You often face heavy lifting tasks that seem impossible with just your own strength. A block and tackle gives you a smart solution. This system uses two or more pulleys connected by rope, cable, or chain.

When you pull the rope, the block and tackle multiplies your force and lifts the load with less effort. Many industries rely on a block and tackle system because it makes moving and lifting large objects much easier.

Key Takeaways

A block and tackle system uses pulleys to multiply force, making heavy lifting easier and safer.

Select the appropriate materials for your block and tackle components to ensure durability and minimize maintenance costs.

Regularly inspect your block and tackle system for wear and damage to maintain safety and performance.

Select a block and tackle system that matches your specific lifting needs for maximum efficiency and safety.

Powerful Machinery offers certified products that meet strict safety standards, ensuring reliable performance in various industries.

Block and Tackle System Overview

What is a Block and Tackle?

You can think of a block and tackle as a simple yet powerful lifting tool. This system uses two or more pulleys, called blocks, connected by a rope, cable, or chain. When you pull on the rope, the pulley system multiplies your force, making it much easier to lift heavy objects.

The block and tackle system works by spreading the weight across several lines of rope, which means you do not need as much strength to move a load.

A block and tackle system gives you several important advantages over other lifting devices:

Increased mechanical advantage: Multiple pulleys reduce the effort needed to lift heavy loads, which is essential in construction and industrial work.

Enhanced efficiency: The system provides smoother motion and reduces friction, so you can handle loads more easily and protect your equipment.

Application versatility: You can use a block and tackle system in many industries, from marine operations to cargo handling, because it adapts to different load sizes and environments.

Safety and load control: The system gives you better control over heavy loads, which helps prevent accidents and keeps your work area safe.

Cost-effective lifting solutions: Block and tackle systems usually cost less than other lifting devices, but they still deliver strong performance.

When you use a block and tackle, you benefit from a design that amplifies your pulling force. The number of rope segments supporting the load determines how much easier it becomes to lift. This makes the block and tackle system a favorite choice for lifting and moving large objects in many settings.

Powerful Machinery stands out as a trusted provider of certified lifting and rigging solutions. Their products meet strict international standards, giving you confidence in every lift.

Main Components of a Pulley System

A block and tackle system relies on several key parts. Each component plays a specific role in making the lifting process safe and efficient. Here is a quick overview:

Component | Role in Operation |

|---|---|

Sheaves | Guide the rope and reduce friction, allowing for smooth movement and effective force distribution. |

Ropes | Transfer the lifting force and withstand tension; different materials provide unique benefits for various applications. |

Hooks | Securely attach the load to the system, ensuring safety during lifting operations. |

Sheaves: These are the wheels inside the blocks. They let the rope move smoothly and help reduce friction. Sheaves provide the mechanical advantage that makes lifting easier.

Ropes: The rope connects the blocks and carries the load. You can choose from different types, such as nylon, polyester, or wire, depending on your needs. The right rope ensures strength and durability.

Hooks: Hooks attach the load to the block and tackle system. They keep the load secure and stable during lifting.

You will also find that the materials used in these components matter a lot. Steel pulley blocks offer strength and durability for heavy-duty jobs. Alloy steel gives you high tensile strength, while aluminum provides a lightweight option that still holds up under pressure.

Stainless steel resists rust, making it perfect for marine or corrosive environments. Reinforced polymer composites balance weight and strength for special applications. Coated materials protect against harsh conditions, reducing maintenance and improving safety.

When you select a block and tackle system, you want components that can handle heavy loads and resist wear. Choosing the right materials helps you lower maintenance costs and keep your lifting operations safe.

Powerful Machinery manufactures block and tackle systems with high-quality materials and strict testing. You can trust their products to deliver reliable performance, whether you work in construction, marine, or industrial settings.

Block and Tackle History & Types

Historical Background

You might be surprised to learn that the block and tackle system has roots stretching back over two thousand years. Ancient civilizations, such as Greece and Rome, needed ways to move heavy stones and materials for building temples and ships.

Around the 5th century BC, Archimedes, a famous Greek engineer and mathematician, described how pulleys could multiply force. His work led to the first formal use of the block and tackle, making it possible for workers to lift loads that would have been impossible with human strength alone.

Over time, the design of the block and tackle improved. Ancient builders used simple wooden pulleys and ropes. As technology advanced, people created stronger blocks with metal sheaves and more durable ropes.

Today, you see block and tackle systems in many industries, from construction to shipping. Modern versions even help lift large glass panes in window installations, showing how this ancient idea still solves new challenges.

Tip: Understanding the history of the block and tackle helps you appreciate its importance in both ancient and modern engineering.

Types of Block and Tackle

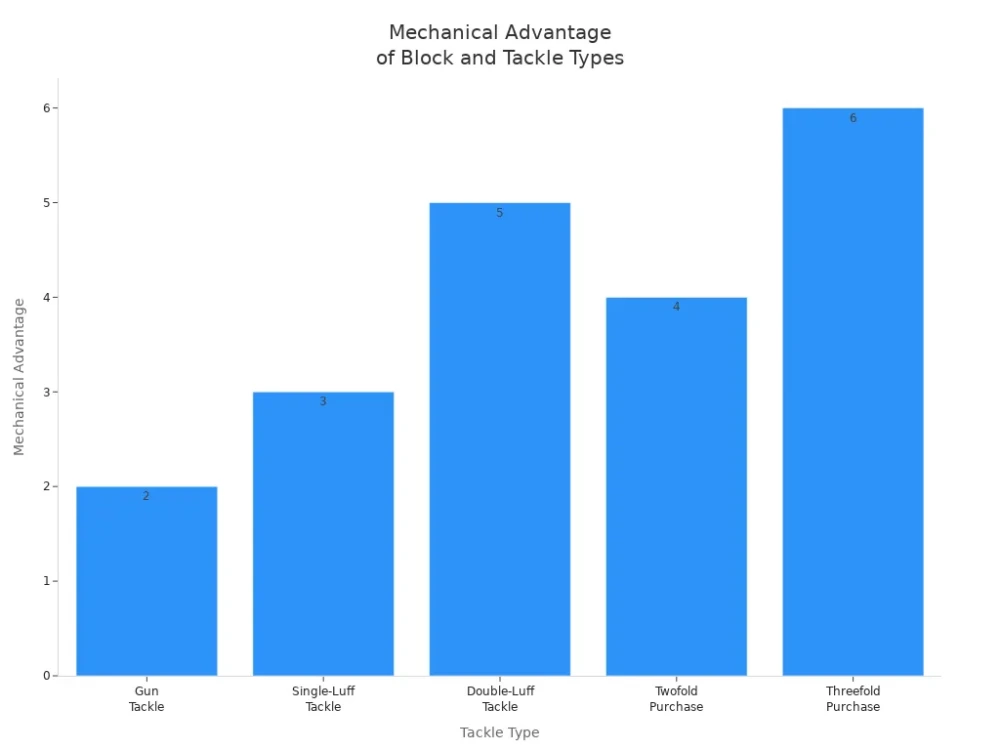

You can choose from several types of block and tackle systems, each designed for specific lifting needs. The structure of each block affects how much force you need to lift a load. Here is a table that shows the main types and their mechanical advantages:

Type of Tackle | Structure Description | Mechanical Advantage |

|---|---|---|

Gun Tackle | Two single-sheave blocks. Used historically for guns. | 2 |

Single-Luff Tackle | One double block and one single block. | 3 |

Double-Luff Tackle | One triple block and one double block. | 5 |

Twofold Purchase | Two double blocks. | 4 |

Threefold Purchase | Two triple blocks. | 6 |

You also find manual and electric block and tackle systems today. Manual systems use your own strength, while electric ones use motors for even heavier loads. By choosing the right block, you make lifting safer and more efficient for your project.

How does a Block and Tackle work?

Force Multiplication Explained

You might wonder how a block and tackle makes lifting heavy loads easier. The answer lies in the principle of mechanical advantage. When you use a pulley system, you multiply the force you apply. This means you can lift a much heavier object with less effort.

Mechanical advantage lets you use less force to move a load.

The pulley distributes the force, so you do not need to pull as hard.

You gain better control and safety during lifting tasks.

A simple movable pulley cuts the force needed to lift a load in half. One end of the rope stays fixed, while the pulley moves with the load. This setup is common in cranes and block and tackle systems. If you combine fixed and movable pulleys, you create a compound system.

Compound pulleys give you even greater mechanical advantage. You attach several pulleys to different points, which increases the force advantage. Complex lifting systems often use this arrangement.

You can calculate the mechanical advantage using a simple formula:

Tip: Mechanical Advantage (MA) = force on load/force applied. If you use three wheels in your block and tackle, the mechanical advantage is 6. You only need to pull with one-sixth of the load’s weight. Four wheels in the bottom block increase the advantage to 8, so you pull with just over one-eighth of the weight.

Efficiency matters too. Real-world block and tackle systems lose some force due to friction in the pulleys and rope stretch. The ideal mechanical advantage shows the best possible performance, but the actual mechanical advantage is lower because of these losses.

You should always check for wear and deflection, which can affect how well your system works.

Manual vs Electric Operation

You have two main choices for operating a block and tackle: manual or electric. Each option offers unique benefits and suits different lifting needs.

Manual Block and Tackle Systems

Manual systems rely on your strength. You pull the chain or rope by hand. This action rotates cogs, sprockets, and gears inside the block. The load rises as the chain moves through the mechanism. A braking system keeps the load secure.

Advantages of manual block and tackle systems:

No need for electricity or fuel.

Portable and easy to use in remote areas.

Lower maintenance compared to powered hoists.

Cost-effective for light to medium lifting jobs.

Limitations:

Slower lifting speeds.

Requires physical effort, which can be tiring.

Not suitable for very heavy loads.

Manual block and tackle systems from Powerful Machinery offer reliable performance. You can use them for construction, marine, and industrial lifting tasks. Their certified products ensure safety and durability.

Electric Block and Tackle Systems

Electric systems use motors to lift loads. You control the operation with a switch or remote. These systems work well for heavy-duty lifting and frequent use.

Feature | Description |

|---|---|

Compact Design | Pre-rigged for vertical rope access and confined spaces. |

Mechanical Advantage | Provides a 4:1 advantage for efficient lifting. |

Continuous Control | Allows bidirectional movement without resetting. |

Redundancy | Includes a dedicated belay system for extra safety. |

Electric block and tackle systems give you a predictable and controlled lifting motion. Safety features like load limiters and emergency stops help minimize risks. You can lift loads faster, which reduces downtime and labor costs. These systems are highly efficient and ideal for industrial settings.

When you choose between manual and electric systems, consider safety. More or larger pulleys increase mechanical advantage but may lower load capacity. Higher grade chains allow for greater working load limits. Quality materials and construction boost rated capacities.

Certified blocks from Powerful Machinery meet strict standards, giving you confidence in every lift.

Note: Always match your block and tackle system to your lifting needs. Manual systems work well for smaller jobs and remote locations. Electric systems excel in heavy-duty and high-frequency lifting environments.

Practical Applications & Powerful Machinery Products

Industry Uses of Block and Tackle

You see block and tackle systems in action across many industries. These tools help you lift, move, and position heavy loads with precision and safety. The following table shows how different sectors use block and tackle systems:

Sector | Applications |

|---|---|

Construction | General construction tasks, lifting heavy materials, and equipment |

Marine | Boat docks, boat lifts, rigging for yachts, and commercial fishing |

Transportation | Aircraft applications, automobile lifts, and vehicle hard-top lifts |

On construction sites, you use a pulley or chain block to raise steel beams, concrete blocks, and machinery. In marine environments, you rely on a block to hoist sails, lift boats, and manage cargo.

Transportation professionals use chain blocks for aircraft maintenance, vehicle lifts, and even locomotive washing tunnels. These examples show the wide lifting capabilities of block and tackle systems.

Tip: Always match your block and tackle system to the specific demands of your job for maximum safety and efficiency.

Powerful Machinery Product Line

Powerful Machinery offers a full range of heavy-duty block and tackle solutions. You can choose from products like the Snatch Block With Shackle, Tail Board Snatch Block, Snatch Block Shackle, and Pulley & Blocks.

Each product features robust construction, pressure lube fittings for easy maintenance, and full material traceability.

Sheave sizes range from 3 to 10 inches, and rope compatibility spans 12mm to 32mm. Safety is a top priority, with all products meeting ASME B30.26 standards and fatigue-rated for demanding tasks.

When selecting the right block or chainblock, consider these factors:

Factor | Why It Matters |

|---|---|

Load Capacity | Make sure your block can handle the weight of your load |

Material and Durability | Choose materials that resist corrosion and suit your environment |

Compliance with Safety Standards | Look for products certified to ASME and other international standards |

Ease of Maintenance | Select blocks with features like pressure lube fittings for quick upkeep |

Manufacturer Reputation | Trust brands like Powerful Machinery for support, warranties, and guidance |

You can also request custom solutions to fit unique lifting needs. Powerful Machinery’s products undergo strict inspection and testing, so you can trust them for safe and reliable performance in any industry.

Conclusion

You have learned that block and tackle systems use pulleys to multiply force, making heavy lifting easier and safer. These systems date back to Ancient Egypt and have evolved through Roman engineering and Archimedes’ innovations.

Today, you benefit from increased efficiency, improved safety, and customizable options. Powerful Machinery’s certified products offer reliability for any lifting project. Regular inspections and genuine parts help you maintain safety and performance.

Explore the latest trends, such as lightweight alloys and smart sensors, to find the best solution for your needs.

Market Trend | Details |

|---|---|

Technology | IoT sensors, self-lubricating sheaves |

Safety Focus | OSHA-compliant, anti-slip coatings |

Choose Powerful Machinery for trusted lifting solutions.

FAQ

What is the main advantage of using a block and tackle system?

You gain a mechanical advantage. This means you can lift heavy loads with less effort. The system multiplies your force, making tough lifting jobs much easier and safer.

How do you choose the right block and tackle for your project?

You should check the load capacity, rope compatibility, and material. Always select certified products. Powerful Machinery offers custom solutions if you have unique requirements.

Can you use a block and tackle outdoors or in marine environments?

Yes, you can. Choose blocks made from stainless steel or corrosion-resistant materials. Powerful Machinery designs products for harsh environments, including marine and outdoor use.

How often should you inspect your block and tackle system?

Inspect your system before each use. Look for wear, damage, or loose parts. Regular maintenance keeps your equipment safe and extends its life.