Wire rope tensile strength determines how much load you can safely lift or rig. When you select wire rope for your project, you need to recognize the difference between yield, ultimate, and breaking strength. Your knowledge of tensile strength directly impacts safety outcomes in construction and heavy industry.

You understand load handling capabilities.

You prevent catastrophic failures with regular maintenance and inspection.

You consider the rope’s condition and construction, which influences breaking strength.

Key Takeaways

Understand wire rope tensile strength to ensure safe lifting and rigging. This knowledge helps prevent accidents and equipment failures.

Always operate below the yield strength of the wire rope. Exceeding this limit can lead to permanent deformation and safety risks.

Select a wire rope with a breaking strength significantly above your maximum expected load. This practice enhances safety and reliability.

Regularly inspect and maintain wire rope to prevent catastrophic failures. Routine checks can identify wear and tear before it becomes a serious issue.

Consult manufacturer specifications and certifications to verify wire rope quality. This ensures you choose the right product for your specific needs.

Wire Rope Tensile Strength: Key Definitions

Yield Strength

You need to understand yield strength when selecting wire rope for lifting or rigging. Yield strength marks the point where the wire rope begins to deform permanently under load. If you exceed this limit, the rope will not return to its original shape, even after you remove the force.

Yield strength helps you determine the safe operational limits for your equipment. You should always operate below this threshold to maintain the integrity and safety of your wire rope.

Tip: Always check the manufacturer’s specifications for yield strength before using wire rope in critical applications.

Ultimate Strength

Ultimate strength refers to the maximum stress your wire rope can withstand before it fails. You measure this property using static tensile testing, break testing, and bending fatigue tests. International standards such as ISO 2307 and ISO 10425 ensure that testing methods remain consistent and reliable.

You can see the main definitions and testing methods in the table below:

Term | Description |

|---|---|

Ultimate Tensile Strength | The maximum stress a material can withstand while being stretched. |

Fracture Point | The exact point where the material breaks. |

Testing Methods | Static tensile testing, break testing, and bending fatigue tests. |

Standards | International standards like ISO 2307 and ISO 10425 ensure reliability. |

Ultimate strength gives you a benchmark for the highest load your wire rope can handle before breaking. You should never use wire rope at or near this limit during normal operations.

Breaking Strength

Breaking strength, also called breaking load, defines the absolute maximum force your wire rope can withstand before failure. This value represents the point at which the rope snaps or fractures.

While ultimate strength describes the maximum stress before failure, breaking strength refers to the actual force applied during a test that causes the rope to break. You use breaking strength to set safety margins and choose the right wire rope for your application.

Wire rope tensile strength varies by grade and diameter. You can refer to the following guide to compare common breaking strength values for different wire rope grades:

Rope Grade | Wire Tensile Strength Guide |

|---|---|

IPS (Improved Plow Steel) | Level 2 or 1570 to Level 4 or 1960 |

EIPS (Extra Improved Plow Steel) | Level 3 or 1770 to Level 5 or 2160 |

EEIPS (Extra Extra Improved Plow Steel) | Level 4 or 1960 to Level 6 or 2160 |

1170 | 1570 or Level 2 to 1960 or Level 4 |

1960 | 1770 or Level 3 to 2160 or Level 5 |

2160 | 1960 or Level 4 to 2160 or Level 6 |

You should always select wire rope with a breaking strength well above your maximum expected load. This practice ensures safety and reliability in demanding environments.

Measuring and Certifying Strength

Minimum Breaking Strength (MBS)

You must understand the minimum breaking strength when you select wire rope for lifting or rigging. This value represents the lowest force at which the rope will fail during a tension test. Manufacturers determine this by pulling the rope until it snaps, recording the force at the breaking point.

You see this value listed in product specifications and certification documents. International standards, such as ASTM A931-18 and Lloyd’s Register, set clear requirements for minimum breaking strength and tensile strength grades. You find ropes categorized by grades like 1420, 1570, 1770, or 1960 N/mm².

The actual tensile strength must not exceed 120% of the specified minimum. This ensures you get consistent performance and safety.

Safe Working Load (SWL) and Safety Factors

Safe working load defines the maximum working load you can apply to a wire rope during normal operations. You calculate this by dividing the minimum breaking strength by a safety factor.

Safety factors protect you from unexpected overloads and wear. For example, regulations such as 1926.1414(e)(4)(ii)(E) require a design factor of at least five for boom hoist reeving systems. You use the following formula:

Safe Working Load = Minimum Breaking Strength / Safety Factor

You must always operate below the safe working load to avoid permanent deformation or failure. The stress-strain curve helps you visualize how the rope behaves under increasing loads, showing you the yield point and ultimate strength.

Certification and Standards

You rely on certification and standards to verify wire rope tensile strength and quality. Organizations like Lloyd’s Register and ISO set strict requirements for construction, testing, and documentation. You need certificates that include proof test details, compliance statements, and authorized signatures.

Annual examinations confirm ongoing safety. Standards such as ISO 2408 and EN 12385 define minimum breaking force, construction methods, and tensile strength benchmarks. The table below summarizes key standards:

Standard | Requirement | Purpose |

|---|---|---|

ISO 2408 | Minimum breaking force | Ensures safety by defining strength limits. |

EN 12385 | Construction and testing | Ensures reliability through rigorous testing. |

ASTM A931-18 | Tension testing procedures | Verifies breaking strength and yield strength. |

You should always request up-to-date certificates before using wire rope in critical applications.

Factors Affecting Wire Rope Strength

Material and Grade

You must pay close attention to the material and grade when choosing wire rope for demanding tasks. High-grade steel wire ropes deliver superior tensile strength and durability. The grade determines the rope’s mechanical properties, including hardness and load capacity.

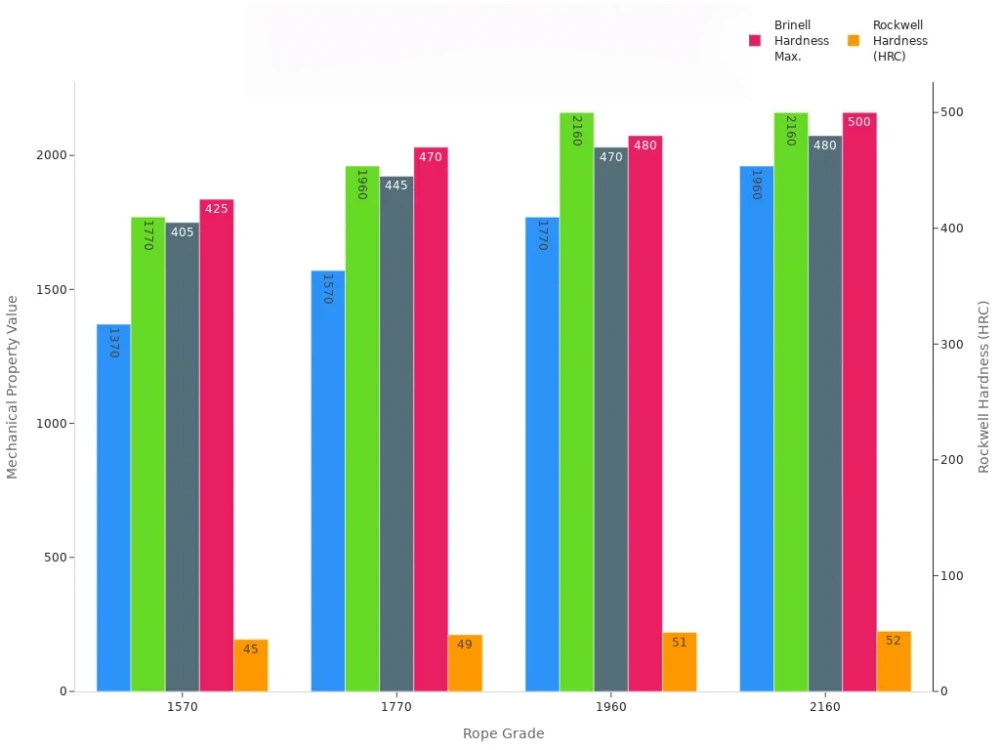

The table below shows the most common steel grades used in wire ropes and their mechanical properties:

Rope Grade | Wire Tensile Strength Min. (N/mm²) | Wire Tensile Strength Max. (N/mm²) | Brinell Hardness (HB) | Rockwell Hardness (HRC) |

|---|---|---|---|---|

1570 | 1370 | 1770 | 405/425 | 45 |

1770 | 1570 | 1960 | 445/470 | 49 |

1960 | 1770 | 2160 | 470/480 | 51 |

2160 | 1960 | 2160 | 480/500 | 52 |

Powerful Machinery’s Steel Wire Rope uses high-grade steel to achieve outstanding strength and reliability. You benefit from ropes that meet strict international standards and perform in the toughest environments.

Structure and Core

The internal structure and core type play a major role in wire rope performance. You can choose between fiber core and steel core options. Fiber cores offer greater flexibility, but they may wear out faster and provide less support.

Steel cores deliver higher strength and crush resistance, making them ideal for heavy-duty lifting and rigging. The table below compares core types:

Core Type | Strength | Flexibility | Service Life |

|---|---|---|---|

Fiber Core | Lower strength, prone to wear | More flexible (10-15% more) | Shorter due to inadequate support |

Steel Core | Higher strength, crush-resistant | Less flexible | Longer due to better support |

Fiber cores provide flexibility but can lead to premature wire breaks.

Steel cores enhance strength and durability, especially in demanding applications.

Powerful Machinery’s Steel Wire Rope features advanced multi-layer construction and a non-rotating design. You gain improved stability, reduced risk of twisting, and extended service life.

Diameter and Product Variation

Wire rope diameter directly affects tensile strength and load-bearing capacity. Larger diameters support heavier loads by distributing stress over more material. You must select the right diameter for your application to ensure safety and efficiency.

You also have access to a wide range of product variations. The market offers carbon steel, stainless steel, and galvanized steel wire ropes, each with unique features and applications. The table below highlights key options:

Material Type | Market Share (%) | Key Features | Applications |

|---|---|---|---|

Carbon Steel | 63.8% | High tensile strength, cost-effective, durable | Construction, Industrial |

Stainless Steel | Fastest-growing | Superior corrosion resistance, ideal for harsh environments | Marine, Oil & Gas |

Galvanized Steel | Nearly 50% | Superior corrosion resistance, durability, and cost-effectiveness | Construction, Marine, Mining |

Powerful Machinery’s Steel Wire Rope comes in multiple configurations, such as 35W×7, 18×19, and 8×55SWS. You can select the best option for your specific lifting, rigging, or hoisting needs. The abrasion and corrosion resistance features ensure long-lasting performance in any environment.

Tip: Always match the wire rope’s material, structure, and diameter to your project requirements for maximum safety and reliability.

Increasing Wire Rope Tensile Strength

Material Selection and High-Grade Steel

You boost wire rope tensile strength by choosing the right materials. The type and composition of steel play a major role in how much load your wire rope can handle.

High-carbon steel wires, such as Extra Improved Plow Steel (EIPS) and Extra Extra Improved Plow Steel (EEIPS), deliver tensile strengths up to 1960N/mm² and 2160N/mm². You gain more durability and reliability when you select these grades for your lifting and rigging tasks.

Manufacturers use several methods to increase tensile strength during production:

Select high-carbon steel for superior strength.

Add alloying elements like carbon or chromium to improve toughness.

Apply heat treatment processes, such as annealing and quenching, to refine the grain structure.

Use cold working techniques, including rolling and drawing at low temperatures, to further enhance strength.

Optimize grain size, since finer grains result in higher tensile strength.

You must consider cost-benefit factors when choosing premium materials. Higher grades of stainless steel, larger diameters, and advanced core types like Independent Wire Rope Core (IWRC) increase both performance and price.

Surface treatments and coatings add value but also raise costs. Bulk orders and supplier reputation can help you manage expenses while maintaining quality.

Tip: Always match the steel grade and material composition to your project’s safety requirements for maximum wire rope tensile strength.

Construction Techniques and Fill Factor

You improve wire rope tensile strength by focusing on construction techniques. The fill factor measures the metallic cross-section of the rope. Traditional wire rope constructions fill about 58% of the cross-section, but advanced high-strength rope constructions can reach up to 80%.

Increasing the fill factor boosts the metallic area, which directly raises the tensile strength and breaking strength of your wire rope.

You can use several methods to enhance construction:

Change rope construction or use compacting techniques to increase fill factor.

Employ die drawing to create denser, stronger ropes.

Integrate reinforcement materials, such as granite or zinc oxide, to improve fatigue resistance and wear.

Use hybrid optimization techniques to predict and enhance performance.

These advancements help you achieve higher wire rope tensile strength and extend service life, especially in demanding environments.

Powerful Machinery Steel Wire Rope Advantages

You benefit from Powerful Machinery’s Steel Wire Rope because it combines high-quality materials with innovative construction. The non-rotating design minimizes twisting and kinking, which improves safety during lifting and hoisting.

Multiple configurations, such as 35W×7, 18×19, and 8×55SWS, allow you to select the best option for your specific needs.

Key advantages include:

High-grade steel construction for superior tensile strength and durability.

Advanced multi-layer design for increased fill factor and stability.

Abrasion and corrosion resistance for long-lasting performance in harsh environments.

Custom-engineered solutions tailored to your project requirements.

Powerful Machinery’s Steel Wire Rope meets strict international certification standards, including ISO9001, TUV Rheinland, and ASTM.

You see real-world results in projects like the Galway City Cathedral Bridge, where 6mm stainless steel wire rope assemblies provide safer travel routes, and in Cirque Du Soleil performances, where lightweight and compact solutions ensure safety for performers.

Project Name | Description |

|---|---|

Galway City Cathedral Bridge | Fabrication and supply of 6mm 1 x19 S/Steel wire rope assemblies for safer travel routes. |

Serenco UK | Supplier of specialized wire rope assemblies for safety applications in the automotive industry. |

Cirque Du Soleil | Provided secondary safety systems for performances, requiring lightweight and compact solutions. |

Hallowe’en – Vintage Fife Cutter | Installation of wire rope for standing rigging to support sailing vessel masts against wind forces. |

You ensure safety and efficiency by choosing wire rope that meets or exceeds industry benchmarks for wear resistance, flexibility, and load capacity. Powerful Machinery’s Steel Wire Rope stands out as a trusted solution for professionals in the construction, marine, and transportation sectors.

Note: Selecting the correct wire rope class and configuration extends equipment life, improves operational efficiency, and minimizes downtime.

Conclusion

You improve safety and efficiency when you understand wire rope tensile strength and apply proper safety factors. Powerful Machinery’s Steel Wire Rope gives you certified strength and reliability for critical lifting and rigging tasks.

Always consult with industry experts before selecting wire rope. Choose the right configuration for your project to ensure maximum performance.

Certified products deliver peace of mind.

Expert advice helps you avoid costly mistakes.

The right wire rope extends equipment life.

FAQ

What is the main advantage of using non-rotating steel wire rope?

You gain increased safety and stability. The non-rotating design prevents twisting and kinking during lifting, which reduces the risk of accidents and extends the rope’s lifespan.

How do you determine the correct wire rope diameter for your application?

You check the load requirements and consult the manufacturer’s specifications. Larger diameters support heavier loads. Always match the diameter to your project’s safety needs.

Which certifications should you look for when selecting wire rope?

You should look for certifications like ISO9001, TUV Rheinland, ASTM, and Lloyd’s Register. These standards confirm the rope’s quality, strength, and safety for demanding tasks.

Can you use Powerful Machinery’s Steel Wire Rope outdoors?

You can use it outdoors. The rope’s high-grade steel construction and corrosion resistance make it suitable for harsh environments, including marine and construction sites.

How often should you inspect wire rope for safety?

You should inspect the wire rope before each use and schedule regular maintenance checks. Look for signs of wear, corrosion, or deformation to ensure safe operation.