You should select the correct turnbuckle size by considering the load capacity, material strength, thread size, application type, and environmental conditions.

Matching turnbuckle sizes to these factors ensures safety and reliability in every project. Powerful Machinery supplies certified turnbuckles designed for demanding environments. Always follow a step-by-step approach and verify each specification for secure installations.

Key Takeaways

Determine the load capacity before selecting a turnbuckle. Always choose one that exceeds your project’s expected load for safety.

Match the turnbuckle to your specific application type. Different projects, like construction or marine, require different features.

Evaluate the environment where the turnbuckle will be used. Consider factors like temperature and exposure to chemicals to choose the right material.

Measure turnbuckle sizes accurately. Use a caliper for diameter and a ruler for body length to ensure a proper fit.

Always check compatibility with other hardware. Ensure the turnbuckle’s working load limit matches or exceeds that of connected components.

Project Needs

Load Capacity

You must determine the load your project will handle before selecting a turnbuckle. The load capacity directly affects the safety and reliability of your installation. Always choose a turnbuckle that supports the expected load with a comfortable safety margin.

For example, if you are tensioning a wire rope size for a heavy-duty application, verify the working load limit (WLL) of both the turnbuckle and the wire rope size. This step prevents failures and ensures stability.

Tip: Always check manufacturer specifications for load ratings. Powerful Machinery provides certified products with clear load limits for every turnbuckle.

Requirement | Description |

|---|---|

Load Requirements | Choose a turnbuckle that can handle the expected load with a comfortable safety margin. |

Material | Options include stainless steel, galvanized steel, and aluminum, affecting strength and corrosion resistance. |

Application Environment | Corrosion-resistant finishes are essential for outdoor or marine environments to ensure longevity. |

Application Type

You should match the turnbuckle to your specific application. Construction, marine, and industrial projects each have unique demands. For instance, a turnbuckle used in a cargo rigging setup may require a different configuration than one used for architectural tensioning.

Consider the type of connection needed—eye, hook, or stub ends—and ensure compatibility with other hardware. The wire rope size also influences the choice, as larger ropes require stronger and larger turnbuckles.

Intended application

Load requirements

Environmental conditions

Environment

You must evaluate the working environment where you will install the turnbuckle. Environmental factors such as temperature, humidity, and exposure to chemicals can impact material performance. Stainless steel turnbuckles resist corrosion and suit outdoor or marine settings.

If your project faces extreme temperatures—above 400°F (204°C) or below 40°F (4°C)—consult with the manufacturer to confirm material suitability. Chemically active environments, like those with caustic or acidic substances, require specialized materials.

Powerful Machinery offers options designed for challenging conditions, ensuring long-term durability.

Environmental factors such as temperature, humidity, and exposure to chemicals are critical in selecting materials for rigging applications, including turnbuckles.

Materials used in rigging, including turnbuckles, should be evaluated for performance at extreme temperatures.

Turnbuckles may be affected by chemically active environments, such as those containing caustic or acidic substances.

Turnbuckle Sizes

Size Measurements

You need to understand how turnbuckle sizes are measured before choosing the right product for your project. Start by closing the turnbuckle completely so the threaded rods touch inside the frame. Use a caliper to measure the diameter of the threaded rod above the first thread.

Next, measure the body length from end to end using a straight ruler. The take-up distance, which is the maximum adjustment range, is also important. This measurement tells you how much you can tighten or loosen the connection. Always check a load chart to match your measurements with the correct working load limit.

Types & Materials

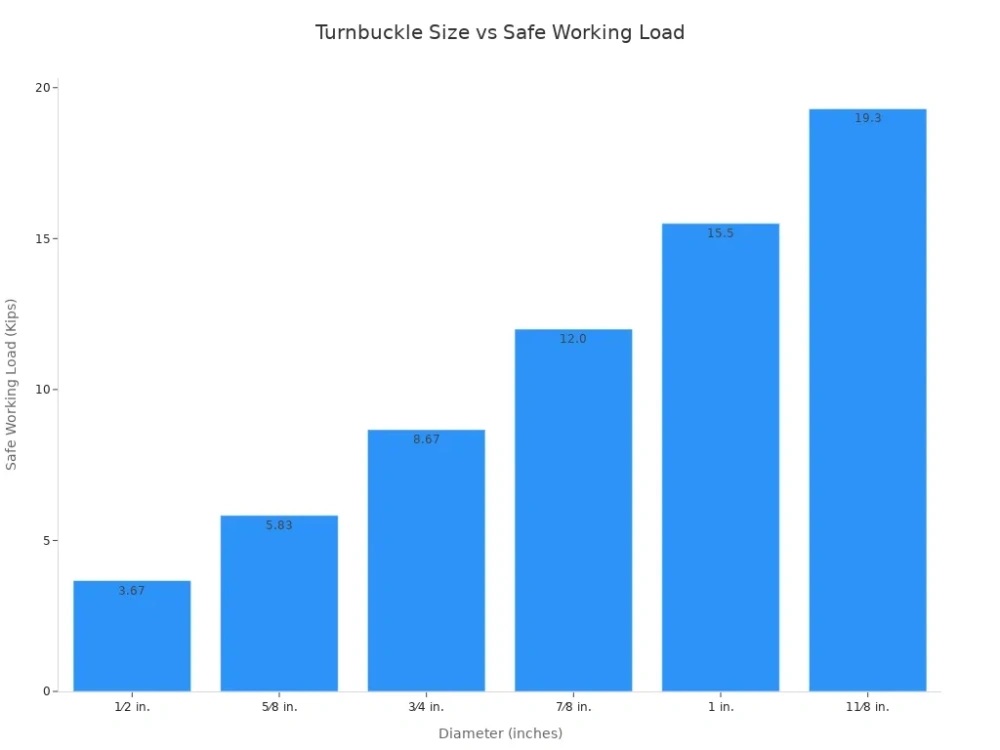

Turnbuckle sizes come in many configurations to fit different needs. Powerful Machinery offers a wide range of options, including stub ends, eye bolts, and hooks. The table below shows some common sizes and their safe working loads:

Dia. (D), in. | Standard Turnbuckles | Weight (lbs) | Safe Working Load (Kips) | Part Number |

|---|---|---|---|---|

1⁄2 | 6 | 0.65 | 3.67 | 18707 |

5⁄8 | 6 | 0.98 | 5.83 | 18708 |

3⁄4 | 6 | 1.45 | 8.67 | 18709 |

7⁄8 | 6 | 1.85 | 12.0 | 18710 |

1 | 6 | 2.60 | 15.5 | 18711 |

1 1⁄8 | 6 | 4.06 | 19.3 | 18712 |

Material choice affects both strength and durability. Drop-forged steel turnbuckles provide high toughness and impact resistance, making them ideal for heavy-duty applications. Stainless steel turnbuckles resist rust and corrosion, which makes them perfect for marine or outdoor use.

Powerful Machinery manufactures turnbuckle sizes that meet strict international standards, such as ISO 9001, ASME B30.26, and the CE mark, ensuring safety and reliability.

Strength & Adjustment

The strength of a turnbuckle depends on its size, material, and adjustment range. Shorter turnbuckle sizes (50 mm to 150 mm) work best for light-duty or compact projects.

Medium sizes (150 mm to 300 mm) suit most industrial and construction needs. Longer turnbuckle sizes (300 mm to 600 mm or more) handle heavy loads and provide a wide adjustment range for large-scale projects.

Note: Always select turnbuckle sizes that match your project’s load and adjustment requirements. Using certified products from Powerful Machinery ensures compliance with international safety standards and long-term performance.

Choosing the Right Size

Selecting the right turnbuckle size is essential for safety and performance in any rigging or tensioning project. You can follow a clear process to ensure your choice matches your load, environment, and hardware requirements.

Powerful Machinery offers certified turnbuckles that meet international standards, giving you confidence in every installation.

Calculate WLL

Start by determining the working load limit (WLL) for your application. The WLL tells you the maximum load a turnbuckle can safely handle. You should never exceed this value. To calculate the correct turnbuckle size, follow these steps:

Identify the total weight or force your system will support or tension.

Add a safety margin, typically 25% or more above the expected load.

Check the WLL of the turnbuckle and ensure it meets or exceeds your calculated requirement.

Confirm that the WLL of all connected hardware, such as slings or wire ropes, matches or surpasses the turnbuckle’s WLL.

Tip: Always use turnbuckles with clear identification markings and certified load ratings. Powerful Machinery provides detailed specifications for every product, making it easy to verify the right turnbuckle size for your needs.

Match to Application

You must match the turnbuckle size and type to your specific project. Different applications require different features and materials. Consider these factors when choosing:

Material suitability: Use stainless steel or galvanized turnbuckles for outdoor, marine, or corrosive environments.

Load capacity: Select a turnbuckle size that supports your application’s maximum load.

Size and thread type: Ensure the turnbuckle fits your cables or rods, whether you need a 3/8 turnbuckle, 3/8 inch turnbuckle, or another size.

Ease of adjustment: Choose models with ergonomic designs or quick-turn features for efficient tensioning.

Safety features: Look for lock nuts or safety pins to prevent accidental loosening.

Certifications and standards: Select products that comply with industry standards for safety and quality.

For example, a 3/8 turnbuckle or 3/8 inch turnbuckle is ideal for light to medium-duty tasks, such as securing shade sails or supporting small structures. Larger turnbuckle sizes are better for heavy-duty construction or marine rigging.

Check Compatibility

Before installation, you need to confirm that your turnbuckle is compatible with all other hardware in your system. Incompatible components can lead to failure or unsafe conditions. Use this checklist:

Ensure the turnbuckle’s WLL matches or exceeds the WLL of slings, wire ropes, and other rigging hardware.

Verify that the thread size and type fit your existing rods or cables.

Check for proper identification markings on the turnbuckle.

Consider the effects of temperature and chemical exposure on material performance.

Make sure all rigging gear is properly stored and that users have received adequate training.

Note: Powerful Machinery’s certified turnbuckles are designed for compatibility with a wide range of rigging systems. Their products undergo rigorous testing to ensure reliable performance in demanding environments.

By following these steps, you can confidently select the right turnbuckle size for your project. Always prioritize safety, reliability, and compliance with industry standards.

Mistakes to Avoid

Undersizing

You must avoid choosing hardware that cannot support the required load. When you select a component that is too small, you risk system failure. Undersized hardware may bend, stretch, or break under tension. This mistake can cause damage to equipment and create safety hazards for workers.

Always check the working load limit and select a size that matches your project’s demands. If you feel unsure, consult with a certified supplier like Powerful Machinery for guidance.

Tip: Always add a safety margin above your calculated load to prevent unexpected failures.

Overestimating Strength

You should never assume that all hardware can handle heavy loads. Overestimating the strength of a component can lead to serious problems. Consider these risks:

Catastrophic failures may occur when you use lower-grade hardware for demanding tasks.

Using hardware beyond its actual load capacity endangers both equipment and personnel safety.

Understanding the working load limit and following safety factors helps prevent accidents.

You must read product specifications and certifications before installation. Powerful Machinery provides clear load ratings and international certifications for every product.

Ignoring Corrosion

You need to consider corrosion resistance when working in outdoor or marine environments. Ignoring this factor can lead to costly and dangerous consequences. The table below highlights the impact of corrosion on hardware selection:

Consequence | Description |

|---|---|

Premature failure of components | Components may fail earlier than expected due to corrosion, leading to operational disruptions. |

Increased maintenance costs | Higher costs incurred for repairs and replacements due to corrosion damage. |

Potential safety hazards | Compromised structural integrity can pose safety risks to users and the surrounding environments. |

Select materials like stainless steel or galvanized steel for projects exposed to moisture or chemicals. You protect your investment and ensure long-term safety by choosing corrosion-resistant options.

Turnbuckle Sizes Reference

Size & Use Table

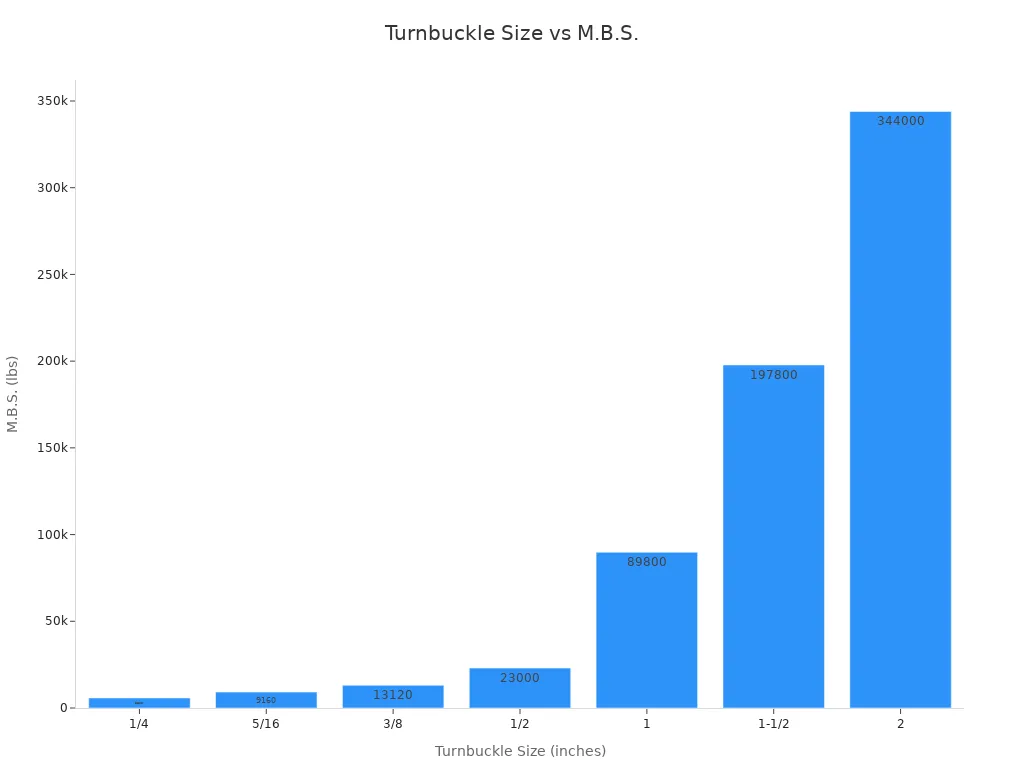

You can simplify your selection process by using a quick reference table for turnbuckle size. This table helps you match the right hardware to your project’s requirements. Powerful Machinery offers a wide range of sizes, each designed for specific load capacities and connection types.

Turnbuckle Size (inches) | Minimum Breaking Strength (lbs) | Recommended Hook Size (inches) | Recommended Jaw/Eye Size (inches) | Typical Applications |

|---|---|---|---|---|

1/4 | 5,800 | 1/2 | 3/8 | Light-duty rigging, fencing |

5/16 | 9,160 | 5/8 | 1/2 | Shade sails, small structures |

3/8 | 13,120 | 3/4 | 5/8 | Medium-duty tensioning, cargo nets |

1/2 | 23,000 | 1 | 3/4 | Construction, marine rigging |

1 | 89,800 | – | 1-1/2 | Heavy-duty lifting, mooring |

1-1/2 | 197,800 | – | 2-1/2 | Industrial, large-scale projects |

2 | 344,000 | – | 2-3/4 | Extreme loads, bridge supports |

You should choose a turnbuckle size that matches your load requirements and hardware compatibility. Smaller sizes work well for light-duty tasks, such as fencing or shade installations. Medium sizes suit cargo handling and construction. Larger sizes provide the strength needed for industrial and marine applications.

Tip: Always check the minimum breaking strength and recommended hardware size before installation. This step ensures safety and reliability in every project.

Powerful Machinery manufactures turnbuckle sizes that meet strict international standards. You can rely on their products for consistent performance in demanding environments. Use this table as a starting point when planning your next rigging or tensioning project.

Conclusion

You can ensure project safety and reliability by following these steps: assess load requirements, evaluate your environment, and confirm hardware compatibility. Always double-check specifications before installation. The table below highlights why this matters and where to find expert advice:

Aspect | Details |

|---|---|

Importance of Double-Checking | Ensures correct fit and adjustments in tie rod assemblies. |

Resource for More Info | Educational website and FAQ section for ordering tie rod assemblies correctly. |

Regular inspections and adherence to international standards help prevent failures. Bookmark or share this guide to support your team and improve future project outcomes.

FAQ

What is the most important factor when choosing a turnbuckle size?

You should always consider the working load limit (WLL) first. This value tells you the maximum safe load. Never exceed the WLL. Always check the manufacturer’s specifications for accurate information.

Can you use stainless steel turnbuckles outdoors?

Yes, you can use stainless steel turnbuckles outdoors. Stainless steel resists rust and corrosion. This makes it ideal for marine, construction, and outdoor environments.

How do you measure a turnbuckle for replacement?

You measure the thread diameter and the body length when the turnbuckle is fully closed. Always match these measurements to your existing hardware for a proper fit.

Does Powerful Machinery offer custom turnbuckle solutions?

Yes, Powerful Machinery provides custom-engineered turnbuckles. You can request specific sizes, materials, or configurations to meet your project’s unique requirements.

Where can you find certified turnbuckles for critical projects?

You can visit Powerful Machinery’s official website to find certified turnbuckles. All products meet strict international standards for safety and reliability.