Synthetic slings must be inspected before every use and at regular intervals to uphold safety and prevent accidents in lifting operations. You protect workers and equipment when you follow strict inspection routines.

Powerful Machinery’s certified products, such as round webbing slings and flat web slings, support your commitment to safety and compliance. Regulatory bodies like OSHA and ASME B30.9 require you to designate a qualified person for daily sling checks and periodic inspections.

Neglecting this responsibility can lead to workplace injuries and costly downtime. Safety starts with you. Synthetic slings must be inspected to meet industry standards and maintain reliable performance.

Standard | Requirement |

|---|---|

ASME B30.9 | Mandates regular inspection of synthetic slings for safety compliance. |

OSHA | Requires periodic inspections of slings and rigging hardware. |

Synthetic slings must be inspected to avoid damage or defects that compromise safety. Inspection also ensures you meet legal obligations and maintain trust in your lifting solutions.

Key Takeaways

Inspect synthetic slings before every use to prevent accidents and ensure safety.

Regular inspections help identify damage early, protecting both workers and equipment.

Follow OSHA and ASME guidelines for inspection frequency to maintain compliance and avoid legal issues.

Use certified products from trusted manufacturers to enhance safety and reliability in lifting operations.

Document all inspections and any issues found to support a culture of safety and continuous improvement.

Risks of Skipping Synthetic Sling Inspections

Workplace Accidents and Injuries

You face serious risks when you skip synthetic sling inspections. Sling failure during lifts can cause catastrophic accidents. Misuse of synthetic slings creates real safety hazards for everyone on site.

Each year, approximately 90 lift and material handling equipment workers lose their lives in lifting accidents, with 90% of these tragedies linked to human error. Poorly managed construction sites often see injuries from hoisting and rigging tasks.

Worn-out or misused slings can snap under pressure, resulting in dropped loads and injuries.

Key risks include:

Sling failure during lifts

Misuse of synthetic slings

Dropped loads from worn or damaged slings

Injuries from hoisting and rigging tasks

Tip: Always inspect your slings before use to protect your team and prevent accidents.

Equipment Damage and Downtime

Neglecting sling inspections not only endangers people. You also risk damaging valuable equipment. Nearly all failures of synthetic fiber slings come from improper use, not manufacturing defects. Chemical damage, UV exposure, cuts, punctures, and poor handling weaken sling strength.

Equipment damage from sling failures leads to significant operational downtime and increased repair costs. Improper storage and skipped inspections can reduce sling strength by 15% each season, causing unexpected failures.

Consequences include:

Increased repair costs

Lost productivity due to downtime

Shortened equipment lifespan

Regular maintenance and inspections help you avoid these problems. Investing in a maintenance program enhances safety, increases equipment lifespan, and ensures regulatory compliance.

Compliance and Legal Issues

You must comply with strict safety regulations for synthetic sling inspections. Regulatory bodies mandate regular inspections to maintain safety standards. Companies that ignore these requirements face significant penalties and legal consequences.

Non-compliance can result in legal liabilities, workplace accidents, and reputational damage. You protect your business and reputation when you follow inspection protocols and use certified products like those from Powerful Machinery.

Synthetic Slings Must Be Inspected: Key Reasons

Preventing Sling Failure

You must inspect synthetic web slings to prevent unexpected failures during lifting operations. Even minor damage can reduce a sling’s capacity and increase the risk of accidents. Regular inspections help you identify cuts, abrasions, or contamination before each use.

You protect your team and equipment when you follow a structured inspection process, which includes initial, frequent, and periodic checks.

Regular inspections reveal damage before use.

Minor damage can lower sling strength and cause failure.

A structured inspection schedule maintains sling integrity.

Industry incident reports show that inadequate sling protection devices and contact with load edges are leading causes of synthetic sling failure. You must ensure slings do not touch sharp edges and always use proper protection.

Cause of Failure | Description |

|---|---|

Inadequate Sling Protection Devices | The primary cause of failure is the lack of proper protection when slings contact sharp edges. |

Contact with Load Edges | All evaluated cases of failure involved slings making contact with the edges of their loads. |

Vague Industry Standards | Existing standards do not clearly define the necessary protection measures for synthetic slings. |

Note: Contaminants like dirt and grease can reduce sling strength by up to 25%. You must keep synthetic web slings clean and protected to maintain their integrity.

Meeting Safety Standards

You must meet strict safety standards to ensure reliable lifting operations. Synthetic web slings must comply with ASME B30.9 standards, which require regular inspection and clear identification. Each sling needs a visible tag with manufacturer details, material type, load capacity, and safety instructions.

High-quality synthetic fibers provide durability.

Identification tags display essential information.

Working Load Limit (WLL) indicates the maximum safe load.

Inspections detect wear, damage, or degradation.

Remove slings from service if you find significant damage.

You must conduct thorough inspections before each use and follow a periodic schedule based on how often you use the sling and the environment. Meeting ASME B30.9 standards protects your business from legal risks and ensures the safety of your lifting operations.

Tip: Always verify the identification tag and WLL before using synthetic web slings. This step helps you avoid overloading and ensures compliance with ASME B30.9 standards.

Powerful Machinery’s Certified Products

You improve safety and efficiency when you choose certified products from Powerful Machinery. The brand’s round webbing sling, slings & tie downs, and flat web slings offer superior performance compared to uncertified alternatives.

These products meet ASME B30.9 standards and provide reliable lifting solutions for various industries.

Feature | Round Webbing Slings | Flat Web Slings |

|---|---|---|

Flexibility | Highly flexible, molds around loads | Lightweight and easy to handle |

Load Distribution | Ensures even load distribution | Wide load-bearing surface |

Durability | Resistant to abrasion and wear | Made from 100% polyester webbing |

Safety Certification | Supplied with an individual serial ID and certification | CE marked and compliant with standards |

Versatility | Ideal for irregularly shaped objects | Suitable for various lifting applications |

You reduce the risk of accidents when you use synthetic web slings that are certified and manufactured to meet international standards.

Powerful Machinery’s products feature high-strength synthetic webbing, clear identification tags, and compliance with ASME B30.9 standards. You benefit from enhanced durability, reliable load distribution, and peace of mind during every lift.

🛡️ Using uncertified synthetic web slings increases the risk of failure and workplace accidents. Industry case studies show that 81% of rigging accidents involve synthetic slings, with 34% of organizations reporting inadequate sling protection. You must prioritize certified products to safeguard your operations.

Synthetic web slings from Powerful Machinery help you maintain compliance, prevent sling failure, and achieve safe lifting operations. You set a higher standard for safety when you inspect your equipment and choose certified synthetic webbing solutions.

Synthetic Web Slings Inspection Process

Visual Checks for Damage

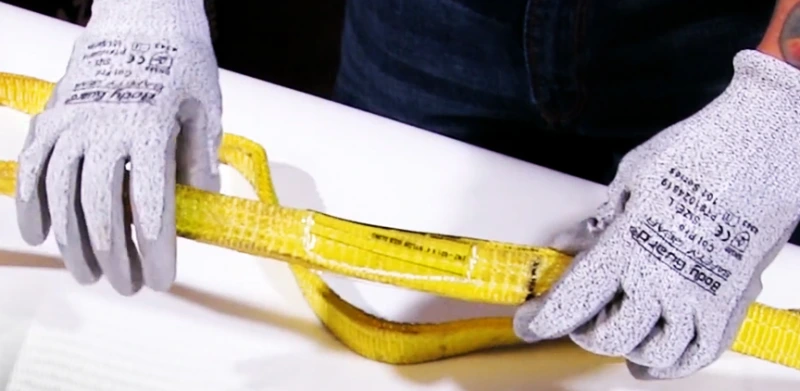

You must perform a visual inspection of synthetic web slings before each use and during every shift. This step helps you identify visible damage that can compromise safety. Look for cuts, abrasions, burns, or snags along the sling body. Examine the stitching in load-bearing splices for signs of wear or breakage.

Check for discoloration, brittle or stiff areas, and any melting or charring. Inspect fittings for corrosion, cracks, bends, or other deformities. Remove any sling from service if you find missing or illegible identification, acid or caustic burns, holes, tears, knots, or excessive wear.

Inspect daily for serious damage or deterioration.

Remove from service if you see:

Missing or illegible identification

Acid or caustic burns

Melting or charring

Holes, tears, cuts, or snags

Broken or worn stitching

Excessive wear or abrasion

Knots in any part of the sling

Discoloration, brittle or stiff areas

Damaged fittings

Tip: Training your team on proper rigging practices and inspection routines reduces the risk of accidents and equipment failure.

Powerful Machinery recommends following these inspection steps for all synthetic web slings, including round webbing slings and flat web slings. Their products feature high-strength polyester and color-coded designs, making it easier for you to spot visible damage and ensure safe lifting.

Reviewing Sling Identification Tags

You must review the identification tag during initial inspection and before each use. The tag provides essential information about the sling, including the manufacturer’s name, code, rated load, type of fiber, and number of legs. For polyester round slings, the tag also lists the core and cover materials.

Always verify that the tag matches the specifications for your lifting application. If the tag is damaged, missing, or illegible, remove the sling from service and notify a qualified person.

Sling Type | Required Information |

|---|---|

Synthetic Web Sling | Manufacturer’s name, manufacturer’s code, rated load, type of fiber, number of legs |

Polyester Round Sling | Manufacturer’s name, manufacturer’s code, rated load, core material, cover material, number of legs |

Note: Powerful Machinery’s synthetic web slings come with clear, durable identification tags to help you meet industry standards and maintain compliance.

Frequency and Periodic Inspection

You must conduct periodic inspections of synthetic web slings at least every 12 months under normal work conditions. Increase the frequency to monthly or quarterly if you operate in severe environments or handle heavy loads regularly. Consult a qualified person for special work conditions.

Document each periodic inspection in your maintenance log or employee task card. You do not need individual records for each sling, but you must keep a general record of the inspection event.

Work Condition | Recommended Inspection Frequency |

|---|---|

Normal Work Conditions | Annual inspection |

Severe Work Conditions | Monthly or quarterly inspection |

Special Work Conditions | Consult a Qualified Person |

Record the date, names of inspectors, number of slings inspected, and number rejected.

Example: “On this date, 04/15/24, John Smith and Maria Lee inspected all synthetic web slings on site. Out of 150 slings, 12 were rejected due to visible damage. The remaining slings stayed in service.”

Regular periodic inspections help you comply with OSHA and ASME guidelines. You reduce legal liability and avoid increased insurance premiums by maintaining proper documentation and following inspection schedules.

Powerful Machinery’s certified products support your efforts to meet these requirements and keep your operations safe.

🛡️ Consistent inspection and documentation protect your business, your team, and your equipment.

Synthetic Sling Inspection Checklist

Signs of Wear and Damage

You must check synthetic slings for signs of wear and damage before every lift. Look for cuts, tears, or holes along the sling body. Examine the stitching for loose threads or broken seams. Inspect for abrasive wear, which appears as fuzzing or thinning that reduces the sling’s width by 10 percent or more.

Remove slings with embedded particles, broken core yarns, or cracked metal fittings. Watch for acid or alkaline burns, melting, charring, or weld splatter. If you see faded webbing color, shortened sling length, or reduced elasticity, the sling may have lost strength.

Signs of Damage and Wear | Description |

|---|---|

Missing or illegible sling identification | Indicates potential safety issues. |

Acid or caustic burns | Can weaken the sling material. |

Evidence of heat damage | Compromises the integrity of the sling. |

Holes, tears, cuts | Exposes core yarns, reducing strength. |

Broken or damaged core yarns | Directly affects lifting capabilities. |

Weld splatter | Can damage core yarns. |

Discoloration and stiffness | May indicate chemical damage. |

Tip: Remove any sling from service if you find knots, broken stitching, or excessive wear. These issues can lead to sudden failure during lifting.

Chemical and UV Exposure

You must inspect synthetic slings for chemical and ultraviolet (UV) exposure. Chemicals like acids or alkalis can cause burns, stiffness, or brittleness in the sling fibers. UV exposure leads to fading color, stiffness, and visible fiber dust. Polyester web slings can lose up to 30% of their strength in one year of UV exposure.

Nylon web slings may lose up to 60% of their strength after three years in sunlight. Long-term exposure to sunlight and chemicals breaks down the sling’s molecular structure, making it unsafe for lifting.

Look for faded color or stiff texture.

Check for brittle areas or visible fiber dust.

Remove slings with signs of chemical burns or UV degradation.

⚠️ Regular inspections help you catch chemical and UV damage early, keeping your lifting operations safe.

Tag and Certification Verification

You must verify the sling’s tag and certification during every inspection. The tag must be present and legible. It should show the manufacturer’s name, code, rated loads, material type, number of legs, and serial number.

Missing or unreadable tags mean you cannot confirm the sling’s capacity or safety. Always check that the tag matches the sling’s specifications and lifting requirements.

Requirement | Description |

|---|---|

Tag Present | Must be present and legible |

Manufacturer Name | Must include the manufacturer’s name or trademark |

Manufacturer Code | Must show a manufacturer code or stock number |

Rated Loads | Must list rated loads for the type of hitches used and their angles |

Material Type | Must specify the type of synthetic web material |

Number of Legs | Must indicate the number of legs (if more than one) |

Serial Number | Must include a serial number or batch number |

Note: Powerful Machinery’s synthetic slings feature clear, durable tags and full certification, helping you meet safety standards and maintain compliance.

Actions After Failed Inspection

Immediate Removal from Service

When you find a synthetic sling that fails inspection, you must remove it from service right away. Do not allow anyone to use a sling that shows signs of damage or uncertainty. The following table outlines the main conditions that require immediate removal:

Condition for Removal from Service | Description |

|---|---|

Red Core Yarn Visible | Indicates damage to the sling. |

Missing or Unreadable Tag | Compromises safety information. |

Acid or Alkali Burns | Weakens material integrity. |

Melting, Charring, or Weld Spatter | Indicates exposure to extreme heat. |

Holes, Tears, Cuts, Snags | Compromises load-bearing capacity. |

Broken or Worn Stitching | Weakens the sling’s structure. |

Excessive Abrasive Wear | Reduces effectiveness. |

Knots in Sling | Can create weak points. |

Distortion or Corrosion | Affects the sling’s strength. |

Any Doubtful Conditions | Safety is paramount. |

You should also inspect for visible damage such as holes, cuts, and abrasions. Check for corrosion and fading of web color. Make sure that every sling is thoroughly inspected by a qualified person before each use.

⚠️ Never use a sling that fails inspection. Immediate removal prevents workplace accidents and protects your team.

Proper Disposal Procedures

After you remove a damaged sling from service, you must follow strict disposal procedures. Proper disposal ensures that no one accidentally reuses unsafe equipment. Follow these steps:

Tag the sling clearly as ‘Do Not Use’ as soon as you determine it is unusable.

Cut the eye and fittings from the sling to make sure it cannot be reused.

Dispose of the destroyed sling as soon as possible.

You must dismantle the sling and render it unusable before recycling or discarding. Always follow OSHA and ASME guidelines for disposal. This process keeps your workplace safe and compliant.

Documentation and Reporting

You need to document every failed inspection and removal action. Keep a record of the date, the reason for removal, and the person responsible for the inspection. This documentation helps you track trends, identify recurring issues, and prove compliance during audits.

Record the sling’s identification details and the specific damage found.

Note the disposal method and date.

Report the incident to your safety manager or supervisor.

📋 Good documentation supports a culture of safety and continuous improvement in your lifting operations.

Conclusion

You protect your team and equipment when you inspect synthetic slings regularly. Routine inspections help you spot wear early, prevent accidents, and maintain OSHA compliance. Staff training ensures everyone knows how to identify damage and follow safety standards.

Using certified products from Powerful Machinery boosts operational excellence and reduces workplace incidents.

Benefit | Description |

|---|---|

ISO-9001 Certification | Consistent product quality |

Accident Reduction | Fewer workplace incidents |

Longevity | Extended sling lifespan |

Make safety your priority. Choose Powerful Machinery for reliable lifting solutions.

FAQ

How often should you inspect synthetic slings?

You should inspect synthetic slings before every use and schedule periodic checks. Daily inspection helps you catch damage early and maintain safety standards. Always follow manufacturer guidelines and industry regulations for inspection frequency.

What signs indicate a synthetic sling needs removal?

You must remove a sling if you see cuts, burns, missing tags, broken stitching, or visible core yarn. Discoloration, stiffness, or chemical damage also signal that the sling is unsafe for lifting.

Can you repair a damaged synthetic sling?

You should never repair a damaged synthetic sling. Always replace it with a certified product. Repairs can compromise the sling’s integrity and increase the risk of accidents during lifting operations.

Why is certification important for synthetic slings?

Certification ensures your sling meets strict safety and quality standards. Certified products from Powerful Machinery provide reliable performance and help you comply with OSHA and ASME regulations.

What should you do if a sling fails inspection?

You must remove the sling from service immediately. Tag it as unusable and follow proper disposal procedures. Document the incident and notify your safety manager to prevent future risks.