A d shackle plays a vital role in connecting and securing loads in rigging and lifting tasks. You often see this type of shackle in construction, marine, and outdoor settings where strength and reliability matter. Choosing the right shackle ensures safety and boosts your efficiency in demanding operations.

Definition of D Shackle | Primary Functions in Rigging and Lifting Applications |

|---|---|

A D shackle, also known as a bow shackle, is a type of fastener that consists of a U-shaped body with a pin or a bolt that secures it in place. | 1. Rigging Systems: Connects ropes and cables for secure rigging in sailing and marine applications. |

The demand for high-quality shackles continues to rise across industries because strict safety regulations and the need for reliable equipment drive market growth. Powerful Machinery stands out as a trusted source for certified solutions, helping you meet the highest standards in every project.

Key Takeaways

D shackles are essential for connecting and securing loads in rigging and lifting tasks. Choose the right type to ensure safety and efficiency.

Understand the differences between D shackles and bow shackles. Use D shackles for straight-line pulls and bow shackles for side loading.

Select the appropriate pin type for your needs. Screw pin shackles are great for temporary setups, while bolt-type shackles offer extra security for permanent connections.

Always check the working load limit (WLL) before use. Never exceed this limit to maintain safety during lifting operations.

Regularly inspect D shackles for damage or wear. Replace any shackles that show signs of corrosion, bending, or other issues to ensure safe operation.

D Shackle Basics

What is a D Shackle?

When you work with rigging or lifting equipment, you often encounter d shackles. These essential components, sometimes called dee shackles or d ring shackles, feature a narrow, D-shaped body with a removable pin.

The design gives you a strong, stable connection point for chains, ropes, or lifting slings. You use shackles in straight-line applications where the load pulls directly along the shackle’s axis. This shape prevents twisting and ensures maximum strength.

If you wonder what is a dee shackle, think of it as a connector that links different parts of your lifting system. D-ring shackles are common in construction, shipping, manufacturing, and marine industries.

You rely on them for tasks like hoisting heavy loads, securing cargo, or connecting rigging components. Their robust design and versatility make them a staple in any professional toolkit.

D Shackle Parts

Understanding the main parts of the shackles helps you select the right one for your job. Each component plays a specific role in safety and performance. The table below breaks down the key parts and their functions:

Component | Function |

|---|---|

D-shaped fitting | Provides a robust connection point for various components, ensuring strength and stability. |

Removable pin | Allows for easy attachment and detachment, secured by a locking device for safety. |

Galvanized/Stainless Steel | Offers durability and resistance to corrosion, suitable for marine applications. |

Connection to the chain | Facilitates the connection of the anchor’s standard shackle to the chain or rope. |

Compatibility with stud-link chains | Ensures versatility in use with different types of chains. |

You find the shackles made from high-quality materials such as stainless steel, galvanized steel, or alloy steel. The removable pin, often threaded or secured with a bolt, lets you quickly attach or detach the shackle.

This feature is especially useful when you need to change rigging setups frequently. Powerful Machinery manufactures certified d shackles using advanced materials and precision engineering, ensuring each part meets strict safety standards.

Dee Shackles vs Bow Shackles

You may ask about the difference between d shackles and bow shackles. Both serve as connectors in rigging, but their shapes and functions differ. The table below highlights the key distinctions:

Feature | D Shackles | Bow Shackles |

|---|---|---|

Shape | Narrow, D-shaped | Larger, rounded ‘O’ shape |

Function | Designed for in-line tension only | Accommodates side loading and multi-leg connections |

Application | Not suitable for side loading | Versatile for various rigging tasks |

D shackles, or d ring shackles, excel in straight-line pulls where you need maximum strength and stability. You should avoid using them for side loading, as this can reduce their load capacity and compromise safety.

Bow shackles, with their wider, rounded shape, handle side loads and multi-leg slings better. When you compare d shackles vs bow shackles, always match the shackle type to your specific application.

Powerful Machinery specializes in both dee shackles and bow shackles, offering a full range of certified products for every rigging scenario. You benefit from their expertise, rigorous testing, and commitment to quality, ensuring your lifting operations remain safe and efficient.

Tip: Always check the manufacturer’s markings and certifications on your shackle. Certified shackles from Powerful Machinery meet international standards, giving you peace of mind in demanding environments.

D Shackle Types and Materials

D Shackle Types

You encounter several types of shackles in rigging and lifting work. Each type serves a specific purpose based on its design and application. The two most common are anchor shackles and chain shackles.

Anchor shackles feature a larger, rounded shape that allows you to handle loads from multiple directions. Chain shackles have a narrow D shape, which gives you maximum strength for straight-line pulls but makes them less suitable for side loads.

Type of Shackle | Design Characteristics | Applications |

|---|---|---|

Anchor Shackle | Larger, rounded ‘O’ shape; handles multi-directional loads | Load distribution, stability, multi-leg slings |

Chain Shackle | Narrow D shape; best for in-line, high-strength applications | Direct pulls, lifting, towing, and cargo securing |

Heavy-duty shackles, especially those made from hardened steel, provide the strength you need for demanding jobs. Powerful Machinery offers a full range of stainless steel d shackles and galvanised d shackles, ensuring you find the right fit for your project.

Pin Options

Selecting the right pin option is crucial for safety and efficiency. You typically choose between screw pin and bolt-type pins. Screw pin shackles allow for quick installation and removal, making them ideal for temporary or frequently changed setups.

Bolt-type shackles use a nut and cotter pin, giving you extra security for permanent or critical connections.

Feature | Screw Pin Shackle | Bolt-Type Shackle |

|---|---|---|

Pin Configuration | The threaded pin screws into the body | Pin with nut and cotter pin |

Ease of Use | Quick to install and remove | More time-consuming, requires tools |

Applications | Temporary, field use, frequent removal | Permanent, long-term, heavy-duty applications |

Security | May unscrew under vibration | Very secure, prevents loosening |

Typical Use Cases | General rigging, temporary connections | Long-term, critical, heavy-duty shackles |

Powerful Machinery’s stainless steel screw pin shackles stand out for their ease of use and reliability. You can also choose bolt-type options for extra security in heavy-duty applications.

Materials and Corrosion Resistance

The material you select for your shackle affects both its strength and its ability to resist corrosion. Stainless steel d shackles offer excellent corrosion resistance, making them perfect for marine and offshore environments.

Galvanised shackles provide a protective coating that resists rust, so you can use them outdoors or in deck applications. Alloy and hardened steel heavy-duty d shackles deliver the highest strength, which you need for construction and industrial lifting.

Stainless steel d shackles: High corrosion resistance, moderate strength, ideal for marine and outdoor use.

Galvanised d shackles: Rust protection, moderate to high strength, suitable for cranes and deck work.

Alloy and hardened steel: Maximum strength, moderate corrosion resistance, best for heavy-duty lifting.

Powerful Machinery uses high-quality materials and advanced manufacturing to ensure every shackle meets strict standards. Their stainless steel d shackles, including screw pin and bolt-type models, perform reliably in harsh conditions.

Galvanised d shackles and heavy duty d shackles from Powerful Machinery also meet the needs of demanding industries. You can trust these products for both durability and safety.

Tip: For the longest service life, always match the shackle material to your environment. Stainless steel d shackles excel in saltwater and corrosive settings, while galvanised d shackles work well for general outdoor use.

Heavy-duty shackles made from hardened steel are your best choice for maximum strength in construction or industrial lifting.

D Shackle Sizes and D Shackle Load Capacity

How to Measure D Shackle?

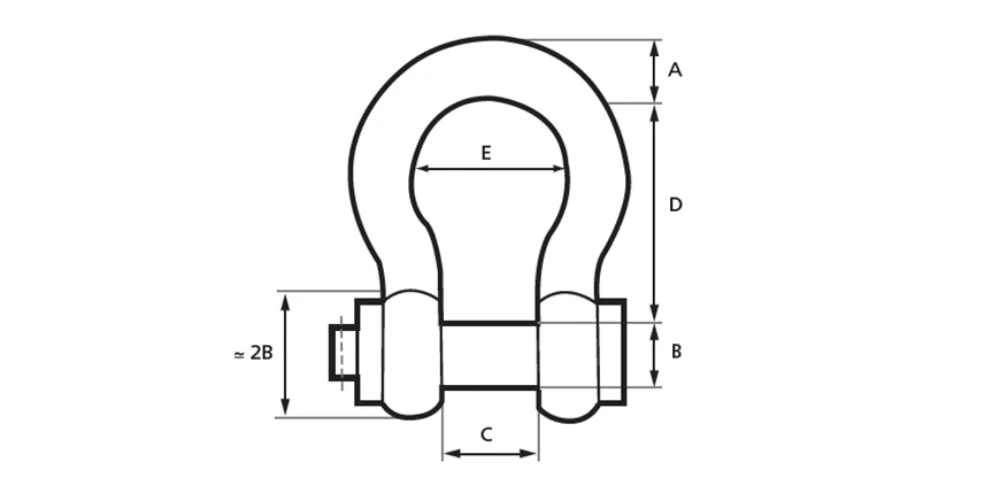

You need to understand how to measure a d shackle before selecting one for your rigging setup. Manufacturers use two main measurements: the pin diameter and the internal dimensions of the shackle body. The pin diameter determines the strength and compatibility with chains or ropes.

The internal width and length affect how the shackle fits with other components. Always match the shackle size to your maximum lifting weight and the type of connection you need.

Measurement | Description |

|---|---|

Pin Diameter | Thickness of the removable pin |

Internal Width | Distance between the inner sides of the body |

Internal Length | Distance from pin to top of shackle |

Powerful Machinery provides a wide range of certified sizes, ensuring you find the right fit for your application. You can rely on their precise engineering for high load capacity and safe working load requirements.

Working Load Limit (WLL)

The working load limit is the maximum lifting weight a shackle can safely handle during normal operations. You must check this rating before every lift. Manufacturers determine the working load limit by dividing the minimum breaking strength by a safety factor, usually between 4:1 and 6:1.

This calculation ensures that the shackle performs reliably under stress.

The working load limit is always marked on the shackle.

You must never exceed the safe working load.

Safety factors vary by use: 4:1 for general tasks, 5:1 or 6:1 for heavy-duty, and up to 10:1 for personnel lifting.

Rigorous testing confirms that each shackle meets industry standards for high load capacity.

Powerful Machinery’s shackles undergo strict testing and certification. You can trust their products to deliver consistent maximum lifting weight and high load capacity in demanding environments.

Certification and Identification

You should always inspect the markings and certifications on your d shackle. These markings confirm compliance with safety regulations and help you verify the maximum lifting weight.

CE Mark shows compliance with European safety standards.

The working load limit must be clearly visible.

Standards such as BS EN 13889 should appear on the shackle.

Serial numbers and test details must match the manufacturer’s certificate.

Powerful Machinery includes all required identification markings on every shackle. You gain peace of mind knowing your equipment meets global safety standards and supports your high load capacity needs.

Tip: Always choose a shackle with certified sizing and clear identification. This practice ensures a safe working load and maximum lifting weight for every lift.

Choosing D Shackles for Your Application

Selection Criteria

Selecting the right d shackles for your project is essential for safety and performance. You can follow a clear step-by-step process to make the best choice:

Determine the Load Requirements

Start by identifying the working load limit (WLL) you need. Always check the maximum weight your lifting d shackles must handle. Never exceed this limit to maintain safety.Consider the Direction of the Load

Examine how the force will be applied. Use d shackles for straight-line pulls. If your application involves side loading, choose a different shackle shape.Choose the Right Pin Type

Decide between screw pin, bolt-type, or round pin shackles. Screw pin types work well for temporary setups. Bolt-type pins offer extra security for permanent or critical connections.Evaluate the Environment

Assess where you will use the lifting d shackles. Stainless steel resists corrosion in marine or chemical settings. Galvanized steel works well outdoors. For heavy-duty lifting, select alloy steel.Match Components Correctly

Ensure your d shackles fit with the rest of your rigging system. Check that the pin diameter and internal dimensions are compatible with your chains, ropes, or slings.Verify Certification and Quality

Only use shackles that meet industry standards. Look for markings such as CE, ASME, or ISO. Always request documentation like a Manufacturer’s Test Certificate.

The table below summarizes the main factors you should consider:

Factor | Description |

|---|---|

Load Capacity | Confirm the required WLL and never exceed it. |

Environmental Conditions | Select materials that resist corrosion and suit your environment. |

Size | Ensure dimensions match your hardware and rigging setup. |

Pin Type | Pick a screw pin or bolt type based on how often you will remove the shackle. |

Certification | Check for compliance with standards and proper documentation. |

Quality Assurance | Choose suppliers with strong quality control and traceability. |

Tip: Always double-check the markings and certificates before using any lifting d shackles. This step helps you maintain the highest level of safety.

Typical Uses of D Shackles

You will find d shackles in a wide range of industries and applications. Their strength and reliability make them a top choice for many professionals. Here are some of the most common sectors and typical uses and applications:

Construction: Securing scaffolding, lifting beams, and connecting rigging equipment.

Transportation: Attaching cargo, securing loads, and towing vehicles.

Marine and Offshore Energy: Mooring lines, anchor chains, and lifting gear on ships and platforms.

Land-Based Energy: Supporting wind turbines and solar panel installations.

Power and Utilities: Hoisting transformers and electrical equipment.

Oil and Gas: Handling pipes, valves, and heavy machinery.

Cargo Handling: Lifting containers and securing freight.

Infrastructure: Bridge building and maintenance.

Mining: Moving heavy equipment and ore.

Agriculture and Forestry: Towing, lifting, and securing machinery.

Towing: Connecting tow lines and recovery straps.

Entertainment: Theatrical rigging for lighting and stage equipment.

Lifting shackles from Powerful Machinery meet the needs of these demanding industries. You can rely on their certified products for both routine and critical lifting operations.

Note: Always select lifting d shackles that match your specific application. Using the correct type and size ensures safety and extends the life of your equipment.

Where to Buy D Shackles?

When you need reliable lifting shackles, sourcing from a reputable supplier is crucial. Follow these best practices to ensure you get certified and safe products:

Research the supplier’s reputation in the industry.

Confirm that the shackles comply with safety standards such as ASTM, ISO, or CE.

Check if the supplier can handle large orders or custom requirements.

Request a Manufacturer’s Test Certificate or Certificate of Conformance with each order.

Make sure the certificate includes details on standards, chemical analysis, and mechanical testing.

Evaluate the supplier’s product range, pricing, and customer service.

Maintain open communication for technical support and after-sales service.

Powerful Machinery stands out as a trusted manufacturer of certified lifting shackles. You benefit from their 20+ years of experience, global certifications, and commitment to quality.

Their stainless steel and heavy-duty shackles undergo strict testing to meet international standards. You can explore their full range of products and request expert advice for your next project by visiting Powerful Machinery’s official website.

Safety Reminder: Always use certified lifting d shackles from reputable suppliers. This practice protects your team, your equipment, and your reputation.

D Shackles Maintenance and Safety

D Shackle Inspection and Best Practices

You must inspect the shackles regularly to maintain safety and performance. Begin with an initial inspection when you purchase new shackles or after repairs. Certified professionals should handle this step. Before each use, check for distortions or damage.

Replace any shackle that shows signs of wear. Schedule an annual inventory inspection, considering how often you use the shackles and the environment.

Follow these steps for effective inspection:

Check for clear identification markings on the body and pin.

Inspect for shape damage. Discard shackles with more than 10% wear or elongation.

Look for corrosion or pitting, especially on pin threads.

Assess for bending, twisting, or cracking. Never attempt repairs.

Evaluate for heat damage, such as discoloration.

Powerful Machinery’s commitment to safety ensures every d shackle meets strict standards. You can trust their products for reliable performance in critical applications.

Tip: Regular maintenance and inspection help prevent costly failures and keep your team safe.

Common Mistakes to Avoid

You can avoid many problems by following proper procedures. Always inspect the shackles before use and storage. Select the correct pattern and pin type for your application. Make sure the shackles are strong enough for the full load. Fully tighten the pin and ensure the load acts through the centerline.

Do not use shackles with bent pins or deformed bodies. Never force, hammer, or wedge shackles into place. Avoid loading shackles eccentrically or replacing pins with bolts from other shackles. Do not fit screw pins in contact with moving parts, which may loosen them. Prevent shock loading at all times.

Note: Statistics show that improper use of the shackles can lead to anchor loss and high replacement costs. Proper selection and maintenance reduce these risks.

When to Replace D Shackles?

Replace the shackles immediately if you notice any of the following conditions:

Condition Number | Description |

|---|---|

1 | Physical size is reduced, unable to handle the rated load |

2 | Excessive pitting, corrosion, nicks, or gouges |

3 | Bent, twisted, distorted, stretched, elongated, cracked, or broken parts |

4 | Signs of heat damage, such as discoloration or weld spatter |

5 | Missing or illegible manufacturer’s name, working load limit, or size |

6 | Bent load pins or visibly damaged threads |

You protect your equipment and team by replacing damaged shackles promptly. Regular maintenance and inspection routines help you identify these issues early.

Conclusion

You improve safety and efficiency when you understand shackle types, sizing, and proper selection.

Select the right size for your task, such as 3/4-inch for heavy-duty towing or 1/2-inch for lighter loads.

Match the shackle type to the load and application to prevent accidents.

Certified products from trusted manufacturers like Powerful Machinery deliver reliability and quality.

For expert guidance, consult organizations such as ABS, DNV, Bureau Veritas, and Lloyd’s Register.

Certification Body | Description |

|---|---|

ABS | Approved manufacturer for industrial applications |

DNV | Approved for lifting and mooring applications |

Bureau Veritas | Certification for quality management system |

Lloyd’s Register | Certification for heat treatment procedures |

FAQ

What size D shackle should you choose for your project?

You should match the shackle size to your load and the diameter of your chain or rope. Always check the working load limit (WLL) and consult the manufacturer’s sizing chart for guidance.

How do you maintain stainless steel D shackles?

You should inspect shackles regularly for wear or corrosion. Clean them after use, especially in marine environments. Always ensure the pin is fully tightened before each use.

Can you use D shackles in saltwater environments?

Yes, you can use stainless steel D shackles in saltwater. Powerful Machinery’s AISI316 stainless steel shackles offer excellent corrosion resistance, making them ideal for marine and offshore applications.

Where can you buy certified D shackles?

You can purchase certified D shackles directly from Powerful Machinery’s website. The company offers a wide range of sizes and materials, all tested to meet international safety standards.