You rely on clevis shackles when you need secure connections for lifting and rigging tasks. These components play a vital role in material handling, ensuring that loads remain stable and safe during transport or lifting.

Choosing certified, high-quality products protects you and your team from accidents and equipment failure. Powerful Machinery delivers trusted clevis shackles and rigging hardware, meeting strict industry standards for strength and reliability.

Key Takeaways

Clevis shackles provide secure connections for lifting and rigging tasks, ensuring safety during transport.

Choose certified shackles made from stainless steel or drop-forged steel for strength and durability in various environments.

Inspect shackles before every use to prevent accidents and ensure they meet safety standards.

Select the right type and size of shackle based on your specific lifting needs to avoid equipment failure.

Stay informed about market trends and technological advances to make the best choices for your rigging equipment.

Clevis Shackles: Definition and Design

What Are Clevis Shackles?

You use clevis shackles when you need a strong, reliable connection in lifting and rigging. A clevis shackle features a U-shaped body with a removable pin or bolt that closes the open end. This design allows you to quickly attach or detach the shackle from chains, ropes, or slings.

The pin secures the load and keeps it stable during lifting or towing. Clevis shackles serve as a critical link in many material handling systems, making them essential for safety and efficiency.

Powerful Machinery stands out as a trusted manufacturer of high-quality shackles. You can find specialized products like Stainless Steel Shackles and the G209 Shackle in their lineup. These products meet strict industry standards and deliver reliable performance in demanding environments.

Key Features and Materials

When you select clevis shackles, you look for features that guarantee strength and durability. The U-shaped body and removable pin create a secure connection that resists bending and breaking. You can choose from different pin types, such as screw pins or bolt-type pins, depending on your application.

Materials play a vital role in the performance of clevis shackles. Powerful Machinery uses premium stainless steel and drop-forged steel to manufacture their shackles. Stainless steel resists corrosion, making it ideal for marine and outdoor use. Drop-forged steel provides high tensile strength for heavy-duty lifting.

Tip: Always check for certification marks on your shackles. Certified materials ensure that your equipment meets international safety standards and performs reliably under load.

Types and Variations

You will find several types of clevis shackles, each designed for specific tasks. The most common types include anchor shackles (also called bow shackles) and chain shackles (also known as D shackles).

Anchor shackles have a rounded shape, allowing them to handle loads from multiple directions. Chain shackles have a narrower profile, making them suitable for straight-line pulls.

Powerful Machinery offers a wide range of shackles, including the G209 Shackle, which features a screw pin for easy installation and removal. You can also choose from European and U.S. types, with options for both Dee and Bow shapes.

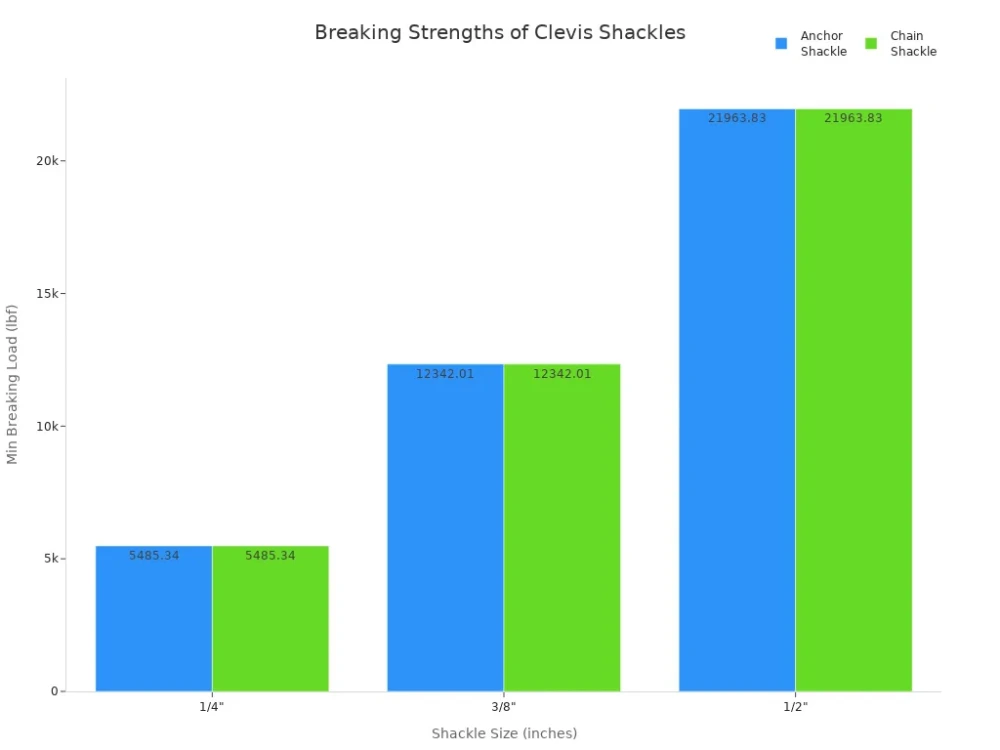

The following table shows typical load ratings and breaking strengths for different shackle types and sizes:

Shackle Type | Shackle Size (“D”) | Min Breaking Load (Pounds-force lbf) | Pin Diameter (“P”) |

|---|---|---|---|

Anchor Shackle | 1/4″ | 5,485.34 | 5/16″ |

Anchor Shackle | 3/8″ | 12,342.01 | 7/16″ |

Anchor Shackle | 1/2″ | 21,963.83 | 5/8″ |

Chain Shackle | 1/4″ | 5,485.34 | 5/16″ |

Chain Shackle | 3/8″ | 12,342.01 | 7/16″ |

Chain Shackle | 1/2″ | 21,963.83 | 5/8″ |

You can see how the minimum breaking load increases with the size of the shackle. This information helps you select the right shackle for your lifting needs.

You should always match the shackle type and size to your specific application. Certified clevis shackles from Powerful Machinery give you the confidence to handle heavy loads safely, whether you work in construction, marine, or industrial settings.

How Clevis Shackles Work?

Working Mechanism

You rely on clevis shackles to create secure connections between lifting equipment and loads. The U-shaped body forms the main structure. The removable pin fits through holes at the open end, locking the shackle in place. When you tighten the pin, the shackle holds the load firmly.

This design allows the shackle to distribute force evenly, reducing stress on the connection point. You can use clevis shackles in vertical lifts, towing, or anchoring tasks. The robust construction ensures that the shackle resists bending and deformation, even under heavy loads.

Attachment and Detachment

You attach clevis shackles by sliding the pin out of the shackle body. You then position the shackle around the chain, rope, or sling. Once in place, you insert the pin and tighten it securely. This process takes only a few seconds, making clevis shackles ideal for tasks that require frequent setup changes.

You detach the shackle by unscrewing or removing the pin, allowing you to release the load quickly. The screw pin design offers convenience for temporary connections, while bolt-type pins provide extra security for permanent installations.

Tip: Always check that the pin is fully engaged before lifting. A loose pin can cause the shackle to fail during operation.

Safety and Flexibility

You must follow strict safety standards when using clevis shackles in industrial environments. Regular inspection and proper use help prevent accidents. The following table summarizes two key rules that govern safe shackle operation:

Rule | Description |

|---|---|

1 | Inspect Before Every Use: A thorough visual inspection is required before using a shackle, as mandated by OSHA. |

9 | Always Respect the Working Load Limit (WLL): Never exceed the WLL stamped on the shackle to prevent failure. |

You gain flexibility with clevis shackles because they adapt to different rigging setups. You can use them with multi-leg slings, load rings, or towing lines. The rounded shape of anchor shackles allows for multi-directional loading, while chain shackles excel in straight-line pulls.

You improve safety by choosing certified products from trusted manufacturers. Powerful Machinery tests every shackle to meet international standards, giving you confidence in demanding applications.

Note: Always match the shackle type and size to your specific task. Proper selection and regular inspection keep your lifting operations safe and efficient.

Industry Applications

Clevis shackles serve as essential tools in many industries. You depend on them for secure connections, reliable lifting, and safe material handling. Their versatility allows you to use them in a wide range of demanding environments.

Maritime and Marine

You often face harsh conditions at sea. Saltwater and constant moisture can damage ordinary hardware. Powerful Machinery’s stainless steel shackles resist corrosion and maintain strength in marine environments. You use these shackles to connect anchor chains, secure mooring lines, and rig sails.

Their smooth finish and robust design make them ideal for both commercial vessels and recreational boats.

Tip: Always inspect shackles for signs of corrosion before each voyage to ensure safety on the water.

Construction and Infrastructure

On construction sites, you need equipment that handles heavy loads and frequent used frequently. Powerful Machinery’s G209 Shackle provides the strength and reliability you require for lifting beams, hoisting machinery, and securing scaffolding.

You benefit from the easy installation of screw pin designs, which save time during setup and teardown. Certified shackles help you meet strict safety standards on every project.

Industrial and Logistics

In warehouses and logistics centers, you move goods quickly and safely. You use clevis shackles to attach slings, connect lifting hooks, and secure cargo. Powerful Machinery offers a range of shackles that fit different rigging systems. Their products help you streamline operations and reduce downtime.

You can trust their certified hardware to perform under pressure.

Mining and Oil & Gas

You work in some of the toughest environments when handling mining or oil and gas operations. Heavy equipment and extreme conditions demand high-performance shackles. Powerful Machinery’s drop-forged steel shackles withstand intense loads and resist wear.

You use them to connect lifting chains, secure drilling equipment, and manage heavy transport. Their durability ensures safety and efficiency in critical tasks.

Note: Always match the shackle type and size to your specific application for maximum safety and performance.

Leading Brands and Buying Guide

Top Clevis Shackle Manufacturers

You want to choose clevis shackles from brands that set the standard for quality and reliability. Powerful Machinery ranks among the top global manufacturers, trusted for certified products and innovative solutions. Other recognized leaders in the market include:

Apex Dynamics Corporation

BlueWave Innovations Inc.

Crestline Manufacturing Corp.

NovaTech Industries Limited

Zenith Business Solutions LLC

These companies have built reputations for delivering high-performance rigging hardware to industries worldwide.

Buying Considerations

Selecting the right clevis shackles for your application requires careful attention to detail. You should follow a checklist to ensure safety and efficiency:

Determine Load Capacity: Match the working load limit (WLL) to your lifting requirements.

Choose the Correct Material: Stainless steel offers corrosion resistance for marine use. Drop-forged steel provides strength for heavy-duty tasks.

Select the Proper Type: Decide between screw pin and bolt-type shackles based on how often you need to attach or detach them.

Inspect Before Every Use: Look for signs of wear, deformation, or corrosion.

Verify Pin Installation: Make sure the pin is properly seated and secured.

Center the Load: Place the load in the bow, not on the pin, to avoid side loading.

Check Sling Angles: Calculate tension based on sling angles, not just the weight.

Use Original Components: Never replace the original pin with a substitute.

Respect Environmental Limits: Avoid exposing shackles to extreme temperatures or chemicals.

Confirm Compliance: Ensure the shackle meets international safety standards.

Tip: Always respect the working load limit stamped on the shackle. Exceeding it can lead to equipment failure and safety risks.

Certification and Standards

You should only use clevis shackles that comply with recognized international standards. These certifications guarantee product safety and performance:

Certification Body | Standard/Requirement | Purpose |

|---|---|---|

ISO | ISO 8539 | Global safety standards |

ASTM | ASTM A952 | Testing and performance |

OSHA | OSHA 1910 | Workplace safety regulations |

TUV Rheinland, EURO CERT | Product certification | Independent quality assurance |

You gain peace of mind when you choose shackles from Powerful Machinery, as their products meet or exceed these standards. Certified hardware ensures your lifting operations remain safe and compliant.

Market Trends and Innovations

Growth and Demand

You see strong growth in the clevis shackle market. Industries such as marine, construction, aerospace, and automotive drive demand for reliable rigging hardware. You notice that advancements in technology, especially AI and automation, improve manufacturing processes and product reliability.

AI-driven tools help you forecast demand and manage inventory more efficiently. You benefit from better supply chain planning, which ensures you have the right products when you need them.

Marine, construction, aerospace, and automotive sectors require high-performance shackles.

AI and automation enhance product quality and consistency.

Improved demand forecasting leads to smarter inventory management.

Tip: You should monitor industry trends to stay ahead of changes in demand and technology.

Technological Advances

You witness rapid innovation in clevis shackle technology. Manufacturers now offer IoT-enabled shackles that provide real-time monitoring of load and usage. Advanced alloy compositions give you greater strength and durability. Corrosion-resistant coatings protect your equipment in harsh environments.

You also see digital technologies integrated into lifting equipment, making your operations safer and more efficient.

IoT-enabled shackles allow real-time data tracking.

Advanced alloys increase strength and reliability.

Corrosion-resistant coatings extend product life.

Digital integration improves safety and efficiency.

Note: You gain peace of mind when you use shackles with smart features and enhanced materials.

Future Outlook

You can expect continued growth and innovation in the clevis shackle market. Lightweight alloys will improve the strength-to-weight ratio, making your equipment easier to handle without sacrificing safety. Improved corrosion resistance will help you work confidently in marine and industrial environments.

Smart shackles with embedded sensors will become more common, giving you instant feedback on load conditions and helping you prevent accidents.

Innovation | Benefit |

|---|---|

Lightweight alloys | Easier handling, higher safety |

Corrosion resistance | Better performance in harsh settings |

Smart sensors | Real-time load monitoring |

You should look for certified, high-quality shackles from trusted brands like Powerful Machinery. Staying informed about market trends and technological advances helps you make the best choices for your rigging needs.

Conclusion

You rely on clevis shackles for secure lifting and rigging in demanding environments. You understand that their U-shaped design and removable pin provide reliable connections for many industries. You improve safety by choosing certified products and inspecting them before every use.

Powerful Machinery delivers high-quality shackles that meet strict standards. You should review market trends and innovations when selecting equipment.

Safety Standard | Description |

|---|---|

Certified for lifting | Shackles must be certified and marked with the WLL, manufacturer’s mark, and batch ID to ensure reliability. |

Regular inspections | Inspections for wear, corrosion, or damage are essential before every use to maintain safety. |

Correct type and size | Selecting the appropriate shackle for the specific load is crucial to prevent catastrophic failure. |

You make the best choice for your team when you prioritize certified, innovative clevis shackles.

FAQ

What is the difference between a screw pin and a bolt-type clevis shackle?

You use a screw pin shackle for quick, temporary connections. You choose a bolt-type shackle for permanent or long-term setups. Bolt-type shackles provide extra security with a nut and cotter pin.

How do you select the correct size clevis shackle?

You match the shackle size to your load requirements. Always check the working load limit (WLL) stamped on the shackle. Never exceed this limit. Consult manufacturer charts for guidance.

Can you use stainless steel shackles in saltwater environments?

Yes, you can use stainless steel shackles in marine or saltwater settings. Stainless steel resists corrosion and maintains strength in harsh conditions. Always inspect for signs of wear before each use.

How often should you inspect your clevis shackles?

You should inspect shackles before every use. Look for cracks, deformation, or corrosion. Remove any damaged shackles from service immediately.

Tip: Regular inspection helps you prevent accidents and maintain safe lifting operations.