You can achieve effective hand pallet truck repair by focusing on accurate diagnosis, following clear repair steps, and prioritizing regular maintenance. Using reliable solutions helps you ensure safety and save costs.

Powerful Machinery delivers trusted hand pallet truck options known for strength and reliability. When you use practical tips and structured service schedules, you spot issues early and avoid expensive repairs.

Early detection prevents major problems.

Prompt repairs lower overall costs.

Proactive maintenance extends equipment life and performance.

Key Takeaways

Regular inspections help you catch problems early. Check all components daily to ensure safe operation.

Proactive maintenance extends the life of your pallet truck. Follow a structured maintenance schedule to avoid costly repairs.

Understanding the hydraulic system is crucial. Properly maintain and bleed the system to ensure efficient lifting.

Choose between DIY repairs and professional services wisely. Complex issues often require expert knowledge for safe and effective solutions.

Document all repairs and inspections. Keeping records helps track the condition of your pallet truck and plan future maintenance.

Hand Pallet Truck Components and Functions

Understanding the main pallet truck parts helps you maintain and repair your equipment efficiently. The ORM-HP model from Powerful Machinery stands out due to its robust construction and user-friendly design. Each component plays a vital role in ensuring smooth operation and long-lasting performance.

Component | Function |

|---|---|

Forks | Support and carry pallets and goods; made of steel for strength and durability. |

Hydraulic System | Allows the forks to rise and fall through hydraulic oil flow. |

Wheels | Enable smooth movement; steering wheels control direction. |

Control Handle | Adjusts the lifting and moving direction of the forks. |

Hydraulic System Basics

The hydraulic system forms the core of every pallet truck. When you operate the pump handle, the hydraulic pump draws oil from the tank and pressurizes it. This pressurized oil moves into the hydraulic cylinder, pushing the piston upward and lifting the load.

To lower the forks, you adjust the directional valve, which lets the oil flow back into the tank and allows the piston to descend. Powerful Machinery’s ORM-HP model features a high-strength hydraulic pressure oil cylinder with a built-in safety valve. This design ensures safe, efficient lifting and reduces the risk of hydraulic failure.

Forks, Frame, and Wheels

The forks and frame of your pallet truck must withstand heavy loads and frequent use. Powerful Machinery uses tough C-grade steel for the forks, providing maximum strength and durability. The high-balanced welded frame adds stability, even under maximum capacity.

Wheels play a crucial role in movement and maneuverability. The ORM-HP model offers polyurethane wheels with nylon hubs, which glide smoothly and resist wear. These materials reduce noise and protect warehouse floors. You can choose from different wheel types to match your specific needs.

Handle and Controls

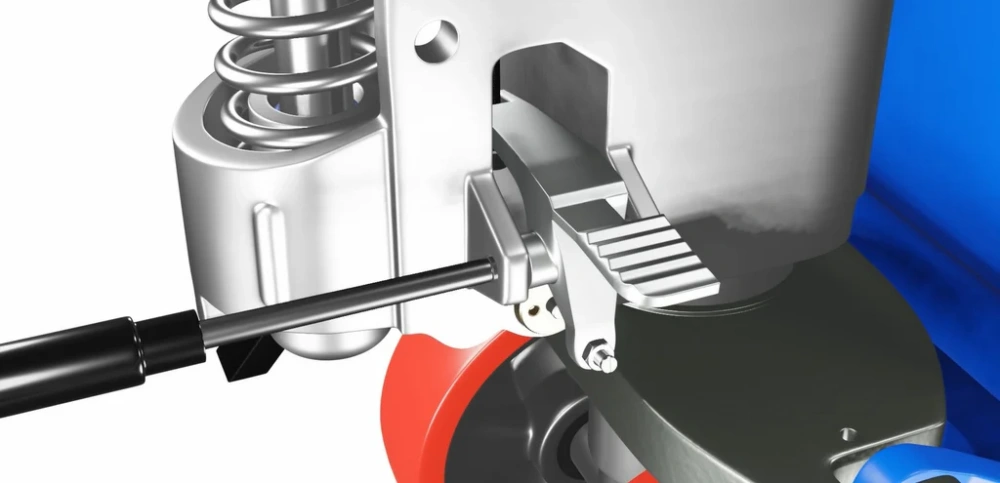

Operator comfort and safety depend on the handle and controls. The ORM-HP pallet truck features an ergonomic handle that minimizes fatigue during long shifts. The handle includes a hydraulic lock and release lever, shaped for a secure grip and easy operation.

Cushioned grips and accessible controls help you maintain precise control over lifting and movement. These ergonomic features not only improve productivity but also reduce the risk of strain or injury.

Tip: Regularly inspect all pallet truck parts to ensure each component functions correctly. Early detection of wear or damage keeps your equipment running safely and efficiently.

Diagnosing Pallet Truck Issues

Diagnosing issues with your pallet truck requires a systematic approach. You need to identify symptoms early and use a structured maintenance checklist. This process helps you prevent unexpected breakdowns and ensures safe operation.

Powerful Machinery recommends regular inspections to keep your equipment in top condition and minimize downtime.

Hydraulic Problems

Hydraulic issues are among the most common problems you will encounter during hand pallet truck repair. These problems can stop your truck from lifting or lowering loads properly.

You might notice oil leaks, reduced lifting power, or forks that will not stay raised. The table below outlines typical hydraulic problems and the steps you should take to diagnose them:

Problem Description | Diagnostic Steps |

|---|---|

Insufficient Lifting Power | 1. Check hydraulic fluid levels. 2. Bleed the system if air is present. |

Complete Lifting Failure | 1. Inspect for fluid leaks. 2. Check the pump mechanism for damage. |

Forks Won’t Stay Raised | 1. Ensure the release valve is fully closed. 2. Check for internal seal damage. |

You should also watch for these frequent issues:

Oil pump problems can halt operation. Replace worn parts such as dust rings and O-rings.

Oil cylinder damage can prevent lifting. Inspect and adjust or replace as needed.

Oil seal failures often cause leaks. Replace aging seals to restore performance.

: Always use the correct hydraulic oil and keep the system clean. Contaminated oil can lead to further problems and costly repairs.

Wheel and Steering Issues

Wheels and steering components play a vital role in the safe movement of your pallet truck. Problems in these areas can make your truck hard to maneuver or even unsafe to use. The table below highlights symptoms and their implications:

Symptoms | Implications |

|---|---|

Worn or Damaged Load Wheels | Difficult maneuverability and uneven load distribution stress the frame. |

Steering Problems | Dangerous operation, potential for accidents or damage to goods and equipment. |

If you notice your truck pulling to one side, making unusual noises, or becoming hard to steer, inspect the wheels for wear or damage. Replace any wheels that show cracks, splits, or excessive wear. Proper wheel maintenance prevents instability and protects the frame from unnecessary stress.

Fork and Frame Damage

Fork and frame problems can lead to serious safety risks and equipment failure. You need to understand the main causes of breakdown in pallet truck components, like the forks and frame. The most common problems include:

Overloading: Carrying loads above the rated capacity can cause instability and tip-overs.

Uneven surfaces: Operating on rough or sloped ground can make the truck unstable.

Collisions: Impacts with other objects can bend or crack the forks and frame.

If you see visible cracks, bends, or deformation, stop using the truck immediately and arrange for repair. Addressing these issues quickly helps you avoid accidents and extends the life of your equipment.

Inspection and Cleaning Steps

A thorough inspection and cleaning routine is essential for identifying problems before they become serious. Use Powerful Machinery’s maintenance checklist to guide your daily and weekly checks. Follow these steps:

Load Wheels

Check for smooth rolling and remove any banding, tape, or string.

Inspect for splits or cracks in the tires.

Steer Wheels

Ensure they roll smoothly and are free from obstructions.

Look for any splits or damage.

Handle

Confirm all bolts are secure and not missing.

Test that the pump operates smoothly.

Lift Action

Make sure the truck lifts to its full height.

Trigger

Test for correct operation and control during lowering.

Brakes (if applicable)

Ensure they engage and release properly.

General Condition

Look for cracks on the frame and signs of oil leakage.

Note: Always document your inspection findings. Keeping records helps you track the condition of your pallet truck, identify recurring issues, and comply with workplace safety regulations.

By following these steps, you can quickly spot common problems and apply effective solutions. Regular inspection and cleaning reduce the risk of breakdowns and keep your pallet truck operating safely and efficiently.

Hand Pallet Truck Repair Steps

Safety and Tools

You must always put safety first when you repair a hand pallet truck. Before you begin any pallet truck repair, wear gloves and safety glasses. Make sure the work area is clean and free of obstacles.

Powerful Machinery’s ORM-HP model includes safety features such as overload protection and a high-strength frame, which help prevent accidents during repair.

Essential tools for hand pallet truck repair include:

Wrenches for tightening bolts

Screwdrivers for adjusting components

Lubricants for moving parts

Pliers for gripping and twisting

Replacement parts for damaged components

A jack for lifting the pallet truck during repairs

Regularly check the hydraulic system for leaks. Inspect wheels and forks for damage. Lubricate all moving parts to prevent wear and tear. These steps help you avoid problems and keep your equipment safe.

Tip: Always disconnect the truck from any load before starting repairs. This reduces the risk of injury and protects the pallet truck.

Disassembly and Cleaning

Start by laying the pallet truck on its side for easy access. Remove the wheels and handle if necessary. Use a clean rag to wipe all surfaces. For serious dirt, apply a proper amount of detergent.

Avoid highly corrosive chemicals to protect metal surfaces and oil seals. Cleaning each part helps you spot problems like cracks, splits, or leaks.

Cleaning Agent | Purpose |

|---|---|

Clean rag | Wipe surfaces and remove dust |

Mild detergent | Remove stubborn dirt and grease |

Non-corrosive spray | Protect metal and seals from damage |

Note: Clean components before reassembly to ensure smooth operation and prevent future problems.

Seal and O-Ring Replacement

Seals and O-rings prevent hydraulic fluid from leaking. You need to inspect these parts during every hand pallet truck repair. Replace them if you notice any of the following problems:

Moisture around the seals or O-rings

Fluid is seeping out of the hydraulic system

Loss of pressure in the hydraulic system

Visible splits or damage on the O-rings

Leakage in the hydraulic cylinders or hoses

Remove the old seals and O-rings with pliers. Install new ones carefully to avoid pinching or twisting. Powerful Machinery’s design allows easy access to these components, making replacement straightforward.

Tip: Always use manufacturer-approved replacement parts to maintain safety and performance.

Bleeding Hydraulic Air

Air trapped in the hydraulic system can cause lifting problems. You must bleed the hydraulic air to restore proper function. Follow these repair instructions:

Unload the pallet truck and prepare to pump it.

Bring the tow bar down.

Lower the pallet truck. Do not loosen or remove the oil cap.

Repeat the first three steps several times.

Test the pallet truck with a load.

If problems persist, set the lowering valve to its lowest setting and remove the oil cap to check the oil level.

This process removes air and restores lifting power. Powerful Machinery’s hydraulic system is designed for easy maintenance, so you can complete this step quickly.

Hydraulic Oil Change

Changing hydraulic oil is a key part of pallet truck repair. Old or dirty oil can cause problems such as poor lifting or leaks. To repair a hand pallet truck, follow these steps:

Lower the forks completely.

Remove the oil cap and drain the old oil into a container.

Fill the reservoir with fresh hydraulic oil.

Replace the oil cap securely.

Pump the handle several times to circulate the new oil.

Check the oil level regularly and refill as needed. Clean oil keeps the hydraulic system working smoothly and prevents future problems.

Wheel and Roller Replacement

Wheels and rollers wear out over time. Replacing them is a common pallet truck repair task. Follow these steps:

Gather a hammer, a pin punch, grease, and an old cloth.

Lay the pallet truck on its side for easy access.

Remove the spring pin using the hammer and pin punch.

Fold the wheel holder and pull the wheels off the axle.

Lubricate all moving parts with grease, especially the linkage rod.

Attach the new wheels onto the axle and secure with the spring pin.

Return the pallet truck to an upright position and check all functions.

Powerful Machinery’s PU wheels and tough steel forks make replacement easy and extend the life of your pallet truck.

Fork and Frame Repair

Inspect the forks and frame for cracks, bends, or deformation. If you find any problems, stop using the pallet truck immediately. Use a wrench to tighten loose bolts. Replace damaged forks or frame sections with manufacturer-approved parts.

Powerful Machinery’s high-strength welded frame and C-grade steel forks resist damage, but regular inspection is essential.

Safety first: Never attempt to repair a severely damaged frame or forks without proper training. Contact a certified technician if you are unsure.

Reassembly and Testing

After completing all repairs, reassemble the pallet truck carefully. Make sure all bolts and pins are secure. Test the truck to ensure it operates correctly:

Raise the pallet truck without a load by moving the control lever into the lifting position and pumping with the handle.

Push the handle all the way down to the stop and move the control lever into the lowering position.

Keep the control lever in the lowering position and pump multiple times with the handle to allow air to escape from the hydraulic system.

Repeat steps 1 – 3 several times.

Test the functionality of the loaded pallet truck.

Check and adjust the lowering valve if the lowering function malfunctions. Regularly check hydraulic oil levels and refill as necessary. Perform regular oil changes to prevent damage from dirt particles.

Tip: Document each repair and test result. This helps you track problems and plan future maintenance.

Powerful Machinery’s ergonomic design and safety features simplify every step of hand pallet truck repair. By following these steps, you can solve most problems and keep your pallet truck in top condition.

Repair Options for Pallet Trucks

DIY vs Professional Service

When you face problems with your hand pallet truck, you must decide whether to repair the pallet truck yourself or call a professional. DIY repairs can save time if you have the right tools and experience. However, some problems require expert knowledge and specialized equipment.

Professional repair services often cost less than buying a new truck. On average, you pay about one-third of the price of a new unit for a full service. Choosing a professional ensures the repair of a pallet truck job is done right and comes with a guarantee.

Professional repairs are more affordable than replacement.

You get peace of mind with expert service.

DIY works for minor problems, but complex issues need specialists.

When to Replace vs Repair?

You should consider several factors before you repair a pallet truck or replace it. Think about how often you use the truck and the weight of your loads. Trucks that handle heavy loads every day wear out faster.

The environment also matters. Rough floors, outdoor use, and extreme weather can cause more problems. Maintenance routines play a big role in equipment life. Skipping regular checks leads to bigger problems later.

Frequency of use affects wear and tear.

Heavy loads put extra strain on parts.

Harsh conditions speed up damage.

Good maintenance prevents many problems.

Timely maintenance and inspection can prevent accidents caused by damage to key components, such as failure of the hydraulic system causing cargo to fall, and axle breakage causing equipment loss of control.

If you notice repeated problems or major damage, replacement may be the best solution.

Specialist Services

Specialist services offer advanced solutions for tough problems. When you repair a pallet truck with a certified technician, you ensure compliance with safety standards.

Look for services that follow health and safety regulations, PUWER, and LOLER. Regular inspections and servicing keep your equipment safe and reliable. Powerful Machinery’s support team provides certified repair a pallet truck services and expert advice for all your repair needs.

Compliance with safety laws

Regular inspections and servicing

Expert solutions for complex problems

Choosing the right repair option saves money, reduces downtime, and keeps your hand pallet truck running smoothly.

Preventive Maintenance for Hand Pallet Trucks

Keeping your hand pallet truck in top condition starts with a strong preventive maintenance plan. Powerful Machinery recommends a daily inspection routine and regular lubrication to maximize equipment life and reduce repair costs. By following these steps, you ensure safety and reliable performance every day.

Daily Inspection Checklist

A daily inspection routine helps you catch problems early. Before each shift, check these points:

Operate the lifting mechanism to confirm smooth raising and lowering.

Test movement and steering for easy operation.

Check the braking system for effective stopping.

Clean the pallet jack thoroughly.

Inspect wheels for wear or damage.

Verify forks are secure and undamaged.

Look for hydraulic leaks around the pump and seals.

Test the hydraulic pump for smooth operation.

Document any issues in the maintenance logbook and report major defects.

This daily inspection routine keeps your equipment safe and ready for use.

Lubrication and Fluid Care

Proper lubrication is essential for smooth operation and long equipment life. You should follow a monthly lubrication schedule for all critical bearings and axles. Focus on designated lubrication points to prevent wear.

Check hydraulic fluid levels every six months and change the oil annually with the correct type for pallet trucks. Regular lubrication and fluid care reduce friction, prevent breakdowns, and extend equipment life.

Tip: Powerful Machinery’s design makes lubrication easy, helping you stick to your maintenance schedules and avoid costly repairs.

Operator Safety Tips

You play a key role in safety. Always inspect your pallet jack before use. Wear gloves and eye protection. Never exceed the weight limit. Center the load under the forks.

Push the load instead of pulling to maintain visibility and reduce strain. Move at a safe speed and keep your feet clear of the raised truck. Plan your route, remove obstacles, and alert coworkers before lowering a load. Store the pallet jack with forks lowered after use.

Extending Truck Lifespan

Consistent maintenance practices help you get the most from your hand pallet truck. The table below shows how you can extend equipment life:

Maintenance Practice | Description |

|---|---|

Hydraulic Oil Management | Inspect oil every six months, and change it yearly with the right oil. |

Regular Lubrication | Follow a monthly lubrication schedule for bearings and axles. |

Safe Operational Protocols | Avoid using or parking the truck on slopes to prevent damage. |

By following these preventive maintenance steps, you protect your investment and ensure long-term performance. Powerful Machinery’s durable construction and easy-to-maintain features support your maintenance goals and keep your operations running smoothly.

Conclusion

You protect your team and boost productivity when you follow a systematic hand pallet truck repair routine and stick to preventive maintenance. Regular care brings many benefits:

Enhanced safety and fewer accidents

Smoother operation and less downtime

Longer equipment life and lower costs

Using a high-quality hand pallet truck from Powerful Machinery reduces strain, saves time, and supports efficient inventory management. For tailored solutions, Powerful Machinery offers:

Feature | Description |

|---|---|

Customization Options | Fork size, pump type, and OEM ODM diagrams |

Comprehensive Warranty | 1-year coverage on the core parts and the product |

Inspection Support | Video checks and machinery test reports |

Stay proactive and consult Powerful Machinery for expert support.

FAQ

How often should you perform preventive maintenance on a hand pallet truck?

You should inspect your hand pallet truck daily and perform full preventive maintenance every month. Regular checks help you catch issues early and keep your equipment running smoothly.

What hydraulic oil should you use for your pallet truck?

Use high-quality hydraulic oil recommended by the manufacturer. Powerful Machinery suggests ISO VG32 or VG46 hydraulic oil for optimal performance and long service life.

Can you repair a leaking hydraulic system yourself?

You can replace seals and O-rings if you have basic tools and follow safety steps. For major leaks or persistent problems, contact a certified technician for professional repair.

How do you know when to replace the wheels?

Check wheels for cracks, flat spots, or excessive wear. If you notice difficulty steering or increased noise, replace the wheels to maintain safe and smooth operation.

Where can you find replacement parts for Powerful Machinery hand pallet trucks?

You can order genuine replacement parts directly from Powerful Machinery’s website or authorized distributors. Using original parts ensures safety, compatibility, and long-term reliability.