Choosing the right steel wire rope for lifting means you protect your team and your equipment. The construction and durability of steel wire rope directly affect safety. Industry studies show that ropes can last up to 289,457 cycles, but 10% may break before 240,000 cycles if you ignore proper steel wire rope selection.

Metric | Value | Implication |

|---|---|---|

Z_A10 | 240,000 cycles | 10% of ropes may break before this cycle count |

Z_Am | 289,457 cycles | 90% of ropes are expected to last 2 years under specified conditions |

You must look beyond breaking load and diameter. Consider fatigue resistance, bending fatigue, and how your environment impacts steel. Powerful Machinery provides certified solutions trusted worldwide for reliable lifting.

Key Takeaways

Choose the right steel wire rope to ensure safety for your team and equipment. Consider factors like breaking load, working load, and environmental conditions.

Understand the difference between breaking load and working load. Use a safety factor to calculate the working load for safe lifting operations.

Select steel wire rope based on its construction. Features like multi-layer design and non-rotating construction enhance durability and fatigue resistance.

Regularly inspect and maintain your steel wire rope. Look for signs of wear, corrosion, and damage to extend its lifespan and ensure safety.

Consult experts for tailored advice on steel wire rope selection. Their guidance can help you choose the best options for your specific lifting needs.

Steel Wire Rope Selection Essentials

Breaking Load and Working Load

When you begin steel wire rope selection, you must understand the difference between breaking load and working load. Breaking load refers to the minimum force that a steel wire rope can withstand before failure.

Working load, also known as safe working load, is the maximum workload you can safely apply during regular use. You should never operate near the breaking load. Instead, you must use a safety factor to calculate the working load.

For general lifting, a 5:1 safety factor is standard. In critical lifting, such as personnel lifts, you may need a safety factor of 10:1 or higher. For rigging, a 4:1 safety factor is common.

Term | Definition |

|---|---|

Minimum Breaking Load | The minimum force that a product can withstand before failing. |

Safe Working Load (SWL) | The maximum load that a product can safely handle during regular use. |

Safety Factor (SF) | The ratio of breaking strength to SWL shows how much stronger the product is than its working load. |

You must calculate the working load by dividing the minimum breaking load by the safety factor. For example, if your steel wire rope has a minimum breaking load of 20,000 lbs and you use a safety factor of 5, the working load is 4,000 lbs. This calculation ensures safe operation and protects your team and equipment.

Powerful Machinery’s certified steel wire rope meets international standards such as ISO 2408 and EN 12385, giving you confidence in every lift.

Tip: Always check the certification and documentation for your steel wire rope before use. Regular inspections help maintain compliance and safety.

Fatigue and Destruction Resistance

Fatigue resistance is a critical criterion in steel wire rope selection. You must consider how many bending cycles your rope can withstand. Laboratory tests show that steel wire rope with multi-layer construction and non-rotating design can resist bending fatigue under repeated use.

When you select a rope with high breaking load and resistance to fatigue, you extend its lifespan and reduce the risk of unexpected failure.

The fatigue resistance of steel wire rope is determined by the number of bending cycles it can withstand.

Testing involves running the rope over a sheave with a specific line pull that matches the minimum breaking load.

Features like multi-layer construction and non-rotating design enhance fatigue resistance.

Destruction resistance depends on the rope’s construction. An 8-strand rope offers flexibility and high resistance to fatigue but is less durable against abrasion. A 6-strand rope provides greater durability and high resistance to destruction.

You must match the rope’s construction to your application and the factors present in your environment.

Note: Powerful Machinery’s steel wire rope features advanced construction for high breaking load and resistance to fatigue, ensuring reliable performance in demanding lifting applications.

Application and Environment

Your application determines the steel wire rope selection process. You must analyze the load type, lifting method, and environmental factors. For marine or coastal applications, salt exposure accelerates corrosion.

In industrial zones, chemicals or acids can weaken the steel surface. High temperatures may lower tensile capacity.

Environmental Factor | Impact on Steel Wire Rope |

|---|---|

Marine/Coastal Areas | Salt exposure accelerates corrosion. |

Industrial Zones | Chemicals or acids can weaken the wire surface. |

UV and Temperature | High temperatures may lower tensile capacity. |

You should choose zinc-coated or stainless steel wire rope for enhanced corrosion resistance. Efficient operation in harsh environments is crucial. Powerful Machinery’s steel wire rope meets certification standards such as ISO 2408, EN 12385, and DIN 3060.

Regular inspections and maintenance, along with thorough documentation, help you maintain compliance and extend the lifespan of your steel wire rope.

Corrosion is a significant factor affecting the lifespan of industrial wire ropes.

Zinc-coated or stainless steel wire ropes enhance corrosion resistance.

Efficient operation in harsh environments ensures safety and reliability.

Powerful Machinery’s certified products give you peace of mind for every application. You can rely on their expertise and rigorous testing to meet the toughest demands.

Tip: Consult Powerful Machinery’s experts for guidance on steel wire rope selection tailored to your specific application and environment.

Steel Wire Rope Construction Overview

Structure: Wires, Strands, Core

You need to understand the basic construction of steel wire rope to make the right selection for lifting. The composition of wire rope includes three main elements: wires, strands, and the core. Wires form the smallest part and provide tensile strength.

Strands hold these wires together, adding durability and flexibility. The core sits at the center and supports the strands, maintaining the rope’s shape and stability under stress.

The core provides stability and support to the strands.

Strands hold the individual wires, contributing to overall strength and durability.

Steel wires form a strand, contributing to the rope’s strength.

Strands wrap around the core, enhancing flexibility and durability.

The construction of steel wire rope determines its performance in lifting, rigging, and hoisting. Powerful Machinery’s products meet international standards, ensuring you get reliable strength and safety for every application.

Core Types: Fiber, IWRC, Plastic

The core type affects the flexibility, load capacity, and resistance of steel wire rope. You can choose from fiber core, IWRC (Independent Wire Rope Core), or plastic core. Each type offers unique advantages for different environments.

Core Type | Flexibility | High-Temperature Resistance | Load Capacity | Crush Resistance | Self-Weight |

|---|---|---|---|---|---|

Fiber Core | Excellent | Poor | Lower | Poor | Light |

IWRC | Less | Excellent | Higher | Excellent | Heavy |

Fiber core gives you excellent flexibility and light weight, making it ideal for frequent bending and general utility. IWRC provides higher tensile strength, crush resistance, and heat resistance, which is best for heavy-duty lifting. Plastic cores offer stability and moisture resistance for specialized needs.

Tensile Strength Grades

Tensile strength grades define the minimum strength your steel wire rope can handle. The most common tensile strength grades are 1770, 1960, and 2160. These grades indicate the minimum tensile strength, which is critical for lifting capacity and safety.

Wire Rope Grade | Minimum Tensile Strength |

|---|---|

1770 | 1770 N/mm² |

1960 | 1960 N/mm² |

2160 | 2160 N/mm² |

You must select the right grade to match your lifting requirements. Higher grades provide greater tensile strength and reduce the risk of failure. Powerful Machinery’s steel wire rope construction meets or exceeds these grades, giving you confidence in every lift.

Note: Always verify the construction and tensile strength grade before use. Powerful Machinery’s certified products ensure you meet safety standards in every operation.

Measurement and Sizing Standards

Diameter Measurement Methods

You must measure steel wire rope diameter with precision to ensure safety and compliance. Accurate measurement helps you select the right rope for your lifting application and prevents mismatches that can lead to failure. The most reliable way to measure diameter is with a calibrated calliper gauge.

You should always measure across the largest part of the rope, making sure the rope is straight and not twisted or coiled.

Measurement Method | Description |

|---|---|

Calliper Gauge | Use a calliper gauge to measure across the largest diameter of the rope. |

Multiple Measurements | Take two measurements at right angles and average them for accuracy. |

Tolerance Specifications | Follow tolerances set by standards like EN 12385-4, API 9A, and ISO 2408. |

You should take two measurements at right angles to each other and calculate the average. This process ensures you get an accurate reading, even if the rope is slightly out of round. Always check the tolerances specified by international standards to confirm your steel wire rope meets the requirements.

Tip: Always measure the rope when it is straight and under no load for the most accurate results.

Industry Standards and Allowable Loss

Industry standards set clear guidelines for allowable loss in steel wire rope diameter. A noticeable reduction in diameter signals wear or damage. You need to monitor for signs such as external abrasion, internal or external corrosion, and changes in the rope lay.

Other warning signs include inner wire breakage, rope stretch, or the ironing of strands.

Compare the current diameter with the original diameter under load conditions.

Watch for rapid diameter reduction, which may indicate core deterioration.

Remove the rope from service if you see significant loss or damage.

Regular inspection and measurement help you maintain the integrity of your steel wire rope. Following these standards ensures you operate safely and extend the life of your lifting equipment.

Steel Wire Rope Types and Applications

6-Strand vs 8-Strand Ropes

You must choose between 6-strand and 8-strand steel wire rope based on your lifting needs. A 6-strand rope gives you high durability and strong abrasion resistance. You often use this type for winch lines and drag lines where wear is a concern.

An 8-strand rope offers maximum flexibility, making it easier to handle and bend around pulleys. You find 8-strand ropes in complex reeving systems and overhead cranes where you need smooth movement and less fatigue.

Tip: Select 8-strand ropes when your application demands maximum flexibility and frequent bending. Use 6-strand ropes for tasks that require high abrasion resistance and durability.

Common Constructions (6×19, 6×25, etc.)

General wire rope constructions like 6×19 and 6×25 serve different purposes. You see 6×19 ropes in winch lines and heavy-duty lifting because they resist wear and last longer.

The 6×25 construction provides more flexibility, which helps in crane hoist lines and general lifting tasks. Powerful Machinery offers steel wire rope in multiple configurations to match your requirements.

Wire Rope Type | Flexibility | Durability | Wear Resistance |

|---|---|---|---|

6×19 | Less | Moderate | High |

6×25 | More | High | Moderate |

You can select galvanized steel for logging, rigging, and hoisting. Stainless steel works best in mining, oil, and marine environments due to its corrosion resistance. Bright carbon steel gives you cost-effective strength and maximum flexibility for crane hoisting and general industrial use.

Material | Key Features | Common Applications |

|---|---|---|

Galvanized Steel | High breaking strength, ductile, and fairly flexible | Logging, rigging, hoisting, and general industrial |

Stainless Steel | Excellent corrosion resistance, high strength | Mining, oil, gas, marine |

Bright Carbon Steel | High strength, very flexible, cost-effective | Crane hoisting, rigging, and general industrial |

Flexibility and Durability Comparison

Flexibility impacts how you use steel wire rope in lifting and rigging. Ropes with maximum flexibility, such as 6×37, bend easily and suit overhead cranes and complex reeving systems.

Ropes with lower flexibility, like 6×19, resist abrasion and last longer in tough conditions. You must balance flexibility and durability to match your lifting task.

Rope Class | Flexibility | Abrasion Resistance | Best Use Cases |

|---|---|---|---|

6×19 | Low | High | Winch lines, Drag lines |

6×26 | Medium | Medium | Crane hoist lines, General lifting |

6×37 | High | Low | Overhead cranes, Complex reeving systems |

You should choose steel wire rope with maximum flexibility for applications that require frequent bending and smooth operation. For heavy loads and abrasive environments, select ropes with higher durability.

Powerful Machinery provides a full range of steel wire rope options, ensuring you get the right balance for your project.

Note: Always match the flexibility and durability of your steel wire rope to the demands of your lifting environment. Consult Powerful Machinery for expert recommendations on the best configuration for your needs.

Advanced Features of Powerful Machinery Steel Wire Rope

Non-Rotating Design

You need a steel wire rope that delivers stability and safety during every lift. Powerful Machinery’s non-rotating design uses multiple layers of strands wound in opposite directions. This construction resists spinning under load and keeps your lifting operations precise.

You gain better control when positioning heavy loads, which reduces the risk of accidents in industrial environments.

Multiple-strand layers wound in opposing directions prevent twisting and kinking.

Load stability improves, making your lifting operations safer.

You achieve accurate placement, even in complex lifting scenarios.

The table below shows how non-rotating steel wire rope outperforms traditional designs:

Feature | Non-Rotating Steel Wire Rope | Traditional Designs |

|---|---|---|

Load Stability | Exceptional | Variable |

Twisting and Kinking | Prevented | Common |

Safety in Heavy-Duty Use | High | Moderate to Low |

Application Versatility | High | Limited |

Abrasion and Corrosion Resistance

You face harsh conditions in many lifting environments. Powerful Machinery’s steel wire rope stands up to these challenges with advanced abrasion and corrosion resistance.

The high-quality steel construction gives you good resistance to abrasion, which means the rope lasts longer even when dragged over rough surfaces or exposed to heavy use.

The rope’s surface resists wear from contact with drums, sheaves, and other equipment.

Corrosion resistance protects the steel core from moisture, chemicals, and salt.

You can use this rope in marine, construction, and industrial settings without worrying about rapid deterioration.

Regular inspections help you spot early signs of abrasion or corrosion, so you can replace the rope before safety becomes an issue.

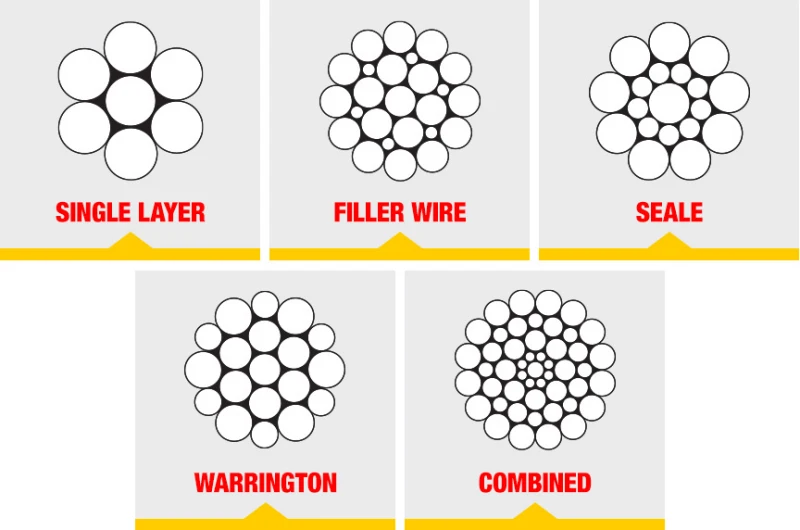

Filler Wires and Plastic Impregnation

You benefit from advanced features like filler wires and plastic impregnation in demanding lifting applications. These innovations extend the life of your steel wire rope and improve performance.

Filler wires increase durability and wear resistance by reducing internal corrosion and maintaining the rope’s structure.

Plastic impregnation forms a barrier that blocks harmful substances from reaching the steel core.

Internal friction drops, which means smoother operation and less wear.

Load distribution improves, reducing bending fatigue and increasing the rope’s service life.

You get increased bending fatigue resistance, which is essential for frequent lifting cycles.

These features ensure your steel wire rope performs reliably, even in the toughest environments.

Practical Use and Expert Advice

Handling and Maintenance

You must handle steel wire rope with care to ensure safety and extend its service life. When you uncoil or unreel the rope, lay the coil flat on the floor or stand it on edge. This method prevents kinks and loops that can weaken the rope. Always avoid creating sharp bends or knots, as these can damage the steel wires inside.

Use proper winding techniques on winch drums, paying attention to the rope’s natural rotation. Store your wire rope in a dry, temperate place, away from weather and acids. Apply a high-quality lubricant regularly to protect against corrosion and keep the rope flexible.

Uncoil and unreel using the correct methods to prevent kinks.

Avoid loops and sharp bends during handling.

Wind the rope properly on the drums, considering its rotation.

Store in a dry, protected environment.

Lubricate with a suitable product to maintain flexibility and resist corrosion.

Tip: Regular inspections help you spot early signs of wear or damage, allowing you to replace the rope before failure occurs.

Lifespan and External Influences

The lifespan of steel wire rope depends on how you use and maintain it. External factors can shorten its service life. Moisture, chemicals, and extreme temperatures speed up corrosion.

In marine environments, saltwater can break down protective coatings and make the steel brittle. Abrasion from rough surfaces wears down the outer strands, exposing the inner structure to more damage.

Moisture and chemicals increase the risk of corrosion.

Saltwater in marine settings can quickly degrade the rope.

Abrasive surfaces cause wear and expose the core.

High or low temperatures affect the rope’s strength and flexibility.

You should always consider these factors in your application and use regular maintenance to maximize the rope’s lifespan.

Consulting Powerful Machinery Experts

When you face complex lifting challenges or unique environments, you can rely on Powerful Machinery’s expertise. Their team understands the demands of every industry and can recommend the best steel wire rope for your needs. You receive guidance on selection, installation, and ongoing maintenance.

Powerful Machinery offers custom solutions, ensuring your lifting equipment matches your exact requirements. Reach out to their experts for advice on maximizing safety, performance, and value in every project.

Note: Expert consultation helps you avoid costly mistakes and ensures your steel wire rope performs reliably in every application.

Conclusion

You protect your team and investment when you match steel wire rope construction to your lifting needs. The statistics below show why careful selection matters:

Statistic Description | Value |

|---|---|

Nonfatal workplace injuries in 2023 | Over 2.6 million |

Average cost of a workplace injury | $43,000 |

Percentage of load drops tied to poor rigging practices | 27% |

Follow these steps for safe and effective lifting:

Assess load capacity.

Review wire rope construction.

Check the sling length.

Evaluate environmental conditions.

Maintain your equipment.

Powerful Machinery’s steel wire rope holds certifications like ISO 2408 and EN 12385, with third-party endorsements from TÜV and SGS. For more guidance, explore resources on strength, fatigue resistance, and abrasion resistance, or consult Powerful Machinery’s experts for custom solutions.

FAQ

What is the main advantage of non-rotating steel wire rope?

You gain superior load stability and safety. Non-rotating wire rope resists twisting and kinking during lifting, which helps you control heavy loads and reduces the risk of accidents.

How often should you inspect steel wire rope?

You should inspect your steel wire rope before each use. Schedule detailed inspections every one to three months, depending on usage and environment. Look for wear, corrosion, and broken wires.

Can you use steel wire rope outdoors?

Yes, you can use steel wire rope outdoors. Choose galvanized or stainless steel options for the best corrosion resistance. Powerful Machinery offers ropes designed for harsh environments.

How do you select the right wire rope for your application?

Identify your load requirements.

Consider flexibility and abrasion resistance.

Check environmental factors.

Consult Powerful Machinery experts for certified recommendations.

Where can you get technical support for steel wire rope selection?

You can contact Powerful Machinery’s technical team for expert advice. Visit Powerful Machinery’s website for support and custom solutions.