You want simple solutions for pallet truck repair and maintenance. Powerful Machinery’s manual pallet truck offers easy upkeep and straightforward repairs. Regular visual inspection helps you catch issues early and maintain operational safety.

You can prevent up to 70% of breakdowns by following a routine care schedule. For safety reasons, call a professional when you notice complex hydraulic or electrical problems. Consistent attention keeps your equipment reliable and saves you money over time.

Key Takeaways

Regular maintenance can prevent up to 70% of pallet truck breakdowns. Create a simple care schedule to keep your equipment running smoothly.

Perform weekly inspections to catch issues early. Check for damage, test lifting functions, and verify safety features to ensure safe operation.

You can handle common repairs yourself, like bleeding hydraulics and changing oil. This saves time and reduces downtime in your warehouse.

Always use original parts for repairs. Genuine components ensure safety and compatibility, helping to maintain your pallet truck’s performance.

Know when to call a professional. Complex hydraulic or electrical issues require expert attention to avoid further damage and ensure safety.

Pallet Truck Repair and Maintenance Basics

Why Regular Maintenance Matters

You rely on your pallet truck every day to move heavy loads safely and efficiently. Regular pallet truck maintenance keeps your equipment in top condition and helps you avoid unexpected breakdowns.

When you perform routine checks, you reduce the risk of common problems such as oil pump failure, oil cylinder issues, and oil seal leakage.

You also prevent issues like incorrect hydraulic fluid pressure, leaking hydraulic oil, poor lubrication, damaged wheels, brake failure, and overloading. These problems can cause operational delays and create safety hazards for your team.

Timely pallet truck repair and maintenance extend the lifespan of your equipment. If you neglect maintenance, you may face engine failures and damaged parts, which can shorten the life of your pallet truck. Regular pallet truck maintenance can reduce repair costs by 25%.

You identify potential breakdowns before they happen, saving you time and money. Running your pallet truck to failure can lead to maintenance costs up to ten times higher than following a regular pallet truck maintenance schedule. Preventive maintenance also enhances the resale value of your equipment.

Tip: Create a simple schedule for pallet truck repair and maintenance. Weekly inspections and annual compliance checks help you catch issues early and keep your pallet truck running smoothly.

Benefits of Powerful Machinery Pallet Trucks

Powerful Machinery designs pallet trucks with durability and reliability in mind. You get a robust steel construction and a hydraulic system that requires minimal maintenance. The ergonomic handle and polyurethane wheels make operation comfortable and safe.

These features simplify pallet truck repair and maintenance, allowing you to perform basic repairs without specialized tools.

You benefit from certified products that meet international safety standards. Powerful Machinery’s commitment to quality means your pallet truck can withstand daily use in demanding environments.

You experience fewer breakdowns and lower maintenance costs. When you choose Powerful Machinery, you invest in equipment that delivers long-term value and dependable performance.

Repairing the Pallet Truck Yourself

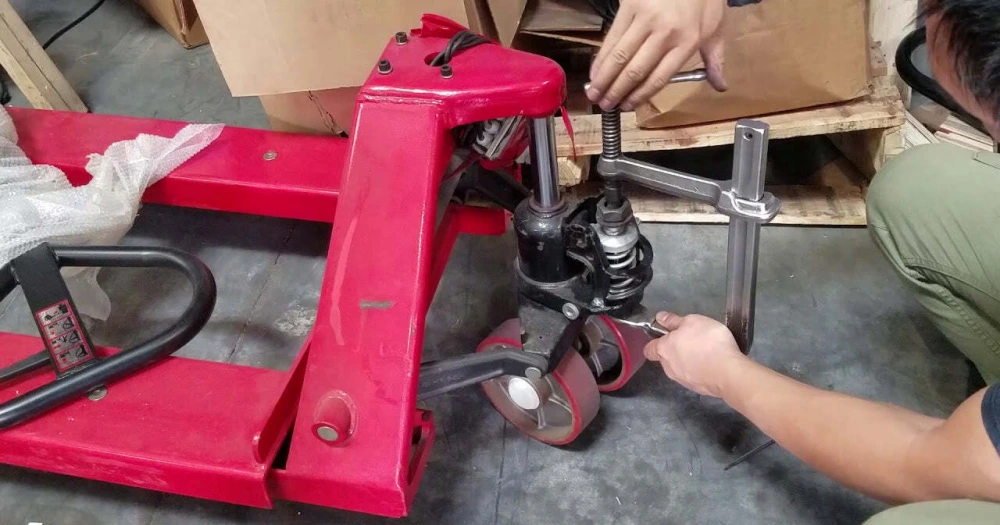

Taking care of your pallet truck repair needs does not have to be complicated. Many common issues can be fixed with basic tools and a little know-how. By repairing the pallet truck yourself, you can save time and reduce downtime in your warehouse.

Machinery designs its pallet trucks for easy access to key components, making routine repairs straightforward.

Common DIY Repairs

You can handle several frequent repairs without calling a professional. These tasks help keep your pallet truck in top condition and extend its service life. Here are the most common repairs you can perform:

Bleeding the pallet truck to fix lifting or lowering problems caused by air in the hydraulic system.

Refill/change oil in the hydraulic pump when levels are low or the oil is dirty.

Changing pallet truck oil after heavy use to maintain smooth operation.

Replace steering and load wheels when they show signs of wear.

Tip: Always perform a full inspection before starting any repair. This helps you spot other issues that may need attention.

Hydraulic System Care

The hydraulic system is the heart of your pallet truck. Regular care prevents breakdowns and ensures safe operation. You should check the hydraulic fluid weekly.

Lower the forks completely before checking the fluid level for an accurate reading. Most manufacturers recommend you refill/change oil and replace the filter every year or after a set number of operating hours.

Powerful Machinery pallet trucks include features that make the repair of the hydraulics easier and more reliable. The table below highlights these features and their benefits:

Feature | Benefit |

|---|---|

High-performance hydraulic cylinder | Simplifies lifting with minimal effort and ensures smooth operation. |

Built-in safety valve | Prevents overloading, enhancing safety during operation. |

Hard chrome-plated piston | Resists rust, extending equipment lifespan and reducing maintenance needs. |

Regular checks and timely repair of the hydraulics help you avoid workplace accidents and keep your pallet truck in top condition.

Wheel Replacement

Worn wheels can make your pallet truck hard to maneuver and may damage floors. Replacing them is a simple process you can do yourself. You will need a small flathead screwdriver, snap-ring pliers, and a plastic hammer. Follow these steps:

Use the screwdriver to remove the wheel cover.

Take the snap-ring pliers to release the retaining ring.

Gently tap the wheel out with the plastic hammer.

Install the new wheel and secure it with the retaining ring.

Replace the cover.

Note: Always check both the steering and load wheels during your repairs. Replacing worn wheels promptly helps keep your pallet truck in top condition and prevents further damage.

By repairing the pallet truck yourself, you can handle most routine pallet truck repair tasks quickly. Regular checks, proper repair of the hydraulics, and timely wheel replacement will keep your pallet truck running smoothly and safely.

Pallet Truck Inspection Checklist

A reliable pallet truck inspection checklist helps you maintain safety and efficiency in your workplace. You should use a checklist to guide your weekly inspections and annual compliance checks. This approach ensures you catch issues early and meet legal requirements.

Weekly Inspection Points

You need to inspect your pallet truck every week. A thorough pallet truck inspection checklist covers the most important areas. Use this checklist to keep your equipment in top condition:

Check the structure and all visible components for damage or wear.

Test the lifting function under load to confirm stability.

Verify safety features, including emergency stop mechanisms and load capacity indicators.

Examine the handle controls for smooth operation.

Inspect wheel safety components and look for hydraulic leaks.

Tip: Consistent weekly inspections help you prevent breakdowns and reduce repair costs.

Annual Compliance Checks

Annual compliance checks are required by law in many regions. You must follow regulations to keep your pallet truck safe and compliant. The table below summarizes the main requirements:

Regulation | Description |

|---|---|

PUWER | Requires annual inspection of all work equipment, including pallet trucks, by a competent person. |

LOLER | Applies to high lift pallet trucks (lifting above 300mm) requiring thorough examination at least annually. |

You should increase inspection frequency if your risk assessment or usage conditions demand it.

Maintenance Documentation

Proper documentation supports your pallet truck inspection checklist and compliance efforts. You need to keep accurate records of all maintenance activities. The table below outlines best practices:

Documentation Practice | Description |

|---|---|

Maintenance Logbooks | Document maintenance activities in writing, stating the components serviced. |

Regular Inspections | Ensure safety and compliance with regulations. |

Compliance with Safety Regulations | Adhere to safety standards in regulated industries. |

Routine care and documentation help you maximize the lifespan and efficiency of your pallet truck. Following these practices minimizes downtime and reduces the risk of costly repairs or accidents.

When to Call a Professional for Pallet Truck Repair?

You can handle many routine repairs yourself, but some problems require expert attention. Knowing when to call a professional protects your equipment and keeps your workplace safe. Powerful Machinery offers comprehensive pallet truck service and support, ensuring your equipment receives the care it needs.

Hydraulic and Electrical Issues

Hydraulic and electrical problems often need specialized skills and tools. If you notice hydraulic oil leaks or unresponsive controls, you should contact a qualified technician.

Complex damage to hydraulic components, such as leaking lines or cylinders, can affect lifting performance and safety. Electric pallet trucks may experience battery draining too quickly, controller malfunctions, or electronic scale errors. These issues require professional diagnosis and repair.

Common signs that indicate you need expert help include:

Hydraulic oil leaks under the truck

Controls that do not respond as expected

Forks that fail to rise or descend properly

Electric lock switch or power switch failure

Main contactor failure is causing power loss

Brake failure due to worn pads or loose wires

If you see any of these signs, stop using the pallet truck and schedule a professional inspection. Attempting to fix complex hydraulic or electrical problems without proper training can lead to further damage or safety risks.

Major Damage and Safety Concerns

Major damage can compromise the integrity of your pallet truck. You should call a professional if you encounter issues with hydraulic components that require replacement, damage to the hydraulic pump, or problems with the electrical system.

Trained personnel have the expertise to repair these components safely and efficiently.

Safety concerns demand immediate attention. Look for these warning signs:

A leaky hydraulic system that reduces lifting capacity

Malfunctioning brakes that may cause the truck to roll unexpectedly

Stuck or jammed wheels that prevent smooth movement

Broken handle that makes the operation difficult

Uneven lifting, which can lead to accidents

Safety Concern | Why You Need a Professional |

|---|---|

Leaky hydraulics | Loss of lifting power, risk of spills |

Malfunctioning brakes | Hazardous movement, injury risk |

Jammed wheels | Operational delays, floor damage |

Broken handle | Inefficient operation, safety hazard |

Uneven lifting | Imbalance, potential accidents |

Never ignore safety issues. Professional repair ensures your pallet truck meets industry standards and keeps your team safe.

Warranty and Service Support

Powerful Machinery stands behind every pallet truck with certified warranty coverage and reliable after-sales support. If your equipment is under warranty, you should contact the manufacturer or authorized service provider for repairs.

Using official pallet truck service protects your investment and guarantees that only original parts and approved methods are used.

You can access expert technicians who understand Powerful Machinery’s products and follow strict safety protocols. The service team provides fast diagnostics, genuine replacement parts, and thorough repairs. Keeping your warranty valid also helps you avoid unexpected costs and ensures compliance with safety regulations.

Tip: Always check your warranty status before arranging repairs. Using authorized pallet truck service maintains your coverage and extends the life of your equipment.

You keep your workplace safe and your pallet truck running efficiently when you know when to call a professional. Trust Powerful Machinery’s certified service team for complex repairs, major damage, and warranty support.

Ongoing Care Tips for Powerful Machinery Pallet Trucks

You can maximize the lifespan and performance of your pallet truck by following a few essential care practices. Powerful Machinery recommends a proactive approach to daily use and routine checks. These tips help you avoid unexpected breakdowns and keep your equipment running smoothly.

Use Original Parts

Always choose original parts for repairs and replacements. Genuine components from Powerful Machinery ensure compatibility and maintain safety standards. When you use certified parts, you protect the hydraulic system and reduce the risk of leaks or malfunctions.

You also guarantee that the pallet truck oil works efficiently with the system, supporting optimal lifting power.

Keep a small inventory of popular parts onsite. This allows you to perform quick repairs and minimize downtime.

Follow Manufacturer Guidelines

You should always follow the manufacturer’s instructions for maintenance of the pallet truck. Powerful Machinery provides clear guidelines for daily inspections, cleaning, and lubrication. Check the chain position and inspect the forks for wear every day.

Examine hydraulic parts for leaks and damage. Verify pallet truck oil levels at least once a year, and check every six months. Lubricate the truck monthly or after each cleaning. These steps help you avoid costly repairs and extend the life of your equipment.

Perform daily inspections.

Clean wheels regularly to prevent debris buildup.

Inspect forks and report any damage.

Check pallet truck oil and refill as needed.

Employee Training

Proper training ensures your team operates pallet trucks safely and identifies issues early. You can enroll employees in specialized programs to boost their skills. The table below lists popular training options:

Training Program | Description |

|---|---|

Pallet Jack Online Training | Covers operational hazards and best practices for safe handling. |

Motorized Pallet Jacks: Safe Operation | Teaches safe usage and effective maneuvers for powered pallet jacks. |

Pallet Jack Safety Training and Certification | Prepares operators to meet OSHA requirements. |

Electric Pallet Jack Training | Reviews standards from regulatory bodies. |

Trained operators help maintain equipment health and reduce downtime.

Accessing Support Services

You benefit from Powerful Machinery’s support services. Rapid repair capabilities and emergency services keep your pallet truck operational. Preventive maintenance identifies issues before they become major failures.

On-site parts inventory allows for faster repairs. Real-time asset management helps you track equipment status and plan maintenance. These services ensure you always have the right pallet truck oil and parts available.

Note: Access to certified support reduces downtime and keeps your operations efficient.

By following these ongoing care tips, you maintain safety, efficiency, and reliability. Powerful Machinery’s certified products and support services help you achieve long-term value from your pallet truck.

Conclusion

You keep your Powerful Machinery pallet truck reliable by following simple steps:

Bleed the hydraulics if lifting or lowering fails.

Check and refill hydraulic oil regularly.

Change the oil for long-term performance.

Replace worn wheels to maintain smooth movement.

Regular maintenance reduces failures by 70%, saves costs, and improves safety. Use the inspection checklist to catch issues early. Seek professional help for complex repairs.

Tip: Always inspect your pallet truck before use, push for better control, and clear the path to prevent accidents.

Safety Compliance | Proactive Safety |

|---|---|

Inspections ensure safe operation | Prevent workplace incidents |

FAQ

How often should you inspect your pallet truck?

You should inspect your pallet truck every week. Regular checks help you spot wear, leaks, or damage early. Annual compliance inspections are also required for safety and legal standards.

What hydraulic oil works best for Powerful Machinery pallet trucks?

You should use high-quality hydraulic oil recommended by Powerful Machinery. This oil ensures smooth lifting and protects the hydraulic system from wear. Always check your manual for the correct specification.

Can you replace pallet truck wheels yourself?

You can replace worn wheels using basic tools. Follow the steps in your manual for safe removal and installation. Always use original wheels from Powerful Machinery for best performance.

What should you do if your pallet truck will not lift?

Check the hydraulic oil level first. Bleed the system to remove air. If the problem continues, contact a professional technician for further inspection and repair.

Where can you find support or spare parts for Powerful Machinery pallet trucks?

Visit Powerful Machinery’s official website for support, spare parts, and service information. You can also contact their certified service team for expert assistance.