You depend on your equipment every day, so regular wire rope hoist maintenance keeps your workplace safe and your operations running smoothly. Neglecting maintenance can lead to costly repairs or dangerous accidents. By following the right guidelines, you protect your team and extend the life of your hoist.

Safety should always come first, and proactive care reduces risks while saving you money in the long run.

Key Takeaways

Regular inspections are crucial. Check your wire rope hoist daily for wear and damage to ensure safety and reliability.

Keep your hoist clean. Remove dirt and old lubricant to prevent hidden damage and extend the life of your equipment.

Use the right lubricant. Apply heavy-duty lubricants designed for wire ropes to reduce friction and protect against corrosion.

Invest in operator training. Proper training helps users understand equipment limits and promotes safe lifting practices.

Follow maintenance schedules. Consistent care prevents costly repairs and enhances safety, boosting overall operational efficiency.

Hoist Components Overview

Main Parts and Functions

Understanding the main parts of a wire rope hoist helps you maintain your equipment and spot issues early. Each component plays a key role in safe and efficient lifting. The table below shows the essential parts and their functions:

Component | Function |

|---|---|

Motor | Provides power to lift and lower loads, typically electric for reliability and efficiency. |

Gearbox | Transmits power from the motor to the drum, reducing speed and increasing torque. |

Drum | Wound and unwound the wire rope, guiding it to prevent overlapping. |

Wire Rope | Primary lifting medium, made of steel strands for strength and flexibility. |

Hook | Attaches to the load for lifting and moving, designed for high strength. |

Brake | Holds the load in place and stops it during operation, essential for safety. |

Limit Switches | Prevents overtravel of the hoist, ensuring safe operation by stopping at travel limits. |

Controls | Operates the hoist, allowing lifting, lowering, and movement of loads available in various types. |

Tip: Regularly check each part for signs of wear or damage. Early detection keeps your hoist running safely and extends its lifespan.

Types and Applications

You will find different types of hoists designed for specific tasks. Chain hoists and wire rope hoists are the most common. Chain hoists work well for lighter loads and smaller spaces. They are portable and easy to install. Wire rope hoists handle heavier loads and offer smoother, quieter operation.

They suit high-frequency and demanding jobs.

Hoist Type | Key Characteristics |

|---|---|

Chain Hoists | More compact, portable, and easier to install. Suited for lighter loads (under 5 tons). Lower maintenance and cost. |

Wire Rope Hoists | Smoother, quieter, and capable of higher speeds and capacities (over 10 tons). Ideal for production and severe-duty use. |

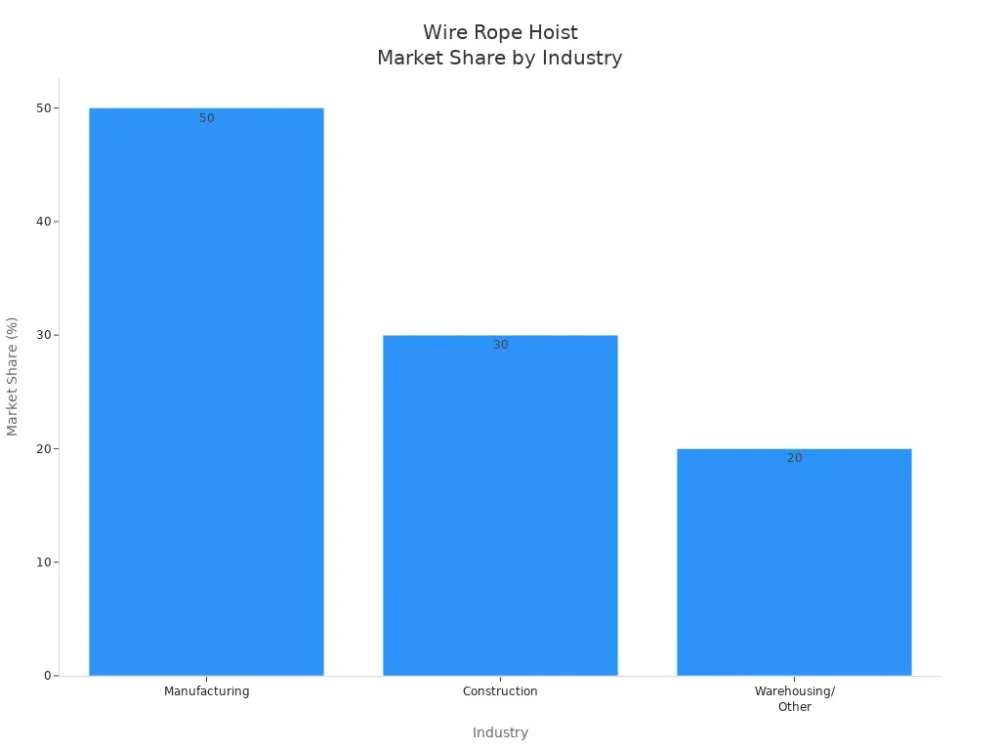

Wire rope hoists serve many industries. Manufacturing uses them for material handling and automation. Construction relies on them for lifting heavy materials. Warehousing depends on hoists for efficient logistics.

Manufacturing leads in adoption due to a focus on productivity and safety.

Construction requires reliable hoist systems for diverse conditions.

Warehousing needs efficient material handling solutions for optimization.

By knowing the main parts and types of hoists, you can choose the right equipment and keep it in top condition.

Wire Rope Hoist Maintenance Essentials

Regular Inspections

You need to make regular inspections a core part of your wire rope hoist maintenance routine. Daily visual inspections help you spot early signs of wear or damage before they become serious problems. Start each shift by checking the wire rope, hooks, and all visible components.

Look for broken wires, corrosion, or any flattening along the rope. Pay close attention to high-stress areas and contact points. Make sure the rope sits correctly in the sheaves and on the drum. Check for kinks, birdcaging, or any structural deformation. Confirm that the lay direction of the rope remains consistent.

A proactive inspection approach helps you catch issues early. Powerful Machinery recommends daily visual inspections and periodic detailed inspections. You should document your findings, including the date, inspector’s name, and any issues you find.

This record-keeping supports a comprehensive maintenance regimen and helps you track the condition of your equipment over time.

Service Class | Inspection Frequency |

|---|---|

Normal | Monthly |

Heavy | Weekly |

Severe | Daily to Weekly |

You can perform inspections yourself if you have the right training, or you can hire third-party experts.

Keep all inspection records for the life of your hoist.

Periodic detailed inspections go deeper. These occur annually, semi-annually, or quarterly, depending on how often you use your hoist and the environment. During these inspections, check all mechanical components, including the brake system, limit switches, and electrical systems.

Powerful Machinery suggests regular load testing to confirm your hoist can handle its rated capacity. This level of care supports preventative maintenance and keeps your equipment reliable.

Tip: Never skip regular inspections. Early detection of problems saves you time and money and keeps your team safe.

Cleaning Practices

Cleanliness plays a big role in wire rope hoist maintenance. Dirt and old lubricant can hide damage and reduce the effectiveness of new lubricant. You should clean your wire ropes whenever you notice dirt buildup or hardened lubricant. Use a wire rope cleaner to remove debris and prepare the rope for proper lubrication.

Clean ropes help prevent internal wire breakage and extend the life of your equipment.

Clean ropes before applying new lubricant.

Remove all dirt, rust, and old grease for best results.

Make cleaning part of your daily maintenance routine.

Regular cleaning also helps you spot hidden issues, such as corrosion or pitting. By keeping your hoist clean, you support regular winch maintenance and reduce the risk of unexpected breakdowns.

Lubrication Steps

Proper lubrication is essential for wire rope hoist maintenance. Lubricants reduce friction, protect against corrosion, and help your wire rope stay flexible. Always use lubricants designed for heavy-duty environments.

Look for products with good adhesion, resistance to mechanical removal, and strong anti-wear properties. Moisture resistance and long-term stability are also important, especially if you work in wet or corrosive conditions.

Requirement | Description |

|---|---|

Good adhesion to the rope | Prevents fling-off and loss of coating. |

Resistance to mechanical removal | Ensures the lubricant does not scrape off during bending. |

Good anti-wear properties | Protects the rope from wear during heavy-duty use. |

Moisture resistance | Maintains lubricant effectiveness in wet conditions. |

Corrosion protection | Critical for offshore and corrosive environments. |

Long-term stability | Keeps the lubricant effective over time. |

Thixotropic characteristics | Allows for good adherence under stress. |

Ease of application | Makes relubrication easier, especially in tough jobs. |

Resistance to UV degradation | Protects against sunlight exposure. |

High corrosion resistance | Only use lubricants with these properties in heavy-duty environments. |

You should lubricate the wire rope and all moving parts as part of your daily maintenance. Re-lubrication keeps your hoist running smoothly and prevents wear.

Powerful Machinery recommends checking the lubrication schedule in your hoist’s manual and following it closely. Always apply lubricant to a clean rope for maximum benefit.

Note: Proper lubrication not only extends the life of your wire rope but also improves safety and performance.

By following these wire rope hoist maintenance essentials—regular inspections, thorough cleaning, and proper lubrication—you protect your investment and ensure reliable operation. Powerful Machinery’s products are designed for easy maintenance, helping you keep your equipment in top condition with less effort.

Electric Wire Rope Hoist Care by Powerful Machinery

Product Features and Safety

You want your electric wire rope hoist to work safely and reliably every day. Powerful Machinery designs each hoist with advanced features that protect you and your team. The CD1/MD1 electric wire rope hoist uses a high-torque conical motor and durable steel wire rope to deliver strong lifting performance.

Overload protection and fault diagnostics help prevent accidents and keep your equipment running smoothly. You can trust the emergency stop button and limit switches to stop the hoist when needed. Noise-reduction technology creates a quieter workspace.

User-friendly controls make operation simple and efficient. You can choose from a range of options:

Control panels

AC drives and support tools

Custom DC control panels

DC drives and support tools

Pendant pushbutton stations

Handheld transmitters

Receivers

Collision avoidance systems

These controls let you operate your electric wire rope hoist with precision and confidence. You can select the best setup for your environment and lifting needs.

Maintenance Guidelines

You need clear guidelines to keep your electric wire rope hoist in top condition. Powerful Machinery recommends daily inspections to check for wear on hooks, chains, and ropes. Listen for unusual noises during operation.

Clean and lubricate moving parts regularly to reduce friction and extend the life of your hoist. Test safety features like load brakes and limit switches to confirm they work correctly.

Monitor electrical connections for signs of damage or overheating. Tighten any loose connections to maintain safe operation. Keep a detailed maintenance log. Record all inspections and repairs. This helps you follow preventive guidelines and track the health of your equipment.

For the mini electric rope hoist, follow these guidelines:

Inspect hooks, chains, and ropes daily.

Clean and lubricate moving parts.

Test safety features periodically.

Check wiring and controls for damage.

Maintain a log of all inspections and repairs.

By following these guidelines, you improve performance and reduce downtime. You ensure your electric wire rope hoist operates safely and reliably in every situation.

Operator Training and Best Practices

Training Importance

You play a key role in maintaining safety and efficiency when you operate a wire rope hoist. Operator training gives you the knowledge to use equipment correctly and avoid mistakes. You learn how to inspect your hoist, follow operational best practices, and respond to emergencies.

Training helps you understand the limits of your equipment and the importance of daily checks.

Many companies use a structured training program. You receive hands-on instruction and review training, and documentation. You practice safe lifting techniques and learn how to spot hazards. You also study the manufacturer’s guidelines and safety rules.

This approach prepares you to handle real-world situations and keeps you alert to risks.

Tip: Regular training refreshes your skills and keeps you updated on new practices and safety standards.

Recognizing Wear and Issues

You need to recognize signs of wear and damage to keep your hoist running smoothly. Operators should inspect wire ropes, hooks, and controls before each shift. Look for broken wires, corrosion, and unusual noises. You should check for misalignment, loose bolts, and worn brakes.

These practices help you catch problems early and prevent accidents.

The table below shows common issues and what you should look for:

Issue | What to Look For | Best Action |

|---|---|---|

Wire Rope Damage | Broken strands, kinks, rust | Replace rope |

Hook Wear | Deformation, cracks | Replace hook |

Brake Problems | Slipping, slow response | Service brakes |

Electrical Faults | Overheating, sparks | Inspect wiring |

You should report any problems right away. Operators who follow best practices help maintain safety and efficiency. You also support a culture of responsibility and teamwork.

Stay alert and use your training every day. Your attention to detail protects you and your coworkers.

Cable Management and Protection

Proper Rolling and Storage

You protect your wire rope hoist by following smart storage practices. When you receive a new wire rope, check it to make sure it matches your order. Store the rope in a dry, well-ventilated area. This prevents condensation and stops corrosion before it starts.

If you must store the rope outdoors, cover it with a waterproof material and keep the reel off the ground. Avoid high-temperature areas and places with chemical fumes. These conditions can damage the rope and shorten its lifespan.

Tip: Support the reel on a stable structure. This keeps the rope from getting crushed or bent.

You should apply a protective lubricant if the rope sits idle for a long time. Regularly examine ropes in storage for signs of wear or damage. If you notice any issues, re-wrap the rope to maintain its integrity. Use a compatible dressing when needed, and ask your supplier for advice on maintenance products.

Wire Rope Storage Checklist:

Inspect upon delivery

Store in a dry, ventilated space

Cover and elevate if outdoors

Avoid heat and chemicals

Lubricate for long-term storage

Check and re-wrap regularly

Environmental Protection

You face many environmental challenges when you use wire rope hoists. High humidity can cause condensation on metal surfaces. This leads to corrosion and rust, which weaken your hoist and trolley. Moisture can also get into electrical parts, causing short circuits and malfunctions.

You can shield your equipment by storing wire ropes in dry, temperate environments. Keep storage areas free from acids and chemical fumes. Apply high-quality lubricant to protect against moisture and keep the rope flexible and strong.

Protecting your wire rope hoist from harsh conditions helps you avoid costly repairs and keeps your lifting operations safe.

Common Environmental Risks and Solutions

Risk | Solution |

|---|---|

Humidity/Condensation | Store in a dry area, use a lubricant |

Chemical Exposure | Use acid-free storage |

Temperature Extremes | Avoid high heat, shield reels |

You maintain your equipment’s strength and reliability by managing cables and protecting them from the environment.

Neglect Consequences

Equipment Failure Risks

You face serious risks when you neglect wire rope hoist maintenance. Equipment failure can happen suddenly and without warning. A wire rope may snap during a lift, causing the load to drop. This type of failure puts workers and property in danger.

You might see hooks bend or brakes stop working. These problems often start small but grow quickly if you ignore them.

Real-world cases show how neglect leads to disaster. In one construction site, a hoist failed because the wire rope had not been inspected for months. The rope broke, dropping a heavy load and damaging expensive machinery. Workers had to stop all operations for emergency repairs.

You lose valuable time and money when equipment failure disrupts your schedule.

You can prevent most failures by following a regular maintenance schedule and checking your hoist before each use. Manufacturer guidelines help you spot trouble early and keep your equipment safe.

Safety and Cost Impacts

Neglecting maintenance affects safety and your bottom line. You put everyone at risk when you ignore routine checks. The table below shows how poor practices impact workplace safety:

Statistic | Description |

|---|---|

27% | Load drops linked to poor rigging practices (Konecranes Training Institute) |

60% | Crane-related fatalities due to rigging failures (CDC) |

You see that failure to maintain equipment leads to injuries and even fatalities. These numbers highlight the importance of regular inspections and proper care.

Financial consequences also hit hard. You may face:

Equipment breakdown and operational disruption. Unexpected failure causes downtime and lost revenue.

Workplace injuries and fatalities. Poor maintenance can result in severe harm, leading to emotional and safety concerns.

Legal and financial repercussions. Fines, lawsuits, and penalties can damage your reputation and financial health.

You protect your team and your business by following maintenance schedules and manufacturer guidelines. Regular care keeps your wire rope hoist reliable and safe.

Conclusion

You gain many advantages by practicing regular wire rope hoist maintenance.

You improve safety for your team and equipment.

You boost operational efficiency and reduce downtime.

You extend the lifespan of your hoist, saving money over time.

A manufacturing facility saw a 35% increase in sling lifespan and zero safety incidents after adopting a proactive maintenance program. Powerful Machinery’s guidelines help you spot wear early, keep hoists running smoothly, and prevent misuse. Consistent care builds a culture of reliability and long-term success.

FAQ

How often should you inspect your wire rope hoist?

You should inspect your wire rope hoist daily for visible damage. Schedule detailed inspections monthly or quarterly, depending on usage. Always follow the manufacturer’s recommendations for inspection frequency.

What signs show your wire rope needs replacement?

Look for broken wires, kinks, rust, or birdcaging. If you see any of these signs, replace the wire rope immediately. Regular checks help you spot problems early.

Can you use any lubricant for wire rope hoist maintenance?

No. You must use lubricants designed for wire ropes. These products protect against wear and corrosion. Always clean the rope before applying new lubricant.

Why is operator training important for hoist safety?

Operator training teaches you safe lifting practices and how to spot equipment issues. Trained operators reduce accidents and keep your workplace safe.