When you handle rigging tasks, choosing the right hook makes a direct impact on both safety and efficiency. Common types include eye hooks, clevis hooks, swivel hooks, grab hooks, and foundry hooks, each designed for specific industrial needs. The table below highlights their features and typical applications:

Hook Type | Description | Applications |

|---|---|---|

Eye Hooks | Versatile and secure for heavy loads; closed-loop design enhances safety. | Construction, marine, mining |

Clevis Hooks | Easy attachment/detachment; suitable for dynamic lifting environments. | Transportation, logistics, industrial settings |

Swivel Hooks | Rotate freely to prevent twisting; ideal for confined spaces. | Marine, oil & gas, heavy machinery |

Grab Hooks | Secure grip on loads; designed to shorten or hold the chain. | Construction, mining, and agricultural applications |

Foundry Hooks | Engineered for high-temperature environments; handles molten metal. | Foundries, steel mills |

Others | Includes sorting hooks and drum hooks for niche applications. | Various specialized applications |

Understanding the advantages of each type helps you select the right industrial hooks and hoists for your job. Powerful Machinery provides certified solutions trusted across industries for reliable lifting operations.

Key Takeaways

Choose the right hook type for your lifting needs to enhance safety and efficiency. Each hook serves a specific purpose.

Always verify the working load limit of hooks before use to prevent accidents and ensure safe lifting operations.

Select hooks with safety features like self-locking latches to minimize the risk of accidental disengagement during lifts.

Regularly inspect your hooks for wear and damage to maintain safety standards and prolong the life of your equipment.

Consult with experts to find the best lifting solutions tailored to your specific applications and environmental conditions.

Types of Industrial Hooks and Hoists

Selecting the right industrial hooks and hoists is essential for safe and efficient lifting. Each hook type serves a unique purpose, and understanding its features helps you make the best choice for your application.

Below, you will find a detailed overview of the most common hook types used in rigging and lifting, along with their typical uses and advantages.

Eye Hooks

Eye hooks are among the most versatile hook types in industrial rigging. You can use them for a wide range of lifting tasks, from construction to marine operations. The closed-loop design of an eye hook provides a secure connection, reducing the risk of accidental disengagement.

Powerful Machinery offers eye hooks crafted from high-strength forged steel, ensuring durability and reliability.

Tip: Choose forged eye hooks for heavy-duty applications and stainless steel eye hooks for marine or corrosive environments.

Type of Eye Hook | Characteristics | Typical Applications |

|---|---|---|

Forged Eye Hooks | Strong, durable, and ideal for heavy-duty lifting. | Construction, mining, heavy industry |

Non-Forged Eye Hooks | Suitable for lighter loads and less demanding tasks. | Light industrial, marine |

Shoulder Eye Hooks | Resist bending, allow for angular loading. | Lifting with slings at angles |

Non-Shoulder Eye Hooks | Only for vertical lifts, not for side loading. | Vertical lifting only |

Galvanized Eye Hooks | Corrosion-resistant, suitable for dry environments. | General industrial |

Stainless Steel Eye Hooks | Excellent corrosion resistance, ideal for marine and outdoor use. | Marine, construction, agriculture |

Clevis Hooks

Clevis hooks feature a U-shaped attachment point secured with a pin, making them easy to connect and disconnect from chains or slings. You often use clevis hooks in transportation, logistics, and industrial settings where quick changes are necessary.

Powerful Machinery’s Clevis Grab Hook stands out for its robust construction, zinc coating, and compatibility with Grade 43 chains. These hooks meet strict industry standards, including ASME B30.10-2019, ensuring safety and reliability.

Standard | Description |

|---|---|

ASME B30.10-2019 | Covers safety requirements for fabrication, use, inspection, and maintenance of clevis hooks. |

Note: Always verify that your clevis hooks meet recognized safety standards for your lifting operations.

Swivel Hooks

Swivel hooks provide a rotating connection, allowing the load to turn freely without twisting the lifting chain or sling. This feature improves load alignment and reduces wear on your equipment. Powerful Machinery offers swivel hooks with safety latches that prevent accidental disengagement, enhancing operational safety.

Swivel hooks allow smooth rotation, preventing load twisting.

They improve load alignment and distribute forces evenly.

Safety latches keep loads securely attached during lifting.

The swivel mechanism allows 360-degree rotation, minimizing load imbalance.

High-strength materials ensure durability under heavy loads.

Safety latches add an extra layer of security.

Drum and Barrel Hooks

Drum and barrel hooks are designed specifically for lifting cylindrical objects such as barrels and drums. You can use them with multi-leg sling assemblies for added stability. These hooks work best at angles between 30 and 45 degrees, ensuring a secure grip on the load.

Industry/Scenario | Description |

|---|---|

Lifting Barrels/Drums | Designed for safe lifting of barrels or drums. |

Multi-leg Sling Assembly | Used with multi-leg slings for stability. |

Angle of Use | Most effective at 30-45 degree angles. |

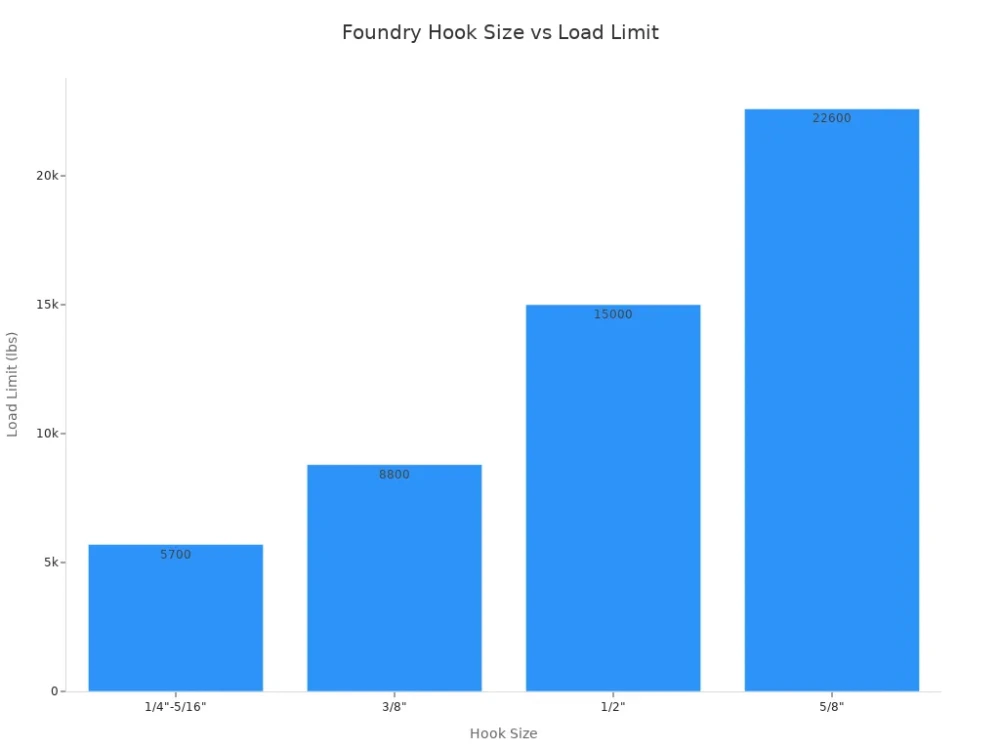

Foundry Hooks

Foundry hooks are engineered for extreme environments, such as steel mills and foundries, where you need to handle molten metal and high temperatures. These hooks are made from high-quality steel and offer impressive working load limits.

Size | Working Load Limit (lbs) |

|---|---|

1/4″-5/16″ | 5,700 |

3/8″ | 8,800 |

1/2″ | 15,000 |

5/8″ | 22,600 |

Material | High-quality steel |

Sorting Hooks

Sorting hooks are specialized for handling flat metal plates, pipes, and tube-like objects. You can use them with single or multi-leg bridle sling assemblies. For maximum safety and engagement, always use sorting hooks at a sling angle of 30° to 45°.

Designed for sorting and laying flat or tubular materials.

Compatible with single or multi-leg sling assemblies.

Require a 30° to 45° sling angle for proper use.

J Hooks

J hooks have a simple, open design that makes them easy to attach and remove. You often use J hooks for temporary lifting or quick rigging tasks. Their shape allows for fast connections, but you should avoid using them for critical lifts where load security is paramount.

Crane Hooks

Crane hooks are a staple in heavy lifting operations. You will find them on overhead cranes, gantries, and hoists. These hooks come in various sizes and configurations, including single and double hooks, to handle a wide range of load capacities.

Powerful Machinery supplies crane hooks that meet international safety standards, ensuring dependable performance in demanding environments.

Grab Hooks

Grab hooks are essential for chain shortening and load securing. The unique throat design grips the chain securely, preventing it from slipping through the hook. You can use grab hooks to adjust chain length or bind loads tightly.

Powerful Machinery’s Clevis Grab Hook offers a secure bolt and cotter pin system, heat-treated steel construction, and a corrosion-resistant finish, making it ideal for construction, mining, and marine applications.

User Preference | Description |

|---|---|

User 1 | Prefers grab hooks for shortening the chain, based on availability in the shop. |

User 2 | Favors shortening clutches for added options in rigging. |

User 3 | Uses the Eliminator with two legs of chain, highlighting its versatility in load management. |

Sling Hooks with Self-Closing Latch

Sling hooks with self-closing latches, also known as self-locking hooks, provide an extra layer of safety. The latch automatically closes and locks when you apply a load, preventing accidental disengagement. These hooks are required by OSHA and other safety regulations for many lifting applications.

Regulation | Description |

|---|---|

OSHA Requirement | Hooks must meet manufacturer recommendations, and safety latch-type hooks should be used wherever possible. |

Safety Hook Definition | A safety hook is defined as a hook with a latch to prevent slings or loads from accidentally slipping off. |

Maritime Provision | Crane hooks must be latched or secured to prevent accidental load disengagement. |

Construction Provision | Hooks with self-closing safety latches must be used to prevent components from slipping out of the hook. |

Alert: Always use self-locking hooks when lifting personnel or critical loads to maximize safety.

Positive Latching Hooks

Positive latching hooks, another form of self-locking hooks, automatically close and lock when you apply a load. This design eliminates the need for manual connection and significantly reduces the risk of accidental load release. You benefit from enhanced safety and efficiency during lifting operations.

Positive latching hooks close automatically under load, preventing accidental opening.

The design reduces the risk of load slippage and improves overall lifting safety.

No manual connection required, minimizing the chance of human error.

Powerful Machinery’s industrial hooks and hoists, including Clevis Grab Hook, Hooks, and Stainless Steel Hooks, are fully certified and engineered for maximum safety and versatility. You can trust these products to meet the highest standards in construction, marine, and transportation industries.

Features and Advantages

Secure Connections

You need hooks that provide a reliable and secure connection for every lift. Powerful Machinery’s hooks feature precision-engineered designs that reduce the risk of accidental disengagement.

For example, the Clevis Grab Hook uses a bolt and cotter pin system to lock the chain in place. Stainless steel hooks offer a closed-loop or latch mechanism, ensuring your load stays attached even in dynamic environments.

Hook Type | Key Features |

|---|---|

Clevis Hook | Non-permanent connection, easy to replace damaged hooks without scrapping the entire sling. |

Positioning Swivel Hook | Rotates to align loads but should not rotate when the load is attached. |

True Swivel Hook with Bearing | It can rotate 360 degrees with the load attached, suitable for preventing twisting under load. |

Foundry Lifting Hook | Designed for high-temperature applications, includes a safety latch, requires a reduced WLL for safety. |

Sorting Hook | Best used at 30°-45° angles for effective load engagement, which affects the working load limit. |

J Hook | Slimmer profile, often used with eye bolts, has lower working load limits. |

Crane Lifting Hook | Includes single and double hooks, used for different load capacities. |

Grab Hook | Narrow throat for grabbing chains, includes standard and cradle types with different WLL reductions. |

Quick Attachments

You save time on the job when you use hooks designed for fast attachment and removal. Clevis hooks from Powerful Machinery allow you to swap out damaged hooks quickly, keeping your rigging system efficient. The user-friendly design means you can connect or disconnect chains without special tools.

Rotational Alignment

Swivel hooks help you align loads easily. You can rotate the hook to prevent twisting and tangling of chains. True swivel hooks with bearings allow 360-degree rotation under load, which is essential for precise positioning in tight spaces.

Wide Lifting Points

Crane hooks and foundry hooks offer wide lifting points. You can lift bulky or irregular loads with better stability. The broad opening accommodates various sling types and load shapes.

High-Temperature Use

Foundry hooks from Powerful Machinery withstand extreme heat. You can use them in steel mills or foundries without worrying about deformation or failure. The safety latch and robust steel construction ensure performance in high-temperature environments.

Load Distribution

Proper load distribution prevents accidents. Sorting hooks and sling hooks distribute weight evenly, reducing stress on chains and slings. You achieve safer lifts and extend the life of your rigging equipment.

Versatile Profiles

You need hooks for different tasks. Powerful Machinery offers J hooks, grab hooks, and stainless steel hooks in multiple profiles. You can select the right shape for your specific application, whether you need a slim profile or a wide throat.

Heavy Lifting

You handle heavy loads with confidence using hooks rated for high working load limits. Powerful Machinery’s forged steel hooks and Clevis Grab Hook support demanding lifts in construction, mining, and marine industries.

Chain Shortening with Clevis Grab Hook

The Clevis Grab Hook lets you shorten chains quickly and securely. Its narrow throat grips the chain, preventing slippage. You can adjust chain length for load binding or tensioning with ease.

Enhanced Security

Hooks with self-closing latches or positive locking mechanisms give you peace of mind. Loads stay attached, even if the rigging shifts. This feature is critical for personnel lifts and high-value cargo.

Maximum Safety

You protect your team and equipment by choosing hooks with certified safety features. Powerful Machinery’s stainless steel hooks resist rust and corrosion, even in harsh marine environments:

Stainless steel hooks do not rust or suffer damage from environmental factors, making them ideal for challenging conditions such as coastal and marine environments.

316 stainless steel offers superior corrosion resistance, particularly in aggressive environments with exposure to chlorides and acids.

You can trust Powerful Machinery’s certified hooks to deliver maximum safety and long-term reliability in every lift.

Comparison and Safety

Quick Reference Table

When you select a hook for your lifting operation, you need to compare its features and best use cases. The table below helps you quickly identify which hook fits your needs:

Hook Type | Key Feature | Best Use Case | Typical Working Load Limit Range |

|---|---|---|---|

Eye Hook | Closed loop for secure connection | Permanent rigging, minimal movement | Medium to High |

Clevis Hook | Quick pin connection | Rapid load changes, construction | Medium to High |

Swivel Hook | Rotates to prevent twisting | Dynamic lifts, confined spaces | Medium |

Grab Hook | Grips chain links securely | Chain shortening, load binding | Medium |

Foundry Hook | Wide throat, heat-resistant | High-temperature, foundry operations | High |

Note: Always check the working load limit for each hook before use.

Working Load Limits

You must always verify the working load limit for every hook in your rigging system. The working load limit tells you the maximum weight a hook can safely handle. For example, Powerful Machinery’s Clevis Grab Hook offers a range of working load limits depending on the size, from 2,600 lbs to over 15,000 lbs.

Stainless steel hooks and crane hooks also come with clear working load limit markings. Never exceed these limits, as doing so can cause equipment failure and endanger your team.

Safety Considerations

You need to prioritize safety in every lifting operation. Choose hooks that meet international standards such as ISO and ASME. These standards create a common language for quality and performance, making it easier for you to use certified hooks across global markets.

Powerful Machinery’s products comply with ISO9001, TUV Rheinland, and other major certifications. This compliance ensures you get reliable hooks that pass strict safety and quality checks.

ISO standards help you reduce trade barriers and streamline your procurement process.

Certified hooks give you confidence in both domestic and international projects.

Always inspect hooks for wear and confirm the working load limit before each use.

Tip: Using certified hooks from Powerful Machinery helps you maintain high safety standards and avoid costly downtime.

Choosing for Safety and Efficiency

Assessing Load and Application

You must always match the hook to your lifting requirements. Start by identifying the weight, shape, and balance of your load. For lifting in heavy-duty applications, select hooks rated for the maximum load you expect. Consider the type of movement involved.

Some hooks, like grab hooks, excel at chain shortening, while others, such as eye hooks, provide secure connections for steady lifting. Using certified products from Powerful Machinery ensures compliance with safety regulations and reduces the risk of workplace accidents.

Environment and Connection Type

Your operating environment plays a critical role in hook selection. Exposure to chemicals or extreme temperatures can affect hook performance. High temperatures may compromise protective coatings on stainless steel, leading to permanent changes in material properties.

Choose specialized alloys for lifting in harsh environments to maintain durability and safety. For marine or corrosive settings, stainless steel hooks offer excellent resistance and long-term reliability.

Safety Features

Prioritize safety features when choosing hooks for lifting.

Self-locking hooks and rated shackles minimize risk during lifting operations.

Always ensure hooks meet OSHA and manufacturer safety standards.

Conduct regular inspections to catch early signs of damage.

Industry regulations, such as ASME B30.20 and OSHA codes, set strict requirements for lifting devices. Compliance with these standards helps prevent accidents and ensures efficient lifting.

Maintenance and Replacement

Routine maintenance keeps your lifting equipment safe.

Maintenance Requirement | Frequency/Condition |

|---|---|

Visual inspection for cracks, wear, or deformation | Before each use |

Annual inspection for self-locking hooks | At least once a year |

Immediate removal of hooks with wear over 10% | Required |

Inspection for hooks under frequent load cycles | Periodically, with advanced methods |

Remove any hook from service if you find cracks, excessive wear, or deformation. Follow ANSI and OSHA guidelines for inspection intervals.

Expert Consultation

Consulting with certified experts ensures you select the right lifting solution. Industry professionals understand load requirements, environmental factors, and safety regulations. Powerful Machinery offers custom-engineered hooks and collaborates with you to design products that fit your unique lifting needs.

You benefit from expert guidance on installation, maintenance, and compliance with international standards. This approach reduces risk and increases efficiency in complex lifting scenarios.

Conclusion

Selecting the right chain hook protects your team and boosts productivity. Certified industrial hooks help you handle loads safely, comply with regulations, and improve efficiency.

Certified hooks support secure lifting.

Industry standards keep your operations compliant.

Specialized devices speed up load handling.

Consulting with experts at Powerful Machinery gives you an edge:

Step | Importance |

|---|---|

1 | Ensures operational safety |

2 | Enhances efficiency |

3 | Improves compliance |

Choose certified solutions for every rigging and lifting need.

FAQ

What certifications do Powerful Machinery hooks have?

Powerful Machinery hooks meet international standards like ISO9001, TUV Rheinland, and ASME B30.10. You can trust these certifications for safety and quality in demanding industrial environments.

How do you choose the right hook for your application?

Start by checking your load weight and environment. Select a hook rated for your maximum load. For corrosive or marine settings, choose stainless steel hooks. Always verify compatibility with your chain or sling.

Can you use Clevis Grab Hooks for lifting?

Yes, you can use Clevis Grab Hooks for lifting when paired with the correct chain grade. Always confirm the working load limit and certification before starting any lift.

How often should you inspect your lifting hooks?

Inspect your hooks before each use. Look for cracks, wear, or deformation. Schedule annual inspections for self-locking hooks. Remove any hook from service if you find damage.

Does Powerful Machinery offer custom hook solutions?

Yes. Powerful Machinery provides custom-engineered hooks and rigging hardware. You can request specific sizes, finishes, or branding to fit your project requirements.