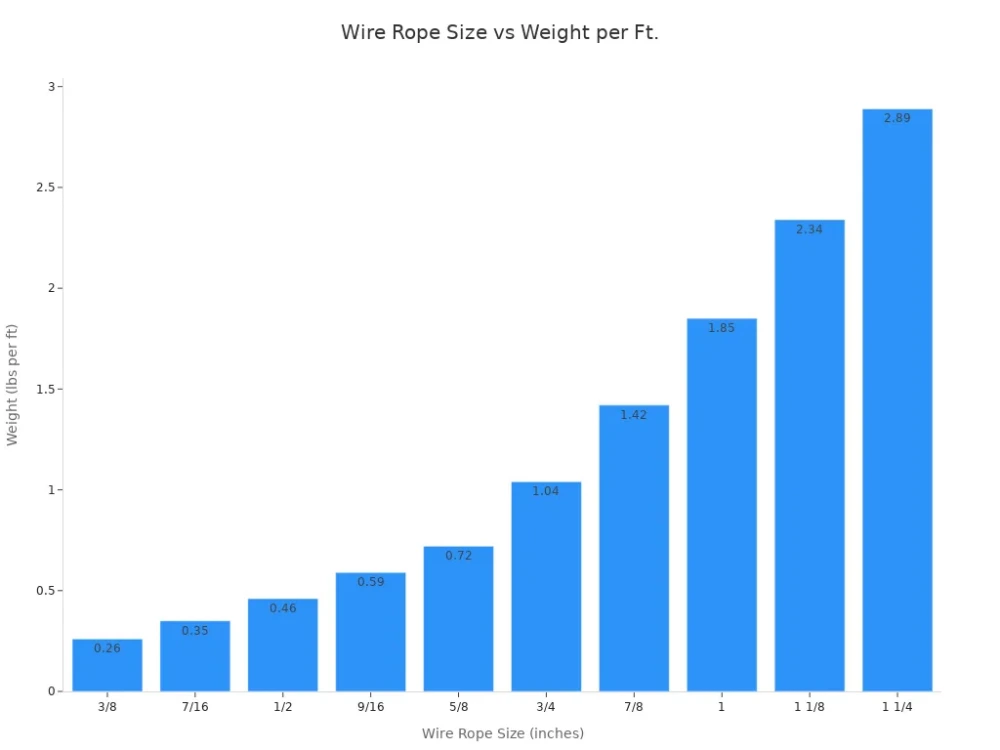

You can determine wire rope weight by referencing the standard table below, which lists weights per foot for common sizes. Accurate wire rope weight calculation protects you during lifting and rigging operations. The right information helps you select equipment that meets safety and compliance standards.

Powerful Machinery delivers certified wire rope solutions trusted by professionals worldwide.

Wire Rope Size | Weight (Lbs. Per Ft.) |

|---|---|

3/8 | 0.26 |

7/16 | 0.35 |

1/2 | 0.46 |

9/16 | 0.59 |

5/8 | 0.72 |

3/4 | 1.04 |

7/8 | 1.42 |

1 | 1.85 |

1 1/8 | 2.34 |

1 1/4 | 2.89 |

Key Takeaways

Accurate wire rope weight calculations are crucial for safe lifting and rigging. Always refer to certified tables to avoid accidents.

Understanding wire rope construction and diameter helps you select the right equipment. Choose the type that matches your load requirements.

Regular inspections and proper storage of wire ropes extend their lifespan. Keep them clean and protected from harsh conditions.

Always calculate the total weight of your load, including fittings. This ensures you stay within safe load limits and prevents equipment failure.

Follow OSHA standards and manufacturer guidelines to maintain safety and compliance in your lifting operations.

Why Wire Rope Weight Matters?

Safety and Compliance

You must know the exact wire rope weight before starting any lifting or rigging operation. This information helps you calculate the safe load for your equipment. If you guess or use the wrong numbers, you risk overloading your slings and hardware.

Overloading can cause accidents and damage, putting workers and property in danger.

Powerful Machinery provides certified products that meet strict international standards. You can trust their wire rope to deliver the minimum breaking strength required for your job. Their certifications include ISO9001, TUV Rheinland, and OSHA compliance.

These certifications show a strong commitment to safety and quality.

Accurate wire rope weight is essential for determining the working load limit of slings. You must follow OSHA standards and manufacturer recommendations to keep your workplace safe.

You need to document periodic inspections of wire rope slings as required by ASME B30.9.

Employers must keep records of the most recent thorough inspection.

Missing these records can lead to compliance issues with OSHA regulations.

Risks of Miscalculation

If you miscalculate wire rope weight, you put your entire operation at risk. Using the wrong weight can lead to choosing the wrong equipment or exceeding the safe load. This mistake can cause the wire rope to fail before reaching its minimum breaking strength.

You should always use certified tables and formulas to check the wire rope weight. This practice ensures you stay within the safe load and do not exceed the minimum breaking strength. Following these steps protects your team and helps you meet industry standards every time.

Wire Rope Weight Calculation

Weight Per Foot Formula

You need to know the weight per foot of your wire rope before you start any lifting or rigging operation. The most common way to calculate wire rope weight is by using a standard formula or reference table. The formula considers the diameter and construction of the rope.

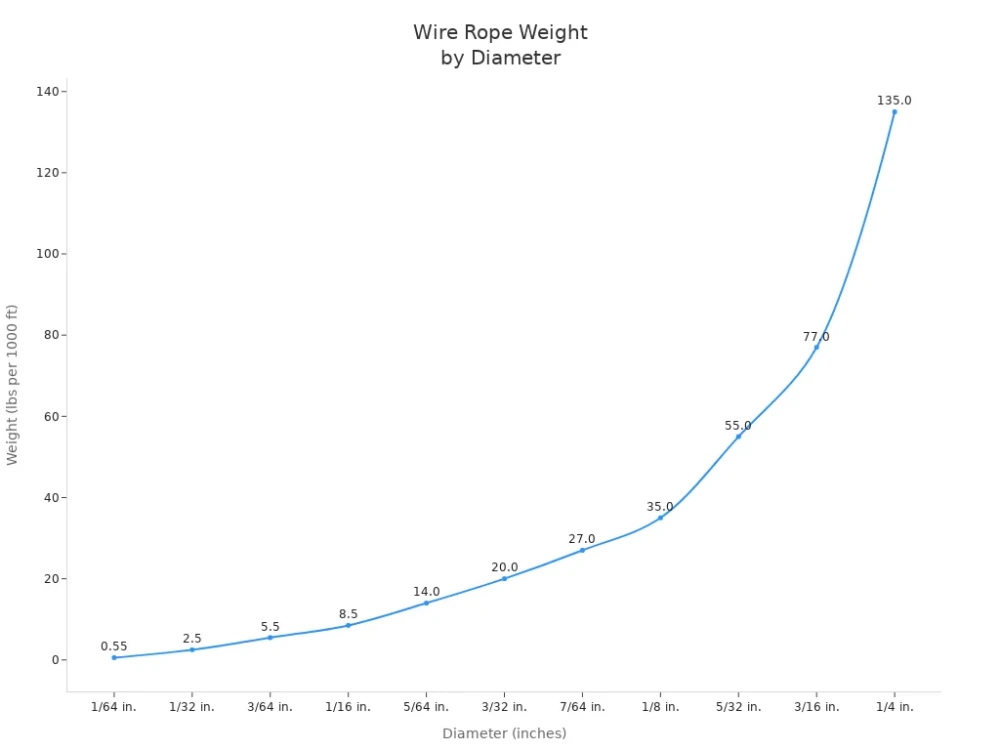

You can use the following table to estimate the weight per 1,000 feet for different diameters:

Diameter (in.) | Weight (lbs/mft) |

|---|---|

1/64 | 0.55 |

1/32 | 2.5 |

3/64 | 5.5 |

1/16 | 8.5 |

5/64 | 14.0 |

3/32 | 20.0 |

7/64 | 27.0 |

1/8 | 35.0 |

5/32 | 55.0 |

3/16 | 77.0 |

1/4 | 135.0 |

You can also visualize the relationship between diameter and wire rope weight using the chart below. This helps you quickly estimate the total weight for your project.

Tip: Always round up your calculations to account for fittings and splices. This practice ensures you do not exceed the safe load or minimum breaking strength.

Using Weight Tables

Weight tables provide a fast way to determine wire rope weight for standard sizes and constructions. You should always check the construction type, such as 6×19 or 6×37, because it affects the weight and performance of the rope.

The 6×19 class wire rope has 6 strands with 16 to 26 wires per strand. This construction offers strong abrasion and crush resistance.

The 6×37 class wire rope consists of 6 strands with 27 to 49 wires per strand. This type provides excellent flexibility, which changes the overall weight.

You must select the right construction to match your application and ensure you stay within the safe load and minimum breaking strength.

Powerful Machinery offers both Steel Wire Rope and Galvanized Steel Wire Rope in multiple constructions and diameters. You can find detailed weight tables for each product on their official website. These tables help you choose the correct rope for your lifting, rigging, or marine project.

Example Calculations

Let’s look at how you can calculate wire rope weight for a specific job. Suppose you need 200 feet of Steel Wire Rope with a diameter of 1/2 inch. The table shows that 1/2 inch wire rope weighs about 0.46 lbs per foot.

Calculation:

Wire Rope Weight = Length (ft) × Weight per Foot (lbs)

Wire Rope Weight = 200 × 0.46 = 92 lbs

You should use this total weight to select the right lifting equipment and ensure you do not exceed the safe load or minimum breaking strength.

If you choose Galvanized Steel Wire Rope for a marine application, you might select a 3/4 inch diameter. The table lists the weight as 1.04 lbs per foot. For a 150-foot length, the calculation is:

Wire Rope Weight = 150 × 1.04 = 156 lbs

You must include the weight of any fittings or end terminations in your final calculation. This step helps you maintain safety and compliance.

Note: Powerful Machinery provides custom-engineered wire rope solutions. You can request specific diameters, constructions, and coatings to match your project’s requirements. Their certified products ensure you meet all safety standards and achieve the minimum breaking strength needed for your operation.

When you select a wire rope, always consider the total weight, construction type, and application. This approach helps you avoid overloading your equipment and keeps your team safe.

Factors Affecting Wire Rope Weight

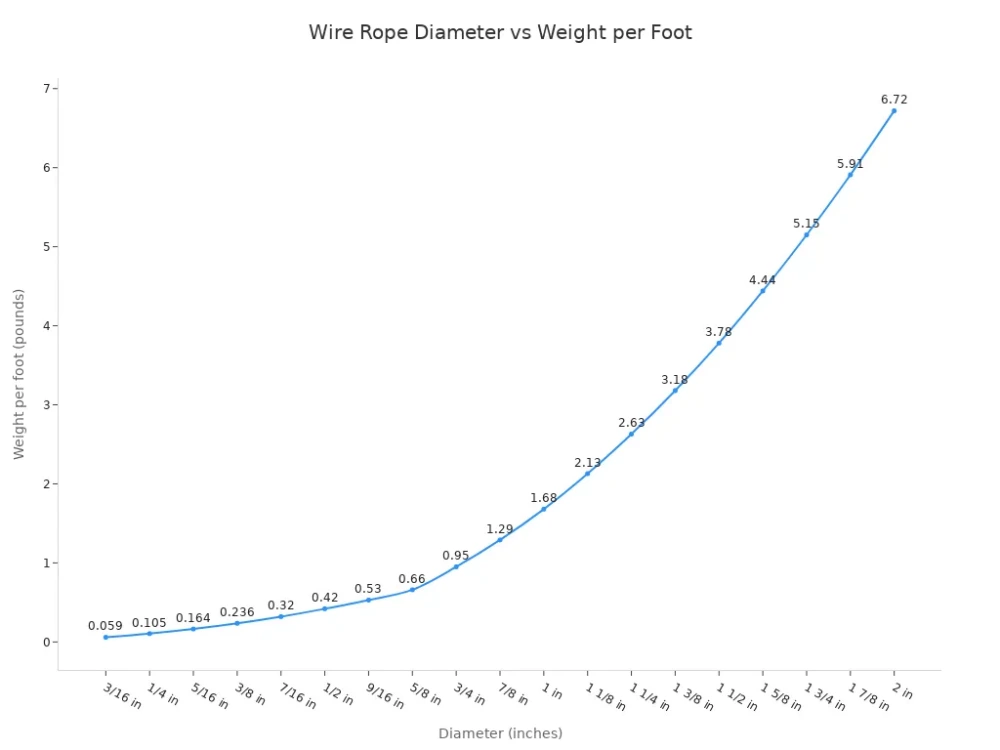

Diameter and Construction

You need to pay close attention to diameter and construction when estimating wire rope weight. Larger diameters increase the weight per foot, which can affect your equipment selection and handling.

The construction type, such as the number of strands and wires, also plays a role. For example, ropes with more wires per strand tend to be heavier and more flexible. The following table shows how the diameter influences the weight per foot:

Diameter (inches) | Weight per foot (pounds) |

|---|---|

3/16 | 0.059 |

1/4 | 0.105 |

5/16 | 0.164 |

3/8 | 0.236 |

7/16 | 0.32 |

1/2 | 0.42 |

9/16 | 0.53 |

5/8 | 0.66 |

3/4 | 0.95 |

7/8 | 1.29 |

1 | 1.68 |

1 1/8 | 2.13 |

1 1/4 | 2.63 |

1 3/8 | 3.18 |

1 1/2 | 3.78 |

1 5/8 | 4.44 |

1 3/4 | 5.15 |

1 7/8 | 5.91 |

2 | 6.72 |

You should also consider the core type. Steel core ropes weigh more than fiber core ropes of the same diameter. This difference impacts handling and installation, especially for longer lengths.

Material Types

Material selection changes the weight and performance of your wire rope. Stainless steel ropes are heavier than galvanized steel ropes because of their higher density. You will find that stainless steel offers excellent corrosion resistance, making it ideal for marine and architectural applications.

Galvanized steel provides moderate corrosion resistance and is suitable for general use. The table below compares common material types:

Material Type | Characteristics |

|---|---|

Stainless Steel | Excellent corrosion resistance, high strength, and used in harsh environments. |

Galvanized Carbon Steel | Cost-effective, good strength, zinc-coated for protection. |

Bright Carbon Steel | High strength, flexible, and requires additional protection against corrosion. |

Stainless steel wire ropes are generally heavier than galvanized steel due to higher density.

For example, a 0.54mm stainless steel wire rope weighs about 0.001kg/m, while a 7/16″ galvanized steel wire rope weighs approximately 0.35 lbs per foot.

Powerful Machinery offers a wide range of material options, including custom coatings and finishes. You can select the best configuration for your project to meet both weight and environmental requirements.

Length and Total Weight

The total weight of your wire rope depends on the length you need for your operation. You must multiply the weight per foot by the total length to get an accurate estimate. This calculation helps you determine the safe load for your lifting equipment and ensures you do not exceed the minimum breaking strength.

Always include the weight of end fittings and splices in your final total. Powerful Machinery provides custom-engineered solutions, so you can request specific lengths and configurations to match your project needs.

Tip: Accurate weight calculations help you stay within the safe load and minimum breaking strength limits, protecting your team and equipment.

Applications and Best Practices

Load Ratings and Capacity

You must always calculate the total weight of your load, including the wire rope, before starting any lift. The Working Load Limit (WLL) comes from dividing the minimum breaking strength by a design factor, usually 5:1 for lifting slings.

This design factor helps account for dynamic forces, wear, and unexpected conditions during lifting. You should check that every sling or assembly is marked with its WLL and other critical information. Following these steps ensures you stay within the safe load and do not exceed the minimum breaking strength.

Exceeding load ratings can have severe consequences:

Overloaded slings may fail, causing dropped loads and injuries.

Underestimating the total weight can lead to equipment tipping or catastrophic failure.

Accurate calculations protect both your team and your investment.

Equipment Selection

Selecting the right lifting and rigging equipment depends on the weight and type of your load. You must match the wire rope’s minimum breaking strength to the maximum weight you plan to lift. The table below highlights a key factor in equipment selection:

Factor | Description |

|---|---|

Strength-resistance to breaking | The wire rope must handle the maximum intended weight without risk of failure. |

Choose wire rope or chain slings for heavy or irregular loads, such as steel beams or machinery.

Use synthetic slings for delicate or fragile materials.

Always consider dynamic loading and environmental factors, such as temperature or chemical exposure, which can affect the minimum breaking strength.

Handling and Storage Tips

Proper handling and storage extend the life of your wire rope and keep your workplace safe.

Inspect wire rope regularly for wear, corrosion, or damage.

Pull the rope straight off the reel to prevent kinks.

Clean and re-lubricate the rope to reduce friction and protect against corrosion.

Store reels in a dry, cool, and well-ventilated area. Keep them off the ground and covered with weatherproof materials.

Avoid exposing the rope to chemicals, acids, or extreme temperatures.

Educate all handlers on safe lifting and rigging practices.

Tip: Routine inspections and correct storage help you maintain the minimum breaking strength and ensure every lift stays within the safe load.

Powerful Machinery supports your operation with certified wire rope solutions for construction, marine, transportation, and cargo handling. You can rely on their expertise and product range to meet the highest safety standards in any environment.

Conclusion

Accurate wire rope weight calculation keeps your lifting and rigging operations safe. You avoid equipment overload, instability, and injury by confirming the exact load weight. Certified wire ropes from Powerful Machinery prevent twisting, improve stability, and resist harsh conditions, giving you confidence in every lift.

Key steps for safe selection:

Check the sling capacity and construction.

Choose proper fittings and length.

Assess environmental factors.

Always consult weight tables and follow best practices. For certified solutions and expert support, explore Powerful Machinery’s wire rope products.

FAQ

How do you calculate the total weight of wire rope for your project?

You multiply the weight per foot by the total length needed. Always add the weight of fittings and splices. This method helps you select the right equipment and maintain safety.

Why does wire rope construction affect its weight?

Wire rope construction changes the number of strands and wires. More wires increase flexibility and weight. You must check the construction type to match your application and load requirements.

Can you use galvanized steel wire rope outdoors?

Yes. Galvanized steel wire rope resists corrosion because of its zinc coating. You can use it for marine, construction, and outdoor lifting tasks. Powerful Machinery offers custom coatings for extra protection.

Where can you find certified wire rope weight tables?

You can access certified weight tables on Powerful Machinery’s website. These tables help you choose the correct wire rope for safe lifting and rigging.