When you prepare for wire rope replacement, you must focus on critical safety and reliability factors. Using certified steel wire rope products ensures you meet mechanical property standards and maintain operational integrity.

Certified ropes help prevent failures caused by tension, bending fatigue, abrasion, corrosion, or overloading.

The reliability of every wire influences the safety of your lifting system.

Powerful Machinery delivers certified solutions trusted across demanding industries. You protect your team, your equipment, and your reputation by choosing proven products.

Key Takeaways

Inspect wire ropes regularly to catch early signs of wear, such as broken wires or corrosion, to prevent failures.

Always use certified wire ropes that meet safety standards to ensure reliability and protect your team and equipment.

Follow strict compliance standards during wire rope replacement to maintain legal safety and operational integrity.

Document all inspections and maintenance activities to enhance traceability and support long-term safety.

Prepare thoroughly before installation, ensuring proper tools and techniques are used to avoid installation errors.

Wire Rope Replacement Criteria

Signs of Wear

You must inspect wire rope regularly to identify early signs of deterioration. Visual indicators often provide the first clues that replacement is necessary. The following table summarizes the most common signs you should look for during inspection:

Visual Sign of Wear | Description |

|---|---|

Broken Wires Exceeding Acceptable Limits | More than six broken wires in one lay for running ropes, or more than two for standing ropes, require immediate replacement. |

Significant Diameter Reduction | A diameter loss of around 5% indicates core damage or major external wear, necessitating replacement. |

Advanced Corrosion | Rust or pitting, especially at connections, suggests weakened wires and may require immediate removal. |

Structural Distortion or Kinking | Permanent unstranding or kinking alters load distribution and poses a risk, warranting replacement. |

Damaged or Improper End Terminations | Compromised end fittings can weaken the rope, requiring replacement if damage is severe. |

Shock Loading or Overload Events | Sudden tension spikes can weaken the rope, leading to replacement if micro-fractures are found. |

Possible Internal Core Failure | Signs of internal damage, such as abnormal shrinkage or sponginess, indicate the need for immediate retirement. |

Condition Over Time, Not Just Age | Ropes may fail earlier than expected due to heavy use or poor conditions, necessitating a condition-based approach to replacement. |

Visual inspection remains the primary method for assessing wire rope condition. You should compare current findings with previous inspection records to track changes over time.

In some cases, especially with low-rotational ropes, internal defects may not be visible. Magnetic Rope Testing (MRT) can help you detect hidden damage when visual inspection is insufficient.

Mechanical Issues

Mechanical failures often occur due to improper handling, careless operation, or exposure to harsh environments. You must recognize these issues early to prevent accidents and costly downtime. Common mechanical problems include:

Kinking from sharp bends or twisting during use.

Increased risk of kinking in hurried operations or when handling is careless.

Accidental entanglement causing sharp bends.

Mechanical damage from contact with crane structures or external objects.

Broken wires or crushed rope resulting from localized operational conditions.

Insufficient tension leading to crushing damage in the lower layers of coiled ropes.

Excessive pressure or improper operation causes the rope to be squeezed or knotted.

Industry experts also observe failures such as corrosion, mechanical wear and tear, and fatigue from improper coiling or sharp bends. You must address these issues promptly to maintain safety and extend the lifespan of your equipment.

Tip: Always select wire rope with the right strength, fatigue resistance, and abrasion resistance for your application. Ensure the rope meets all relevant safety standards and manufacturer recommendations.

Compliance Standards

You must follow strict compliance standards when performing wire rope replacement. Regulatory bodies such as OSHA and ISO set clear guidelines for inspection, installation, and retirement procedures. The following tables highlight key requirements and their importance:

Section | Description |

|---|---|

1926.1414(a) | Original and replacement wire rope must be selected and installed according to manufacturer recommendations. |

1926.1414(b) | Wire rope design must meet specific criteria to prevent sudden failure. |

1926.1414(c) | Wire rope must be compatible with the equipment’s safe functioning. |

1926.1414(e)(2) | Rotation-resistant ropes must have a minimum operating design factor of 3.5. |

Compliance Standard | Importance of Wire Rope Replacement Procedures |

|---|---|

OSHA 1910.184 | Provides guidelines for safety and functionality during inspections. |

ASME B30.9 | Establishes criteria for periodic inspections and maintenance records. |

You must select a wire rope that matches or exceeds the original specifications. Any changes in size, grade, or construction require approval from the equipment manufacturer or a qualified professional. Following these standards ensures you maintain legal compliance and protect your team from unnecessary risks.

Powerful Machinery’s steel wire rope meets or exceeds all major international standards, including ISO and OSHA. You can trust these certified products to deliver reliable performance and maximum safety in every application.

Inspection and Safety Steps

Pre-Replacement Checks

You must complete thorough inspections before starting any wire rope replacement. Authorized personnel should determine inspection intervals based on national regulations, crane type, environmental conditions, and previous inspection results.

You need to inspect the entire length of the wire rope, focusing on critical areas such as the anchoring point on the drum, sections near end fittings, segments passing through sheaves, and hook sheave assemblies.

If a crane remains inactive for over three months, you should follow the scheduled guidelines before resuming operations. Visual inspections before and after each operation help you identify potential failures early.

Pre-Replacement Check | Description |

|---|---|

Abrasion | Damage from contact with abrasive surfaces. Maintain components properly. |

Corrosion | Internal degradation, often shown by rust. Lubricate immediately. |

Wire Breaks | The number of broken wires shows the condition. Follow ASME standards for replacement. |

Diameter Reduction | Indicates deterioration. Measure and monitor regularly. |

Crushing | Caused by improper installation. Affects wire rope integrity. |

Shock Loading | Sudden tension release causes irreversible damage. Replace if found. |

Safety Protocols

You must follow strict safety protocols during wire rope replacement. Regulatory agencies such as OSHA and ASME require frequent and periodic inspections to identify wear and prevent failures.

Operators must receive proper training and certification to ensure safe and efficient use of hoisting equipment. You should document all inspections and maintenance activities to maintain compliance and track the condition of your equipment.

Safety Protocol | Description |

|---|---|

ASME B30.16 | Specifies construction, marking, inspection, use, and training requirements. |

OSHA Regulations | Covers safe operation, operator training, equipment inspection, and maintenance. |

Inspection Requirements | Mandates frequent and periodic inspections to identify wear and failure points. |

Documentation and Compliance | Requires detailed records of inspections and maintenance. |

Training and Certification | Emphasizes operator training for safe and efficient use. |

🛡️ Tip: Always use certified wire rope and follow manufacturer instructions to maximize safety during inspections and replacement.

Recordkeeping

You must maintain detailed records to support long-term safety and compliance. Keep logs of all inspections, repairs, and maintenance activities. Use standardized checklists to ensure thorough inspections of critical components. Preserve certificates and registers for at least five years after the latest entry.

Accurate recordkeeping helps you identify wire ropes and gear that require certification and enhances traceability for cargo gear. Document load tests, including results and personnel involved, to ensure accountability.

Maintain records aboard vessels to identify wire ropes and gear needing certification.

Preserve certificates and registers for at least five years.

Provide adequate means to identify items of cargo gear.

Keep detailed logs of inspections, repairs, and load tests.

You strengthen your safety culture and ensure compliance by following these inspection and recordkeeping practices.

Wire Rope Replacement Procedure

Preparation

You must prepare thoroughly before starting wire rope replacement. Begin by inspecting the wire rope for any damage or wear. Replace any damaged wire rope before installation. Gather all necessary tools, including wire rope clips, a wrench, a socket set, and a tape measure. Confirm that the clamp size matches the wire rope diameter.

Measure and prepare the wire rope for the intended loop. Always follow the manufacturer’s guidelines when installing and maintaining wire rope clamps. Use the correct number of clips, ensure the hardware matches the rope diameter, and apply the recommended torque.

These steps help you maintain safety and efficiency throughout the wire rope replacement process.

Tip: Careful preparation reduces the risk of installation errors and ensures compliance with safety standards.

Removing Old Rope

You must remove the old wire rope with care to prevent equipment damage and protect worker safety. Inspect the rope regularly for visible damage, wear, corrosion, or distortion. Lubricate the rope to reduce friction and guard against corrosion.

Store wire ropes in a dry place, away from corrosive substances and extreme temperatures. Avoid dragging, kinking, or crushing the rope during handling. Retire any wire rope that has exceeded its service life or shows signs of damage. These best practices help you avoid accidents and extend the lifespan of your equipment.

Inspect for damage or wear before removal.

Lubricate to reduce friction.

Store in a dry, safe location.

Avoid dragging or kinking during handling.

Retire ropes that show signs of damage.

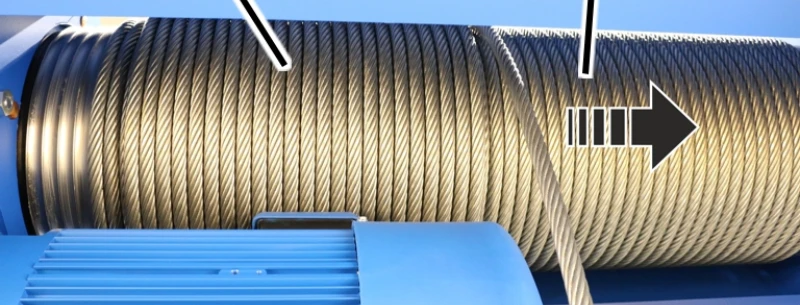

Installing Steel Wire Rope

You must install the new steel wire rope with precision. Powerful Machinery’s Steel Wire Rope offers several advantages during installation. The non-rotating design prevents twisting and kinking, which improves safety and stability.

High-tensile strength and resistance to abrasion and corrosion ensure reliable performance in demanding environments. Select the appropriate configuration, such as 35W×7, 18×19, or 8×55SWS, based on your application requirements.

Follow these steps for a successful installation:

Align the wire rope with the equipment’s drum or sheave.

Attach end fittings securely, using the correct number of wire rope clips.

Apply the recommended torque to all hardware.

Check that the rope runs smoothly through all pulleys and sheaves.

Confirm that the rope is free from twists, kinks, or improper bends.

🛠️ Note: Powerful Machinery’s Steel Wire Rope meets international safety standards, providing peace of mind during installation.

Safety Feature | Description |

|---|---|

Overload Protection | Stops the hoist if the load is too heavy, protecting both people and equipment. |

Emergency Stop Button | Lets you halt the hoist instantly in an emergency. |

Effective Braking | Anti-friction brakes keep loads secure and prevent sudden drops. |

Testing and Verification

You must test and verify the installation after completing the wire rope replacement. Begin by performing a load test to confirm that the wire rope operates safely under working conditions. Monitor the rope for any signs of abnormal movement, noise, or wear.

Check all end fittings and hardware for secure attachment. Document the results of the load test, including the personnel involved and the test outcomes. Maintain detailed records to support future inspections and compliance audits.

✅ Alert: Regular testing and verification ensure ongoing safety and reliability for your lifting operations.

Common Mistakes to Avoid

When you replace wire rope, you must avoid common mistakes that can compromise safety and equipment reliability. Following a thorough checklist and using certified products from Powerful Machinery helps you prevent these errors.

Ignoring Early Signs

Many professionals overlook early warning signs of wire rope wear. If you ignore broken wires, corrosion, or diameter reduction, you risk catastrophic failure. Delaying repairs or replacements for critical components like wire ropes leads to severe operational issues and safety hazards.

Regular inspections help you catch these problems before they escalate. Neglecting inspections or maintenance increases the chance of machinery failure and puts your team at risk. Always act on the first signs of damage and never postpone necessary repairs.

Skipping Safety Steps

You must never skip safety steps during wire rope replacement. Each step in the process protects both your equipment and your crew. As the saying goes, “A chain is only as strong as its weakest link.” Wire rope is a vital part of your lifting system.

If you skip inspections, you may miss hidden damage that could cause sudden failure. Regular inspections are critical to prevent accidents and ensure safe operation. Maintenance is not just about avoiding downtime; it is about safeguarding lives and property.

Ignoring safety protocols or pushing equipment beyond its limits can have dire consequences.

🛡️ Tip: Make inspections a routine part of your workflow. Document every inspection and follow all safety guidelines.

Incorrect Installation

Incorrect installation of wire rope can shorten its lifespan and reduce reliability. If you do not align or tension the rope properly, you create stress points that lead to premature failure. Always follow the manufacturer’s instructions and use the correct tools.

Proper installation, including correct tensioning and alignment, ensures your lifting operations remain safe and efficient. Certified wire rope from Powerful Machinery, when installed correctly, delivers maximum performance and durability.

Double-check all connections and fittings.

Use only approved hardware and accessories.

Schedule inspections after installation to verify proper setup.

By avoiding these mistakes and prioritizing regular inspections, you protect your team, your equipment, and your reputation.

Conclusion

You strengthen safety and compliance when you follow a wire rope replacement checklist. Regular inspections help you spot damage early and prevent costly failures. The table below highlights why these steps matter:

Key Benefit | Description |

|---|---|

Safety | Certified wire ropes handle stress and reduce the risk of accidents. |

Compliance | Meeting OSHA and ISO standards keeps your operations within legal guidelines. |

Reliability | Consistent inspections and certified products ensure dependable performance. |

Choose Steel Wire Rope from Powerful Machinery for proven quality. Make wire rope safety your top priority every day.

FAQ

How often should you inspect wire rope?

You should inspect the wire rope before each use and perform a detailed inspection at least once a month. High-use or critical applications may require more frequent checks.

What is the main advantage of non-rotating steel wire rope?

Non-rotating steel wire rope resists twisting under load. This feature increases safety and extends the rope’s lifespan in lifting and hoisting operations.

Can you use steel wire rope outdoors?

Yes. Steel wire rope from Powerful Machinery resists corrosion and abrasion. You can use it in both indoor and outdoor environments with confidence.

How do you know when to replace wire rope?

You should replace the wire rope if you see broken wires, significant diameter reduction, corrosion, or kinks. Always follow manufacturer guidelines and industry standards for retirement criteria.

Why choose certified wire rope from Powerful Machinery?

Feature | Benefit |

|---|---|

International Certification | Meets strict safety standards |

High-Grade Steel | Ensures strength and durability |

Non-Rotating Design | Reduces the risk of twisting |

You get reliable performance and peace of mind.