Imagine you are lifting a massive steel beam at a busy construction site. The choice between grade 80 vs grade 100 chain can decide how safely you complete the job. Grade 100 chain offers 25% more strength than grade 80, making it ideal for heavy-duty lifting and rigging tasks.

Every year, improper chain selection leads to serious workplace accidents.

Between 2011 and 2017, crane-related deaths averaged 42 per year.

Proper rigging techniques protect both your load and equipment.

Marked, certified chains help reduce industrial accidents by improving safety.

You want reliability and safety. Powerful Machinery delivers certified lifting solutions trusted by professionals worldwide.

Chain Grade | Strength Comparison | Applications |

|---|---|---|

Grade 80 | Standard strength | Overhead lifting, heavy-duty towing |

Grade 100 | 25% stronger than 80 | Heavy-duty lifting, construction, rigging |

Key Takeaways

Grade 100 chain is 25% stronger than grade 80 chain, making it ideal for heavy-duty lifting tasks.

Choosing the right chain grade is crucial for safety; using the correct grade prevents accidents and protects your equipment.

Regular inspections of your lifting chain are essential; check for wear, corrosion, and damage to ensure safe operation.

Grade 80 chain is suitable for standard lifting needs, while grade 100 chain excels in high-stress environments.

Investing in grade 100 chain may cost more upfront, but it offers better long-term value due to its durability and higher working load limit.

Grade 80 vs Grade 100 Chain Overview

Key Differences

You need to understand the main differences between grade 80 vs grade 100 chains before you choose the right option for your project. Both chains use alloy steel and meet strict safety standards, but the grade 100 chain offers higher strength and better performance for demanding jobs.

The following table gives you a clear chain grade overview:

Feature | Grade 80 | Grade 100 |

|---|---|---|

Ultimate Breaking Strength | 800 N/mm² | 1000 N/mm² |

Recommended Applications | Overhead lifting | Overhead lifting |

Compliance Standards | ASTM, ASME, OSHA | ASTM, ASME, OSHA |

Elongation Before Fracture | Minimum 20% | Minimum 20% |

Alloying Elements | Required for strength and durability | Required for strength and durability |

Grade 80 chain works well for overhead lifting, towing, and cargo handling. Grade 100 chain is best for heavy-duty lifting, construction, and rigging tasks that demand extra strength. Both grades meet international standards, so you can trust their safety and reliability.

Powerful Machinery specializes in both chain grades. You get certified products that meet or exceed global standards. The company’s experience ensures you receive chains that deliver consistent performance in every application.

Which to Choose?

You want to select the right chain for your job. Grade 80 chain handles most lifting and rigging needs. Grade 100 chain gives you 25% more strength, making it ideal for high-stress environments. The price difference between the two grades is not significant, so you can focus on safety and performance instead of cost.

You see a general increase in price with higher grades of chain.

The price difference between grade 80 and grade 100 chains is usually small.

Many suppliers offer both grades interchangeably.

If you need maximum strength and traceability, choose grade 100 chain. For standard lifting tasks, grade 80 chain provides reliable value. Powerful Machinery’s expertise helps you match the right chain grade to your specific requirements.

Understanding Chain Grades

What Are Chain Grades?

You see chain grades every time you look at a certified lifting chain. Chain grades tell you how strong and reliable a chain is for different jobs. Manufacturers use numbers like 80 or 100 to show the tensile strength of each chain. The higher the grade, the stronger the chain.

Determining chain grades involves testing the chain’s breaking strength and durability. International organizations set strict rules for chain grades to keep you safe.

Organization | Role in Chain Standards |

|---|---|

ASTM | Publishes safety standards for chain manufacturing and testing |

ASME | Establishes mechanical engineering standards for chains |

OSHA | Regulates safety standards for the use and inspection of chains |

Powerful Machinery follows these standards closely. You get chains that meet or exceed requirements from ASTM, ASME, and OSHA. Every chain grade from Powerful Machinery is tested and certified, so you can trust its performance.

Why Grades Matter?

Chain grades play a big role in lifting and rigging safety. You need to choose the right chain grade for your job to avoid accidents and keep your team safe. Chain grades show you the tensile strength, which helps you handle heavy loads without risk.

Picking the correct chain grade for each application keeps your work efficient and secure.

Chain grades indicate the tensile or breaking strength of the chain, which is essential for safely handling loads.

Selecting the correct chain grade is vital for specific applications, ensuring safety and efficiency.

Using a chain with an appropriate grade prevents accidents caused by overloading.

You protect your equipment and your crew when you use the right chain grade. Powerful Machinery’s commitment to international standards means every chain grade is reliable for lifting tasks. You can count on certified chain grades for construction, marine, and cargo handling projects.

Grade 80 Chain

Grade 80 Chain Specs & Features

You want a chain that stands up to tough jobs and meets strict safety standards. Grade 80 chain uses high-quality alloy steel and advanced heat treatment for maximum strength.

Manufacturers design this chain specifically for overhead lifting. Each chain receives a unique trace code for complete traceability. You can trust its performance because every chain is proof-tested and certified.

Feature | Description |

|---|---|

Material | Premium high-strength alloy steel |

Heat Treatment | Special induction process for strength and elongation |

Finish | Black armor coat for durability |

Standards Met | NACM, ASTM, ISO 9001-2000, OSHA |

Proof Testing | Tested to twice the working load limit |

Minimum Break Strength | Four times the working load limit |

Traceability | Unique code for full traceability |

G80 chain meets or exceeds all major industry standards. You get a product that is safe, reliable, and ready for demanding environments.

Applications

You see grade 80 chain used in many industries. Construction crews use it for overhead lifting and rigging. Marine workers rely on it for heavy-duty towing. Cargo handlers choose it for secure load movement.

Grade 80 chain also works well as a sling component for lifting. Many companies in construction, manufacturing, and mining prefer this grade because it balances strength and cost.

Overhead lifting in construction

Heavy-duty towing in marine operations

Rigging and load securing in cargo handling

Sling components for lifting tasks

Tip: Grade 80 chain is an economical choice for standard lifting needs and moderate loads.

Advantages

Grade 80 chain gives you several important benefits over lower grades. The high-quality alloy steel and special heat treatment make it strong and durable. Each chain is proof tested and certified for overhead lifting.

You get a high safety margin, with a minimum break strength four times the working load limit. This chain resists wear in harsh conditions, so you can use it again and again.

Feature | Grade 80 Chain | Lower Grade Chains |

|---|---|---|

Material | High-quality alloy steel | Standard steel |

Heat Treatment | Special induction process | Standard treatment |

Proof Testing | Yes, certified for overhead lifting | Not always tested |

Minimum Break Strength | Four times the working load limit | Lower safety margin |

Durability | High resistance to wear | Prone to wear |

Many industry professionals trust grade 80 chain for its proven safety and reliability. You can find testimonials from construction managers and marine operators who rely on this chain for daily operations.

Grade 100 Chain

Grade 100 Chain Specs & Features

You need a chain that delivers maximum performance in the toughest environments. G100 chain uses premium alloy steel and advanced heat treatment to achieve a 25% higher strength-to-weight ratio compared to grade 80.

Manufacturers design this grade for overhead lifting and heavy-duty rigging. You see rigorous testing and certification for every chain, meeting NACM, ASTM, ISO, and OSHA standards.

Each chain includes unique trace codes, so you can track its manufacturing history and steel origin. You can choose between Black Thermadep or Silver Shield finishes, which provide improved abrasion resistance and corrosion protection.

Chain Grade | Strength Advantage |

|---|---|

Grade 100 | 25% more strength than Grade 80 |

Grade 80 | Baseline strength for comparison |

Note: Grade 100 chain is approved for overhead lifting by OSHA and ASME, giving you confidence in demanding jobs.

Applications

You use grade 100 chain in high-stress environments where safety and reliability matter most. This grade supports heavy industrial lifting in foundries, shipyards, and manufacturing plants.

Construction crews rely on it for lifting steel beams and precast concrete. Mining and quarry operations choose grade 100 chain for handling abrasive and heavy loads. Port operators use this chain for critical cargo handling during loading and unloading.

Heavy industrial lifting

Construction sites for steel beams and concrete

Mining and quarry operations

Port operations and shipping

Grade 100 chain works best when you need dependable performance in harsh conditions.

Advantages

Grade 100 chain gives you clear benefits over lower grades. You get 25% more strength, which means you can lift heavier loads with the same chain size. The manufacturing process includes rigorous testing and certification, so you know your chain meets strict safety standards.

Both grade 100 and grade 80 chains have unique trace codes for complete traceability, but the grade 100 chain provides more detailed information about its history and steel origin.

Chain Grade | Working Load Limit Increase |

|---|---|

Grade 100 | 20% increase compared to Grade 80 |

Grade 80 | Baseline for comparison |

Grade 100 chain offers improved abrasion resistance due to its harder surface material.

You get reliable traceability for every chain, supporting safety and compliance.

The high-strength chain design ensures long service life in demanding lifting tasks.

You choose a grade 100 chain when you want maximum strength, durability, and full certification for your lifting operations.

Grade 80 vs Grade 100 Chain Comparison

Grade 80 Chain Strength VS Grade 100 Chain Strength

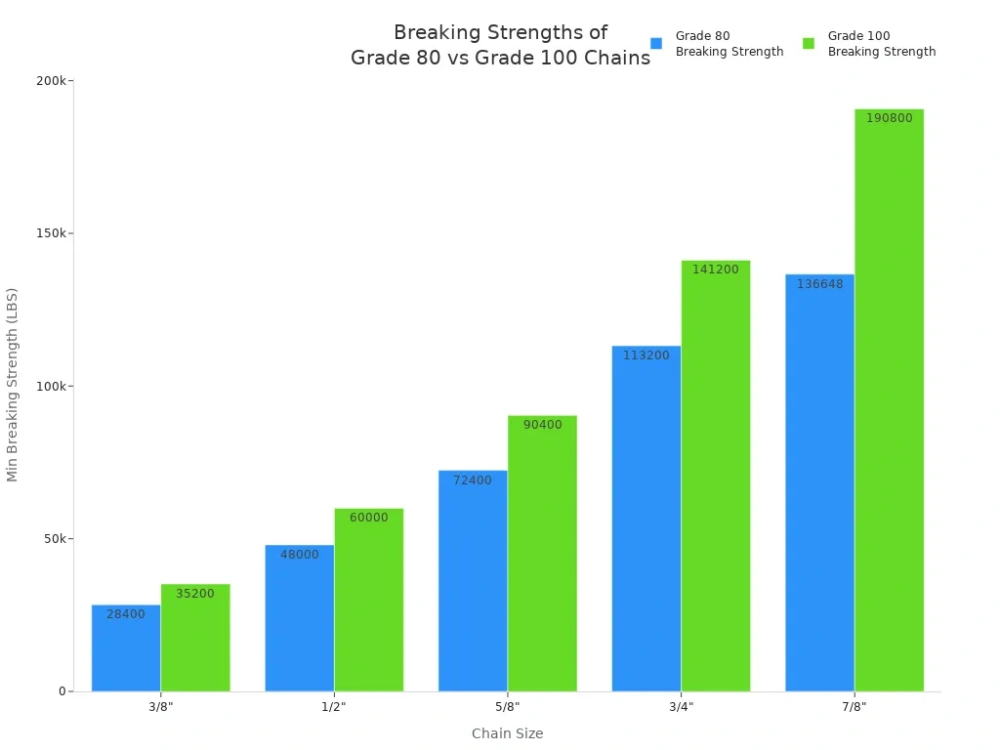

You want to know how strong each chain grade is before you choose one for your project. Grade 80 vs grade 100 chain shows a clear difference in breaking strength.

Grade 100 chain offers higher strength for the same size, which means you can lift heavier loads with a smaller chain. The table below compares minimum breaking strengths for common chain sizes:

Chain Size | Grade 80 Minimum Breaking Strength (LBS) | Grade 100 Minimum Breaking Strength (LBS) |

|---|---|---|

3/8″ | 28,400 | 35,200 |

1/2″ | 48,000 | 60,000 |

5/8″ | 72,400 | 90,400 |

3/4″ | 113,200 | 141,200 |

7/8″ | 136,648 | 190,800 |

You see that grade 100 chain always has a higher breaking strength than grade 80 chain. For example, a 3/8″ grade 80 chain has a breaking strength of 28,400 lbs, while a grade 100 chain of the same size reaches 35,200 lbs. This difference gives you more flexibility and safety in lifting operations.

Grade 80 Chain Working Load Limit VS Grade 100 Chain

Working load limit (WLL) tells you how much weight a chain can safely lift. Grade 80 vs grade 100 chain comparison shows that grade 100 chain supports heavier loads. You can use a smaller grade 100 chain to lift the same weight as a larger grade 80 chain. The table below highlights the working load limits:

Chain Grade | Working Load Limit |

|---|---|

Grade 80 | Up to 47,700 lbs |

Grade 100 | 25% stronger than Grade 80 |

Grade 100 chain gives you a 25% higher working load limit compared to grade 80 chain. This means you can choose a lighter chain for the same job, which makes handling easier and improves safety.

Durability & Resistance

You want your chain to last through tough jobs and harsh environments. Grade 80 vs grade 100 chain comparison shows that grade 100 chain offers superior durability and resistance. The table below summarizes the differences:

Chain Grade | Strength | Durability | Resistance to Wear | Resistance to Corrosion |

|---|---|---|---|---|

Grade 80 | High | Good | Resistant | Resistant |

Grade 100 | Very High | Excellent | Superior | Superior |

Grade 100 chain stands out for its excellent durability and resistance to wear and corrosion. You get a chain that performs well in demanding conditions and lasts longer. Grade 80 chain also provides good durability, but grade 100 chain is the better choice for extreme environments.

Tip: Choose a grade 100 chain for jobs that involve frequent use or exposure to harsh weather and chemicals.

Cost & Value

You want to make sure your investment brings long-term value. Grade 80 vs grade 100 chain comparison shows that grade 100 chain costs a bit more, but it offers greater value over time. Grade 100 chain has a higher working load limit, so you can use a smaller and lighter chain for the same job.

This feature makes handling easier and reduces fatigue. Grade 100 chain is also more rugged and fatigue-resistant, which means it lasts longer and needs less replacement.

Grade 80 chain gives you reliable performance at a lower initial cost. Grade 100 chain provides better long-term value because of its strength and lifespan. You save money over time by choosing grade 100 chain for heavy-duty lifting tasks.

Use Cases

You need to match the right chain grade to your application. Grade 80 vs grade 100 chain comparison helps you decide which chain fits your needs. The table below lists common use cases:

Feature | Grade 80 Chain | Grade 100 Chain |

|---|---|---|

Strength | High strength and durability | Even stronger, designed for heavier loads |

Working Load Limit (WLL) | Specific WLL marked on fittings | Higher WLL can lift heavier loads |

Advantages | Strong, lightweight, good balance | Smaller diameter for the same lifting capacity |

Applications | Construction, manufacturing, transportation | Heavy construction, mining, offshore operations |

You see grade 80 chain used in construction, manufacturing, and transportation. Grade 100 chain works best for heavy construction, mining, and offshore operations. Grade 100 chain is the top choice when you need maximum strength and durability.

Note: Powerful Machinery offers both chain grades with full certification and traceability, so you can trust the safety and performance of every chain.

This chain grade comparison gives you a clear view of the strengths, working load limits, durability, cost, and use cases for grade 80 vs grade 100 chain. You can make an informed decision for your lifting project and choose the chain that delivers the best performance.

Safety & Standards

Industry Certifications

You need to trust that your chain meets the highest safety standards for chains. International organizations set strict rules for the grade 80 and grade 100 chains. These standards help you ensure safe lifting and reliable performance. The table below shows the main certifications and what each one means for your chain:

Standard | Description |

|---|---|

OSHA | Ensures compliance with safety regulations for lifting equipment. |

ASME B30.9 | Requires proofloading of alloy lifting chain assemblies before initial use. |

NACM | Specifies chain specifications and requirements for safe use. |

ASTM | Sets standards for materials and performance of chains used in lifting. |

You see these certifications stamped on every chain from Powerful Machinery. This gives you confidence that your chain meets global safety standards for chains and will perform safely in lifting tasks.

Inspection Tips

You keep your chain safe and strong by following regular inspection routines. Always check for twisting, bending, wear, corrosion, and elongation. If you spot any damage, remove the chain from service right away.

Clean and oil your chain often to prevent rust. If you see pitting or the chain wears below the minimum thickness, it is no longer safe to use.

Inspection Aspect | Recommendation |

|---|---|

Temperature Range | -40º F to 400º F (-40º C to 204º C) |

Inspection Frequency | Regular inspections are necessary to ensure safety and compliance. |

Signs of Wear | Remove the chain from service if worn to less than the minimum thickness. |

Signs of Corrosion | Clean and oil the chain; if pitting is visible, do not use the chain. |

Regularly inspect for twisting, bending, wear, corrosion, and elongation.

Follow ASME and OSHA guidelines for compliance.

Remove the sling from service if any issues are detected.

Tip: You extend the life of your chain by keeping it clean and storing it in a dry place. Always follow the manufacturer’s instructions for inspection and maintenance.

You protect your team and equipment when you follow these inspection tips. Regular checks help you catch problems early and keep your chain ready for every lifting job.

Choosing the Right Chain

Assessing Needs

You want to select the best chain for your project. Start by thinking about the type of load you need to move and the environment where you will use the chain. Different grades offer unique benefits. Grade 100 chains have higher tensile strength, which makes them ideal for direct lifting tasks.

Grade 70 chains work well for load security because they bend under shock loading. This flexibility helps prevent load ejection. If your job involves frequent cycles of shock loading, the elasticity of grade 70 chains becomes important.

Consider the weight and type of load.

Think about the working conditions, such as exposure to chemicals or weather.

Decide if you need a chain for lifting or for securing loads.

Powerful Machinery provides custom-engineered solutions. You can get help choosing the right chain grade for your specific needs.

Safety Factors

Safety matters most when you choose a chain. Grade 100 chains are made from heat-treated alloy steel. They are about 25% stronger than grade 80 chains. This extra strength makes grade 100 chains better for heavy-duty and demanding lifts.

The surface material of grade 100 chains is harder, so you get better abrasion resistance.

Chain Grade | Strength Comparison | Working Load Limit (WLL) | Suitability for Lifting Operations |

|---|---|---|---|

Grade 80 | Standard strength | Lower WLL | General lifting operations |

Grade 100 | Approximately 25% stronger | Higher WLL | Heavy-duty and demanding lifts |

Grade 100 chains are engineered for exceptional strength. You should use them for hoisting and overhead lifting projects where safety and reliability are critical.

Budget & Performance

You may wonder if the added strength of grade 100 chains is worth the higher cost. Many customers ask about the safety and load management benefits of hardened grade 100 chains.

Grade 80 chains are becoming less available, so you might look for alternatives. Grade 100 chains last longer and handle heavier loads, which can save you money over time.

Compare the initial cost with the long-term value.

Think about how often you will use the chain.

Ask Powerful Machinery for advice on balancing budget and performance.

Tip: Powerful Machinery offers consultation services to help you select the right chain for your budget and performance needs. You get expert guidance and custom solutions for every application.

Conclusion

When you compare a grade 80 vs a grade 100 chain, you see clear differences in lifting capacity and size. Grade 100 chain lifts to 25% more with a smaller diameter. Grade 80 chain offers standard strength with a larger diameter.

Chain Grade | Lifting Capacity | Diameter Comparison |

|---|---|---|

Grade 80 | Standard | Larger diameter |

Grade 100 | Up to 25% more | Smaller diameter |

Choose the safest and most cost-effective option for your job. For certified solutions, visit Powerful Machinery’s website or contact their team for custom advice.

FAQ

What is the main difference between grade 80 and grade 100 chain?

Grade 100 chain gives you 25% more strength than grade 80 chain. You use grade 100 for heavier loads and tougher jobs. Grade 80 works well for standard lifting and rigging tasks.

Can you use a grade 100 chain for overhead lifting?

Yes, you can use a grade 100 chain for overhead lifting. It meets strict safety standards like OSHA and ASTM. You get higher strength and better durability for demanding lifting operations.

How do you identify a certified lifting chain?

You look for stamped markings on the chain. Certified chains show grade, manufacturer, and trace codes. Powerful Machinery chains include these marks for easy identification and full traceability.

What industries use grade 80 and grade 100 chains?

Chain Grade | Common Industries |

|---|---|

Grade 80 | Construction, Marine |

Grade 100 | Mining, Heavy Lifting |

You see grade 80 in construction and marine work. Grade 100 fits mining, heavy lifting, and industrial jobs.

How often should you inspect your lifting chain?

Tip: You should inspect your chain before each use. Check for wear, corrosion, and damage. Remove the chain from service if you find any problems.