean Register.

These certifications confirm that Powerful Machinery meets or exceeds global safety and quality benchmarks.

The company’s dedication to compliance ensures that clients receive equipment tested against the highest industry standards. Powerful Machinery’s certified products help organizations achieve regulatory compliance and maintain safe lifting operations worldwide.

Rigging and Slinging Safety Practices

Rigging and slinging safety forms the backbone of every successful lifting operation. Workers must follow strict procedures, use proven techniques, and manage hazards to protect people and property.

Powerful Machinery supports these efforts by providing certified equipment and promoting industry-leading safety standards.

Safe Procedures

Rigging and slinging safety begins with clear procedures that address common hazards. Workers must understand the risks associated with hoisting, capacity, slings, and loads. The table below outlines specific hazards that teams must control:

Hazard Type | Specific Hazards |

|---|---|

Hoisting | Unknown working load limits, defective parts, unreliable equipment, wind, weather, electricity, line not vertical |

Capacity | Swinging loads, equipment condition, moving forces, tackle weight |

Slings | Damaged, unknown maximum capacity, sharp bends, rust, unsafe angles, and friction |

Loads | Shifting or dislodging, uncontrolled motion, unhooked or unslung before landing, pinch points |

Overloading, Handling, Sling Protection

Teams must never overload rigging equipment. Each component has a rated capacity, and exceeding this limit can cause catastrophic failure. Workers should always check the load weight and select slings and hardware that match or exceed the requirements.

Proper handling prevents damage to slings and chains. Workers must avoid dragging equipment across rough surfaces or exposing it to sharp edges. Using protective pads or sleeves helps shield slings from abrasion and cutting.

Load Stability, Sling Angles

Load stability depends on correct sling configuration and angle. Workers must understand that improper rigging can lead to crane incidents and dropped loads. The angle of the sling affects its lifting capacity. As the angle decreases, the force on the sling increases, which can reduce its ability to support the load.

Teams should use trigonometry to estimate the load on each sling leg, especially in two-leg bridle configurations. Selecting the right sling material and following manufacturer guidelines for inspection and retirement ensures ongoing safety.

Techniques

Rigging and slinging techniques play a vital role in maintaining safety and efficiency. Workers must choose the right hitch type and use standardized hand signals to communicate during lifts.

Hitch Types

Different hitch types provide unique advantages for various lifting scenarios. The table below summarizes common hitch types, their descriptions, and safety implications:

Hitch Type | Description | Safety Implications |

|---|---|---|

Choker Hitch | Wraps a sling around the load, creating a tightening loop. | Provides a strong grip but can damage fragile items due to its tightness. |

Basket Hitch | Sling is placed under the load, forming a basket shape. | Excellent stability and balance, distributes weight evenly, reducing stress on lifting points. |

Bridle Sling | Multiple slings connected to a single hook, distributing weight evenly. | Ensures stability and balance for large or irregularly shaped loads. |

Double Wrap Choke | Similar to a choker hitch, but wraps the sling around the load twice. | Enhances stability and grip, preventing movement during the lift. |

Vertical Hitch | Attaches a single sling to lift the load directly upward. | Simple method, but requires a well-balanced load for safety. |

Multiple Slings | Combines two or more slings for lifting complex loads. | Provides enhanced stability and load distribution for large machinery or structural components. |

Workers must select the appropriate hitch based on the load’s shape, weight, and lifting requirements. Consistent use of proper rigging and slinging techniques reduces mistakes and legal issues.

Hand Signals

Clear communication is essential for rigging and slinging safety. Standardized hand signals allow the crane operator and signal person to coordinate movements without confusion. The table below highlights the importance of hand signals:

Key Point | Explanation |

|---|---|

Clear Communication | Hand signals ensure that the crane operator and signal person maintain clear communication. |

Prevention of Misunderstandings | Standardized signals help avoid confusion and potential accidents on the job site. |

Continuous Signals | Signals must be continuous; if unclear, the crane operator must stop to ensure safety. |

Teams must use hand signals consistently. If the operator does not understand a signal, they must stop the lift until clarification occurs. This practice prevents accidents and supports safe rigging practices.

Hazard Management

Effective hazard management strengthens rigging and slinging safety. Only qualified personnel should handle rigging operations. A signal person must direct lifts when visibility is limited. Teams conduct pre-lift planning, including a Job Hazard Analysis, to assess load weight and select the right gear.

Workers inspect all slings, hooks, shackles, and spreader bars before use. Proper rigging and slinging techniques, such as using correct sling angles and staying within rated capacities, reduce stress on equipment.

Safe lifting practices include clear communication, load control, and maintaining a safe zone around the operation. Teams must follow OSHA standards and manufacturer guidelines.

Written plans ensure that every task is documented and organized. Workers keep non-involved personnel at a safe distance and store rigging equipment in designated areas to protect both people and gear.

Powerful Machinery supports hazard management by supplying certified, high-performance rigging products. Their commitment to quality and compliance helps organizations maintain the highest standards of rigging and slinging safety.

Tip: Regular training and equipment inspection are the best defenses against workplace accidents. Teams that prioritize rigging and slinging safety create a culture of accountability and trust.

Training & Safety Culture

Training Methods

Classroom, Practical, Assessment

Rigging and slinging training relies on a blend of classroom instruction, hands-on practice, and formal assessment. Instructors teach participants about the types, uses, and limitations of rigging equipment. They guide students through accurate load weight calculations and explain equipment limits.

Workers learn inspection procedures to identify wear or damage before each lift. Trainers demonstrate proper rigging techniques and emphasize the importance of following safety regulations and standards, including OSHA and ANSI guidelines.

Practical sessions allow trainees to apply classroom knowledge in real-world scenarios. They practice maintaining load stability and controlling the center of gravity during lifting operations. Instructors show how to use tag lines for load control and teach effective team communication.

Emergency procedures form a key part of every rigging and slinging course, preparing workers to respond quickly and safely if an incident occurs.

Assessment ensures that every participant meets the required competency level. Trainers evaluate skills through written tests and practical demonstrations. Workers must show proficiency in equipment inspection, load calculation, and safe rigging practices before receiving certification.

Tip: Powerful Machinery supports training initiatives by providing certified equipment for classroom and field exercises. Their commitment to safety helps organizations deliver effective rigging and slinging training programs.

Certification Process

Certification validates a worker’s ability to perform rigging and slinging tasks safely and competently. Individuals pursue credentials accredited by organizations such as the National Commission for the Certification of Crane Operators (NCCCO) and the Lifting Equipment Engineers Association (LEEA).

The most common certifications include Qualification Certification, Level I, Level II, and Signalperson Certification.

Candidates must pass both a practical exam and a written exam. Training programs cover comprehensive safety topics and meet regulatory requirements for sling and rigging workers. Certification demonstrates that a worker understands industry standards and can apply safe practices on the job site.

Employers value certified personnel because they help maintain compliance and reduce the risk of accidents. Powerful Machinery’s certified products support training programs by ensuring that workers practice with equipment that meets international standards.

Ongoing Education

Ongoing education strengthens safety culture in rigging and slinging operations. Workers participate in refresher courses and advanced training to stay current with industry developments. Regular updates help teams adapt to new regulations and technologies.

The table below highlights the benefits of ongoing education:

Benefit | Description |

|---|---|

Enhanced Workplace Safety | Reduces the likelihood of accidents, injuries, and near-miss incidents during lifting tasks. |

Regulatory Compliance | Assures compliance with safety laws and global standards, addressing legal requirements. |

Stronger Team Communication | Improves coordination among riggers, signallers, and crane operators through standardized signals. |

Continuous learning encourages workers to share knowledge and support each other. Organizations that invest in ongoing education build a culture of accountability and trust.

Powerful Machinery promotes ongoing education by collaborating with clients on training initiatives and providing resources for skill development.

Building Safety Culture

A strong safety culture forms the backbone of successful rigging and slinging operations. Leaders set the tone by prioritizing safety in every aspect of the job. They encourage open communication and empower workers to report hazards without fear of reprisal.

Teams that value safety create environments where everyone feels responsible for protecting themselves and their colleagues.

Managers establish clear safety policies and procedures. They provide regular training and ensure that every worker understands the risks associated with lifting operations. Supervisors conduct safety meetings and review incident reports to identify areas for improvement.

Workers participate in toolbox talks and share lessons learned from previous projects.

A safety culture thrives when organizations recognize and reward safe behavior. Supervisors acknowledge workers who follow procedures and demonstrate hazard awareness. Teams celebrate milestones such as accident-free days or successful safety audits.

These practices reinforce positive habits and motivate employees to maintain high standards.

Powerful Machinery supports a safety culture by supplying certified equipment and promoting best practices. The company collaborates with clients to develop customized safety programs.

They offer resources such as training materials, inspection checklists, and technical support. Clients benefit from access to industry expertise and ongoing education.

Tip: Leaders should encourage workers to speak up about unsafe conditions. Open dialogue helps identify risks early and prevents accidents.

The following table highlights key elements of a safety culture in rigging and slinging operations:

Element | Description |

|---|---|

Leadership Commitment | Managers prioritize safety and allocate resources for training. |

Worker Engagement | Employees participate in safety meetings and report hazards. |

Recognition Programs | Organizations reward safe behavior and celebrate achievements. |

Continuous Improvement | Teams review incidents and update procedures regularly. |

Certified Equipment | Companies use products that meet international safety standards. |

Safety culture requires ongoing effort and commitment. Leaders must set expectations and hold everyone accountable. Workers must stay vigilant and follow established procedures. Organizations that invest in safety culture reduce accidents, improve morale, and achieve better project outcomes.

Powerful Machinery remains dedicated to supporting safety initiatives. Their certified products and training resources help clients build strong safety cultures. Teams that embrace safety as a core value protect lives and ensure the success of every lifting operation.

Conclusion

Rigging and slinging demand a strong focus on safety, training, and compliance. Certified equipment from trusted brands like Powerful Machinery helps teams achieve reliable results. Workers who follow best practices reduce risks and improve workplace safety.

Invest in regular training programs

Conduct thorough equipment inspections

Choose certified products for every lift

Certified solutions build confidence and support safer operations. Teams that prioritize ongoing improvement create a culture of safety and reliability.

FAQ

What is the difference between rigging and slinging?

Rigging involves setting up equipment to lift and move loads. Slinging refers to attaching the load to the rigging gear. Both require careful planning and certified equipment.

How often should rigging equipment be inspected?

Teams inspect rigging equipment before each use. Regular inspections help identify wear, damage, or defects. Daily checks and scheduled maintenance keep operations safe.

Why is certification important for rigging products?

Certification verifies that products meet international safety standards. Certified equipment reduces risk and ensures reliable performance during lifting operations.

What training do riggers need?

Riggers complete classroom instruction, hands-on practice, and assessments. Training covers equipment use, safety procedures, and hazard recognition. Certification demonstrates competency.

How does Powerful Machinery support rigging safety?

Powerful Machinery supplies certified, high-performance rigging products. The company offers training resources and technical support to help organizations maintain safe lifting practices.

What are common hazards in rigging and slinging?

Hazards include overloading, damaged equipment, poor communication, unstable loads, and electrical risks. Teams manage hazards through planning, inspection, and proper technique.

Can synthetic slings be used for all lifting tasks?

Synthetic slings suit many applications but may not handle extreme heat or sharp edges. Workers select sling types based on load requirements and environmental conditions.

How do teams communicate during lifting operations?

Teams use standardized hand signals and clear verbal instructions. Effective communication prevents misunderstandings and supports safe rigging and slinging practices.