You use clevis pins when you need a strong and simple way to connect parts. These pins have a round shape that fits through holes in a clevis, allowing the joint to move while remaining secure. You often see these pins in heavy equipment, farm machinery, and boats.

Construction crews rely on them for quick assembly and safe lifting. Marine workers select stainless steel clevis pins for their ability to resist rust and moisture. When you choose a pin from a trusted brand like Powerful Machinery, you can be confident that your clevis connections will last.

Key Takeaways

Clevis pins provide a strong and simple way to connect parts, allowing for movement while ensuring security.

Choosing the right clevis pin size and type is crucial for safety and performance; always match the diameter and length to your application.

Different clevis pin designs, like grooved and headless, offer unique benefits for specific tasks, enhancing efficiency in assembly and disassembly.

Using the correct fastener, such as cotter pins or R-clips, is essential for securing clevis pins and preventing accidental disconnection.

Regularly inspect clevis pins for wear and damage to maintain safety and reliability in your mechanical assemblies.

Clevis Pin Anatomy

Understanding clevis pin anatomy helps you choose the right fastener for your project. You see clevis pins in many industries because they offer a simple yet strong way to connect moving parts.

Powerful Machinery uses precision engineering to create certified rigging hardware that meets strict standards for safety and reliability.

Key Parts of Clevis Pins

You find several main parts in every clevis pin. The head sits at one end and stops the pin from sliding through the hole. The shaft runs the length of the pin and fits inside the clevis or other component. At the opposite end, you see a cross-drilled hole or groove.

This feature lets you insert a cotter pin or retaining clip, locking the pin in place. Some pins have a bent or L-shaped extension for easy removal. Each part works together to keep your assembly secure and allow movement where needed.

Tip: Always check the head and locking feature before installation. A missing cotter pin or clip can lead to failure under load.

Clevis Pin Measurements

You need to pay close attention to the measurements of each pin. The diameter and length must match the holes in your clevis or machinery. If the pin is too loose, you risk unwanted movement or misalignment. If the pin is too tight, you may damage the parts or struggle with assembly.

Tolerances play a big role in performance. Manufacturers like Powerful Machinery produce pins with tight tolerances, ensuring a secure fit and dependable operation. Proper sizing keeps your mechanical assemblies aligned and prevents shifting under heavy loads.

Measurement | Description |

|---|---|

Diameter | The thickness of the pin shaft. Must fit the hole snugly. |

Length | The distance from the head to the locking feature. Should match the width of the clevis. |

Tolerance | The allowed variation in size. Tight tolerances mean better fit and function. |

Design Variations

You can choose from several design variations to suit your needs. Each type offers unique benefits for different applications. The table below shows common clevis pin designs and where you might use them.

Clevis Pin Type | Description | Applications |

|---|---|---|

Standard Clevis Pin | Formed head on one end, cross-drilled hole at the other for a cotter pin. | General-purpose pivoting connections. |

Headless Clevis Pin | Simple cylindrical rod with cross-drilled holes or grooves for clips. | Used where a head would interfere or for securing from both sides. |

Grooved Clevis Pin | Features a machined groove for retaining clips instead of a hole. | Faster assembly in manufacturing and assembly scenarios. |

Bent Clevis Pin | Angled or L-shaped extension for easy grip and removal. | Common in agricultural equipment and towing applications for quick connections and disconnections. |

You see standard pins in most mechanical linkages. Headless pins work well when space is tight. Grooved pins speed up assembly in factories. Bent pins make quick changes possible in the field.

Powerful Machinery follows international standards such as ISO 2341 and ASTM F1145 when manufacturing clevis pins. These standards define the required features and testing methods, so you get consistent quality and safety in every pin.

Standard | Description |

|---|---|

ISO 2341 (DIN 2341) | Specifies characteristics of clevis pins with specific design elements. |

ASTM F1145 | Covers fasteners with or without jam nuts, detailing their specifications and classifications. |

You benefit from this attention to detail. Every pin from Powerful Machinery is engineered for strength, reliability, and long service life.

Clevis Pin Types

You find many types of clevis pins in the market. Each type serves a specific purpose and fits different applications. Knowing the differences helps you select the right pin for your project.

Powerful Machinery offers a wide range of clevis solutions, including Clevis Grab Hooks, Shackles, and Clevis Slip Hooks, to meet your needs in construction, marine, and cargo handling.

Standard and SAE Clevis Pins

Standard clevis pins and SAE clevis pins are the most common choices for mechanical linkages. You use these pins when you need a reliable connection that allows movement but stays secure under load. Standard clevis pins have a head on one end and a hole for a cotter pin on the other.

SAE clevis pins follow the Society of Automotive Engineers (SAE) standards, which means you get consistent quality and fit.

Here is a table that shows the main characteristics of standard and SAE clevis pins:

Characteristic | Description |

|---|---|

Intended Use | Used with clevises and rod end eyes |

Length Measurement | From under the head to the end of the pin |

Effective Grip Length | From under the head to the top of the hole |

Diameter Range | 3/16″ (4.8 mm) to 5/8″ (15.9 mm) |

You often see standard clevis pins in agricultural equipment, trailers, and heavy machinery. SAE clevis pins give you extra assurance of compatibility and strength. When you choose certified pins from Powerful Machinery, you know your assemblies will meet industry standards.

Note: Always match the pin diameter and length to your clevis or rod end eye for a secure fit.

Grooved and Headless Clevis Pins

Grooved clevis pins and headless clevis pins offer unique features for special applications. Grooved pins have a machined groove near the end. This groove holds a retaining ring or clip, which keeps the pin in place even when the assembly vibrates.

Headless clevis pins do not have a head. You secure them with cotter pins or clips on both ends, making them easy to remove when needed.

The table below compares these two types of clevis pins:

Type of Pin | Design Features | Applications |

|---|---|---|

Grooved Pins | Grooves create friction to hold the pin in place, suitable for vibration resistance | Used in original equipment, as dowels, handles, pivot points, or spring anchors. |

Headless Clevis Pins | Designed for hinged connections, secured with cotter pins for easy disassembly | Commonly used in applications requiring quick assembly and disassembly of hinged components. |

You use grooved pins when you want extra security against vibration. Headless clevis pins work well in places where you need to take things apart quickly. Both types of clevis pins help you save time during assembly and maintenance.

Powerful Machinery manufactures these pins with precise tolerances, so you get a perfect fit every time.

Adjustable, Detent, and Bent Clevis Pins

Some applications require more flexibility or faster assembly. Adjustable, detent, and bent clevis pins give you these options. You find these types of clevis pins in equipment that needs frequent changes or quick connections.

Detent pins use a spring-loaded ball or detent instead of a hole. You push the pin in, and the detent locks it in place. You can remove it just as easily. This design works best when you need to assemble and disassemble parts quickly.

Bent pins have a 25° bend at one end. You often use these heavy-duty steel pins as a low-cost alternative to hitch pins. They make it easy to connect and disconnect equipment, especially in farming or towing.

Adjustable clevis pins let you change the length or locking position. You use them when you need to adapt to different setups or when you want to secure parts at various positions.

You see these types of clevis pins in industries like agriculture, construction, and transportation. Powerful Machinery’s product range, including Clevis Grab Hook and Clevis Slip Hooks, uses high-quality pins for secure and flexible connections. These solutions help you handle heavy loads safely and efficiently.

Tip: Choose the right type of clevis pin for your application. The correct pin improves safety, saves time, and reduces wear on your equipment.

You now understand the main types of clevis pins. Each type offers unique benefits for specific tasks. When you select pins from Powerful Machinery, you get certified quality and a wide range of options for every job.

What Are Clevis Pins Used For?

Clevis pins play a vital role in many industries. You see these pins in a wide range of applications because they offer strength, flexibility, and easy assembly. When you use clevis pins, you create secure connections that allow movement or hold parts together under heavy loads.

Let’s look at the main ways you use clevis pins in different fields.

Mechanical Linkages and Suspension

You often use clevis pins in mechanical linkages and suspension systems. These pins connect rods, levers, or arms, giving you a pivot point for smooth movement. Here are some common applications:

Mechanical linkages: Clevis pins connect two components, such as rods or arms, and allow them to rotate or move together.

Suspension systems: You find clevis pins in vehicles and machinery, where they attach control arms to steering knuckles or connect shock absorbers to the chassis.

These applications show how clevis pins help transfer motion and absorb forces in moving parts. You rely on the pin’s strength and precise fit to keep your equipment running smoothly.

Agriculture, Marine, and Construction

Clevis pins are essential in agriculture, marine, and construction applications. You use them to assemble and secure heavy equipment, attach implements, or connect rigging hardware. Powerful Machinery’s clevis pins, shackles, and hooks support you in these demanding environments.

In agriculture, you use clevis pins to attach plows, trailers, and other implements to tractors.

In marine settings, you rely on clevis pins for mooring lines, rigging, and load measurement on offshore equipment.

In construction, clevis pins secure crane hooks, excavator buckets, and lifting gear, ensuring safe and efficient operations.

Powerful Machinery’s products, such as Clevis Grab Hooks and Clevis Slip Hooks, demonstrate their effectiveness in lifting, mooring, and cargo handling. You benefit from certified quality and real-time load monitoring in critical applications.

Furniture, Rigging, and Lifting

You also find clevis pins in furniture assembly, rigging, and lifting operations. The table below shows how you use these pins in different contexts:

Role in Context | Description |

|---|---|

Furniture Assembly | Clevis pins make it easy for you to assemble and disassemble ready-to-assemble furniture. |

Rigging and Lifting | Clevis pins let you securely attach hooks, shackles, and lifting devices to chains or cables. This ensures safe and efficient lifting operations. |

You trust clevis pins for their reliability and ease of use. Whether you work in a factory, on a ship, or at a construction site, you depend on the right pin for every job.

Compatible Fasteners

When you use a clevis pin, you need the right fastener to keep your assembly secure. The fastener you choose must match the pin and the clevis for a safe and reliable connection. You often see these fasteners in heavy equipment, marine hardware, and lifting systems.

Powerful Machinery offers secure attachment systems like the Clevis Grab Hook and Clevis Slip Hooks, which use high-quality pins and mating clips, and fasteners for dependable performance.

Fasteners for Clevis Pins

You have several options when selecting a fastener for your clevis pin. The most common choices include:

Cotter pins: These are simple wire fasteners that you insert through the hole at the end of the pin. You bend the ends to lock them in place.

R-clips: These springy clips snap into the hole and hold the pin securely. You can remove them quickly when needed.

Retaining rings: These fit into a groove on the pin and prevent it from sliding out.

Hairpin clips: These fasteners slide through the hole and provide a quick-release option.

The table below shows common fastener types and their typical uses:

Fastener Type | Typical Use |

|---|---|

Cotter Pin | Permanent or semi-permanent joints |

R-Clip | Quick assembly and disassembly |

Retaining Ring | High-vibration environments |

Hairpin Clip | Temporary or adjustable connections |

You should always match the fastener to the pin and the clevis for the best results.

How to Use Clevis Pins Securely?

You want to know how to use clevis pins securely in your assemblies. Follow these steps for a safe and reliable connection:

Align the holes in your clevis and the connected part so they match perfectly.

Insert the pin through the aligned holes until the head sits firmly against the outer face.

Choose your fastener. Insert a cotter pin, R-clip, or other mating clips and fasteners through the hole at the end of the pin.

Lock the fastener. For a cotter pin, bend the ends in opposite directions. For an R-clip, snap it into place.

Tip: Always double-check that the fastener is fully engaged before you use the assembly under load.

To remove the pin, straighten or remove the fastener first, then slide the pin out. This process helps you maintain safety and prevents accidental disconnection.

When you use products like Powerful Machinery’s Clevis Grab Hook or Clevis Slip Hooks, you get secure attachment systems designed for heavy-duty applications. These solutions use certified pins and fasteners to keep your equipment safe and reliable.

Clevis Pin Selection

Choosing the Right Clevis Pin

You want to choose the right clevis pin for your project to ensure safety and long-lasting performance. Start by thinking about the load and movement your assembly will handle. If you work in construction, marine, or heavy equipment, you need a pin that can handle high stress and vibration.

Always check for certifications like ISO or Mil-Spec. These standards show that the pin meets strict quality and safety rules.

When you select clevis pins from Powerful Machinery, you get several benefits:

Versatility in design for many uses across industries.

Easy installation that saves you time during repairs or maintenance.

Secure fastening with a dual-locking system to prevent accidental release.

Reduced wear and tear, which means your equipment lasts longer.

Adjustability for precise alignment in your assemblies.

Cost-effective solutions that lower your maintenance costs.

Tip: Always inspect your clevis pins for signs of damage, such as wear or elongation. Replace any pin that looks worn to prevent failure.

Material and Size Considerations

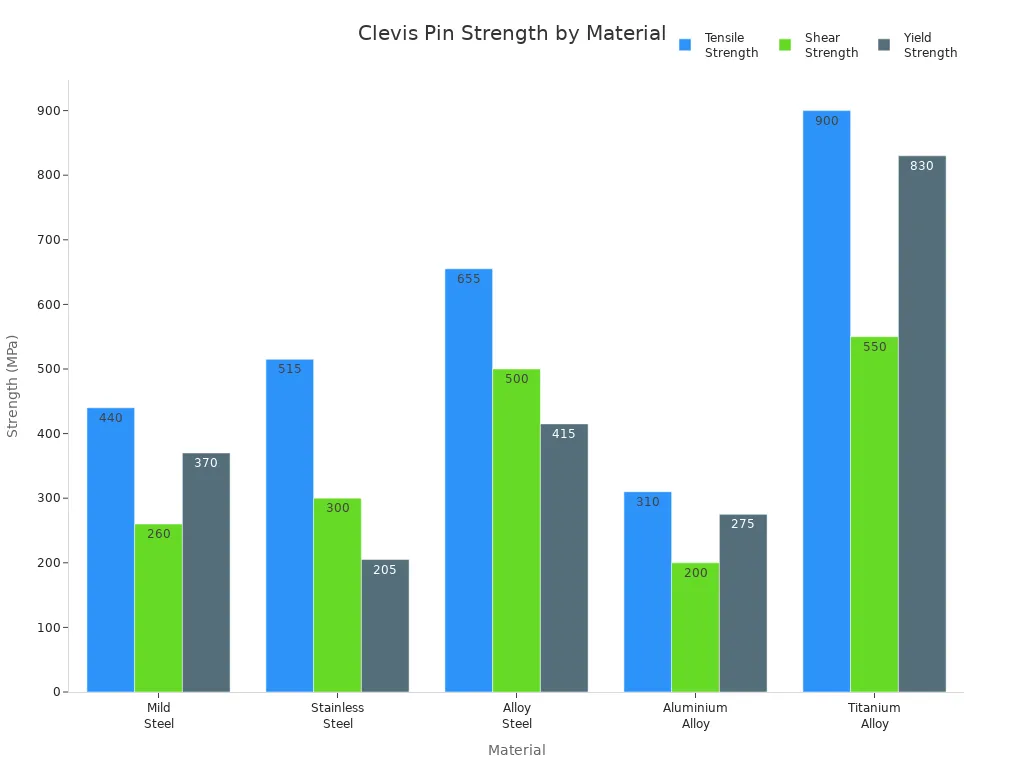

Material and size are key clevis pin buying considerations. The material you choose affects the pin’s strength, durability, and resistance to harsh environments. The table below compares common materials and their properties:

Material | Tensile Strength (MPa) | Shear Strength (MPa) | Yield Strength (MPa) | Common Uses |

|---|---|---|---|---|

Mild Steel (AISI 1018) | 440 | 260 | 370 | General-purpose mechanical parts, pins |

Stainless Steel (AISI 304) | 515 | 300 | 205 | Marine, food industry, corrosion-resistant parts |

Alloy Steel (AISI 4140) | 655 | 500 | 415 | High-strength, automotive, industrial |

Aluminium Alloy (6061-T6) | 310 | 200 | 275 | Lightweight, aerospace, structural |

Titanium Alloy (Grade 5) | 900 | 550 | 830 | High-strength, lightweight, aerospace |

You should also match the pin diameter and length to your clevis. A snug fit prevents wear and keeps your assembly safe. For outdoor or marine use, stainless steel clevis pins offer excellent corrosion resistance and reduce environmental impact because they last longer and are recyclable.

Common failure modes include using the wrong size or material, loose fits, and ignoring regular inspections. You can prevent these problems by choosing the right pin, checking for a tight fit, and replacing damaged parts.

Powerful Machinery’s certified clevis pins meet international standards and offer reliable performance in demanding environments. You can trust these pins for your lifting, rigging, and heavy-duty needs.

Conclusion

You see clevis pins used in many industries because they offer strength and flexibility. You rely on each pin to secure parts while allowing movement in clevis assemblies. You find these pins in bicycles, gear shafts, and agricultural machinery. You improve safety and performance when you choose the right pin and fastener.

You can learn more about Clevis products and their uses on the Powerful Machinery website.

Clevis pins feature a capped head and a side hole for a retainer.

You use clevis pins with cotter pins for quick-release and secure connections.

Common clevis applications include temporary fencing and heavy equipment.

Visit Powerful Machinery for certified clevis solutions and expert advice.

FAQ

What is the main purpose of a clevis pin?

You use a clevis pin to connect two parts so they can move or pivot. The pin holds the parts together while allowing rotation or quick removal when needed.

How do you secure a clevis pin in place?

You secure a clevis pin with a cotter pin, R-clip, or retaining ring. Insert the fastener through the hole at the end of the pin to prevent it from sliding out.

Can you reuse clevis pins and fasteners?

You can reuse clevis pins if they show no signs of wear, bending, or damage. Always use a new cotter pin or clip for safety. Inspect all parts before reassembly.

What materials work best for outdoor or marine use?

Stainless steel clevis pins work best for outdoor or marine use. They resist rust and corrosion, so your assemblies last longer in harsh environments.

Where can you find certified clevis pins for heavy-duty jobs?

You can find certified clevis pins at Powerful Machinery. Visit Powerful Machinery’s website for high-quality, tested products that meet international standards.