You face critical choices in lifting operations, especially when it comes to the differences between rotating and non-rotating wire ropes. Selecting the right wire rope type impacts both safety and efficiency.

Using the wrong option can cause reduced service life, structural changes, or even sudden breaks. Industry trends show strong adoption across sectors:

Construction accounts for about 40% of the global market share in 2024.

The industrial segment holds a 70% market share.

The rotation-resistant wire rope market is set to reach USD 2.5 billion by 2034.

Powerful Machinery delivers certified steel wire rope solutions trusted by professionals worldwide.

Key Takeaways

Choose non-rotating wire rope for high-stakes lifting tasks to ensure maximum stability and safety.

Use rotating wire rope for short-term or low-load applications where load spinning is not a concern.

Understand the construction differences: non-rotating ropes balance internal torque, while rotating ropes can twist under load.

Always match your wire rope selection to the specific lifting application to enhance safety and efficiency.

Regularly inspect wire ropes for wear and damage to maintain safety and prevent costly failures.

Non Rotation vs Rotation Resistant Wire Rope: Differences Comparison

What Is Rotating Wire Rope?

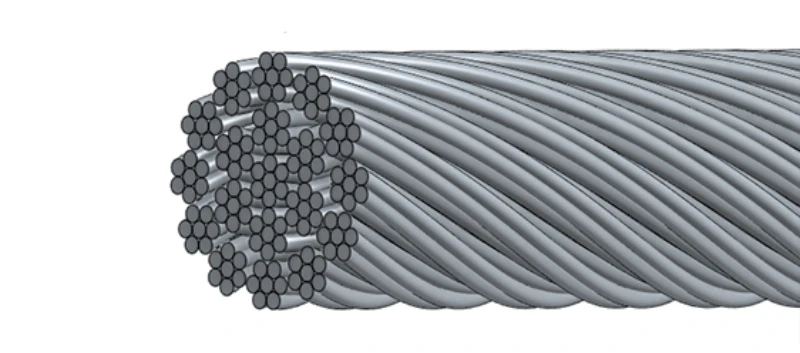

You encounter rotating wire rope in many lifting and rigging applications. This type of rope features single-layer strands twisted in the same direction. The design allows the rope to spin or unlay when placed under load. Rotating wire rope often uses a round strand point or a line contact structure.

This construction does not balance internal torque, so the rope can rotate during lifting. You typically use rotating wire rope for short-term hoisting or low-load handling tasks. These ropes work well in situations where load spinning does not pose a safety risk.

What Is Non-Rotating Wire Rope?

Non-rotating wire rope, also called rotation-resistant rope, uses a multi-layer reverse twisting process. The strands in each layer twist in opposite directions. This design balances internal torque and minimizes the rope’s tendency to spin under tension.

Non-rotating wire rope often features surface contact or special strand arrangements. You rely on these ropes for high-rise lifting, tower cranes, and long-distance traction equipment.

The construction ensures stability and safety, especially in vertical lifting operations where uncontrolled rotation could cause accidents.

Tip: The number of strand layers in rotation-resistant ropes affects their performance. A three-layer rope resists rotation better than a two-layer rope.

Why Rotation Resistance Matters?

You must understand the differences between rotating and non-rotating wire ropes to ensure safe and efficient lifting. Rotation resistance plays a critical role in preventing load spinning, which can damage equipment or endanger workers.

Rotation-resistant ropes provide better control and stability during lifting because their specialized strand arrangements create opposing torsional forces. These ropes counteract the natural inclination to spin when under tension, making them essential for cranes, hoists, and other vertical lifting systems.

The differences between rotating and non-rotating wire ropes become clear when you compare their structure, function, and application. The table below highlights these differences:

Feature | Non-Rotating Wire Rope | Rotating Wire Rope |

|---|---|---|

Twisting Process | Multi-layer reverse twisting | Single-layer strands twisted in the same direction |

Strand Design | Surface contact or special strands | Round strand point/line contact structure |

Torque Balancing Mechanism | Achieves torque balance through reverse twisting | Leads to the superposition of residual torque |

Application Scenarios | High-rise lifting, tower cranes, and long-distance traction | Short-term hoisting, low-load handling |

You see the differences between rotating and non-rotating wire ropes in their mechanical properties as well. Rotation-resistant ropes minimize spinning or unlaying under load. They provide enhanced stability and reduce the risk of accidents.

Rotating wire rope, on the other hand, may spin under tension, which limits its use in critical lifting operations.

When you select wire rope for your project, consider the differences between rotating and non-rotating wire ropes. Non-rotating ropes suit high-rise and precision lifting, while rotating wire rope fits temporary or low-load tasks.

Powerful Machinery offers expertise in both types, delivering certified products that meet international standards. The company’s steel wire rope solutions provide high tensile strength, excellent abrasion resistance, and extensive customization options.

You benefit from their commitment to safety, reliability, and performance in every lifting scenario.

Note: Powerful Machinery stands out for its non-rotating design, high tensile strength, and compliance with global safety standards. You can trust their solutions for both rotating and non-rotating wire rope needs.

Construction and Mechanical Behavior

Rotating Wire Rope Structure

You see rotating wire rope built with single or double layers of strands twisted in the same direction. This construction often uses Regular lay, or Lang lay types. In Regular lay, the outer strands twist opposite to the rope’s core, while Lang lay aligns both in the same direction.

The 8×19 class Regular lay wire rope with an independent core offers some rotation resistance, but it still allows for spinning under load. You find that ropes like Blue Strand 6 x 19 and 6 x 36 Class Lang Lay have high rotation, which means you must use a swivel to prevent excessive spinning.

This structure works for applications with low rotational resistance demands.

Non-Rotating Wire Rope Structure

You rely on non-rotating wire rope when you need maximum stability. The construction uses multiple layers of strands, each twisted in opposite directions. This reverse twisting balances internal torque and stops the rope from spinning under tension.

For example, the Endurance 35 LS and Dyform 34LR/PI/MAX types show low rotation and can operate with or without a swivel. You benefit from enhanced load stability, precise control, and improved safety.

Powerful Machinery’s non-rotating steel wire rope uses this advanced construction to meet strict industry standards. The design also extends equipment life by reducing wear and tear.

Rope Construction Type | Rotation Characteristics | Recommendations |

|---|---|---|

Blue Strand 6 x 19, 6 x 36 | High rotation | Use a swivel to prevent spinning |

Endurance Dyform 8 Lang Lay | High rotation | Use a swivel to prevent spinning |

Endurance 35 LS, Dyform 34LR | Low rotation | Swivel optional |

Impact on Performance and Safety

You must consider construction when choosing between anti-rotation wire rope and non-rotation-resistant wire rope. Rotating wire ropes can suffer from block twisting, kinking, and overstressing, which increase the risk of failure.

Non-rotating wire rope prevents uncontrolled load spinning, which is critical for vertical hoisting and offshore lifts. You achieve higher safety standards and longer equipment life with rotation-resistant wire rope.

Powerful Machinery’s steel wire rope solutions deliver the performance and reliability you need for demanding lifting operations.

Tip: Always match your wire rope selection to your application’s rotational resistance demands to ensure safety and efficiency.

Performance and Failure Risks

Torque and Strength Loss

You must understand how torque and strength loss affect your lifting operations. When you use a rotating wire rope, the rope can lose a significant amount of its strength if one end rotates freely under load. This loss can put your team and equipment at risk, especially during heavy lifting tasks.

In contrast, non-rotating wire ropes maintain almost all their breaking strength, even when exposed to high tension. Here is how strength loss compares:

Non-rotating ropes can maintain 95% to 100% of their breaking strength.

Two-layer spin-resistant ropes develop only 55% to 75% of their breaking strength if one end rotates freely.

Three-layer non-rotating ropes show minimal strength loss, keeping nearly full breaking strength.

Rotating ropes experience a much greater reduction in strength during lifting.

When you select the right rope for cranes or other lifting equipment, you reduce the risk of sudden failure caused by torque imbalance.

Internal Failure and Fatigue

You face several internal failure modes when using rotating wire ropes, especially under repeated load cycles. The most frequent issues include:

Wire breakage

Strand breakage

Wear

Mechanical bending

Severe corrosion

Arc burning

Rope loosening (cage deformation)

Severe wave deformation

These problems can develop inside the rope, making them hard to spot during routine checks. If you use the wrong rope for your lifting application, you increase the risk of fatigue and internal damage, which can lead to dangerous situations for cranes and other lifting systems.

Importance of Correct Selection

You protect your team and equipment by choosing the correct wire rope for each lifting task. Industry standards and certifications guide you in making safe choices. The table below highlights key certifications:

Certification | Purpose |

|---|---|

ISO 2408 | Specifies the minimum breaking force for safety |

EN 12385 | Ensures safety and performance standards |

ISO 9001 | Guarantees quality management systems |

When you use certified wire ropes from Powerful Machinery, you gain several safety outcomes:

Safety Outcome | Description |

|---|---|

Certified Strength and Reliability | Certified wire ropes assure strength and reliability for critical lifting tasks. |

Expert Consultation | Consulting with experts helps in selecting the right wire rope, enhancing safety and performance. |

Extended Equipment Life | Using the right wire rope configuration can prolong the lifespan of equipment. |

Routine Inspection and Maintenance | Regular inspections ensure safety and reliability, preventing costly failures. |

Compliance with Industry Standards | Certified products meet industry standards, enhancing overall performance and safety. |

Protection of Team and Equipment | Prioritizing inspection and care protects both personnel and equipment from hazards. |

Adherence to Inspection Schedules | Following strict inspection schedules is crucial for maintaining safety and preventing hazards. |

Prevention of Costly Failures | Neglecting inspections can lead to significant safety risks and financial losses. |

Reliability and Peace of Mind | High-quality wire ropes contribute to overall reliability and peace of mind in operations. |

You ensure the highest level of safety and performance by following these guidelines and relying on Powerful Machinery’s certified solutions for all your lifting needs.

Application and Selection Guide

When to Use Non-Rotating Wire Rope?

You should choose non-rotating wire rope when your lifting tasks demand maximum stability and safety. This type of rope works best in situations where load rotation can cause hazards or damage.

In industries like construction, mining, and marine, non-rotating wire rope ensures precise control and reduces accident risks. The table below shows common uses:

Industry | Application Description |

|---|---|

Crane Industry | Used in cranes and hoists for precise control and stability, minimizing load rotation. |

Offshore and Marine | Essential for lifting heavy loads in harsh conditions, maintaining stability and control. |

Mining Industry | Employed in cranes and winches to safely maneuver large loads, reducing accident risks. |

You benefit from non-rotating wire rope in high-rise construction, tower cranes, and offshore platforms. These ropes help you keep loads steady and prevent dangerous spinning during vertical lifts.

When to Use Rotating Wire Rope?

You may select rotating wire rope for lifting tasks where load spinning does not create safety concerns. Rotating wire rope fits well in short-term or low-load applications. You often see this type in temporary hoisting, light rigging, or when the load can rotate freely without risk.

Rotating wire rope offers flexibility for general construction, maintenance, and some industrial settings.

When you decide between rotating and non-rotating wire rope, consider these key factors:

Factor | Description |

|---|---|

Resistance to Rotation | Decide if you need a rope that resists spinning during lifting. |

Fatigue Resistance | Choose ropes with smaller wires for frequent bending around sheaves. |

Abrasive Wear Resistance | Select ropes with larger outer wires if abrasion is a concern. |

Corrosion Resistance | Use galvanized ropes or regular lubrication in corrosive environments. |

Crush Resistance | Install with back tension to prevent damage in multi-layer spooling applications. |

Powerful Machinery Solutions

You can rely on Powerful Machinery for both rotating and non-rotating steel wire rope solutions. Their products deliver high strength, excellent crush resistance, and long-lasting durability.

Powerful Machinery offers versatile configurations like 35W×7, 18×19, and 8×55SWS, which suit most lifting needs. These ropes maintain their diameter and shape over time, even in demanding conditions.

Advantage | Description |

|---|---|

High strength | Provides superior load-bearing capacity. |

High crush resistance | Maintains integrity under heavy loads. |

Suitable for most uses | Versatile for various industrial applications. |

Highly durable | Long-lasting performance in tough environments. |

Longer-lasting rope diameter | Retains size and shape over time. |

Tip: Always match your wire rope selection to the specific lifting application. Consider load weight, rotation risk, and environmental conditions. Powerful Machinery’s certified steel wire ropes help you achieve safe and efficient lifting every time.

Conclusion

You need to choose the right wire rope for your lifting tasks to ensure safety and efficiency. The table below highlights the core differences:

Feature | Non-Rotating Wire Rope | Rotation-Resistant Wire Rope |

|---|---|---|

Construction | 3 layers, 14+ outer strands | 2 layers, 8–13 outer strands |

Resistance to Rotation | High | Moderate |

Application | High-stakes lifting | General lifting |

You use non-rotating wire ropes for tower cranes, hoists, elevators, and marine lifts. Proper selection prevents accidents and extends equipment life. Powerful Machinery’s certified steel wire ropes help you achieve reliable lifting in every project.

FAQ

What is the main difference between rotating and non-rotating wire rope?

You will notice that rotating wire rope can twist under load, while non-rotating wire rope resists spinning. Non-rotating wire rope uses a special construction that balances internal forces, making it safer for vertical lifting.

When should you use non-rotating wire rope?

You should use non-rotating wire rope for high-rise lifts, tower cranes, or any application where load stability is critical. This rope prevents dangerous spinning and keeps your lifting operations safe.

How do you select the right wire rope for your project?

You need to consider load weight, lifting height, and the risk of rotation. Always check the rope’s construction and certifications. Powerful Machinery offers expert guidance to help you choose the best solution.

Why is certification important for wire rope?

Certification ensures your wire rope meets strict safety and quality standards. You protect your team and equipment by using certified products from trusted suppliers like Powerful Machinery.

Tip: Always inspect your wire rope before each use. Look for signs of wear, corrosion, or damage to maintain safety and performance.