You use anchor shackles to connect lifting equipment and secure heavy loads safely. These strong metal connectors play a vital role in rigging, lifting, and marine operations. You rely on them to hold chains, ropes, or cables together under intense pressure.

When you choose the right anchor shackle, you help prevent accidents and keep your operations running smoothly. Their sturdy design gives you confidence in demanding environments.

Key Takeaways

Anchor shackles are essential for safely connecting lifting equipment and securing heavy loads in various industries.

Always check the working load limit (WLL) and choose a shackle with a higher capacity than your maximum load to ensure safety.

Regularly inspect anchor shackles for damage or wear before each use to prevent accidents and ensure reliable performance.

Select the right type of shackle (bow or D-shackle) based on your lifting needs to enhance safety and efficiency.

Choose certified shackles from trusted manufacturers to guarantee compliance with international safety standards.

Anchor Shackles Overview

Definition

You use anchor shackles when you need a strong, reliable connector for lifting, rigging, or marine tasks. Anchor shackles have a large O-shaped body that makes them ideal for connecting chains, ropes, or straps to heavy loads. You often see them in industries like automotive, manufacturing, warehousing, and steel mills.

These shackles help you fasten equipment safely and efficiently. When you work with multiple-leg lifting setups, you must pay attention to the working load limit, as side pulling or angular lifts can reduce the safe capacity.

Powerful Machinery brings over 20 years of expertise to the design and production of anchor shackles. You can trust their certified products to meet the strictest international standards. Their shackles support your operations in construction, marine, transportation, and cargo handling, giving you peace of mind in demanding environments.

Key Features

Anchor shackles stand out because of their robust construction and thoughtful design. You benefit from several key features:

High load-bearing capacity due to strong materials like carbon steel and alloy steel.

Corrosion resistance, especially important when you choose stainless steel shackles for marine or outdoor use.

Versatile shapes and sizes to fit different rigging needs.

Secure closure systems, such as screw pins or bolt-type pins, make installation and removal easy.

Here is a quick look at the main components of an anchor shackle:

Component | Description |

|---|---|

Bow | The curved part opposite the pin takes the weight of the load. |

Shoulder | The part of the pin that makes contact against the ear when fully threaded. |

Pin | Usually, a steel bolt that spans the two shackle ears. |

Ear | Part of the shackle body that supports the pin. |

You will find that most anchor shackles are made using drop forging or upset forging methods. These processes give the shackles extra strength and durability.

Tip: Always check the material and manufacturing process before choosing a shackle for critical lifting tasks.

How Does an Anchor Shackle Work?

When you use an anchor shackle, you connect the bow to the load and secure it with the pin. The design allows the shackle to handle both static and dynamic loads. The diameter and material of the shackle determine how much weight it can safely support.

You must always follow the working load limit marked on the shackle. If you lift at an angle or experience shock loads, the safe working limit drops, so you need to plan your lifts carefully.

The load-bearing capacity depends on the shackle’s diameter and the type of steel used.

You should always consider the maximum loads, both static and dynamic, that the shackle will face.

Angular lifts and sudden movements can reduce the safe working load, so you must adjust your plans accordingly.

Powerful Machinery tests every anchor shackle to meet or exceed international safety standards. You can rely on their products for consistent performance, even in harsh or unpredictable conditions.

Anchor Shackle Types

When you choose anchor shackles, you find several types designed for different tasks. Each type has unique features that help you match the right shackle to your job.

Bow Shackles

Bow shackles have a wide, rounded shape. You use them when you need to connect multiple slings or handle loads from different directions. The bow design spreads the load evenly, which helps reduce wear on your rigging hardware.

Bow shackles distribute loads across multiple points, making them ideal for multi-leg lifting setups.

You often use them in marine, construction, and heavy lifting applications.

Shackle Type | Load Distribution Characteristics |

|---|---|

Bow Shackle | Distributes loads across multiple points, allowing for even load spreading. |

D-Shackles

D-shackles, also called Dee shackles, have a straight, narrow profile. You use them for straight-line pulls or when you need a strong connection along one axis.

D-shackles handle loads in a single direction, which gives you stability for lifting or towing.

These shackles work best when you want to avoid side loading.

Shackle Type | Load Distribution Characteristics |

|---|---|

D-Shackle | Handles loads in a single direction, concentrating the load along a single axis for stability. |

Screw Pin

Screw pin shackles let you connect and disconnect quickly. You use them for jobs that require frequent assembly and disassembly.

The screw pin design makes setup fast and easy.

You should use screw pin shackles for static loads or short-term connections.

Shackle Type | Typical Use Cases | Characteristics |

|---|---|---|

Screw Pin Anchor | Used for static loads, side loading, and multi-leg directions. | Quick to assemble, suitable for quick-connect applications, but not for long-term use. |

Bolt Type

Bolt-type shackles give you extra security. You use them for long-term or semi-permanent connections.

These shackles have a bolt, nut, and cotter pin to prevent accidental loosening.

You choose bolt-type shackles for heavy-duty lifting and rigging tasks.

Shackle Type | Typical Use Cases | Characteristics |

|---|---|---|

Bolt Type Anchor | Suitable for applications with movement or for semi-permanent/long-term connections. | Enhanced strength and reliability, designed for heavy-duty applications. |

Safety Pin

Safety pin shackles add another layer of protection. You use them in critical operations where you cannot risk the pin coming loose.

The safety pin design prevents the shackle pin from accidentally loosening or detaching. By using a cotter pin through a hole in the shackle pin, you keep the connection secure during demanding jobs.

Note: Safety pin shackles are essential for high-risk environments, such as offshore lifting or heavy construction.

Other Types

You may also encounter these shackle types:

Round pin shackles: Good for light-duty, non-critical applications.

Chain shackles: Designed for use with chain slings.

Stud link shackles: Used in mooring and anchor chains.

Twist shackles: Allow for a 90-degree twist between the pin and bow.

Wide body shackles: Offer increased surface area for web slings.

High tensile shackles: Made for extreme loads.

Synthetic shackles: Lightweight and non-conductive, ideal for marine and recreational use.

Stainless steel shackles: Resist corrosion, perfect for marine and food industry applications.

Powerful Machinery offers a full range of certified anchor shackles, including stainless steel, screw pin, bolt-type, and synthetic shackles. You can trust their products for marine, industrial, and construction use. Each shackle meets strict international standards, so you get safety and reliability in every application.

Anchor Shackles Features & Uses

Strength & Durability

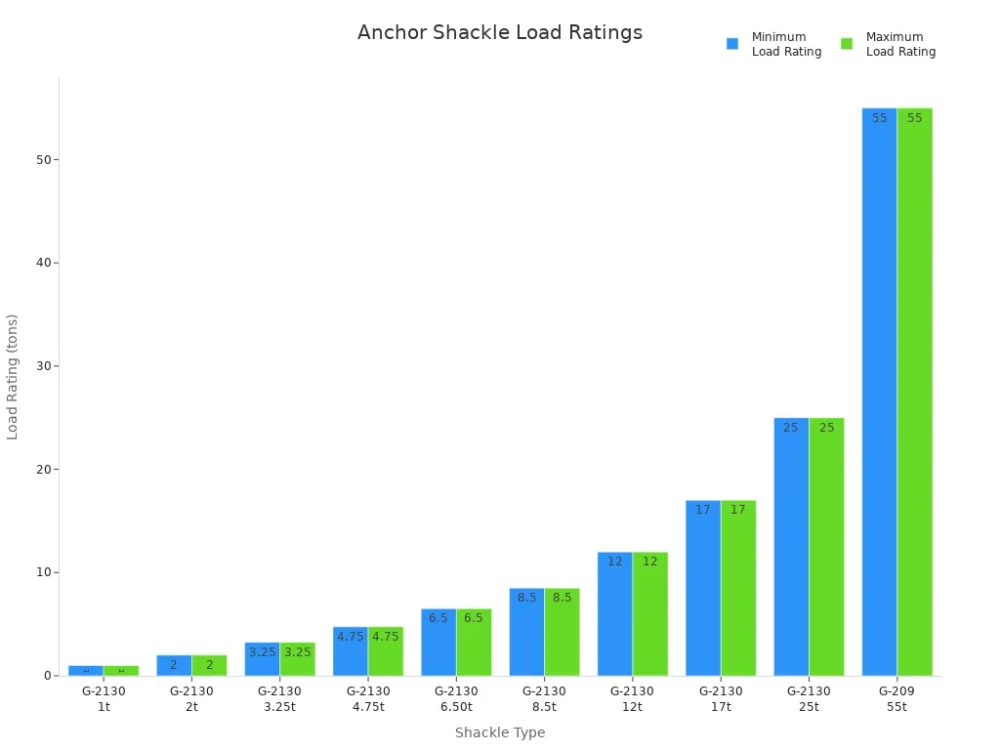

You depend on anchor shackles for their strength and long-lasting performance. Manufacturers use high-quality steel or stainless steel to create these connectors. This choice of material gives you excellent resistance to wear and corrosion. You can see the strength of different shackles in the table below:

Shackle Type | Minimum Load Rating | Maximum Load Rating |

|---|---|---|

G-2130 1t | 1 ton | 1 ton |

G-2130 2t | 2 tons | 2 tons |

G-2130 3.25t | 3 1/4 tons | 3 1/4 tons |

G-2130 4.75t | 4 3/4 tons | 4 3/4 tons |

G-2130 6.50t | 6 1/2 tons | 6 1/2 tons |

G-2130 8.5t | 8 1/2 tons | 8 1/2 tons |

G-2130 12t | 12 tons | 12 tons |

G-2130 17t | 17 tons | 17 tons |

G-2130 25t | 25 tons | 25 tons |

G-209 55t | 55 tons | 55 tons |

To make sure each shackle meets safety standards, you will find several testing methods in use:

Testing Method | Description |

|---|---|

Visual inspection | You check for cracks, chips, or surface damage. |

Mechanical load test | You apply force to confirm the shackle can handle its rated load. |

Environmental test | You expose the shackle to moisture, heat, and sunlight to test durability. |

What is an Anchor Shackle Used For?

You use anchor shackles in many industries because they offer secure connections and flexibility. Here are some common applications:

In the marine industry, you connect anchors to chains or ropes to keep vessels secure.

On construction sites, you use them to attach slings to lifting equipment and secure heavy loads.

In oil and gas, you rely on them for mooring and anchoring drilling rigs, where corrosion resistance is vital.

At concerts and events, you use them in rigging setups to hold lighting and sound equipment safely.

Bow shackles help you handle loads from different directions, which increases safety and efficiency. You must always select the right shackle for the weight and environment. When you use multi-leg sling setups, you need to calculate the tension based on sling angles to avoid overloading.

Powerful Machinery Advantages

When you choose Powerful Machinery, you get anchor shackles that stand out for their quality and reliability. The company uses premium materials to ensure durability and corrosion resistance, especially in marine environments. You benefit from products that last longer and perform well under tough conditions.

Feature | Advantage |

|---|---|

Material Quality | Durability and corrosion resistance |

Resistance to Marine Environments | Longer life in harsh conditions |

You can trust Powerful Machinery because its products meet strict international standards. Certifications like EN 13889 and third-party verifications from DNV GL prove that these shackles deliver safe and consistent performance. You get peace of mind knowing your rigging hardware is tested and certified for demanding jobs.

Selection & Safety

Choosing Anchor Shackles

You need to select the right anchor shackle for your lifting or rigging job. Start by checking the load limits. Always choose a shackle with a working load limit (WLL) higher than the maximum weight you plan to lift. Do not rely on the size alone, since shackles of the same size can have different load ratings based on the material.

Next, look at the material. Steel, stainless steel, and alloy steel each offer unique benefits. Stainless steel resists corrosion, making it ideal for marine or outdoor use. Alloy steel provides extra strength for heavy-duty tasks.

You must also consider compatibility with your other rigging hardware. The table below shows the main factors to check:

Factor | Description |

|---|---|

Weight Capacity | Choose shackles with a higher capacity than your maximum load. |

Material | Select the right material for your environment and application. |

Design and Shape | Match the shackle type (bow, D-shackle) to your lifting equipment and load direction. |

Safety Standards | Make sure the shackle meets or exceeds industry safety standards. |

When you select anchor shackles, always check for compliance with international standards. The table below highlights two important standards and their key requirements:

Standard | Key Requirements |

|---|---|

ASME B30.26 | Marked with the manufacturer’s name, rated load, and size. Minimum safety factor of 5:1 for carbon steel. Proof tested to twice the WLL. Inspection criteria for removal based on wear. |

EN 13889 | Requires CE mark, WLL, material grade, and manufacturer’s code. Safety factor of 6:1 for Grade 6 shackles. The manufacturer must provide a certificate of conformity. |

Powerful Machinery ensures all products meet or exceed these standards, giving you confidence in every lift.

How to Read Anchor Shackles?

Before you use any shackle, you need to read the markings on its body and pin. These markings tell you the manufacturer, the rated load limit, and the material grade. You will find this information forged, cast, or die-stamped directly onto the shackle.

The working load limit (WLL) is the most important marking. It shows the maximum weight the shackle can safely support. Do not assume that two shackles of the same size have the same WLL. The material and design affect the rating. Always check the stamped WLL before use.

If you see that the markings are missing or hard to read, replace the shackle right away. Using a shackle without clear markings can lead to overloading and accidents.

Tip: Always inspect the markings before every lift. This simple step helps prevent mistakes and keeps your team safe.

How to Secure an Anchor Shackle?

You must secure anchor shackles properly to avoid accidents. Follow these best practices:

Make sure the pin is fully screwed into the shackle eye. Tighten it with a wrench so the collar seats firmly against the shackle.

Use shackles of the correct length to ensure the pin collar fits properly.

For permanent or long-term connections, choose bolt-type shackles and always use cotter pins.

Before each use, confirm that screw pins are completely tightened.

Improper securing can cause failures. Detached securing pins are a common reason for anchor loss, especially with D-shackles. Exceeding the equipment’s design limits, such as during severe weather, also increases the risk of failure.

Note: Always double-check the pin before lifting. A loose or missing pin can lead to dropped loads and serious accidents.

Maintenance

Regular maintenance keeps your anchor shackles safe and extends their lifespan. You should:

Inspect shackles for breaks, corrosion, or looseness before every use.

Clean shackles and chains to remove debris like seaweed or shellfish, especially after marine use.

Apply anti-corrosion coatings to protect the metal surface.

Lubricate the pin and moving parts to reduce wear.

Schedule professional inspections to catch hidden problems.

Industry standards recommend the following inspection intervals:

Inspection Type | Frequency |

|---|---|

Initial Inspection | Upon purchase or alteration |

Before Use Inspection | Every use |

Periodic Inventory Inspection | Annually |

Regular inspections and maintenance help prevent injuries and accidents. By checking for wear or damage before each use, you improve safety and get more life from your equipment.

Powerful Machinery designs anchor shackles to meet strict international safety standards. You can trust their products for reliable performance, even in tough environments.

Conclusion

You play a crucial role in rigging safety by understanding anchor shackles and their proper use. By selecting the right type, conducting regular inspections, and maintaining your equipment, you reduce the risk of accidents. Real-world case studies show how these best practices help ensure safety on the job:

Match bow shackles to multi-leg lifts and D-shackles to straight pulls.

Confirm the material and Working Load Limit fit your job.

Inspect shackles before every use.

Choosing certified anchor shackles from Powerful Machinery gives you confidence in every lift.

Common Mistake | Why It Matters |

|---|---|

Incomplete pin engagement | Can cause failure in use |

Missing or illegible markings | Leads to unsafe operation |

FAQ

What is the difference between a bow shackle and a D-shackle?

You use a bow shackle for multi-directional loads because its rounded shape spreads force. You choose a D-shackle for straight-line pulls. The D-shackle’s narrow profile gives you more strength in one direction.

How do you know which size anchor shackle to use?

You check the working load limit (WLL) stamped on the shackle. Always pick a shackle with a WLL higher than your load. Measure the diameter and match it to your rigging equipment.

Can you use stainless steel shackles in saltwater environments?

Yes, you can. Stainless steel shackles resist corrosion, so they work well in saltwater and marine settings. You get longer service life and less maintenance when you use them in harsh environments.

How often should you inspect your anchor shackles?

You should inspect shackles before every use. Look for cracks, rust, or bent parts. Schedule a full inspection at least once a year. Replace any shackle that shows damage or missing markings.