A hand pallet truck gives you the power to lift and move heavy pallets with minimal effort. You often see hand pallet trucks in action across busy warehouses, distribution centers, and manufacturing plants. You use them to load and unload goods, transfer products between vehicles, and restock shelves in retail stores.

Construction sites also rely on these tools to transport materials efficiently. Powerful Machinery delivers high-performance hand pallet trucks that combine durability, safety, and ergonomic design for your daily operations.

Key Takeaways

Hand pallet trucks are essential tools for moving heavy pallets with ease in warehouses and retail stores.

Ergonomic designs and safety features reduce strain and prevent accidents, making them user-friendly.

Regular maintenance, like inspections and lubrication, keeps hand pallet trucks in top condition and extends their lifespan.

Choosing the right type of hand pallet truck based on load capacity and fork length improves efficiency and safety.

Hand pallet trucks are cost-effective alternatives to electric models, saving money on purchase and maintenance.

Hand Pallet Truck Structure and Operation

Main Components

When you look at a hand pallet truck, you see a simple but powerful piece of material handling equipment. Each part works together to give you reliable performance and long-lasting durability. Here is a table that breaks down the main components and their role in making your hand pallet truck tough and dependable:

Component | Contribution to Durability |

|---|---|

Handle and Control Mechanism | Gives you ergonomic control, reduces fatigue, and improves maneuverability. |

Hydraulic Pump System | Delivers consistent lifting power and stands up to heavy use. |

Forks | Handles heavy loads without bending, so your truck lasts longer. |

Steering and Load Wheels | Quality materials and regular care keep your truck moving smoothly and lasting longer. |

Chassis | Reinforced steel frame protects against damage and supports long-term use. |

Safety Features | Built-in systems help prevent accidents and keep your operation safe. |

Powerful Machinery’s hand pallet trucks use a high-strength welded frame and tough C-grade steel forks. The ergonomic handle features a large, padded grip and a three-position control lever. These features make your daily tasks easier and safer.

How does it work?

You operate a hand pallet truck by using the handle to control the hydraulic pump system. When you pump the handle, the hydraulic system raises the forks and lifts the load. This design lets you move heavy pallets with little effort. Here is how the lifting process works:

The hydraulic pump is manually operated by the handle.

Pumping the handle creates hydraulic pressure, which lifts the forks and the load.

Some models offer a quick-lift feature, so you can raise lighter loads even faster.

You can control the truck with a three-position lever: lift, neutral, and lower. This lever gives you fingertip control over every movement. The strong spring in the handle returns it to an upright position when you let go, which helps prevent accidents and keeps your workspace organized.

Ease of Use

You will find hand pallet trucks easy to use, even if you have never operated material handling equipment before. The ergonomic handle and padded grip reduce strain on your hands and wrists. The control lever makes it simple to lift, move, and lower loads.

You do not need much training to start using a hand pallet truck safely and efficiently.

Training programs for pallet jack operators focus on safety and proper operation. You learn how to identify different types of trucks, follow safety procedures, and perform pre-operation inspections. These steps help you avoid accidents and keep your workplace running smoothly.

Powerful Machinery’s hand pallet trucks are designed for comfort and control. The PU wheels roll smoothly and quietly, even under heavy loads. Overload protection and a safety valve in the hydraulic system help you avoid damage and keep your equipment in top shape.

With a range of load capacity options, you can choose the right truck for your needs and handle any job with confidence.

Tip: Always check the load capacity before lifting. This simple step protects both you and your hand pallet truck.

If you want material handling equipment that is easy to use, safe, and built to last, a hand pallet truck from Powerful Machinery is a smart choice.

Types of Hand Pallet Trucks

When you explore the types of hand pallet trucks, you discover a wide range of models designed for different tasks. Each type helps you handle specific challenges, from moving standard pallets to transporting heavy loads in unique environments.

Understanding these options lets you choose the right pump truck for your workplace.

Manual Models

Manual hand pallet trucks are the most common type you see in warehouses and retail stores. You operate these trucks by pumping the handle, which raises the forks using a hydraulic system.

This design gives you control over transporting and lifting pallets without needing electricity. Manual models work well for short distances and lighter loads.

Feature | Manual Hand Pallet Trucks | Electric Hand Pallet Trucks |

|---|---|---|

Drive Mechanism | Manual pumping of the handle for the hydraulic lift | Powered by an electric motor for lifting and propulsion |

Lift Height | Generally lower lift height, suitable for low-level tasks | Higher lift height, suitable for racking systems |

Accessibility | More cost-effective and easier to maneuver in tight spaces | More expensive but ideal for long distances and heavy loads |

Manual hand pallet trucks usually handle loads from 1 to 2 tonnes. You can use them in tight spaces because they are easy to maneuver. Powerful Machinery offers models with ergonomic handles, overload protection, and PU wheels. These features help you move goods smoothly and safely.

Note: Manual trucks can be physically demanding if you move heavy items often. Always check the weight of your load before lifting.

Electric and Compact Options

Electric pallet trucks make your job easier when you need to move heavy items or cover long distances. You use a motor to lift and move pallets, which reduces the physical effort required. Electric models work well in large warehouses and busy distribution centers.

Electric pallet trucks require less physical effort than manual ones.

You can move heavier loads and reach higher lift heights with electric models.

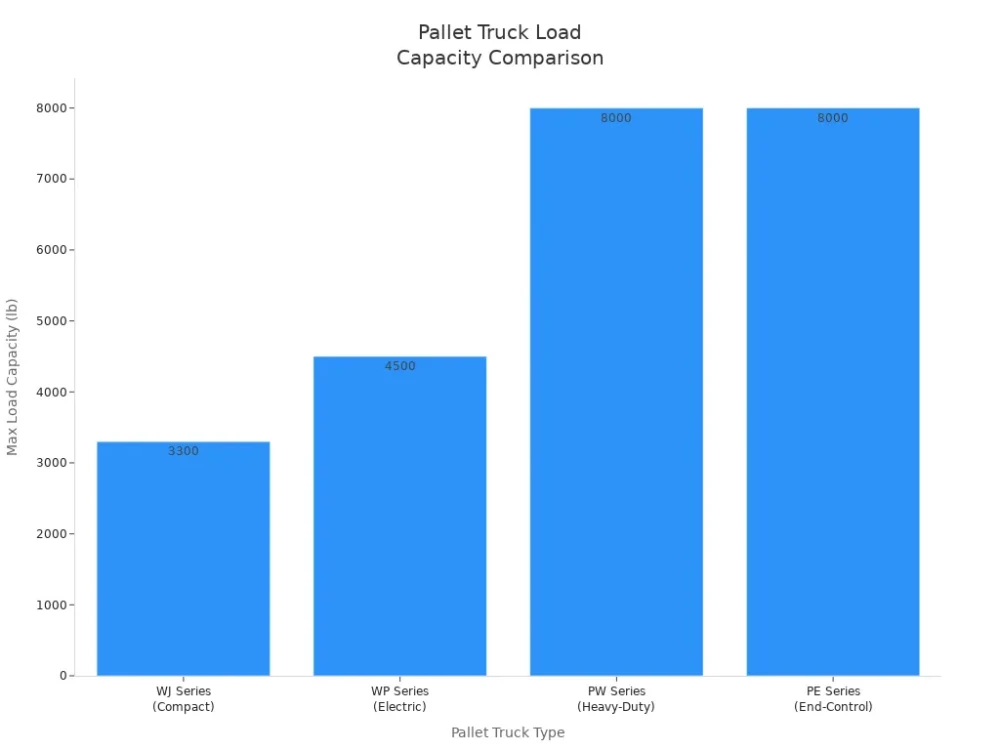

Type of Pallet Truck | Load Capacity Range |

|---|---|

Manual Hand Pallet Truck | 1 to 2 tonnes |

Electric Pallet Truck | 1500 to 5000 kg |

Compact Pallet Jack | Up to 3,300 lb |

Electric Pallet Jack | Up to 4,500 lb |

Heavy-Duty Pallet Jack | Up to 8,000 lb |

Compact pallet jacks are smaller and lighter. You use them in areas with limited space or narrow aisles. These models still offer strong performance, with some handling up to 3,300 lb. Electric and compact options help you save time and energy, especially when transporting heavy loads.

Specialized Types

Some industries need specialized hand pallet trucks to handle unique challenges. You might need a pallet trolley that works outdoors or a model that measures the weight of your load as you move it. Here are some examples:

All-Terrain Pallet Truck: You use this type on rough or uneven ground, such as in lumberyards or farms.

Custom Pallet Truck: You can order a truck with special fork sizes or configurations for unique materials.

Weighing Scale Pallet Truck: This model lets you check the weight of your load instantly, which helps you avoid overloading and improves efficiency.

Powerful Machinery gives you many customization options to fit your needs. You can choose different fork sizes, pump types, and even add your company logo. The table below shows some of the ways you can customize your hand pallet truck:

Customization Type | Details | Minimum Order Quantity |

|---|---|---|

OEM ODM Diagrams | Tailor the forklift to specific needs | N/A |

Customizable Fork Size | Options available for different sizes | N/A |

Customizable Pump Type | Different pump types can be selected | N/A |

Customized Logo | Personalize with a logo | 180 pieces |

Customized Packaging | Tailored packaging options | 300 pieces |

Graphic Customization | Custom graphics available | 1,000 pieces |

You can select a hand pallet truck that matches your exact requirements, whether you need to move heavy items, measure weight, or work in tough environments. Powerful Machinery’s product range covers all these needs, making your material handling tasks safer and more efficient.

Tip: Always match the type of hand pallet truck to your specific application. The right choice improves safety and productivity.

By understanding the types of hand pallet trucks, you can make better decisions for your business. Whether you need a standard pump truck, an electric model, or a specialized pallet trolley, you have options that help you move and weigh materials with confidence.

Features and Benefits of Hand Pallet Trucks

Ergonomics and Safety

You experience the difference when you use a hand pallet truck with advanced ergonomics. Powerful Machinery designs each handle with a cushioned grip, so your hands stay comfortable during long shifts. The ergonomic handle and three-position control lever let you operate the truck with minimal effort.

Polyurethane wheels make maneuvering easy, even in tight spaces. You move heavy loads smoothly, which reduces strain and helps you avoid fatigue. These features support safe working conditions and boost productivity.

Safety features play a key role in your daily operations. Overload protection and a hydraulic safety valve prevent accidents and equipment damage. You can trust the truck to keep your workplace secure.

The weighing hand pallet truck with an integrated weighing unit gives you instant accuracy when handling goods. This accuracy helps you avoid overloading and ensures efficient movement of materials.

Tip: Always check the load weight before lifting to maintain safety and accuracy.

Cost-Effectiveness

You save money when you choose a hand pallet truck over powered alternatives. Hand pallet trucks are a cost-effective alternative because they have a lower purchase price and require less maintenance.

Electric pallet jacks can cost between $5,000-$7,000, but you pay much less for a manual model. You also spend less on repairs and upkeep.

Hand pallet trucks are generally more affordable than powered alternatives.

Lower initial and ongoing maintenance costs help you manage your budget.

Minimal upkeep and long lifespan provide a favorable return on investment.

Durability reduces the need for frequent replacements.

You benefit from maintenance practices for long-term use, such as regular inspections and basic care. These steps keep your truck running smoothly and extend its life. The weighing hand pallet truck also reduces costs by improving logistics accuracy and efficiency.

Versatility in Industry

You find hand pallet trucks in many industries because of their versatility. They adapt to different environments and tasks, making them a valuable asset for logistics and material handling. The weighing hand pallet truck supports logistics operations by providing real-time weight data, which increases accuracy and safety.

Industry | Use Case |

|---|---|

Warehousing | Essential for loading/unloading goods and optimizing space utilization. |

Retail | Used for restocking shelves and managing inventory efficiently. |

Manufacturing | Facilitates the movement of raw materials and finished products. |

Cold Storage | Specialized models for moving perishable goods in low-temperature settings. |

You see the benefits to different industries, from warehousing to food processing. The weighing hand pallet truck improves logistics by ensuring accuracy in every load. Its safety and efficiency benefits make it a top choice for businesses that value productivity and safe working conditions.

The versatility and integrated weighing unit of these trucks help you achieve efficient movement and reliable logistics performance.

Integrated Weighing Technology and Maintenance

Weighing Scale Advantages

You gain a major advantage when you use a hand pallet truck with an integrated weighing scale. Real-time weight measurement gives you instant feedback as you load and unload goods. This accuracy helps you track inventory and manage stock levels with confidence.

You avoid stockouts and overstocking because the scale records each measurement automatically. Built-in scales also help you weigh goods from different storage locations before transport. You protect your equipment and vehicles by making sure loads do not exceed weight limits.

Verified scales are important when pricing depends on weight, so you maintain consumer trust.

Real-time weight measurement for immediate feedback

Accurate data for inventory management and stock control

Automatic recording prevents stockouts and overstocking

Ensures loads stay within safe limits for storage and transport

Supports verified weighing for pricing and consumer protection

Maintenance Tips

You keep your hand pallet truck in top condition by following a regular maintenance schedule. Check your truck every three months, or monthly if you use it often. In harsh environments, inspect it more frequently.

Daily inspections before each shift help you spot visible damage or faults. Every six months, examine critical components and lubricate moving parts. Annual servicing by trained technicians ensures comprehensive care.

Component | Inspection Points |

|---|---|

Fork Arms | Check for wear, scratches, or deformation. |

Wheels | Measure wear and replace if necessary. |

Operating Handle | Test the mechanical linkage. Confirm ergonomic design. Verify safety functions. |

Hydraulic System | Check oil level and purity. |

Safety Devices | Test brake system efficiency. |

You prevent breakdowns by inspecting steer wheels and load rollers for wear or damage. Regularly check chains and linkages for rust or misalignment. Look for leaks around hydraulic components and maintain proper oil levels. Always park your truck correctly to avoid unnecessary strain.

Tip: Consistent maintenance extends the life of your hand pallet truck and keeps your workplace safe.

Selection Guide

You choose the right-hand pallet truck by considering several key factors. Load capacity, ergonomics, ease of use, maintenance needs, durability, and cost versus features all play a role.

Select a truck with a capacity that exceeds your heaviest pallets to ensure safety and longevity. Fork length must match the pallets you use. Standard lengths fit Euro and US pallets, while specialized lengths suit unique pallet types.

Specification Type | Details |

|---|---|

Load Capacity | Choose a truck with a capacity above your heaviest load for safety and longer equipment life. |

Fork Length | Match fork length to your pallet type. Standard sizes fit most pallets; specialized lengths are available. |

You improve efficiency and safety by selecting a hand pallet truck tailored to your specific needs.

Conclusion

You improve warehouse efficiency and safety when you choose a hand pallet truck. Ergonomic designs boost comfort and productivity. Advanced safety features help prevent accidents. You save money because hand pallet trucks cost less to buy and maintain than electric models.

Powerful Machinery delivers reliable solutions that address common operational challenges. If you want equipment that fits your needs, consult Powerful Machinery for expert guidance and custom options.

FAQ

What is a hand pallet truck used for?

You use a hand pallet truck to lift and move pallets in warehouse and logistics environments. It helps you transport goods quickly and safely, making your daily tasks easier.

How do you operate a hand pallet truck safely?

You check the load capacity before lifting. You keep the load balanced and move at a steady pace. You avoid obstacles and always use the handle for control.

Can you use a hand pallet truck on ramps?

You can use a hand pallet truck on ramps. You move slowly and make sure the ramp is smooth. You never overload the truck and always keep control.

How do you maintain a hand pallet truck?

You inspect the wheels, forks, and hydraulic system regularly. You clean the truck and lubricate moving parts. You fix any damage right away to keep it working well.

What is the difference between a manual and an electric pallet truck?

You operate a manual pallet truck by pumping the handle. An electric pallet truck uses a motor for lifting and moving. Electric models handle heavier loads and reduce physical effort.