You install wire rope clips by turning back the wire rope to form a loop, placing the first clip a base width from the rope’s dead end, and tightening the nuts to secure the connection.

Proper wire rope clip installation prevents common mistakes, such as incorrect spacing, using the wrong number of clips, or placing the saddle on the incorrect side.

You protect lives and equipment by matching the clip size to the rope and torquing to specifications. Both DIYers and professionals must follow these steps to achieve safe, reliable results.

Key Takeaways

Gather all necessary tools and materials before starting. This includes stainless steel wire rope clips, a wrench, measuring tape, and safety gear.

Choose the right size wire rope clips to match the diameter of your wire rope. This prevents slippage and ensures a secure grip.

Follow the correct installation steps: prepare the wire rope, position the first clip, add more clips with proper spacing, and tighten them to the specified torque.

Always inspect your wire rope clips and assembly after installation. Check for correct placement, spacing, and tightness to ensure safety.

Use thimbles when creating load-bearing eyes in wire rope. Thimbles protect the rope and enhance its lifespan by reducing wear and friction.

Tools and Materials

What do You Need?

Before you start installing wire rope clips, gather all the necessary tools and materials. Having the right equipment ensures a smooth and safe installation process. Here is what you need:

Stainless Steel Wire Rope Clips from Powerful Machinery

Wrench or suitable tool for tightening nuts

Measuring tape or ruler for accurate spacing

Safety gear, such as gloves and eye protection

You should always use certified products. Powerful Machinery’s Stainless Steel Wire Rope Clips meet international standards and provide reliable performance in demanding environments. These clips come in simplex, duplex, and DIN741 designs, so you can choose the right type for your application.

Tip: Always inspect your tools and clips before use. Damaged or worn equipment can compromise safety.

Choosing Wire Rope Clips

Selecting the correct wire rope clips is critical for safety and reliability. You must match the clip size to the wire rope diameter. If the clip is too small, it can damage the rope. If the clip is too large, it will not grip the rope securely. This mismatch can lead to slippage and reduce the strength of your assembly.

Follow these industry recommendations when choosing wire rope clips:

Choose a reputable manufacturer, such as Powerful Machinery, known for quality rigging products.

Consult the instruction manual for installation and load capacity information.

Seek expert advice if you are unsure about the right clamp for your needs.

Ensure the clip matches the diameter of your wire rope.

Consider the environment—stainless steel clips offer excellent weather resistance.

Inspect clips regularly for wear and tear.

Store clips in a dry, cool place to extend their lifespan.

By following these guidelines, you ensure your wire rope clips perform safely and effectively in any application.

Wire Rope Clip Installation Steps

Prepare the Wire Rope

Start your wire rope clip installation by preparing the wire rope. Measure the required length for the loop or eye you want to create. Mark the point where you need to begin the turnback. The turnback is the section of wire rope that you bend back to form the loop.

Use a measuring tape to ensure accuracy. For most applications, the turnback should be at least 20 times the diameter of the wire rope. This length allows you to fit all the wire rope clips with proper spacing.

Inspect the wire rope for damage before you begin. Do not use wire rope clips on plastic-coated wire rope. Remove any coating from the area where you plan to install wire rope clips.

This step ensures a secure grip and prevents slippage. Wear gloves to protect your hands during the turnback process. Bend the wire rope smoothly to avoid kinks or sharp bends.

Tip: Always use Powerful Machinery’s Stainless Steel Wire Rope Clips for maximum corrosion resistance and reliability in marine or industrial environments.

Position the First Clip

Place the first wire rope clip one base width from the dead end of the turnback. The dead end is the part of the wire rope that does not carry the load. The live end is the section that supports the load.

Position the U-bolt of the wire rope clip over the dead end. The saddle must rest on the live end. This placement follows the “Never Saddle a Dead Horse” rule.

The rule ensures the clamp grips the live end securely, preventing slippage under load.

Proper clamping maintains the wire rope’s full-rated load capacity, enhancing load-bearing efficiency.

It reduces the risk of accidents and equipment damage, promoting safety during operations.

Tighten the nuts evenly using a wrench. Alternate between nuts to distribute pressure. Do not overtighten at this stage. You will perform final tightening after all wire rope clips are in place.

Add More Clips

Continue your wire rope clip installation by adding more wire rope clips along the turnback. Space each clip at intervals of 6 to 7 times the diameter of the wire rope. This spacing ensures even pressure and a secure grip. Always use the minimum number of wire rope clips recommended for your wire rope diameter.

Wire Rope Diameter | Minimum Number of Clips |

|---|---|

Any Diameter | 3 |

Refer to the manufacturer’s guidelines for specific requirements. Powerful Machinery recommends using at least three wire rope clips for most diameters. For larger ropes, increase the number of clips as shown in the table below.

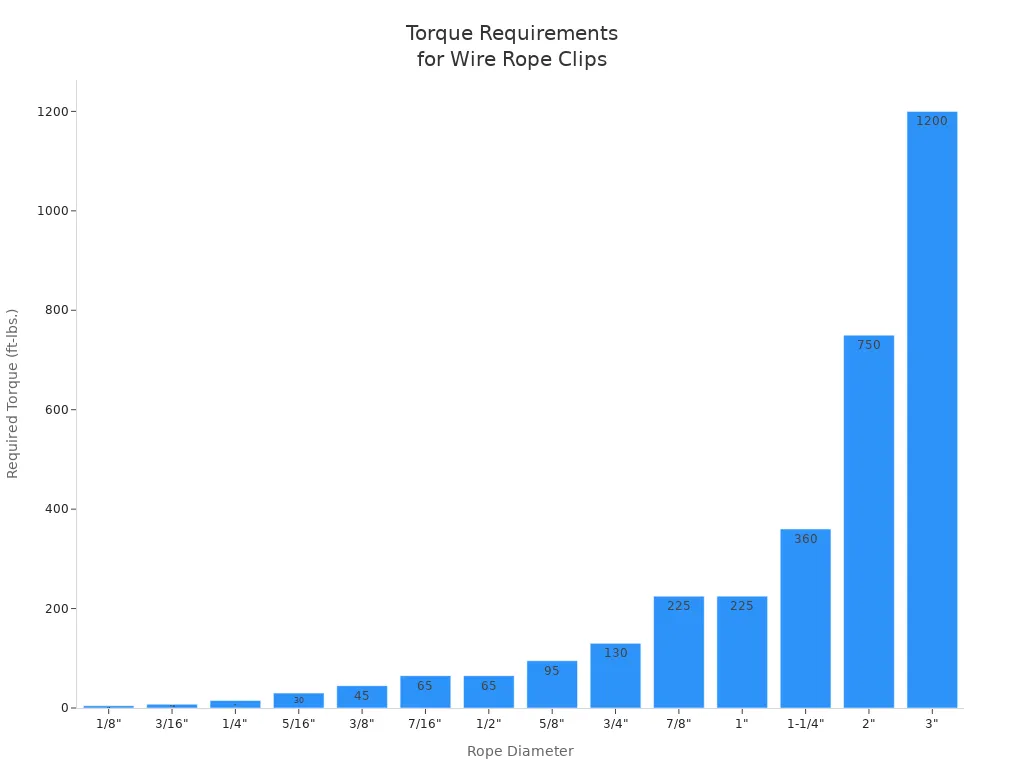

ROPE DIAMETER | MINIMUM # OF CLIPS | REQUIRED TORQUE (ft-lbs.) |

|---|---|---|

1/8″ | 2 | 4.5 |

3/16″ | 2 | 7.5 |

1/4″ | 2 | 15 |

5/16″ | 2 | 30 |

3/8″ | 2 | 45 |

7/16″ | 2 | 65 |

1/2″ | 3 | 65 |

5/8″ | 3 | 95 |

3/4″ | 4 | 130 |

7/8″ | 4 | 225 |

1″ | 5 | 225 |

1-1/4″ | 7 | 360 |

2″ | 8 | 750 |

3″ | 10 | 1200 |

Tighten and Check

Complete your wire rope clip installation by tightening all wire rope clips to the specified torque. Use a torque wrench for accuracy. Tighten the nuts evenly, alternating from one nut to the other.

Follow the torque values listed in the table above. Proper torque ensures the wire rope clips grip the turnback securely and maintain load capacity.

After you install wire rope clips, inspect the assembly. Check for correct placement, spacing, and tightness. Make sure the saddle is always on the live end. Re-torque the nuts after the wire rope has been loaded for the first time. This step compensates for any settling in the wire rope.

Note: Never use wire rope clips on plastic-coated wire rope. Always follow the “Never Saddle a Dead Horse” rule for every wire rope clip installation.

You have now completed the wire rope clip installation. Your wire rope assembly is ready for safe use in lifting, rigging, or securing applications.

Using Wire Rope Clips with Thimbles

Why Use a Thimble?

When you create a load-bearing eye in a wire rope, you want to protect the rope from damage and maintain its strength. Thimbles play a crucial role in this process. You insert a thimble into the loop to form a solid, rounded surface for the rope to bend around. This simple addition offers several important benefits:

Thimbles protect the wire rope from wear and deformation at the eye.

They help the rope keep its shape and distribute loads evenly, which is essential for lifting and securing heavy objects.

You extend the lifespan of your wire rope by preventing crushing or abrasion at the loop.

Thimbles provide a protective barrier, reducing friction and minimizing the risk of kinks that can weaken the rope.

They enhance safety by maintaining the rope’s structural integrity and flexibility, especially under heavy loads.

Tip: Always use a thimble for any permanent or load-bearing eye. This small investment can prevent costly rope damage and improve safety in your rigging setup.

How to Install with a Thimble?

You can install wire rope clips with a thimble by following a few straightforward steps. Using Powerful Machinery’s Stainless Steel Wire Rope Clips ensures a secure and corrosion-resistant connection. Here’s how you do it:

Position the U-bolt of the wire rope clip on the dead end of the rope, with the saddle on the live end.

Prepare the wire rope by measuring a minimum turnback length of 12 inches.

Hand-tighten the first clip at the very end of the wire rope.

Bend the rope to form a loop and insert the thimble into the eye.

Place the second clip as close to the thimble’s base as possible, securing the thimble in place.

Add additional clips as required, spacing them evenly along the turnback.

Tighten all clips to the recommended torque, then inspect the assembly for proper placement and security.

Note: Always check that the thimble fits snugly inside the loop and that the clips hold both the rope and thimble firmly. This ensures maximum strength and safety for your wire rope assembly.

Powerful Machinery Product Features

Stainless Steel Wire Rope Clips

You need reliable hardware when working with wire rope. Powerful Machinery offers stainless steel wire rope clips that set the standard for strength and safety.

These clips use high-quality stainless steel, which gives them outstanding durability and resistance to rust. You can trust them in harsh environments, including marine and industrial settings.

Powerful Machinery wire rope clips come from suppliers who follow strict manufacturing standards. You receive products that meet international safety and quality regulations. The company provides certifications that guarantee compliance and performance. You can see the difference in the build quality and finish.

Certifications include:

ISO9001

ISO14001

TUV Rheinland

EURO CERT

EAC

Geprufte Sicherheit

OSHA

ASTM

You can choose from several types of wire rope clips. Each design fits specific needs and applications. The table below shows the main types and where you might use them:

Type of Wire Rope Clip | Applications |

|---|---|

U-Bolt Wire Rope Clips | Construction sites, Lifting and rigging, Marine applications |

Double Loop Wire Rope Clips | Cable stays for bridges, Tensioning in structural applications, Heavy lifting scenarios |

Plated Wire Rope Clips | Marine environments, Chemical plants, Outdoor rigging operations |

Screw Pin Wire Rope Clips | Temporary installations, Welding and fabrication, Rigging for events |

Specialized Wire Rope Clips | Aerospace applications, Heavy-duty construction, Mining operations |

Advantages for Marine and Industrial Use

You often face tough conditions in marine and industrial work. Powerful Machinery stainless steel wire rope clips give you a clear advantage. These clips show exceptional corrosion resistance, even when compared to galvanized or zinc-plated options.

You can use them outdoors or near saltwater without worrying about rust or failure.

You also benefit from a range of designs. The table below explains the differences between simplex, duplex, and DIN741 types of wire rope clips:

Design Type | Composition | Applications |

|---|---|---|

Simplex | Stamping plate, saddle, bolts | Outdoor light duty |

Duplex | Double-stamped cable clip | Outdoor light duty |

DIN741 | Malleable iron wire rope clamp | Light-duty applications |

You can select the right type for your project, whether you need a secure connection for lifting, rigging, or structural support. Powerful Machinery ensures every clip delivers reliable performance, no matter the challenge.

Tips and Safety Checks

Common Mistakes to Avoid

You must recognize common mistakes when using wire rope clips to maintain safety and reliability. Many incidents occur because users overlook basic installation rules. Review this list before starting your project:

Using fewer clips than recommended by the manufacturer

Incorrectly spacing the clips along the turnback

Placing the saddle on the wrong end of the wire rope

Using the wrong size of wire clip for your rope

Not tightening the clips enough

Correct installation of wire rope clips is essential for safety. Always place the saddle on the live end and the U-bolt on the dead end. This configuration helps the rope maintain its strength under load and prevents slippage or failure.

Incorrectly installed clips can reduce rope strength by up to 40%. In high-stakes environments—construction, shipping, heavy industry—that’s a risk no one can afford.

You should always follow manufacturer guidelines and international standards. Avoid shortcuts and double-check every step to prevent accidents.

Final Inspection

After installing wire rope clips, you need to perform a thorough inspection. This step ensures your assembly meets safety requirements and operates reliably. Follow these checks:

Inspect the wire rope for wear, corrosion, or damage before installation.

Verify that each clip matches the wire rope diameter and shows no signs of wear or alteration.

Confirm that the saddle sits on the live end and the U-bolt covers the dead end.

Tighten all nuts to the recommended torque using a calibrated wrench.

Check that clips are spaced correctly and that you used the minimum number required.

Perform daily visual inspections for running ropes and slings, looking for distortion, broken wires, or lack of lubrication.

Schedule periodic inspections based on service type and environment. Refer to the table below for guidance:

Service Type | Inspection Frequency |

|---|---|

Normal Rope Service | Not to exceed 12 months or 2,000 hours |

Heavy Rope Service | Not to exceed 6 months or 1,000 hours |

Severe Rope Service | Not to exceed 3 months or 500 hours |

Special Rope Service | Less than 500 hours |

You should also inspect end terminations and attachments for signs of corrosion or damage. Ensure all components remain securely fastened and properly aligned. Regular maintenance and inspection routines help you avoid common mistakes when using wire rope clips and extend the life of your rigging setup.

Conclusion

You achieve safe wire rope clip installation by following each step carefully and using certified products. Powerful Machinery’s Stainless Steel Wire Rope Clips deliver high durability and corrosion resistance, making them ideal for demanding environments.

Regular inspections help you spot broken wires or corrosion early.

Proper installation and understanding of load limits prevent accidents.

Expertise in clamp placement protects both equipment and personnel.

Type of Clip | Corrosion Resistance | Durability Level | Suitability for Applications |

|---|---|---|---|

Type 304 Stainless Steel | Moderate | High | General use |

Galvanized Wire Rope Clips | High | Moderate | Affordable, durable |

Zinc-Plated Clamps | Low | Low | Dry applications only |

You protect lives and investments by double-checking your work and choosing reliable hardware. Quality and reliability remain essential in every lifting and rigging application.

FAQ

How do you choose the correct size wire rope clip?

You match the clip size to your wire rope diameter. Always check the manufacturer’s chart or product label. Using the wrong size can cause slippage or damage. Powerful Machinery provides clear sizing information for every clip.

How many wire rope clips should you use for a secure connection?

You use at least three clips for most wire rope diameters. For larger ropes, increase the number based on the manufacturer’s table. Proper spacing and quantity ensure a safe, reliable grip.

Can you reuse wire rope clips after removal?

You should not reuse wire rope clips in critical applications. Removal can weaken the threads or deform the saddle. Always inspect clips for wear. Replace any clip that shows damage or corrosion.

What is the “Never Saddle a Dead Horse” rule?

You place the saddle of the clip on the live end of the rope. The U-bolt goes on the dead end. This rule prevents crushing the load-bearing side and keeps your connection strong.

How often should you inspect installed wire rope clips?

You inspect wire rope clips before each use and during regular maintenance. For heavy or severe service, check clips more frequently. Look for signs of loosening, corrosion, or wear.

Tip: Schedule inspections based on your work environment and load frequency to maximize safety.